文章编号:1004-0609(2008)08-1371-06

高应变速率冲击下2519A铝合金组织结构的转变

张新明,高志国,陈明安,李惠杰,刘 瑛,刘 波

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用分离式Hopkinson 压杆(SHPB)和Gleeble?1500热模拟装置对2519A-T87铝合金分别进行动态冲击和准静态实验,运用XRD和TEM对室温下应变率为0.001 /s和1 287~7 050 /s压缩冲击后试样的微观组织和相组成进行分析,利用小负荷硬度仪对冲击后试样进行显微硬度测试。结果表明:由外力功转化为相界面能和应变能可以补偿θ相形核功(?G),导致试样受冲击后沉淀相θ′向θ相发生转变并粗化,冲击变形应变率越高,冲击后试样硬度越低;随着冲击变形应变率上升,与基体共格或半共格的正方结构θ′相体积分数减小,与基体非共格体心正方结构θ相体积分数增加;减少材料受冲击后θ′相向θ相的转变数量可提高材料抗冲击性能。

关键词:2519A铝合金;显微组织;转变;高应变速率;冲击

中图分类号:TG 115.5; TG 113 文献标识码: A

Microstructure transformation of 2519A aluminium alloy impacted at high strain rates

ZHANG Xin-ming, GAO Zhi-guo, CHEN Ming-an, LI Hui-jie, LIU Ying, LIU Bo

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: 2519A-T87 aluminum alloy was investigated in dynamic impact testing by split Hopkinson pressure bar (SHPB) and in quasistatic compression by Gleeble?1500 thermal simulation setup. The microstructures and phase compositions of compressed specimens subjected to dynamic impact testing at the strain rate range of 1 287?7 050 /s and quasistatic testing at the strain rate of 0.001 /s at room temperature were determined by TEM and XRD. The hardnesses of compressed specimens were measured by using little-duty Vickers hardness tester. The results show that the interface energy and strain energy due to external work can compensate the nucleation energy (?G) of θ phase and lead to θ′ phase transforming into θ phase that coarsens gradually in the impacted specimen. The higher the strain rate, the lower the hardness of impacted specimens. With increasing strain rate the volume fraction of coherent or semi-coherent tetragonal θ′ phase decreases while the volume fraction of incoherent body centered tetragonal θ phase increases obviously. The most effective measure to promote the shock resistance of the alloy is to decrease the number density of θ phase evolving from θ′ phase in the impacted 2519A-T87 alloy.

Key words: 2519A aluminium alloy; microstructure; transformation; high strain rate; impact

2519铝合金是20世纪80年代美国开发的一种装甲铝合金,国内外许多材料科学与工程领域的学者对该合金的力学与抗应力腐蚀性能进行了比较深入的研究。该合金具有优异的抗弹性能、力学性能、抗应力腐蚀性能和可焊接性能[1?4]。2519A铝合金(以下简称2519A)是由2519铝合金发展而来的一种新型装甲材料[5?6]。在承受炮或子弹侵彻时,冲击变形应变速率较高。探明不同应变速率冲击条件下其组织结构特征,对于了解材料的损伤机理,提高抗弹性能的途径具有重要意义。在基于一维波理论和应力均匀性假设基础上的分离式Hopkinson 压杆(SHPB)实验不仅可以模拟装甲材料在承受冲击载荷时的特定服役条件,而且可以避开直接测量试件应变的难题。SHPB为测试材料在高应变率下力学性能的最通用、最有力的实验工具,已被广泛地运用到材料高应变率(102~104 /s)冲击实验研究中[7]。本文作者利用SHPB实验装置,研究了T87状态2519A在应变率为1 287~7 050 /s受冲击变形后的微观组织变化规律,为设计制备高抗冲击铝合金材料提供依据。

1 实验

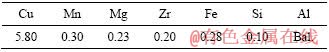

实验用2519A材料采用Al-Cu,Al-Mn,Al-Ti,Al-V和Al-Zr中间合金以及工业纯Al和纯Mg配制, 其化学成分见表1。熔炼时用石墨坩埚在井式电炉中进行,并经铸锭—均匀化—铣面—热轧—固溶—冷轧—时效工序后获得T87状态板材。

表1 实验用材料的化学成分

Table 1 Chemical composition of studied alloy (mass fraction, %)

利用分离式Hopkinson压杆装置进行高应变率常温冲击实验(如图1所示)。压缩试件尺寸为d 8 mm× 6 mm和d 6 mm×4 mm两种,圆柱形试件放置在入射和透射杆之间。

