湿式C/C制动材料的摩擦特性及其数值模拟

张明瑜,黄启忠,朱建军,王秀飞,杨 鑫

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:利用多元耦合场CVI工艺将炭毡增密至1.58 g/cm3,再进行树脂浸渍/炭化增密至1.85 g/cm3制备C/C复合材料。测试由其制成的摩擦实验环的湿式摩擦磨损性能,并利用软件建立的有限元模型对2 500 r/min及1.5 MPa时摩擦实验环的温度场分布进行模拟。结果表明:该湿式摩擦材料的摩擦因数在0.07~0.13间波动,当初始转速恒定时,摩擦因数随刹车压力的增大而减小;当刹车压力恒定时,摩擦因数先增大后减小。建立了C/C复合材料湿式制动过程模型,通过模拟获得了制动盘的各个部位温度场在本模拟研究中呈岛形分布,最高温度出现在0.875 s,这为制动材料的设计提供了参考。

关键词:多元耦合场CVI;C/C复合材料;摩擦磨损;数值模拟

中图分类号:TB331 文献标识码:A 文章编号:1672-7207(2007)02-0195-05

Wet friction properties and numerical simulation of C/C composites

ZHANG Ming-yu, HUANG Qi-zhong, ZHU Jian-jun, WANG Xiu-fei, YANG Xin

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The carbon felt was densified to 1.58 g/cm3 with multi-factor coupling fields CVI, and then it was impregnated with resin/carbonized to 1.85 g/cm3 to make the low cost C/C composites. The wet friction and wear properties were tested by friction ring. The temperature distribution of the friction ring was simulated under the condition of 2 500 r/min and 1.5 MPa. The results show the friction coefficient of wet friction material is in the range of 0.07-0.13. The friction coefficient decreases with the increase of brake pressure for constant initial rev. The friction coefficient increases first, and then decreases with initial rev increasing. The model is established by finite element software for thermal simulation of the wet brake process. The shape of temperature distribution likes an island, and the highest temperature emerges at 0.875 s in this simulation. The results are supposed useful to design better brake materials.

Key words: multi-factor coupling fields CVI; C/C composites; friction and wear; numerical simulation

C/C复合材料(简称C/C)由于具有高强低密和优良的导热摩擦性能以及高承载长寿命等突出优点,因而用于大能量刹车,具有较高的可靠性和可维护性[1-5]。因此,C/C广泛用作高性能刹车装置的关键材料。但是,C/C高昂的制备成本一直是制约其广泛应用的瓶颈问题,而影响其成本的关键是化学气相渗透(CVI)增密过程。鉴于高速列车、赛车和重型车辆等对C/C的迫切需求,寻求成本低廉的C/C刹车材料的制备方法已经成为世界各先进国家研究者的工作重点。

基于此,本文作者使用低成本多元耦合场CVI工艺[6]为主增密工艺快速将整体针刺毡增密至一定密度,然后,用树脂浸渍/炭化增密至使用密度制备C/C复合材料,研究其湿式摩擦磨损性能,并模拟摩擦过程中温度场的分布情况,其结果对今后C/C复合材料的制备和应用具有指导作用。

1 实 验

1.1 样品制备

C/C试样增强体由采用聚丙烯腈(PAN)基炭纤维无纬布+网胎构成的针刺整体毡,x和y方向纤维束密度高,z方向纤维束密度低,坯体密度为0.6 g/cm3,尺寸(长×宽×高)为280 mm×60 mm×20 mm。由于本研究要求材料密度大于1.7 g/cm3才能较好地满足长期高负荷使用的要求,因此,先采用多元耦合场CVI进行一次快速增密,然后用呋喃树脂浸渍补充增密。C/C的热处理温度为 2 300 ℃,时间为2 h。试样的性能如表1所示。

表1 C/C复合材料试样的制备工艺和性能

Table 1 Fabrication processing and properties of C/C composite

1.2 结构分析

利用德国Leica MeF3A金相显微镜,使用正交偏光观察分析试样中热解炭的组织和生长特征及观察试样的摩擦表面。取C/C的粉末样品,用Rigaku-D/ 2550VB型X射线衍射仪扫描材料的(002)面衍射角位置,根据Bragg公式计算出平均层面间距d002,计算石墨化度g。采用排水法测量材料的表观密度。

