文章编号:1004-0609(2010)10-1868-08

ZK60镁合金微弧氧化硅酸盐电解液的优化及膜层特性

芦 笙1,徐荣远1,陈 静2,侯志丹1,王泽鑫1,汤 莉1

(1. 江苏科技大学 材料科学与工程学院, 镇江 212003;2. 江苏科技大学 机械工程学院, 镇江 212003)

摘 要:在硅酸钠、氢氧化钠、四硼酸钠和柠檬酸钠组成的电解液中,采用交流脉冲电源对ZK60镁合金进行微弧氧化,研究电解液组分对膜层的影响规律,并优化电解液配方。利用光学显微镜、扫描电镜(SEM) 、能谱分析(EDS)和X射线衍射分析(XRD)等,研究膜层厚度、表面与截面的微观组织,通过静态腐蚀质量损失法和动电位极化曲线法测试膜层在3.5%NaCl介质中的耐蚀性能。结果表明:各电解液组分浓度对成膜过程的电压变化、膜层厚度和耐蚀性能的影响规律各不相同,并在不同的合适浓度下获得厚的膜层和较高的耐蚀性能。通过单变量实验和正交实验优化电解液配方:60 g/L NaSiO3+20 g/L NaOH+25 g/L NaB4O7+20 g/L C6H5Na3O7,制备出的膜厚高达164.89 μm,结构均匀、致密,腐蚀速率极低,仅为ZK60镁合金空白试样的1.8%。

关键词:ZK60镁合金;微弧氧化;Na2SrO3电解液;配方;膜层

中图分类号:TG174.453 文献标志码:A

Optimization of silicate electrolyte for micro-arc oxidation and characteristic of coating fabricated on ZK60 magnesium alloy

LU Sheng1, XU Rong-yuan1, CHEN Jing2, HOU Zhi-dan1, WANG Ze-xin1, TANG Li1

(1. School of Materials Science and Engineering,

Jiangsu University of Science and Technology, Zhenjiang 212003, China;

2. School of Mechanical Engineering, Jiangsu University of Science and Technology, Zhenjiang 212003, China)

Abstract: The micro-arc oxidation process was conducted on ZK60 Mg alloy in an electrolyte composed of NaSiO3, NaOH, NaB4O7 and C6H5Na3O7 by AC pulse electrical source. The coating thickness and microstructural characteristics of coating cross-section and surface were investigated by means of OM, SEM coupled with EDS and XRD. The mass loss and dynamicpotential curves were measured in a 3.5%NaCl solution to evaluate the coating resistance to corrosion. The results reveal that different elements of the electrolyte demonstrate different effects on process voltage, coating thickness and corrosion resistance. For an element of the electrolyte, there is usually a suitable concentration to obtain a thicker coating but which does not guarantee a better corrosion resistance. By means of single variable and orthogonal tests, an optimized electrolyte with a composition of 60 g/L NaSiO3+20 g/L NaOH+25 g/L NaB4O7+20 g/L C6H5Na3O7 was developed. The sample prepared with the optimized electrolyte exhibits good corrosion property with only 1.8% of corrosion rate of blank sample due to its thicker (164.89 μm) and denser coating.

Key words: ZK60 magnesium alloy; micro-arc oxide; NaSiO3 electrolyte; formula; coating

在变形镁合金中Mg-Zn-Zr系应用最多,以ZK60为典型代表,其强度最高[1]。与其它镁合金相比,Mg-Zn-Zr系合金的耐蚀性较高,但其电负性也较高,常温下具有很高的化学反应活性,必须进行表面处理才能广泛应用[2-3]。微弧氧化是一项新的表面技术,通过在金属表面原位生长以基体金属氧化物为主的陶瓷层,显著改善金属材料的耐蚀与耐磨性能。目前,该项技术的研究和应用主要以铝、钛、镁合金为主[4-7],对镁合金的研究较少,且多集中在AZ(Mg-Al-Zn)和AM(Mg-Al-Mn)系镁合金[8-9],普遍使用碱性电解液、脉冲交流电源、高电压、大电流工艺 [10] 。其中,磷酸盐、铝酸盐和硅酸盐电解液使用最多,但磷酸盐电解液污染环境。相对铝酸盐,硅酸盐体系更易成膜,制备的膜层耐蚀性也较好[11]。迄今为止,有关ZK60镁合金微弧氧化研究鲜见报道。SU等[12-13]探索磷酸盐电解液中阴极电流密度对ZK60合金交流脉冲双极微弧氧化膜层组织和腐蚀性能的影响规律,并初步研究膜层显微硬度和摩擦特性。

