DOI:10.19476/j.ysxb.1004.0609.2017.12.13

激光近净成形SS316/Ni20复合材料的开裂机理

郝云波,张国会,马广义,闫 帅,牛方勇,吴东江

(大连理工大学 精密与特种加工教育部重点实验室,大连 116024)

摘 要:采用激光近净成形制备梯度材料时异种材料的混合易产生缺陷,严重制约了梯度材料的应用。采用激光近净成形技术制备不同成分比的SS316/Ni20复合材料薄壁结构,并利用OM、SEM、XRD、EDS等检测手段研究不同成分比时复合材料的显微组织、相组成及元素分布。对裂纹的微观形貌、裂纹断面的元素分布进行分析。结果表明:在给定工艺条件下,SS316质量分数为100%、20%~0时成形件形貌较好,无裂纹缺陷,SS316质量比在90%~30%时成形件发生开裂。裂纹沿晶界扩展,裂纹断面上晶粒清晰可辨,属于热裂纹范畴。成形件开裂主要原因是凝固过程中杂质元素在晶界偏析形成连续的液膜,以及硬质相在晶界上的连续析出,降低晶粒间的结合强度,使其在残余应力作用下产生开裂。

关键词:SS316/Ni20复合材料;梯度材料;激光近净成形;裂纹

文章编号:1004-0609(2017)-12-2501-10 中图分类号:TG665 文献标志码:A

梯度材料最早于1984年研究耐热材料时提出[1],主要用于航天飞机外蒙皮和发动机,由于梯度材料的成分和显微组织可以从梯度件的一端向另一端逐渐过渡,与之对应的性能(如物理性能、化学性能和力学性能)也相应地改变,以满足零件在复杂工况条件下不同的性能要求,使梯度材料比传统单一材料具有更广阔的应用前景。316不锈钢具有良好的耐腐蚀性和力学性能,广泛用于石油化工、反应堆及核电站中各种耐酸阀门及高温高压阀门的制造。Ni20镍基合金在提高零件耐酸性和H2S腐蚀及抗高温氧化方面获得广泛应用[2-3]。SS316/Ni20复合材料体系在满足SS316低成本、良好的耐腐蚀性和力学性能的基础上又能实现良好的耐磨性及抗高温氧化性能等,可用于制造高端汽车发动机气门推杆等零部件[4]。激光近净成形技术是利用高能激光束熔化金属表面形成熔池,同时将金属材料同步送入熔池而形成与基体冶金结合的金属层,故通过控制输送的粉末成分即可在成形件的不同位置获得所需的组织和性能。由于激光熔覆具有快速加热和快速冷却的特点,且循环的受热和冷却过程使得成形件容易产生较大残余应力,应力不断累积增大容易导致成形件的开裂。

CARROLL等[5]用直接能量沉积(Directed energy deposition, DED)技术制备了SS304/Inconel625功能梯度块体,研究了显微组织和显微硬度等的变化,并提出一种通过实验数据和热力学计算模型来确定梯度过渡区裂纹附近二次相的方法。REICHARDT等[6]应用激光沉积系统制备Ti6Al4V/V/SS304功能梯度结构件,发现Ti6Al4V/V和SS304/V梯度过渡区内均出现裂纹,认为过渡区内形成的脆性相是引起成形件开裂的原因。HOFMANN等[7]根据Ti-Al-V三元合金相图规划梯度过渡路径,避免了Al含量超过12%,从而避免了引起开裂的脆性相。李涤尘等[8]采用激光金属直接成形技术制备Ti6Al4V/CoCrMo梯度材料实体件,发现CoCrMo含量为10%(体积分数)时成形件不开裂,含量为20%、30%时成形件产生严重开裂,这是由于两种材料形成有限固溶体以及两种材料之间热物性参数的差异造成的。姚建华等[9]采用激光熔覆技术在高温合金基体上熔覆Inconel738合金,发现裂纹的形成主要跟熔覆层的热输入和低熔点共晶相有关。林学春等[10]采用激光熔覆技术在不同基板上沉积镍基合金/WC复合涂层,研究了不同基板对熔覆层裂纹和气孔的影响。激光近净成形结构件产生裂纹的原因主要与材料的显微组织、有害相的生成及成形过程中的残余应力有关。因此,进行激光近净成形SS316/Ni20梯度结构之前研究不同成分比例复合材料的微观组织和有害相的形成对得到无裂纹的功能梯度结构很有必要。

