钢铁表面免水洗锌系磷化膜的常温制备与性能表征

余取民1,李荣喜1,卢红梅2

(1. 长沙学院 生物工程与环境科学系,湖南 长沙,410003;

2. 中南大学 化学化工学院,湖南 长沙,410083)

摘 要:Q235钢铁试片在以磷酸、氧化锌、钼酸铵等材料组成的锌系磷化液中常温快速磷化后,自然干燥2 h以上,生成免水洗的彩色锌系磷化膜。用XPS对膜层的化学组成及结构进行表征,用SEM和EDS对膜层的形貌和元素含量进行分析,探讨磷化机理。研究结果表明:免水洗的磷化膜,由Fe3+和Zn2+的磷酸盐及少量的钼酸盐等组成,膜晶粒尺寸≤2 μm,膜连续、致密,膜重≥0.9 g/m2,耐3%的NaCl溶液腐蚀约2.0 h,喷涂铁红环氧底漆后检验涂层的附着力达1级,比传统工艺(磷化后水洗)形成的磷化膜质量更好。

关键词:锌系磷化膜;常温;免水洗

中图分类号:TG174.4 文献标识码:A 文章编号:1672-7207(2008)05-0940-05

Preparation and characterization of zinc phosphating film on surface of steel without washing at room temperature

YU Qu-min1, LI Rong-xi1, LU Hong-mei2

(1. Department of Bioengineering and Environmental Science, Changsha University, Changsha 410003, China;

2. School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China)

Abstract: The zinc phosphating solution was composed of H3PO4, ZnO, Ba(NO3)2, (NH4)6Mo7O24·4H2O and so on. The zinc color phosphating film without washing can be formed fleetly with the phosphating reaction on steel drying for more than 2 h at room temperature. The chemical components and structures of the films were analyzed by XPS. The morphology and element contents of the films were analyzed by SEM and EDS, respectively. The mechanism for phosphating was also explored. The results show that the phosphating film without washing is composed of phosphate with Fe3+ and Zn2+ and a little of molybdate. The phosphating film, whose crystalline size is small than or equal to 2 μm, is series and thick with weightiness ≥0.9 g/m2. It bears corrupt of 3% NaCl solution for about 2.0 h. The cling force of phosphating film, smeared by lacquer of epoxy resin antirust of iron oxide red, reaches stair, and the quality of the phosphating film is better than that of phosphating film prepared by traditional technique, i.e. washing after phosphating reaction.

Key words: zinc phosphating film; room temperature; without washing

钢铁表面的磷化膜,是钢铁表面在磷酸二氢盐、氧化剂等为主要成分的溶液中生成的几微米厚的薄膜,按成膜阳离子可分为铁系、锌系、锌钙系和锌锰系等类型,锌系磷化应用最广。磷化膜作为涂层底层可明显提高涂层的附着力和防护能力,是保证涂装质量的关键材料[1],是汽车、家电、机械等生产所必备的材料。磷化技术正朝着低成本、低能耗、低毒、无污染和膜均匀致密、膜薄且耐蚀性能强的方向发展[2]。

目前研究和应用的锌系磷化,磷化温度较高;磷化前需要表面调整;磷化后需要1道甚至多道水洗[3-7],以清除磷化膜上残存的磷化液而避免磷化膜锈蚀、挂 灰[8-10]。轻薄型磷化膜从磷化液中带出来的磷化液接近磷化成膜消耗量[10]。水洗并不能消除磷化膜中的有害物质[11]。清洗这些残存磷化液用的洗水,量大,含磷、氮、锌等造成水体富营养化或有毒的物质多。因此,磷化后的工件若免水洗,表面残存的磷化液用于成膜,可显著减少污染物排放,节约资源,增加磷化膜的厚度和耐蚀性[9-11]。解决有害废水的研究,主要有采用原位磷化(ISPR)[12-13]、硅烷偶联剂代替传统的磷化[14]和磷化后的工件免水洗。本文作者研究磷化后免水洗锌系磷化膜的常温制备和膜的形貌、性能。