在此,本文作者以微弧氧化膜层厚度和耐腐蚀性能为主要考察指标,对ZK60镁合金进行硅酸盐系电解液配方的优化研究。在固定的电参数下改变电解液成分,先通过单变量法对膜层性能进行综合评价,确定各组分的最佳浓度范围,掌握ZK60镁合金微弧氧化工艺的基本规律。在此基础上通过正交实验优化电解液配方,并比较优化前、后微弧氧化膜的显微组织和腐蚀性能,从而建立以硅酸钠为主成膜剂的环保型电解液体系,可在ZK60表面形成具有均匀、致密结构和优异耐蚀性能的微弧氧化陶瓷层。

1 实验

实验所用材料为ZK60变形镁合金,其化学成分(质量分数)为:5.2% Zn,0.47% Zr,杂质不大于0.30%,余量为Mg。 将ZK60线切割加工成25 mm×25 mm× 5 mm的试样,用水砂纸逐级打磨至800#,获得光滑表面,再超声波碱洗5 min,蒸馏水清洗、冷风吹干后作微弧氧化处理。

实验使用WHD-20脉冲微弧氧化装置,以不锈钢槽为阴极,ZK60试样为阳极,通过循环水冷保持电解液温度在30~40 ℃。以硅酸钠为主成膜剂,配制基准电解液:硅酸钠70 g/L+氢氧化钠10 g/L+四硼酸钠10 g/L+柠檬酸钠10 g/L。在单变量实验中,电解液的变动范围为:硅酸钠30~110 g/L,氢氧化钠5~35 g/L,四硼酸钠10~40 g/L,柠檬酸钠10~40 g/L。选用恒流方式:电流密度30 A/dm2,频率600 Hz,占空比50%,微弧氧化处理时间15 min。

采用KEYENCE公司的VHE-900超景深光学显微镜观察微弧氧化膜层的截面形貌,用CMI233膜层测厚仪测5点平均值作为膜层厚度。借助JSM-6480扫描电镜观察膜层表面形貌,并用所附能谱仪分析微区成分;利用岛津XRD-6000X射线衍射仪分析膜层物相。

用静态质量损失法评价试样的腐蚀性能:将试样全浸到3.5%NaCl介质,浸泡120 h后取出;再浸于铬酸溶液5 min,去除表面腐蚀产物后清水洗净;试样干燥后用精度为±0.1 mg的电子天平称量,计算试样平均腐蚀速率。

利用EGM283恒电位仪测试试样在3.5%NaCl溶液中的动电位极化曲线,饱和甘汞电极为参比电极,铂电极为辅助电极,试样为工作电极,在自腐蚀电位上、下400 mV左右进行扫描,扫描速率为5 mV/s。

2 结果与讨论

2.1 单变量实验

2.1.1 硅酸钠对膜层的影响及分析

图1(a)、(b)、(c)分别显示主成膜剂硅酸钠浓度对ZK60微弧氧化膜层形成过程的电压—时间曲线、膜层厚度和耐蚀性能的影响规律。其中,微弧氧化电压的变化规律能反映基体材料表面反应的状态[14]。由图1可看出:随着硅酸钠浓度从30 g/L提高到110 g/L,终电压从321 V下降到224 V,表明微弧氧化电压随硅酸钠浓度的增加而显著减低,但仍出现尖端放电现象;膜层厚度呈先增后减的趋势,浓度为90 g/L时,厚度最大(153.41 μm);膜层腐蚀速率则呈先降后升的趋势,浓度为70 g/L时腐蚀速率最低(0.206 g/(m2?h))。有研究[15]表明,在恒电流条件下,随着硅酸钠(SiO32-)浓度的增加,溶液电导率提高,使得微弧氧化过程电压下降。从单个电压—时间曲线来看,在微弧氧化初期,致密层厚度随时间的延长而增加,电压也呈线性增加;而在后期,膜层结构出现疏松的非致密层,故膜层电压随时间的延长而缓慢增加, 这与其它研究[16]工作的结果一致。膜层厚度与耐蚀性并未出现对应的关系,说明微弧氧化膜层的耐蚀性不仅取决于膜层厚度,还与膜层结构相关。