本文作者利用激光近净成形技术制备SS316/Ni20复合材料薄壁件,观察不同成分组成时的裂纹分布、显微组织及相组成。分析成形件内部裂纹的微观形貌特征,研究不同成分组成时裂纹缺陷产生的原因,为近净成形无裂纹的梯度材料奠定基础。

1 实验

本实验所采用的激光近净成形系统主要由半导体激光器、KUKA六轴机械臂、双筒送粉器、冷水机等组成,如图1所示。激光器采用德国Laserline LDF4000-100型半导体激光器,最大输出功率为4000 W,实验采用连续模式输出激光,波长900~1070 nm。采用纯度为99.99%的高纯氩气作为保护气和载粉气。

图1 激光近净成形系统示意图

Fig. 1 Schematic diagram of laser engineered net shaping system

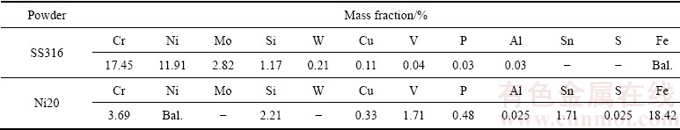

由于304不锈钢与316不锈钢具有相似的化学成分及热物性参数且更廉价,故实验中采用尺寸为100 mm×100 mm×15 mm的304不锈钢作为基板。实验前基板采用砂纸打磨及无水乙醇清洗进行表面处理。所用316不锈钢粉末和Ni20镍基合金粉末的粒度均为45~90 μm,对应的成分见表1。采用预制混合粉末的形式,实验前按一定比例均匀混合两种金属粉末。

316不锈钢粉末的熔点在1371~1398 ℃范围内,Ni20镍基合金粉末的熔点在1050~1150 ℃范围内,两种粉末熔点相差300 ℃左右。通过改变激光功率的方式来满足不同比例下混合粉末熔化过程中对能量的需求,选择激光功率范围为660~960 W,激光扫描速度为6 mm/s,送粉率为3.6 g/min,激光束光斑直径为3 mm。成形过程采用循环往复扫描方式,每成形1层激光头向上提升为0.24 mm。质量分数变化步长为10%,即混合粉末中SS316质量分数每降低10%,相应的Ni20镍基合金的质量分数增加10%。采用上述的工艺参数成形不同成分比例下层数为50层,长度为80 mm的单道多层薄壁件,并观察不同成分下成形件的开裂情况。

用线切割切取不同成分比例下的薄壁件,将其制成标准金相试样,采用王水(体积比为3:1的浓盐酸和浓硝酸混合溶液)进行金相腐蚀,Olympus光学显微镜(OM)和扫描电子显微镜(SEM)对金相试样的显微组织及裂纹断口形貌进行观察,SEM附带的能谱分析仪(EDS)对成形件的成分进行分析,X射线衍射仪(XRD)对成形件的相组成进行检测。

2 结果与分析

2.1 宏观形貌

按照成分变化步长为10%进行激光近净成形薄壁结构制备,其宏观形貌如图2所示。结果表明:成分比为0~20% SS316、100% SS316的成形件外观形貌良好,无宏观裂纹且壁厚均匀,如图2(a)、(b)、(c)、(k)所示。30%~90% SS316这7种不同成分比例时薄壁件出现不同程度的开裂,如图2(d)~(i)所示。裂纹扩展方向与激光束扫描方向近乎垂直,裂纹起始于薄壁件的顶端终止于薄壁件中部甚至底部。