1 实 验

1.1 材 料

工业氧化锌(纯度为99.5%),工业钼酸铵(纯度为99%),工业磷酸,Q235冷轧钢板,其余为分析纯试剂。

1.2 磷化液与磷化膜的制备

磷化液的制备参考文献[10]中的方法。磷化液的组成材料均参加成膜反应且产物为磷化膜、沉渣和易挥发物;磷化液组分的浓度使磷化膜上残液中的水等易挥发物的挥发速度与继续成膜速度相适应[10]。

磷化膜按工艺流程“常温脱脂→水洗→常温强酸除锈脱脂→水洗→磷化→自然干燥”制备,磷化在宁波天恒仪表厂的DC–2006低温恒温槽内的烧杯中进行,自然干燥在广东医疗器械厂的LRH–250A生化培养箱中进行。磷化膜干燥2 h后检测磷化膜的性能。

1.3 磷化膜的检测方法

a. 膜重。按GB/T 9792—2003的规定测定。

b. 膜耐蚀性能。

① 耐硫酸铜点滴时间。在15~25 ℃,将1 L含CuSO4·5H4O 41 g,NaCl 35 g和HCl(0.10 mol/L)13 mL的溶液滴1滴到磷化膜表面,同时启动秒表,测至液滴变成淡红色的时间。

② 耐3% NaCl溶液腐蚀时间。将磷化后的试片浸入温度为20 ℃、质量分数为3%的NaCl溶液中,保持规定时间,取出清洗后吹干。目视检查,表面应无黄色锈迹[15]。

③ 挂片试验。将试片挂于科力实验仪器公司的PY–250H–A恒温恒湿培养箱中,每天检查1次,直至出现淡黄色的锈蚀为止。

c. 附着力。在干燥的磷化膜上喷涂一层25~30 μm铁红环氧底漆后,按GB 1720—79,用天津永利达材料试验机公司的QFD试验仪测定漆膜附着力。

d. 形貌和组成。通过日本的JSM–5600LV扫描电子显微镜及能谱仪(SEM+EDS)、英国的ESCALAB MKⅡ多功能电子能谱仪(XPS)等检测。

2 结果与讨论

2.1 磷化膜的形貌和组成

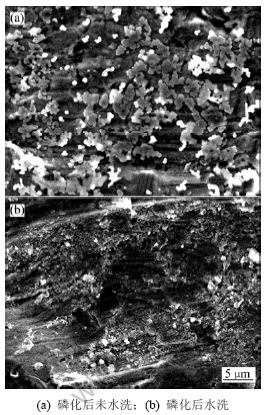

Q235试片在pH值为2.5~3.1并已磷化0.3~ 0.5 m2/L的磷化液中,于15 ℃浸泡5 min,取出后不水洗,自然干燥得到的彩色锌系磷化膜的形貌图见图1(a);取出后水洗、自然干燥得到的彩色锌系磷化膜的形貌图见图1(b)。可见,免水洗锌系磷化膜膜层均匀、致密,膜晶粒尺寸≤2 μm,比水洗的磷化膜膜层均匀、膜晶粒粗,比传统的磷化后水洗的锌系磷化膜的晶体尺寸小、致密得多。