2.1.2 氢氧化钠对膜层的影响及分析

氢氧化钠主要用于调节溶液pH值,促进成膜。图2所示为氢氧化钠浓度对ZK60微弧氧化膜的影响。从图2可见,随着氢氧化钠浓度由5 g/L增加到35 g/L,终电压从268 V降为177 V,微弧氧化电压呈显著下降的趋势,浓度高于15 g/L后,还能显著拟制尖端放电;膜层厚度和腐蚀速率大体都呈先增后减的趋势,

图1 硅酸钠浓度对ZK60微弧氧化膜的影响

Fig.1 Effects of Na2SiO3 concentration on MAO coating of ZK60: (a) Curves of time vs potential at different Na2SiO3 concentrations; (b) Curve of Na2SiO3 concentration vs coating thickness; (c) Curve of Na2SiO3 concentration vs corrosion rate

膜层厚度与耐腐蚀性也未出现对应关系,浓度为10 g/L时,厚度最大(145.25 μm),耐腐蚀性能却最差;而腐蚀速率最低值(0.0394 g/(m2?h))出现在浓度为15 g/L时。

2.1.3 四硼酸钠对膜层的影响及分析

添加适量的四硼酸钠有助于改善微弧氧化膜层的

图2 氢氧化钠浓度对ZK60微弧氧化膜的影响

Fig.2 Effects of NaOH concentration on MAO coating of ZK60: (a) Curves of time vs potential at different NaOH concentrations; (b) Curve of NaOH concentration vs coating thickness; (c) Curve of NaOH concentration vs corrosion rate

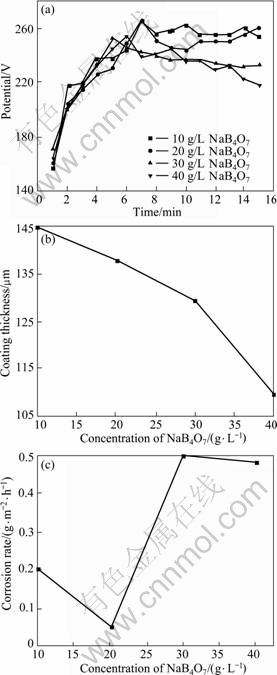

结构,从而提高耐腐蚀性能(见图3)。由图3可看出,当四硼酸钠的浓度由10 g/L提高到40 g/L时,终电压从254 V降到218 V,成膜电压略有下降,也不能抑制尖端放电;膜厚单调下降,膜层腐蚀速率则先减慢后加快,四硼酸钠的浓度为20 g/L时,腐蚀速率最慢(0.048 4 g/(m2?h))。

图3 四硼酸钠浓度对ZK60微弧氧化膜的影响

Fig.3 Effects of NaB4O7 concentration on MAO coating of ZK60: (a) Curves of time vs potential at different NaB4O7 concentration; (b) Curve of NaB4O7 concentration vs coating thickness; (c) Curve of NaB4O7 concentration vs corrosion rate

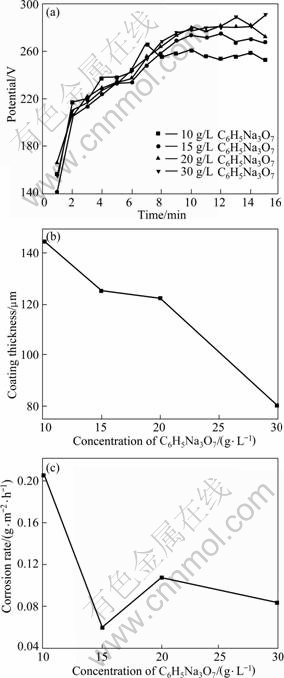

2.1.4 柠檬酸钠对膜层的影响及分析

在硅酸钠体系中,添加柠檬酸钠有利于改善微弧氧化膜层的结构,提高膜层生长的稳定性及耐蚀性(见图4)。由图4可看出,随着柠檬酸钠的浓度由10 g/L增加到30 g/L,终电压从254 V提高到291 V,成膜