表1 SS316和Ni20的化学成分

Table 1 Chemical composition of SS316 and Ni20

图2 不同成分比时SS316/Ni20复合材料的宏观形貌

Fig. 2 Macro-morphologies of SS316/Ni20 composite with different compositions

2.2 显微组织

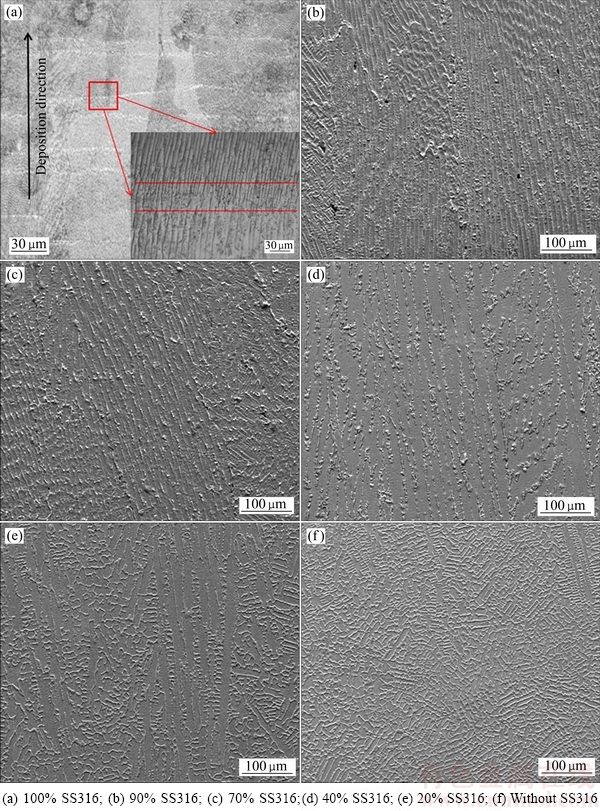

图3所示为不同成分比时SS316/Ni20复合材料的显微组织,100%SS316的显微组织如图3(a)所示。其显微组织主要由与沉积方向基本相同的柱状晶组成,且枝晶穿过沉积层界面连续生长具有明显的外延生长的特点。这是由于激光快速成形是一个高温度梯度高凝固速度的过程,熔池凝固起始于熔池的底部,熔池底部的温度梯度主要沿沉积方向,故枝晶将以与温度梯度最为接近的方向择优生长[11]。成形单道多层结构件是一个重复熔化和凝固的过程,且由于凝固过程是随着液/固界面的推进而进行,因此,组织表现出典型的外延生长特点。加入镍基合金后在扫描电镜下观察不同成分比时相同位置处的显微组织如图3(b)~(f)所示。图3(b)~(d)所示的显微组织是以细长柱状晶为主,并在晶界分布着一些析出相。当镍基合金占据主要成分时,其显微组织是以方向杂乱的树枝晶为主,如图3(e)和(f)所示。出现这种现象的原因主要与混合粉末的成分有关。

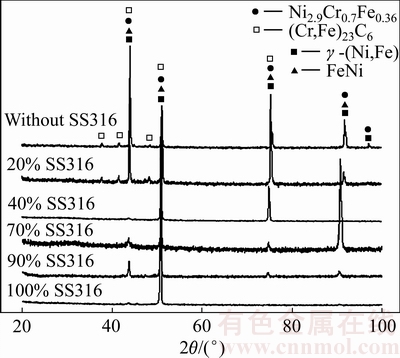

不同成分比例成形件的X射线衍射(XRD)检测结果如图4所示,结果表明不同成分下的成形件主要由γ-(Ni,Fe)固溶体、FeNi、Ni2.9Cr0.7Fe0.36奥氏体、(Cr,Fe)23C6碳化物等相组成。其中M23C6相是无固定组成的碳化物,属于复杂面心立方结构,存在温度范围为760~1100 ℃,一般在870~980 ℃析出较多,通常存在于晶界处。从图4中可以看出,尽管随着镍基合金的增多,合金粉末中形成M23C6相的Cr元素含量降低,但依然形成M23C6相,这是由于随着复合材料中镍基合金的增多,P元素含量增加,P元素溶于M23C6相中,并促进晶界M23C6相的析出[12]。且Ni元素含量的增加会降低C在奥氏体不锈钢中的溶解度,从而使碳化物析出倾向增大。