图1 SHPB装置示意图

Fig.1 Schematic of split Hopkinson pressure bar

两压杆是由材料相同的高强度合金钢制成,直径为14.5 mm,长度为1 200 mm,弹性模量为200 GPa。撞击杆的材料和直径与压杆的完全相同,长度为200 mm。实验中要求试件与压杆端面接触处有良好的润滑性,以消除试件与杆之间的摩擦对实验结果的影响。撞击杆的速度范围是15.79~34.25 m/s,应变率的范围是1 287~7 050 /s。为了对实验结果进行比较,改变撞击杆在枪膛里的位置或气室内气体的压力,可以得到不同材料变形的应变率。利用Gleeble?1500热模拟机进行准静态常温实验,试件形状是两端带有深0.1 mm凹槽的Rastegaev型[8],尺寸为d 8 mm×15 mm。利用Tecnai G2 20型电子显微镜观察和D/max?rA转型X射线衍射仪测试压缩后试样微观结构变化,采用HV?10B型小负荷维氏硬度计测试压缩后试样硬度。

2 结果与讨论

2.1 高应变速率对压缩试样微观组织的影响

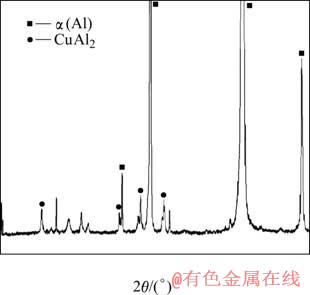

为探明T87状态下的2519A合金试样经过不同高应变速率冲击后的组织结构,需对冲击后试样进行TEM和XRD微观分析。试样经过Hopkinson 压杆 7 050 /s高应变速率冲击后的XRD谱如图2所示。

图2 受应变率为7 050 /s冲击后试样的XRD谱

Fig.2 XRD pattern of specimen impacted at strain rate of 7 050 /s

由图可知,试样经7 050 /s应变速率冲击后相组成为α(Al)和CuAl2相,CuAl2相有可能在高应变率冲击的那一瞬间(200 μs左右)内由亚稳的过渡结构向CuAl2稳态发生转变。研究表明[9],该合金沉淀析出序列为GPⅠ区→θ′′(GPⅡ区)→θ′(正方结构)→θ(体心正方结构),这些相结构向能量低的亚稳态和平衡态转变时会释放一定的能量。图3所示为T87态原始试样、准静态和不同应变速率冲击后对应试样的微观组织TEM形貌明场像(图中直线为Al基体上析出相的惯析面)。由文献[10]可知,时效态2519A TEM微观组织中析出相主要为θ′(CuAl2,惯析面为{100}α)或θ相。由图3(a)可知,T87态试样TEM微观组织以大量类似盘片状θ′析出物为主且呈现列式分布,而准静态实验(0.001 /s)后试样组织由图3(a)演变为图3(b)所示组织,由图3(b)中发现列式分布的θ′强化相分布方向略有偏移,由于材料各向异性导致θ′相分布方向之间夹角偏离90?且半径明显缩短。图3(c)~(f)所示分别为对图3(a)所示T87态试样分别进行应变速率为1 287、3 530、5 730和7 050 /s动态冲击所对应试样中第二相的TEM微观形貌。比较图3(b)与图3(c)~(f)可知,动态冲击试样组织演变与准静态的情况有较为明显差别。应变速率较低时(如图3(c)和(d)所示),θ′析出物形貌未见明显转变;当应变率达到5 730 /s(见图3(e)所示)后θ′析出物形貌发生明显转变且体积分数明显减小,但当应变率达到7 050 /s时,θ′强化相体积分数明显减少,θ相数量显著增加,大量θ′析出物转变为θ相。高应变速率冲击后输入杆的动能部分转化为相界面能、位错能和应变能储存在试样中,这势必促使与基体共格或半共格的亚稳结构向与基体非共格的沉淀相θ转变。因θ相与α相之间界面能较高,θ相临界形核功?G较大,高应变率冲击试样后由外力功转化为应变能和位错能不仅可以补偿?G,而且给θ相长大提供了动力,因而导致试样中沉淀相θ的形成和粗化。

图3 不同应变速率冲击后试样的微观组织TEM明场像

Fig.3 TEM BF images for specimens impacted at different strain rates (parallel to impacted surface): (a) T87 temper; (b) At strain rate of 0.001 /s; (c) At strain rate of 1 287 /s; (d) At strain rate of 3 530 /s; (e) At strain rate of 5 730 /s; (f) At strain rate of 7 050 /s

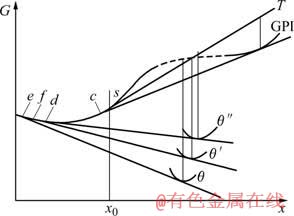

2.2 θ′→θ相转变及θ相粗化

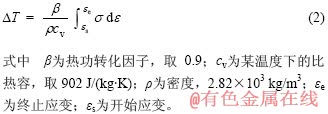

在动态冲击压缩过程中,塑性功大部分转化为热能释放,只有一少部分转化为相界面能和由晶格位错导致的弹性应变能,还有一部分用于使材料发生不可逆的结构变化。试样单位体积试样吸收的能量为[11?12]