图1 磷化膜的SEM形貌图

Fig.1 SEM photographs of phosphating films

磷化液中的磷酸盐与钼到构成磷钼杂多酸,在磷化过程中被还原成钼蓝,不溶于水的钼蓝盐吸附于磷化膜空隙中,提高了磷化膜的致密性和耐蚀性,同时,使磷化膜呈彩色。

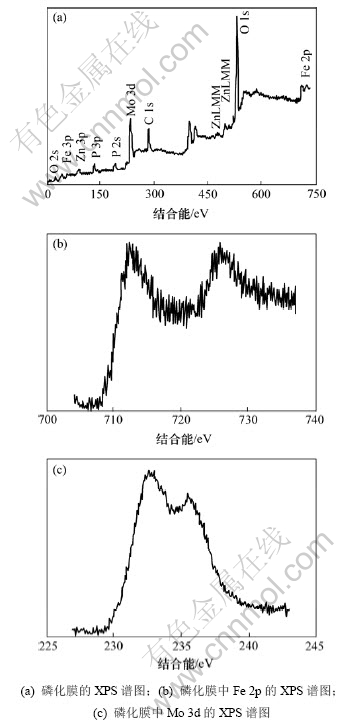

图1(a)和图1(b)对应的EDS谱图分别见图2(a)和图2(b)。将磷化液和图2中磷化膜主要元素P,Zn和Mo原子数的比例进行对比见表1;EDS谱图中Fe来自磷化膜和钢铁基体,无法确定磷化膜中Fe的含量,故表1中不能包括Fe元素。图1(a)中免水洗磷化膜的XPS谱图见图3(a);图3(a)中的Fe 2p和Mo 3d的XPS谱图分别见图3(b)和图3(c)。

图2 磷化膜的EDS谱图

Fig.2 EDS spectra of phosphating film

表1 磷化液和磷化膜中主要元素相对磷的原子数比

Table 1 Ratio of principal elements to phosphorus in phosphating solution and phosphating film

图3 磷化膜的XPS谱图

Fig. 3 XPS spectra of phosphating film

根据图3(b),磷化膜中的Fe元素可能以+3价的化合物存在。根据图3(c),磷化膜中的Mo元素可能以+5价的化合物存在。从表1可知,免水洗磷化膜中的Mo元素占磷化膜中原子数比例是磷化液中的5倍,水洗后的磷化膜中的Mo元素占磷化膜中原子数比例是免水洗磷化膜中比例的5倍,对照图3(a),说明钢铁试片进入磷化液时可能表面立即吸附了钼酸铵,并立即在钢铁基体表面生成铁或锌的钼酸盐,成为磷化膜的晶核;磷化膜主要由Fe3+和Zn2+的磷酸盐和钼酸盐组成。

2.2 免水洗磷化膜的成膜机理

磷化机理很复杂,可大致分为电化学浸蚀、成膜和填充3步,并有明显的重叠[10]。

a. 电化学浸蚀。钢材是一种多晶体材质,表面有许多的电位不同的晶界面等部位,构成无数微电池。在微电池的阳极,Fe被磷钼杂多酸等氧化剂氧化,发生氧化反应:

在微电池阴极,H+接受电子成为H2:

因此,微电池阴极H+浓度减小,pH值立即上升,导致下列电离平衡向右移动:

钢铁表面的HPO42–和PO43–浓度快速升高。微电池阳极产生的Fe2+被磷化液中的氧化剂氧化成Fe3+。当溶液中局部的HPO42–,PO43–,MoO43–与Zn2+,Fe3+和Fe2+等浓度积超过溶度积KSP时,可能产生FeMoO4,FePO4,FeHPO4和Zn2Fe(PO4)2等沉淀。

b. 成膜。大量的FeMoO4,FePO4和Zn2Fe(PO4)2等分子被吸附到微电池的阴极附近,成为磷化膜的晶核,并随着磷化的进行而晶核长大成为磷化膜晶体,最后形成均匀、致密的磷化膜。未参与结晶成膜的FePO4和Zn2Fe(PO4)2等成为磷化沉渣。

c. 填充。钢铁工件从磷化液中取出后,磷化继续,残存磷化液中的水等易挥发物挥发,亚铁盐被空气中的氧等氧化剂氧化成铁盐,磷化膜增厚、致密;磷钼杂多酸继续被还原为钼蓝,蓝色的钼蓝盐吸附到磷化膜微孔或缺陷处,彩色磷化膜进一步致密,消除了潜在的腐蚀点源的晶间缝隙[10],耐蚀性更好。