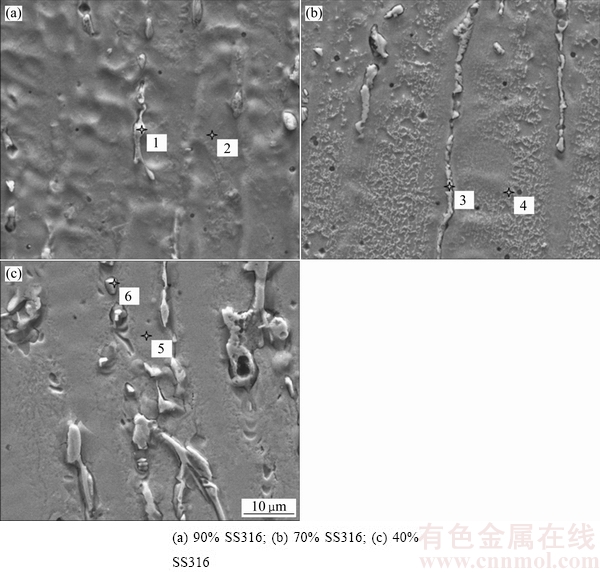

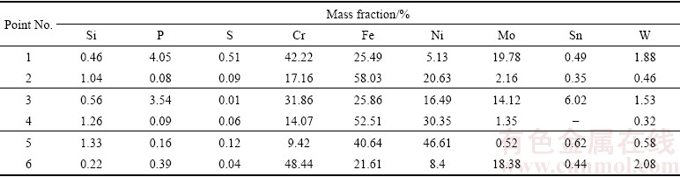

不同比例开裂成形件的显微组织如图5所示,图中不同点的能谱结果如表2所列。由EDS能谱分析结果可知,图5(a)中白色链状析出物中P、S、Cr、Mo、W等元素含量较高,Fe、Ni元素含量较低。由文献[12]可知,当P元素含量较高时,会促进M23C6相的析出并溶于M23C6中,故结合XRD相检测结果,链状析出物为M23C6型碳化物,并有部分Mo、W、P等元素固溶于析出相中。晶界链状析出物中P、Cr、Mo、W等元素含量较高(见图5(b)),Fe、Ni元素含量较低,这与图5(a)中析出物元素含量变化较为相似,认为其与图5(a)中析出相一致。图5(c)块状析出物中元素Cr、Mo、W含量较多,Fe、Ni元素含量较少,结合XRD检测结果认为其为固溶了部分Mo、W元素的M23C6碳化物。M23C6碳化物在晶界上连续析出,阻碍晶界滑移,起到强化作用,但也会导致界面结合强度及成形件塑性的降低。

2.3 裂纹产生原因

将不同成分比例下开裂的复合材料沿激光束扫描方向抛磨制成标准金相试样,在扫描电镜下观察裂纹的微观形貌,发现裂纹扩展具有相同的规律,故选择40% SS316复合材料进行开裂机理研究。图6所示为40% SS316复合材料裂纹的显微形貌。由图6(a)可知,裂纹主要发生在晶界,并呈现出典型的沿晶扩展特征。由图6(b)可知,裂纹附近和裂纹内部具有较多的析出物。对其进行EDS点分析,结果如表3所列。白色链状析出物中元素P、Cr、Mo、Sn、W等元素富集,而Fe、Ni元素含量较少,由前述分析,白色链状析出物为M23C6。裂纹内部元素Si、P、Mo和Sn含量较高,Si、P、S和Sn元素在γ奥氏体不锈钢中的溶解度极低,故凝固过程中会不断从固/液界面前沿排出杂质元素,造成剩余液相中杂质元素的富集。