图4 柠檬酸钠浓度对ZK60微弧氧化膜的影响

Fig.4 Effects of C6H5Na3O7 concentration on MAO coating of ZK60: (a) Curves of time vs potential at different C6H5Na3O7 concentrations; (b) Curve of C6H5Na3O7 concentration vs coating thickness; (c) Curve of C6H5Na3O7 concentration vs corrosion rate

电压稍有增加,当柠檬酸钠的浓度高于10 g/L后,尖端放电消失;膜层厚度随浓度的增加而下降,腐蚀速率则呈先减后增的趋势,浓度为15 g/L时,膜层腐蚀速率最慢(0.0603 g/(m2?h))。

2.2 正交实验

2.2.1 正交实验结果

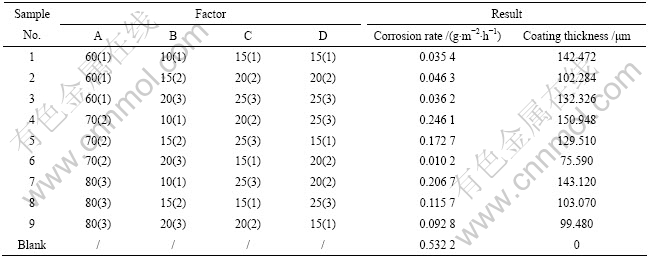

在单变量实验的基础上,根据各电解质组元对膜层的影响规律,按腐蚀性能为主兼顾膜层厚度的原则,并考虑工艺的方便性和可行性,选定电解液的最佳组分筛选范围:A因素(硅酸钠)60~80 g/L,B因素(氢氧化钠)10~20 g/L,C 因素(四硼酸钠)15~25 g/L,D因素(柠檬酸钠)15~25 g/L,进行四因素三水平L9 (34 )正交实验,优化电解液配方。实验方案和结果如表1所列,并将ZK60空白试样的腐蚀数据列入以进行比较。

对表1作直观分析,试样的耐腐蚀性能均优于ZK60空白样的(0.532 2 g/(m2?h)),试样6的腐蚀速率最慢(0.010 2 g/(m2?h)),仅为空白试样的1.9%,膜厚也最小(75.59 μm);相反,膜层最厚试样4(150.948 μm)的腐蚀速率也最快(0.246 1 g/(m2?h)),为空白样的46%。这进一步证明:微弧氧化膜层的耐腐蚀性能与膜层厚度有一定关系,但更主要地取决于膜层显微组织和致密性等微观结构特点。

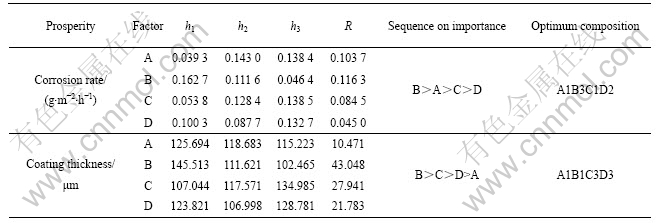

2.2.2 极差分析与优化

表2所列为极差分析结果,hj表示第j个水平对应的实验结果均值,R为极差。对表2分析可知,各因素对膜层腐蚀速率影响的主次顺序为BACD,最佳组合为A1B3C1D2;而对膜层厚度影响的主次顺序为BCDA,最佳组合为A1B1C3D3。显然,无论是对耐腐蚀性能还是膜层厚度,B因素(氢氧化钠)都是最主要的影响因子,但最佳水平不同;而其它3个因素对耐腐蚀性和膜层厚度的影响程度并不一致,如A因素(硅酸钠)在影响腐蚀性能方面排序为第2,但对膜层厚度的影响程度却最小。

依据耐腐蚀性为主兼顾膜层厚度的优化原则,进

表1 正交实验方案及结果

Table 1 Design and results of orthogonal experiments

表2 极差分析

Table 2 Variation analysis of orthogonal experiments

行综合评价和优化筛选。因素A (硅酸钠)作为主成膜剂,取A1水平时,膜层厚度最大且腐蚀速率最低;因素B (氢氧化钠)调节pH值,并能有效拟制膜层尖端放电,促进成膜,因此,成为影响膜层厚度和腐蚀速率的最主要因素,取B3水平时,腐蚀速率最低;因素C (四硼酸钠) 有助于改善膜层结构,并降低成膜电压,取C1水平时,耐腐蚀性最好;因素D (柠檬酸钠)也能有效拟制膜层尖端放电,促进膜层稳定生长,以耐腐蚀性为优选前提可取D2水平。据此,得出优化配方:A1B3C1D2,并进而研究优化膜层的腐蚀性能和显微组织特点。