由于组成磷化液的材料均参加成膜反应且产物为磷化膜、沉渣和易挥发物,没有Cl–,SO42–和F–等造成磷化膜锈蚀的物质,磷化膜免水洗时不会生锈;没有过量的硝酸盐、亚硝酸盐和磷酸盐等物质,且磷化液组分的浓度与磷化后膜表面残存磷化液中的水等易挥发物的挥发速度与继续成膜速度相适应,消除了磷化膜挂灰。因此,磷化膜免水洗亦不会造成磷化膜生锈、挂灰,实现了磷化膜免水洗。

2.3 磷化膜的性能

Q235试片在pH值为2.5~3.1并已磷化0.3~0.5 m2/L的磷化液中,于15 ℃浸泡磷化5 min,自然干燥2 h后得到外观合格的彩色磷化膜,膜重≥0.9 g/m2;耐硫酸铜点滴时间为115 s;耐3% NaCl溶液腐蚀2.0 h不锈,超过GB/T 6807—2001规定的1 h不锈的技术指标;在温度为30 ℃、相对湿度为85%~95%的恒温恒湿箱中挂片5 d不锈,在温度为30 ℃、相对湿度为60%~70%的恒温恒湿箱中挂片32 d不锈;喷涂底漆后的漆膜附着力为1级。

改变磷化液的pH值、磷化温度和磷化时间,被改变的参数与磷化膜耐腐蚀性能的关系见图4和图5。

图4 pH值对磷化膜耐腐蚀性能的影响

Fig.4 Effect of pH value on anti-corrodible performance of phosphating film

图5 磷化时间对磷化膜耐腐蚀性能的影响

Fig.5 Effect of phosphate time on anti-corrodible performance of phosphating film

由图4和图5可知:

a. 磷化膜的耐硫酸铜点滴时间开始随pH值升高而提高,但pH值超过2.9就逐渐下降。PH值太低,钢铁基体腐蚀过快,磷化膜难以生成;pH值太高,磷酸盐沉淀,影响磷化液的稳定。磷化液pH值为2.5~3.5时较好。

b. 磷化膜的耐硫酸铜点滴时间随磷化温度的升高而提高,于5~40 ℃都有较好的效果。

c. 磷化膜的耐硫酸铜点滴时间开始随磷化时间的增加而提高,但磷化时间大于10 min且磷化温度高于10 ℃,或磷化时间大于15 min且磷化温度为5~ 10 ℃时,磷化时间的影响不明显。

3 结 论

a. 免水洗锌系磷化膜,可在pH值为2.5~3.5的磷化液中,于5~40 ℃在15~5 min内生成。

b. 免水洗锌系磷化膜,致密,膜晶粒尺寸≤2 μm,主要由Fe3+和Zn2+的磷酸盐及钼酸盐组成;可耐3% NaCl溶液腐蚀约2.0 h,是GB/T6807—2001标准要求的2倍;在温度为30 ℃、相对湿度为60%~70%的空气环境中挂片32 d不锈;喷涂底漆后附着力达1级。

参考文献:

[1] 李光玉, 连建设, 牛丽媛, 等. AZ91D镁合金上钼改性锌系磷化膜的制备、结构及性能[J]. 高等学校化学学报, 2006, 27(5): 817-820.

LI Guang-yu, LIAN Jian-she, NIU Li-yuan, et al. Preparation, structure and properties of molybdate modified zinc phosphate coating on magnesium alloy AZ91D[J]. Chemical Journal of Chinese Universities, 2006, 27(5): 817-820.

[2] 张圣麟, 陈华辉, 李红玲, 等. 常温磷化处理技术的研究现状及展望[J]. 材料保护, 2006, 39(7): 42-47.

ZHANG Sheng-lin, CHEN Hua-hui, LI Hong-ling, et al. Current state and prospect of ambient phosphating technique[J]. Materials Protection, 2006, 39(7): 42-47.

[3] 柳玉波. 表面处理工艺大全[M]. 北京: 中国计量出版社, 1996.

LIU Yu-bo. Encyclopedia of surface treatment techniques[M]. Beijing: China Metrology Press, 1996.

[4] 叶扬祥, 潘肇基. 涂装技术实用手册[M]. 北京: 机械工业出版社, 1998.