图3 不同成分比时SS316/Ni20复合材料的显微组织

Fig. 3 Microstructures of SS316/Ni20 composite with different compositions

图4 不同成分比时SS316/Ni20复合材料的XRD谱

Fig. 4 XRD patterns of SS316/Ni20 composite with different components

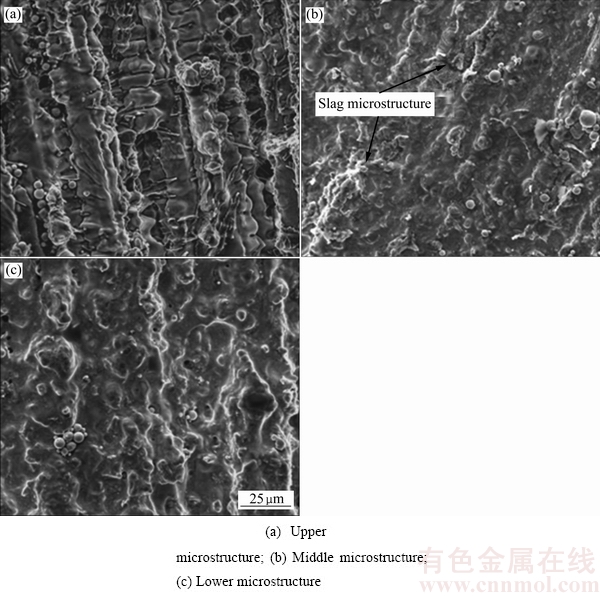

40% SS316复合材料裂纹断面的显微形貌如图7所示。断口的上部为方向性较强的柱状晶组织,树枝晶界面相当圆滑形貌清晰可辨,表现为典型的冰糖葫芦状断口[13]。分析认为,这是晶间液膜在凝固和冷却过程中被拉应力撕开后,晶界残余液相在表面张力的作用下冷却凝固而成的表面,属于热裂纹。断口中下部的微观形貌表明在圆滑的晶粒表面附近覆盖着一层熔渣状组织,如图7(b)所示。分析认为,镍基合金的添加使得混合粉末中Si元素含量增加,其作为脱氧剂与熔池中Fe的氧化物反应,生成密度较小的硅酸盐熔渣,在单道激光熔覆中这些低熔点熔渣上浮,起到氧化保护作用,但在多层激光成形过程中,熔渣可能夹杂在熔覆层中成为裂纹源[14]。

图5 不同成分时SS316/Ni20复合材料的显微组织

Fig. 5 Microstructures of SS316/Ni20 composite with different compositions

表2 图5中不同位置的EDS点分析结果

Table 2 EDS analysis of different points in Fig. 5

图6 40% SS316复合材料的裂纹微观形貌

Fig. 6 Microstructures of crack of composite with 40% SS316

表3 40% SS316复合材料的薄壁件微观裂纹的EDS点分析结果

Table 3 EDS point analysis of micro-crack of composite with 40% SS316 shown in Fig. 6

图7 40% SS316复合材料裂纹断面的显微组织

Fig. 7 Crack surface microstructures of composite with 40% SS316

图8所示为40% SS316复合材料裂纹断面形貌及EDS面扫描分析结果。由图8可知,Si、P、Cr等元素在断面上分布较不均匀,有亮点聚集区,说明这些元素在断面上有偏聚。断面元素的能谱结果如表4所示。表明元素Si、P、Sn、Cr含量远高于设计成分中的元素含量。由于Si、P、Sn杂质元素在γ相中具有较低的溶解度,在凝固过程中,杂质元素会向剩余液相中大量偏聚,降低合金的凝固速度并促进有害相的生成,是形成晶间液态薄膜的主要原因。而Cr元素在裂纹断面上偏聚也印证了(Fe,Cr)23C6碳化物在晶界上的连续析出,造成了晶界结合强度的降低。

图8 40% SS316复合材料裂纹断面的SEM像和元素分布结果

Fig. 8 SEM image(a) and elemental distribution((b)-(f)) of crack surface of composite with 40% SS316

表4 40% SS316复合材料断面部分元素EDS分析结果

Table 4 EDS analysis result of elements in crack surface of composite with 40% SS316

复合材料裂纹产生的直接原因是内应力的产生与集中所导致,激光快速成形过程中的内应力主要由热应力、组织应力和约束应力组成。由熔覆过程急冷急热变化的特点,热应力是主要影响因素。成形过程中产生的残余热应力可用式(1)表示[15]:

(1)

(1)

式中:E、 分别为熔覆层的弹性模量和泊松比;

分别为熔覆层的弹性模量和泊松比; 为熔覆层和基体间热膨胀系数之差;