2.3 优化实验结果与分析

2.3.1 膜层耐腐蚀性能

采用上述优化电解液(A1B3C1D2)制备的微弧氧化试样膜的厚度达164.89 μm,高于正交实验所有试样膜的厚度;同时,腐蚀速率也最低(9.6 mg/(m2?h)),为空白试样的1.8%,表明优化电解液制备的微弧氧化膜层兼具膜层厚、耐腐蚀性能优的优点。

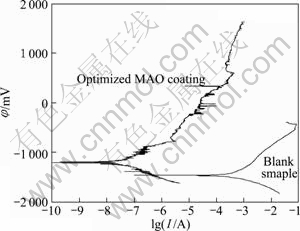

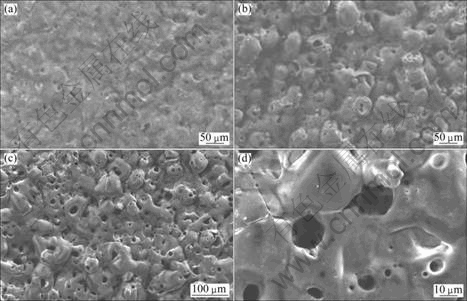

图5所示为优化试样与ZK60空白试样的极化曲线,拟合结果如表3所列。显然,优化配方处理的试样的自腐蚀电位提高,腐蚀电流比空白试样低3个数

图5 ZK60空白样及优化处理试样的超电位极化曲线

Fig.5 Polarization curves of ZK60 blank and optimized samples

表3 动电位极化曲线的拟合电化学参数

Table 3 Fitted Electrochemical parameters from polarization curves

量级。根据法拉第定律,腐蚀速率与腐蚀电流成正比,这与静态腐蚀质量损失结果吻合,进一步证明优化配方大幅度提高了ZK60的耐腐蚀性能。

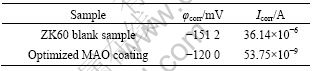

2.3.2 膜层截面显微特征

微弧氧化膜层一般由内、外两层组成,外层疏松多孔,内层结构致密且与基体结合良好。图6(a)、(b)和(c)分别为试样6、7和优化试样膜层在光学显微镜下的横截面形貌。试样6的膜层最薄(75.59 μm),但结构致密,故腐蚀速率低(0.010 2 g/(m2?h));虽然试样7的膜层更厚(143.12 μm),但内部疏松,孔洞较多,腐蚀速率 (0.206 7 g/(m2?h))为试样6的20倍;优化试样的膜层最厚(164.89 μm),膜层结构也非常致密,故耐蚀性能最好。由此可见,虽然膜层厚度对耐蚀性能有一定影响,但更重要的是膜层显微结构,只有在膜层致密的前提下增加膜厚才有利于进一步提高其耐蚀性能。

图6 不同试样的微弧氧化膜层的截面形貌

Fig.6 Cross-section morphologies of MAO coatings of different samples: (a) Sample 6; (b) Sample 7; (c) Optimized sample

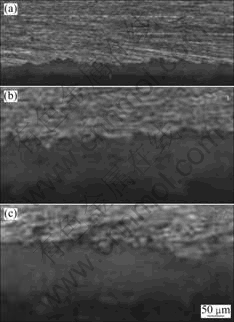

2.3.3 膜层表面显微分析

试样6、7和优化试样微弧氧化膜层的表面形貌分别如图7(a)、(b)和(c)所示,膜层表面由许多圆盘状火山口组织堆叠而成,凹凸不平,圆盘中间孔洞为放电通道,也是气体析出的通道,圆盘周围还随机分布有细小的击穿孔。图7(d)所示为优化试样的高倍图,在膜层表面可见少量裂纹,这是由于熔融物在凝固成壳