1.3 摩擦性能

制动摩擦实验在国产MM-1000型湿式摩擦试验机上进行。试样是内径为65 mm、外径为85 mm的圆环,表面开12个油槽,槽宽2 mm,深0.8 mm。实验前试样浸油1夜。试样对偶为65Mn钢,试样为静盘。使用4634传动油润滑,油压小于1 MPa,流速约为0.8 mm/s。根据GB13826—1992和重载车辆使用要求,设定动盘转速为2 500 r/min,测试压力为0.5~2.5 MPa时材料的摩擦性能;设定制动压力为1.5 MPa,测试 1 500~4 500 r/min时材料的摩擦性能。

2 结果与分析

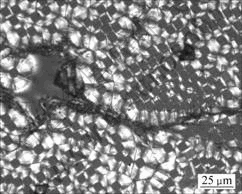

取C/C试样制成金相样品,在正交偏光显微镜下观察。摩擦材料的偏光形貌如图1所示。由图1可知,深色部分是孔隙,而表面光滑、形状不规则的块体是树脂炭。包围在纤维外表面的是具有光学活性的热解炭。热解炭由内圈光滑层状和外圈粗糙层状结构组成,这种带状结构有利于提高材料整体的力学性能[7]。由经热处理后热解炭与碳纤维之间的界面可知它们结合得非常牢固。但热解炭和树脂炭之间存在明显的裂纹和孔隙,表明它们之间的结合力较热解炭和碳纤维之间的结合力弱。

图1 摩擦材料的偏光形貌

Fig.1 Polarized light microscopy of friction material

由图1还可看出,树脂炭边缘部分具有光学活性,这可能是由于在热处理的过程中,树脂固化、炭化时的收缩应力很大,造成其边缘应力石墨化[2, 8]。应力石墨化的具体机理现在还不清楚,但研究表明环绕纤维的树脂炭呈现层状结构[2],表现出各向异性趋势。

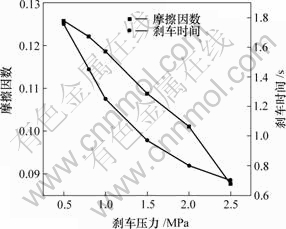

图2所示为试样在摩擦盘初始转速恒定为2 500 r/min改变刹车压力的结果。由图2可知,随着刹车压力的增加,摩擦因数逐渐减小,刹车时间逐渐缩短。由于刹车压力的增大,油膜变薄,摩擦盘之间的实际接触面积增大,但其对应的摩擦因数却呈现降低趋势。根据弹性流体动压润滑理论的粘压效应,当压力增大时,油分子间距减小,内聚力增大,从而粘度随压力的增大而迅速增大,导致摩擦因数减小。同时传动油起到了充分的润滑和散热功效,因此摩擦因数较小。另外,还有C/C本身具有石墨自润滑的特性,这说明摩擦因数减小是多种因素共同作用的结果。当表面压力过低时,刹车盘处于边界润滑状态,摩擦因数较大[9]。

图2 刹车压力对刹车时间和摩擦因数的影响

Fig.2 Influence of brake pressure on brake time and friction coefficient

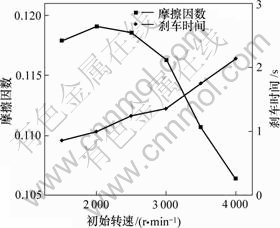

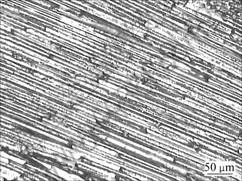

图3所示为刹车压力恒定为1.5 MPa时改变刹车速度的实验结果。由图3可知,随着刹车盘初始转速的提高,刹车惯性力随之增加,刹车所需时间也随之延长,摩擦因数先增大后减小。研究表明[10]:在变速条件下,油温变化引起了油粘度的变化,从而对摩擦因数产生影响。Shima[11]曾由实验得出油粘度的降低会导致摩擦因数的降低。本实验油温在65~85 ℃间变化,由于4634传动油[12]油温改变引起粘度的降低很小,可以忽略其影响。由摩擦盘的制动能量E∝ω2(ω为初始角速度),当初始转速从1 500增大到4 500 r/min时,制动产生的热能增大8倍,部分能量使摩擦盘表面温度升高,导致热导率和热膨胀系数不同的各组分间结合力减弱,且磨屑在高能状态下细化,加上4634传动油的润滑作用都使摩擦因数减小。图4所示为摩擦后平行纤维表面形貌,油膜覆盖在裸露的纤维和基体炭上面。实验结果表明,多元耦合场CVI制备的C/C复合材料经浸渍后可以满足重型车辆制动材料设计要求。