为熔覆层和基体间热膨胀系数之差; 为熔覆温度与室温之差。热裂纹的产生必须满足熔覆层晶间强度小于熔覆层所受的应力。从显微组织角度看,90%~30% SS316复合材料的显微组织为外延生长的柱状晶(见图3(b)~(d)),这种显微组织特点有利于杂质元素(如P、Si、Sn等)的偏析,从而促使晶间液膜的形成并保持很好的连续性[16]。晶间连续液膜的存在,使得固/液界面存在较大的温度梯度,由式(1)可知熔覆层在凝固过程中会产生较大的局部热应力,且晶界析出的链状碳化物与基体相之间由于热膨胀系数、弹性模量等热物性参数差异,在冷却过程中会形成较大的热应力。另一方面,晶间连续液膜和晶界链状碳化物的存在降低了晶粒间的结合强度,使其更容易在内应力作用下开裂。20%~0 SS316复合材料的微观组织为杂乱的树枝晶(见图3(e)、(f)),这一特点打乱了晶界液膜在沉积方向上的连续性,破坏了液态薄膜的通道,提高了熔覆层的抗开裂性。所以在成形相同层数的薄壁结构时,20%~0 SS316复合材料比90%~30% SS316复合材料更不容易开裂。

为熔覆温度与室温之差。热裂纹的产生必须满足熔覆层晶间强度小于熔覆层所受的应力。从显微组织角度看,90%~30% SS316复合材料的显微组织为外延生长的柱状晶(见图3(b)~(d)),这种显微组织特点有利于杂质元素(如P、Si、Sn等)的偏析,从而促使晶间液膜的形成并保持很好的连续性[16]。晶间连续液膜的存在,使得固/液界面存在较大的温度梯度,由式(1)可知熔覆层在凝固过程中会产生较大的局部热应力,且晶界析出的链状碳化物与基体相之间由于热膨胀系数、弹性模量等热物性参数差异,在冷却过程中会形成较大的热应力。另一方面,晶间连续液膜和晶界链状碳化物的存在降低了晶粒间的结合强度,使其更容易在内应力作用下开裂。20%~0 SS316复合材料的微观组织为杂乱的树枝晶(见图3(e)、(f)),这一特点打乱了晶界液膜在沉积方向上的连续性,破坏了液态薄膜的通道,提高了熔覆层的抗开裂性。所以在成形相同层数的薄壁结构时,20%~0 SS316复合材料比90%~30% SS316复合材料更不容易开裂。

根据裂纹形成原因可知通过降低成形过程中的应力、打乱柱状晶的方向性破坏液态薄膜的通道及使析出相均匀分布可抑制成形件的开裂。通过预热基体和成形后缓冷可有效降低成形件温度梯度降低热应力,从而减少和抑制裂纹。除此之外,成形过程中引入超声振动可细化晶粒、使硬质相分布均匀、降低残余应力[17],可有效降低成形件的开裂敏感性。为得到无裂纹的成分梯度薄壁结构,除上述方式外还可避开产生裂纹的成分,采用无裂纹的成分进行梯度结构件的成形。

3 结论

1) 用激光近净成形技术制备了不同成分比例SS316/Ni20复合材料薄壁结构,长为80 mm、层数为50层,其中成分比例为100% SS316、20%~0 SS316复合材料薄壁结构外观形貌良好、无裂纹缺陷,90%~30% SS316复合材料出现不同程度的开裂,裂纹均沿沉积方向扩展,与扫描方向近似垂直。

2) 薄壁结构开裂属于热裂纹,主要原因是杂质元素P、Si、Sn等在晶界处偏析,形成晶间液膜且M23C6碳化物在晶界上连续析出,增大了成形件凝固和冷却过程中的热应力,另一方面,晶间连续液膜以及晶界析出的链状M23C6碳化物降低了晶界面的结合强度使成形件的抗开裂能力降低,造成其在残余应力作用下开裂。

REFERENCES

[1] QIAN Ting-ting, LIU Dong, Tian Xiang-jun, LIU Chang-meng, WANG Hua-ming. Microstructure of TA2/TA15 graded structural material by laser additive manufacturing process[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(9): 2729-2736.

[2] 陈茂军, 李国明. 火焰喷涂Ni20合金涂层耐酸性和H2S腐蚀性研究[J]. 表面技术, 2008, 37(2): 50-51.

CHEN Mao-jun, LI Guo-ming. Study on anticorrosion of acid and hydrogen sulfide corrosion of flare sprayed Ni20 alloy coating [J]. Surface Technology, 2008, 47(2): 50-51.