试样吸收的能量中大约有90%~95%转化为热能,绝热温升[13]可用定量表示为

利用上述两个公式计算所得不同应变速率对应塑性功与绝热温升,结果如图4所示。由图可知,应变率越高,试样吸收的能量越多,绝热温升越高,外力功转化为相界面能和应变能越多。

图4 应变速率对单位体积试样吸收能量和绝热温升的影响

Fig.4 Effects of strain rate on energy absorption per volume material and adiabatic temperature elevation

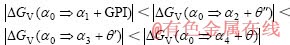

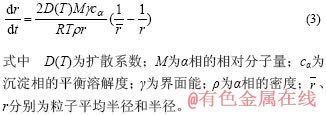

外力功转化为相界面能和应变能对整个体系的总的自由能均有贡献。依据Al-Cu合金在温度T时的自由能G随Cu浓度变化的曲线如图5所示,析出各相都会使得体系自由能下降,即?GV均为负值,并且|?GV|有如下关系:

图5 Al-Cu合金GP区、θ′′、θ′、θ相自由能G随Cu浓度的 变化[14]

Fig.5 Free energies of GP zone, θ′′, θ′ and θ phase in Al-Cu alloys with Cu content

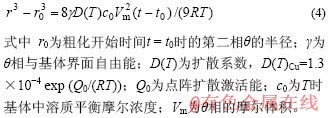

式中 α1、α2、α3和α4分别为与GPI、θ′′、θ′和θ相达到平衡时的α基体母相。考虑析出相沉淀过程中的主要驱动力为△GV,由于T87态2519A属峰值时效态合金,试样在经受实验范围内高应变率冲击时绝热温升可达3~140 K左右,原始组织中亚稳θ′相在冲击后绝热温升的过程中发生转变,结合图3可知,当应变率达到7 000 /s以上时,试样中才出现大量稳定θ相,可见冲击压缩时不同的应变率对应不同的微观组织和绝热温度,θ′→θ转变过程是绝热温升控制,温度越高,溶质Cu原子扩散系数越大,体系总的自由能G降低,亚稳相进一步向稳定相θ转变概率越大。并且,θ′相转变为θ相后在自由能驱动力下会粗化长大。GREENWOOD[15]对大量沉淀粒子的粗化过程提出如下模型:

LIFSHITZ、SLYOZOV和WAGNER[16]在GREENWOOD的粗化模型基础上获得下列模型:

从式(3)和(4)可以得知:

1) θ′→θ转变过程是受温度扩散控制,应变率越高,绝热温度越高,溶质Cu原子扩散系数越大,体系自由能G降低,亚稳相进一步向稳定相θ转变。

2) 影响冲击后试样中θ粗化的因素有绝热温度,相界面能,扩散系数,母相中、母相与析出相平衡界面处和析出相中的溶质平衡摩尔浓度。

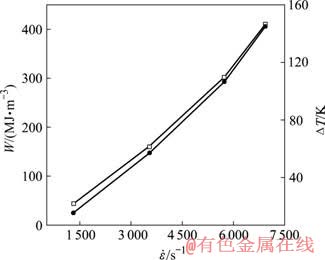

2.3 高应变速率对压缩试样硬度的影响

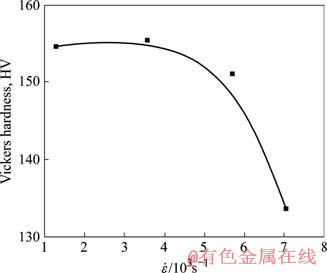

不同应变速率对试样显微硬度的影响如图6所示。由图可知,随着应变速率的升高,材料显微硬度呈先保持后激剧下降趋势,这是因为当应变速率未达到5 730 /s前,细小的且硬度较高的θ′相体积分数变化较小,对硬度的影响较小,当应变速率达到5 730 /s后,θ′相体积分数明显减少,发生转变和粗化后形成大量硬度较低的θ相,从而导致硬度显著下降。

图6 应变速率对试样硬度的影响

Fig.6 Effect of strain rate on hardness of specimens impacted at different strain rates

3 结论

1) 在2519A?T87合金进行动态压缩冲击实验中,当应变速率在1 287~7 050 /s范围内,由Hopkinson 装置输入杆做功转化为相界面能和应变能可以补偿θ相形核功?G,导致试样受冲击后与基体共格或半共格的正方结构θ′沉淀相体积分数减小,与基体非共格体心正方结构θ沉淀相体积分数增大;应变速率越高,冲击后试样硬度越低。

2) 冲击条件下θ′→θ转变过程是受绝热温升控制,应变速率越高,温度越高,溶质Cu原子扩散系数越大,体系自由能G降低,亚稳相进一步向稳定相θ转变。

REFERENCES

[1] FISHER JAMES J Jr, KRAMER L S, PICKENS J R. Aluminum alloy 2519 in military vehicles[J]. Advanced Materials and Processes, 2002, 160(9): 43?46.