图7 不同试样的微弧氧化膜的表面形貌

Fig.7 Surface morphologies of different MAO coatings: (a) Sample 6; (b) Sample 7; (c), (d) Optimized sample

的过程中体积收缩产生了应力,从而形成以孔为裂纹源的微裂纹。这些放电通道和微裂纹的存在为介质中Cl-的渗入提供了通道,使膜层发生腐蚀。故孔洞和裂纹数量越少、尺寸越小,越有利于阻碍Cl-的渗入,从而提高膜层的耐蚀性能。试样6和优化试样的孔径多在3~7 μm,最大为22 μm,孔径较细小,表面较为平整、光洁,故具有优异的耐腐蚀性能;而优化试样的厚度最大,故其耐腐蚀性能最好;反之,试样7的孔洞较多,且表面粗糙,因而耐蚀性能较差。

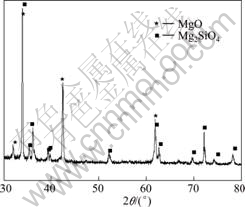

EDS分析表明,优化试样膜层表面主要由Mg、Si、Na、O元素组成,其中Mg为基体元素,Si、O、Na为电解液元素。图8所示为膜层表面的XRD谱。综合分析可知,膜层物相主要为MgO和Mg2SiO4。膜

图8 优化试样微弧氧化膜表面的XRD谱

Fig.8 XRD pattern of oxidation coating of optimized MAO

层形成的一般机制[17]为:在微弧的高温作用下,基体材料表面发生溶解,使氧化膜熔融并在电解液的淬冷作用下迅速凝固形成多孔的氧化膜层,而烧结形成的化合物不断堆垛在基体表面形成氧化膜层。

3 结论

1) 在恒电流模式下固定电参数,通过单变量法研究硅酸钠体系中各电解液组分浓度对ZK60镁合金微弧氧化膜层的影响规律。随着NaSiO3和NaOH浓度的增加,成膜电压显著降低,随着NaB4O7浓度的增加,成膜电压略有降低;提高NaOH和C6H5Na3O7浓度都有利于拟制膜层尖端放电,促进膜层生长的稳定性,使膜层更加致密、均匀。

2) 各电解液组分的浓度对微弧氧化膜层厚度和耐腐蚀性能的影响规律各不相同,并在不同的合适浓度下获得大的膜层厚度和高的耐腐蚀性能,表明微弧氧化膜层的耐腐蚀性不仅取决于膜层厚度,还与膜层结构密切相关。

3) 通过正交实验,按耐腐蚀性为主兼顾膜层厚度的优化原则,筛选出优化的电解液配方:60 g/L NaSiO3+ 20 g/L NaOH+25 g/L NaB4O7+20 g/L C6H5Na3O7,其微弧氧化膜层厚达164.89 μm,膜层结构致密,在3.5%NaCl中的腐蚀速率极低,仅为ZK60镁合金空白试样的1.8%。

REFERENCES

[1] HE S M, PENG L M, ZENG X Q, DING W J, ZHU Y P. Comparison of the microstructure and mechanical properties of a ZK60 alloy with and without 1.3 wt% gadolinium addition[J]. Materials Science and Engineering A, 2006,433 (1/2): 175-181.

[2] YAMASAKI M A, AYASHI N Y, ZUMI S G, KAWAMURA Y H. Corrosion behavior of rapidly solidified Mg-Zn-rare earth element alloys in NaCl solution[J].Corrosion Science, 2007, 49(1): 255-262.

[3] 麻彦龙, 潘复生, 左汝林. 高强度变形镁合金ZK60的研究现状[J]. 重庆大学学报: 自然科学版, 2004, 27(9): 80-85.

MA Yan-long, PAN Fu-sheng, ZUO Ru-lin. Review on the research of high-strength wrought magnesium alloy ZK60[J]. Journal of Chongqing University: Natural Science Edition, 2004, 27(9): 80-85.

[4] LI H X, RUDNEV V S, ZHENG X H, YAROVAYA T P, SONGA R G. Characterization of Al2O3 ceramic coatings on 6063 aluminum alloy prepared in borate electrolytes by micro-arc oxidation[J]. Journal of Alloys and Compounds, 2008, 462(1/2): 99-102.