[3] 曹 艳, 李涌泉, 褚芳芳. 45钢表面Ni20合金激光熔覆层的组织及抗高温氧化性能[J]. 表面技术, 2012, 41(3): 54-56.

CAO Yan, LI Yong-quan, CHU Fang-fang. Microstructure and high temperature oxidation resistance of laser cladding Ni20 alloy on 45 steel[J]. Surface Technology, 2012, 41(3): 54-56.

[4] HOFMANN D C, KOLODZIEJSKA J, ROBERTS S, RICHARD O, DILLION R P, SUH J O, LIU Zi-kui, BORGONIA J P. Compositionally graded metals: A new frontier of additive manufacturing[J]. Journal of Materials Research, 2014, 29(17): 1899-1910.

[5] CARROLL B E, OTIS R A, BORGONIA J P, SUH J O, DILLON R P, SHAPIRO A A, HOFMANN D C, LIU Zi-kui, BEESE A M. Functionally graded material of 304L stainless steel and inconel 625 fabricated by directed energy deposition: Characterization and thermodynamic modeling[J]. Acta Materialia, 2016, 108: 46-54.

[6] REICHARDT A, DILLON R P, BORGONIA J P, SHAPIRO A A, MCENERNEY B W, MOMOSE T, HOSEMANN P. Development and characterization of Ti-6Al-4V to 304L stainless steel gradient components fabricated with laser deposition additive manufacturing[J]. Materials & Design, 2016, 104: 404-413.

[7] HOFMANN D C, ROBERTS S, OTIS R, KOLODZIEJSKA J, DILLON R P, SUH J O, SHAPIRO A A, LIU Zi-kui, BORGONIA J P. Developing gradient metal alloys through radial deposition additive manufacturing[J]. Scientific Reports, 2013, 4(4): 5357-5357.

[8] 解 航, 张安峰, 李涤尘, 贺 斌, 杨洪涛. 激光金属直接成形Ti6Al4V-CoCrMo梯度材料开裂研究[J]. 中国激光, 2013, 40(11): 97-103.

XIE Hang, ZHANG An-feng, LI Di-chen, HE Bin, YANG Hong-tao. Research on the cracking of Ti6Al4V-CoCrMo gradient material fabricated by laser metal direct forming[J]. Chinese Journal of Laser, 2013, 40(11): 97-103.

[9] 陈智君, 张群莉, 楼程华, 姚建华. Inconel 738激光熔覆层的裂纹控制方法[J]. 应用激光, 2013, 33(1): 7-13.

CHEN Zhi-jun, ZHANG Qun-li, LOU Cheng-hua, YAO Jian-hua. Methods of crack control for Inconel738 laser cladding layer[J]. Applied Laser, 2013, 33(1): 7-13.

[10] 刘发兰, 赵树森, 高文焱, 周春阳, 王奕博, 林学春. 基材属性对Ni60A-WC激光熔覆涂层性能的影响[J]. 中国有色金属学报, 2014, 24(5): 1319-1326.

LIU Fa-lan, ZHAO Shu-sen, GAO Wen-yan, ZHOU Chun-yang, WANG Yi-bo, LIN Xue-chun. Effect of Substrate on Ni60A-WC laser cladding coatings[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1319-1326.

[11] 林 鑫, 杨海欧, 陈 静, 黄卫东. 激光快速成形过程中316L不锈钢显微组织的演变[J]. 金属学报, 2006, 42(4): 361-368.

LIN Xin, YANG Hai-ou, CHEN Jing, HUANG Wei-dong. Microstructure evolution of 316l stainless steel during laser rapid forming[J]. Acta Metallurgical Sinica, 2006, 42(4): 361-368.

[12] 胡壮麒, 孙文儒, 郭守仁, 卢德忠. 微量元素磷在铁镍基变形高温合金中的作用[J]. 中国有色金属学报, 2001, 11(6): 947-959.

HU Zhuang-lin, SUN Wen-ru, GUO Shou-yi, LU De-zhong. Effect of trace element P on the steel/Ni-based high temperature alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(6): 947-959.