[2] HAMILTON B C, ASHOK S. Transient crack growth behavior in aluminum alloys C415-T8 and 2519-T87[J]. Engineering Fracture Mechanics, 1999, 62(1): 1?22.

[3] HAMILTON B C, HALL D E, SAXENA A, MCDOWELL D L. Creep crack growth behavior of aluminum alloy 2519(Part I): Experimental analysis[J]. ASTM Special Technical Publication, 1997, 1297(1): 3?18.

[4] STANISLAW D, MAREK D. TEM investigation of age-hardenable Al 2519 alloy subjected to stress corrosion cracking tests[J]. Materials Chemistry and Physics, 2003, 81: 286–288.

[5] 李慧中, 张新明, 陈明安, 龚敏如, 周卓平. 2519铝合金焊接接头的组织与性能[J]. 中国有色金属学报, 2004, 14(6): 956?960.

LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, GONG Min-ru, ZHOU Zhuo-ping. Microstructures and properties of welded joint of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 956?960.

[6] 李慧中, 张新明, 陈明安, 周卓平, 龚敏如. 预变形对2519铝合金组织与力学性能的影响[J]. 中国有色金属学报, 2004, 14(12): 1990?1994.

LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, ZHOU Zhuo-ping, GONG Min-ru. Effect of pre-deformation on microstructures and mechanical properties of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 1990?1994.

[7] MENG H, LI Q M. Correlation between the accuracy of a SHPB test and the stress uniformity based on numerical experiments[J]. International Journal of Impact Engineering, 2003, 28(5): 537?555.

[8] 李慧中, 张新明, 陈明安, 周卓平. 2519铝合金热变形流变行为[J]. 中国有色金属学报, 2005, 15(4): 621?625.

LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, ZHOU Zhuo-ping. Hot deformation behavior of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 621?625.

[9] TAKEDA M, MAEDA Y, YOSHIDA A, ENDO T. Discontinuity of G.P. (I) zone and θ′-phase in an Al-Cu alloy[J]. Scripta Materialia, 1999, 41(6): 643?649.

[10] 张新明, 龚敏如, 李慧中, 陈明安, 周卓平. 2519铝合金薄板在不同时效状态的抗晶间腐蚀能力[J]. 中南大学学报(自然科学版), 2004, 35(3): 349?352.

ZHANG Xin-ming, GONG Min-ru, LI Hui-zhong, CHEN Ming-an, ZHOU Zhuo-ping. Effect of ageing tempers of aluminum alloy 2519 sheet on intergranular corrosion[J]. Journal of Central South University (Science and Technology), 2004, 35(3): 349?352.

[11] 曹晓卿, 杨桂通. 热处理对泡沫铝合金力学性能及吸能性的影响[J]. 稀有金属材料与工程, 2006, 35(7): 1121?1125.

CAO Xiao-qing, YANG Gui-tong. Effects of heat treatment on the mechanical properties and energy absorption Characteristics of open cell aluminum alloy foams[J]. Rare Metal Materials and Engineering, 2006, 35(7): 1121?1125.

[12] SIA N N, GUO Wei-guo. High strain-rate response of commercially pure vanadium[J]. Mechanics of Materials, 2000, 32: 243?260.

[13] LEE W S, LIU Chen-yang. The effects of temperature and strain rate on the dynamic flow behaviour of different steels[J]. Mater Sci Eng A, 2006, 426(1/2): 101?113.

[14] 肖纪美. 合金相与相变[M]. (第二版). 北京: 冶金工业出版社, 2004: 327.

XIAO Ji-mei. Phase in alloy and phase transformation[M]. 2nd ed. Beijing: Metallurgical Industry Press, 2004: 327.

[15] GREENWOOD G W. Mechanism of phase transformation in crystalline solids[M]. London: Institute of Metals, 1969.

[16] PERRIN C, RAINFORTH W M. The coarsening of θ precipitates in an Al-4wt% Cu alloy as a result of frictional heating[J]. Scripta Materialia, 1996, 34(6): 877?881.

基金项目:国家重点基础研究发展计划资助项目(2005CB623700)

收稿日期:2007-11-14;修订日期:2008-03-03

通讯作者:张新明,教授,博士;电话:0731-8830265;E-mail: xmzhang@mail.csu.edu.cn

(编辑 陈爱华)