图3 初始转速对刹车时间和摩擦因数的影响

Fig.3 Influence of initial velocity on brake time and friction coefficient

图4 摩损面在金相显微镜下的形貌

Fig.4 Morphology of friction face under optical microscopy

3 数值仿真

制动盘的瞬态温度场难以进行实验测量,因此有必要进行相应的数值模拟,作为提升材料性能的参考。首先,为对上述刹车盘进行热传导分析仿真假设:

a. 接触面内压力分布是相同的;

b. 材料的摩擦因数为常数;

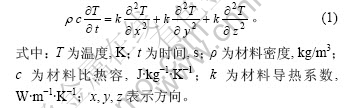

c. 摩擦材料热性能不随温度发生变化。根据传热学理论[13],对于无内热源的各向同性材料其热传导方程为:

制动盘材料的相关物理参数如表2所示。

表2 制动盘相关材料参数

Table 2 Related parameters of brake disc

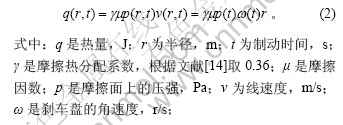

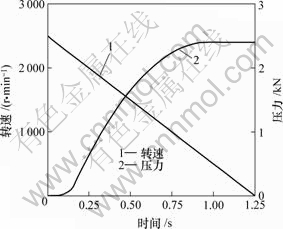

C/C湿式制动实验过程中动盘以2 500 r/min,1.5 MPa与静盘接合摩擦,动盘均速下降直至停止。为便于功的计算及输入,根据实验结果将摩擦过程进行简化(转速拟合为直线,压力拟合为二次曲线),如图5所示。将制动过程中摩擦生热等效为瞬时移动面热源加载于摩擦面上。制动盘的热输入由下式计算:

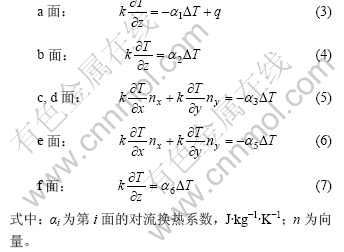

边界条件如下。

图5 制动实验曲线

Fig.5 Curve of brake test

材料的摩擦实验是浸在冷却润滑油中进行的,故模拟分析只考虑制动盘表面与环境的对流换热。对流换热系数取决于流体的流动状态和物理性质(比热容、粘度、导热系数)、制动盘的表面温度及表面形状[13],即:

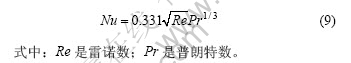

在实验过程中,冷却润滑油的流动状态设为层流,根据平面层流换热的传热学理论,润滑油的层流换热准则方程:

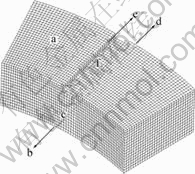

考虑制动盘的几何形状和制动过程中热载荷轴对称分布的特征,实际计算取制动盘的1/12扇形区,对含油槽结构的制动盘进行网格划分,采用八节点六面体单元进行计算,制动盘有限元模型如图6所示。经求解,得到C/C刹车盘湿式制动实验随温度场时间变化的分布情况。图7所示为制动出现最高温度时刻(t=0.875 s)的温度场分布。图8所示为最高温度时刻(t=0.875 s)时摩擦面径向温度分布。从图8中可以看出,温度在摩擦面上呈岛形分布,并沿面中心径向先增大后减小,这是由于外径区域线速度较大,动能转换的热量较多,使其温度升高;而靠近外环面及油槽所在的部位温度较低是油冷却效应所致。

图6 制动盘有限元模型

Fig.6 Finite element analysis (FEA) model of brake disc

图7 在最高温度点制动盘瞬时温度场分布

Fig.7 Transient temperature field distribution of brake discat highest point

图8 沿摩擦面径向温度分布图(t=0.875 s)

Fig.8 Temperature distribution on radius direction of friction face (t=0.875 s)

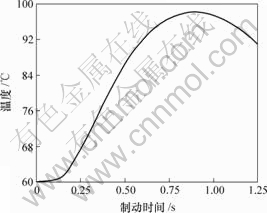

图9所示为出现最高温度节点处在制动过程中的温度变化曲线。从图9可看出,摩擦刚开始时温度上升平缓,随着制动的进行,温度迅速升高,在制动末期温度的上升又趋于平缓,最后温度出现下降,其中最高温度出现在t=0.875 s时刻。这是由于制动过程中,随着动能转化为热能,盘面温度逐渐上升,热量逐渐累积直达最高温度。但同时刹车盘的转速逐渐减小,当温度达到最高点后,动能转化的能量已经不足以抵消热传导和油冷却所带走的热量,因此,温度开始下降。