[13] 陈 静, 林 鑫, 王 涛, 杨海欧, 黄卫东. 316L不锈钢激光快速成形过程中熔覆层的热裂机理[J]. 稀有金属材料与工程, 2003, 32(3): 183-186.

CHEN Jing, LIN Xin, WANG Tao, YANG Hai-ou, HUANG Wei-dong. Mechanism of thermal cracking process of 316L stainless steel in laser cladding rapid prototyping[J]. Rare Metal Material and Engineering, 2003, 32(3): 183-186.

[14] 宋建丽, 邓琦林, 葛志军, 陈畅源, 胡德金. 镍基合金激光快速成形裂纹控制技术[J]. 上海交通大学学报, 2006, 40(3): 548-552.

SONG Jian-li, DENG Yi-lin, GE Zhi-jun, CHEN Chang-yuan, HU De-jin. The cracking control technology of laser rapid forming nickel based alloys[J]. Journal of Shanghai Jiao Tong University, 2006, 40(3): 548-552.

[15] 赵亚凡, 陈传忠. 激光熔覆金属陶瓷涂层开裂的机理及防止措施[J]. 激光技术, 2006(1): 16-19.

ZHAO Ya-fan, CHEN Chuan-zhong. Mechanism of the deform action and preventive measures of the cracks in metal ceramics cladding layer[J]. Laser Technology, 2006(1): 16-19.

[16] 陈 静, 杨海欧, 李延民, 黄卫东. 激光快速成形过程中熔覆层的两种开裂行为及其机理研究[J]. 应用激光, 2002, 22(3): 300-304.

CHEN Jing, YANG Hai-ou, LI Yan-min, HUANG Wei-dong. The research on two kinds of cracking behavior and mechanism of cladding in rapid laser forming process[J]. Applied Laser, 2002, 22(3): 300-304.

[17] 钦兰云, 王 维, 杨 光. 超声辅助钛合金激光沉积成形试验研究[J]. 中国激光, 2013, 40(1): 82-87.

QIN Lan-yun, WANG Wei, YANG Guang. Experimental study on deposition ultrasonic-assisted laser metal of titanium alloy[J]. Chinese Journal of Laser, 2013, 40(1): 82-87.

Cracking mechanism of SS316/Ni20 composite fabricated by laser engineered net shaping

HAO Yun-bo, ZHANG Guo-hui, MA Guang-yi, YAN Shuai, NIU Fang-yong, WU Dong-jiang

(Key Laboratory for Precision and Non-traditional Machining Technology, Ministry of Education, Dalian University of Technology, Dalian 116024, China)

Abstract:The mixed gradient materials produced by the laser engineered net shaping (LENS) process are vulnerable, which restricts seriously the application of these materials. Different proportions SS316/Ni20 composite thin-walled structures were prepared using LENSTM and the microstructure, phase composition and distribution of elements under different compositions were studied by OM, SEM, XRD and EDS. Under the given process conditions, the results show that when SS316 mass fractions are 100%, 20%-0, the components appear well without crack. While, when the mass fractions ranges from 90% to 30%, the components crack. The morphology analysis of crack and elements distribution of the crack surface indicates that the cracks propagate along grain boundaries and the grains on the crack surface are visible, the cracking belongs to the hot crack domain. The main reason of cracking is the grain boundary segregation of impurity elements during solidification and hard phase continuous precipitation on the grain boundary, which reduces the bonding strength between the grains. It is prone to cracking under residual stress.

Key words: SS316/Ni20 composites; gradient material; laser engineered net shaping; cracks

Foundation item: Project(51402037) supported by the National Natural Science Foundation of China; Project(51621064) supported by the Science Fund for Creative Research Groups of National Science Foundation of China; Project(2015CB057305) supported by the National Basic Research Program of China

Received date: 2016-09-12; Accepted date: 2017-02-24

Corresponding author: WU Dong-jiang; Tel: +86-411-84707625;E-mail: djwudut@dlut.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51402037);国家基金委创新群体基金资助项目(51621064);国家重点基础研究发展计划资助项目(2015CB057305)

收稿日期:2016-09-12;修订日期:2017-02-24

通信作者:吴东江,教授,博士;电话:0411-84707625;E-mail: djwudut@dlut.edu.cn