XIE Yang-xiang, PAN Zhao-ji. Practical handbook of painting[M]. Beijing: China Machine Press, 1998.

[5] 胡传炘. 实用表面前处理手册[M]. 2版. 北京: 化学工业出版社, 2006.

HU Chuan-xin. Practical surface pretreatment handbook[M]. 2nd ed. Beijing: Chemical Industry Press, 2006.

[6] 隋永强, 梁成浩. 低温锌系磷化液的研究[J]. 表面技术, 2004, 33(5): 37-39.

SUI Yong-qiang, LIANG Cheng-hao. Study on the phosphating solution of zinc series at low temperature[J]. Surface Technology, 2004, 33(5): 37-39.

[7] 林修洲, 龚 敏, 刘俊杰, 等. 环保型中温磷化工艺[J]. 腐蚀与防护, 2007, 28(2): 96-98.

LIN Xiu-zhou, GONG Min, LIU Jun-jie, et al. Environmental phosphating technology at medium temperature[J]. Corrosion & Protection, 2007, 28(2): 96-98.

[8] 余取民, 李荣喜, 王丽平. 免水洗锌钙系磷化膜的常温制备与表征[J]. 湖南师范大学自然科学学报, 2007, 30(1): 56-59.

YU Qu-min, LI Rong-xi, WANG Li-ping. The preparation and characterization of Zn-Ca system phosphating film without washing at the room temperature[J]. Journal of Natural Science of Hunan Normal University, 2007, 30(1): 56-59.

[9] 余取民, 李荣喜, 许第发, 等. 清洁型常温锌锰系磷化液研究[J]. 湘潭大学自然科学学报, 2007, 29(2): 91-94.

YU Qu-min, LI Rong-xi, XU Di-fa, et al. Study on cleaning Zn-Mn system phosphating solution at room temperature[J]. Journal of Xiangtan University: Natural Science, 2007, 29(2): 91-94.

[10] 余取民. 清洁型常温锌系磷化液研究[J]. 材料保护, 2006, 39(5): 26-28.

YU Qu-min. Study on cleaning zinc-system phosphating solution at room temperature[J]. Materials Protection, 2006, 39(5): 26-28.

[11] 余取民, 杨 建, 许第发. 钡盐改性常温锌系磷化液研究[J]. 材料保护, 2007, 40(5): 34-36.

YU Qu-min, YANG Jian, XU Di-fa. Study on zinc phosphating solution improved by baric ion at room temperature[J]. Materials Protection, 2007, 40(5): 34-36.

[12] YU Tao, Lin C T. Performance of in-situ phosphatizing reagents in solvent-borne paints[J]. Ind Eng Chem Res, 1997, 36(2): 368-374.

[13] Whitten M C, Chuang Y Y, Lin C T. Effects of catalyst and pigment on polyester-melamine in situ phosphatizing coating on a cold-rolled steel system[J]. Ind Eng Chem Res, 2002, 41(21): 5232-5239.

[14] 王雪明, 李爱菊, 李国丽, 等. 硅烷偶联剂在防腐涂层金属预处理中的应用研究[J]. 材料科学与工程学报, 2005, 23(1): 146-150.

WANG Xue-ming. LI Ai-ju, LI Guo-li, et al. Studies on the application for SCA in the metal pretreatment of anti-corrosion coatings[J]. Journal of Materials Science & Engineering, 2005, 23(1): 146-150.

[15] GB/T 6807—2001, 钢铁工件涂装前磷化技术条件[S].

GB/T 6807—2001, Specifications for phosphating treatment of iron and steel parts before painting[S].

收稿日期:2007-11-07;修回日期:2008-02-18

基金项目:湖南省科技计划资助项目(2006GK3070);湖南省教育厅科技计划资助项目(07C137);长沙市科技计划资助项目(K070761-31)

通信作者:余取民(1962-),男,湖南平江人,教授,从事表面处理研究;电话:0731-4261506;E-mail: qumin@vip.163.com