图9 制动过程中节点的温度变化曲线

Fig.9 Temperature change curve of node during brake process

4 结 论

a. 采用多元耦合场CVI和浸渍工艺并经过石墨化后制备的低成本C/C具有优良的湿摩擦磨损特性,可以满足重型车辆的使用要求。

b. 随着刹车压力的增加,摩擦因数逐渐减小,刹车时间逐渐缩短;随着刹车盘初始转速的提高,刹车惯性力逐渐增加,刹车所需时间逐渐延长,摩擦因数先增大后减小。

c. 仿真结果表明,制动盘面的温度呈岛形分布,由于热扩散和油冷却作用,在靠近外环面及油槽处的温度较低。

参考文献:

[1] Donal L S. Unique applications of carbon/carbon composite materials[J]. SAMPE Journal, 1999, 35(3): 27-39.

[2] Savage G. Carbon-carbon composites[M]. London: Chapman & Hall, 1993.

[3] 陈腾飞, 龚伟平, 张红波, 等. 高温热处理对光滑层热解炭裂纹形成的影响[J]. 粉末冶金材料科学与工程, 2006, 11(4): 210-213.

CHEN Teng-fei, GONG Wei-ping, ZHANG Hong-bo, et al. Influence of heat-treatment on crack initiation in smooth laminar pyrolytic carbon matrix[J]. Materials Science and Engineering of Powder Metallurgy, 2006, 11(4): 210-213.

[4] Hutton T J, McEnancy B, Crelling J C. Structural Studies of wear debris from carbon-carbon composite aircraft brakes[J]. Carbon, 1999, 37(6): 907-916.

[5] Shin H K, Lee H B, Kin H S. Tribological properties of pitch-based 2-D carbon-carbon composites[J]. Carbon, 2001, 39(6): 959-970.

[6] 张明瑜, 黄启忠, 谢志勇, 等. 多元耦合场CVI法快速致密化炭/炭复合材料研究[J]. 功能材料, 2006, 37(10): 1623-1626.

ZHANG Ming-yu, HUANG Qi-zhong, XIE Zhi-yong, et al. Preparation and densification mechanism of C/C composites with fast CVI[J]. Journal of Functional Materials, 2006, 37(10): 1623-1626.

[7] Reznik B, Guellali M, Gerthsen D, et al. Microstructure and mechanical properties of carbon-carbon composites with multilayered pyrocarbon matrix[J]. Materials Letters, 2002, 52: 14-19.

[8] Thomas C R. Essentials of carbon-carbon composites[M]. London: Royal Society of Chemistry, 1993.

[9] Awasthi S, Wood J L. C/C composite materials for aircraft brakes[J]. Advanced Ceramic Materials, 1988, 3: 449-451.

[10] H?hn B R, Michaelis K. Influence of oil temperature on gear failures[J]. Tribology International, 2004, 37: 103-109.

[11] Shima M, Suetake H, McColl I R. On the behavior of an oil lubricated fretting contact[J]. Wear, 1997, 210: 304-310.

[12] 姜永盛, 朱国华, 曹 毅. 4634坦克传动油的研制[EB/OL]. http://www.chinalubricant.com, 2006-06.

JIANG Yong-sheng, ZHU Guo-hua, CAO Yi. Study on 4364 drive oil for tank[EB/OL]. http://www.chinalubricant.com, 2006-06.

[13] 杨世铭, 陶文铨. 传热学[M]. 北京: 高等教育出版社, 2003: 130-143.

YANG Shi-ming, TAO Wen-quan. Heat transfer science[M]. Beijing: High Education Press, 2003: 130-143.

[14] Gao C H, Lin X Z. Transient temperature field analysis of a brake in a non-axisymmetric three-dimensional model[J]. Journal of Materials Processing Technology, 2002, 129: 513-517

收稿日期:2006-12-11

基金项目:国家重点基础研究发展规划资助项目(2006CB600901)

作者简介:张明瑜(1974-),男,辽宁沈阳人,博士研究生,从事C/C复合材料的研究

通讯作者:黄启忠,男,教授,博导;电话: 0731-8836078;E-mail: qzhuang@mail.csu.edu.cn