[5] LIM Y W, KWON S Y, SUN D H, KIM H E, KIM Y S. Enhanced cell integration to titanium alloy by surface treatment with microarc oxidation: A pilot study[J].Clinical Orthopaedics and Related Research, 2009, 467( 9 ): 2251- 2258.

[6] SHI X L, WANG Q L, WANG F S, GE S R. Effects of electrolytic concentration on properties of micro-arc film on Ti6Al4V alloy [J]. Mining Science and Technology, 2009, 19(2): 220-224.

[7] ARRABAL R, MATYKINA E, HASHIMOTO T, SKELDON P, THOMPSON G E. Characterization of AC PEO coatings on magnesium alloys [J]. Surface & Coatings Technology, 2009, 203(16): 2207-2220.

[8] BAI A L, CHEN Z J. Effect of electrolyte additives on anti-corrosion ability of micro-arc oxide coatings formed on magnesium alloy AZ91D [J]. Surface & Coatings Technology, 2009, 203(14/15): 1956-1963.

[9] BALA S P, LIANG J, BLAWERT C, STORMER M, DIETZEL W. Effect of current density on the microstructure and corrosion behavior of plasma electrolytic oxidation treated AM50 magnesium alloy [J]. Applied Surface Science, 2009, 255(7): 4212-4218.

[10] 时海芳, 吕文涛, 李 晓, 李智超. 镁合金陶瓷涂层研究现状[J]. 电镀与涂饰, 2008, 27(1): 54-56.

SHI Hai-fang, L? Wen-tao, LI Xiao, LI Zhi-chao. Present status on the research of ceramic coatings on magnesium alloys[J]. Electroplating & Finishing, 2008, 27(1): 54-56.

[11] 骆海贺, 蔡启舟, 魏伯康. AZ91D镁合金微弧氧化工艺参数的优化[J]. 特种铸造及有色合金, 2007, 27(7): 554-557.

LUO Hai-he, CAI Qi-zhou, WEI Bo-kang. Optimization of processing parameters of micro-arc oxidation for AZ91D magnesium alloy in silicate solution[J]. Special Casting & Nonferrous Alloys, 2007, 27(7): 554-557.

[12] SU P B, WU X H, GUO Y, JIANG Z H. Effects of cathode current density on structure and corrosion resistance of plasma electrolytic oxidation coatings formed on ZK60 Mg alloy[J]. Journal of Alloys and Compounds, 2009, 475(1/2): 773-777.

[13] SU P B, WU X H, JIANG Z H. Plasma electrolytic oxidation of a low friction casting on ZK60 magnesium alloy[J]. Materials Letters, 2008, 62(17/18): 3124-3126.

[14] CAI Q Z, WANG L S, WEI B K, LIU Q X. Electrochemical performance of micro arc oxidation films formed on AZ91D magnesium alloy in silicate and phosphate electrolytes[J]. Surface & Coatings Technology 2006, 200(12/13): 3729-3730.

[15] 钱建刚, 李 荻, 王学力, 郭宝兰. 硅酸钠浓度对镁合金阳极化的影响[J]. 材料科学与工艺, 2006(1): 28-30.

QIAN Jian-gang, LI Di, WANG Xue-li, GUO Bao-lan. Effects of concentration of sodium silicate on anodizing for magnesium alloys[J]. Materials Science and Technology, 2006(1): 28-30.

[16] GUO H F, AN M Z. Effect of surfactants on surface morphology of ceramic coatings fabricated on magnesium alloys by micro-arc oxidation [J]. Thin Solid Films 2006, 500(1/2): 186-189.

[17] 陈显明, 罗承萍, 刘江文. 镁合金微弧氧化表面层多孔结构的形成机制[J]. 材料保护, 2009, 42(1): 1-4.

CHEN Xian-ming, LUO Cheng-ping, LIU Jiang-wen. Mechanisms for the formation of porous micro arc oxidation coatings on magnesium alloys[J]. Journal of Materials Protection, 2009, 42(1): 1-4

(编辑 杨 华)

基金项目:江苏省先进焊接技术重点实验室资助项目(JSAWT-06-08);江苏省研究生创新计划2007年资助项目

收稿日期:2009-11-15;修订日期:2010-01-30

通信作者:芦 笙,教授,博士;电话:0511-84407569;E-mail: lusheng119@yahoo.com.cn