Physics characteristic of coupling arc of twin-tungsten TIG welding

ZHANG Guang-jun(张广军), LENG Xue-song(冷雪松), WU Lin(吴 林)

State Key Laboratory of Advanced Welding Production Technology, Harbin Institute of Technology,

Harbin 150001, China

Received 19 September 2005; accepted 24 March 2006

Abstract: Twin-tungsten TIG welding was developed, in which two electrodes were placed in a single welding torch. In order to master this process, the arc physics characteristic was studied. The twin-tungsten coupling arc shape was observed by using CCD camera, and the arc pressure was measured. The results show that the coupling arc includes two arcs that pull each other according to Lorentz force and one big coupling arc is formed; the coupling arc pressure is much lower than that of conventional TIG arc. In the end, a simple welding experiment was carried out. This proves that stable welding process can be achieved by twin-tungsten TIG at higher current than that of conventional TIG because of its low arc pressure and the high efficiency welding is realized.

Key words: arc physics; twin-tungsten TIG; coupling arc; arc pressure; high efficiency welding

1 Introduction

It is well known that high effeciency and high quality welding is the developing target of welding technology[1, 2].

TIG welding is one of the high quality and widely applied welding methods because its arc is stable, its precess is easy to be controled, it is well suitable for all-positional welding, and it can weld diversiform metals, such as stainless steel, aluminium and copper[3]. But TIG welding has low welding efficiency, which is its main shortcoming. The reason is that the rating welding current is in the low level, the heat input to workpiece is small. When the used current rises to high level, the arc pressure becomes very excessive, it induces a big cave in weld pool, and the welding process becomes unstable, the weld quality drops. So there is a limit to improve the welding efficiency by using high current in TIG welding [4].

How to improve the welding efficiency without sacrificing the advantages of the ordinary TIG welding method is a question needed to solve.

Now, some methods have been put forward to improve TIG welding efficiency, such as hot-wire TIG [5], active TIG[6] and double-side TIG[7].

Twin-tungsten TIG welding method was invented by Japan scholars in recent years. This method put two electrodes in a single torch. They are insulated from each other and arranged in perpendicular to welding direction. The welding process is achieved by the coupling arc generated from the two electrodes. Now this method has been successfully applied in welding an inner tank for PCLNG storage tank in Japan[8, 9].

As a new welding method, knowledge about this method, especially about coupling arc physics is little, and the research report is almost about TIG single arc [10-12].

In this paper, a twin-tungsten TIG welding torch was developed, and the coupling arc characteristic was studied.

2 Setup of twin-tungsten TIG welding system

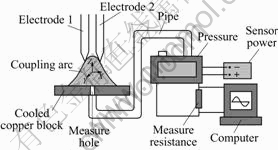

The new-developed twin-tungsten TIG welding system is shown in Fig.1. It includes a special designed torch, two welding power sources, and the auxiliary devices, such as cooling system.

The special designed torch contained two tungsten electrodes insulated from each other. The distance between two tungsten electrodes was very

Fig.1 Twin-tungsten TIG welding system

small and could be adjusted in the range of 1-6 mm. Two welding power sources were separately connected to the two electrodes. Because the electrodes were insulated from each other, the current circles were independent, every electrode generated a single arc, each arc current could be set and controlled independently. Due to the Lorentz force, these two arcs pulled each other, and one big coupling arc was formed.

3 Observation and analysis of arc shape

In this study, arc shape images were sampled through a CCD camera. The anode was water-cooled copper plate.

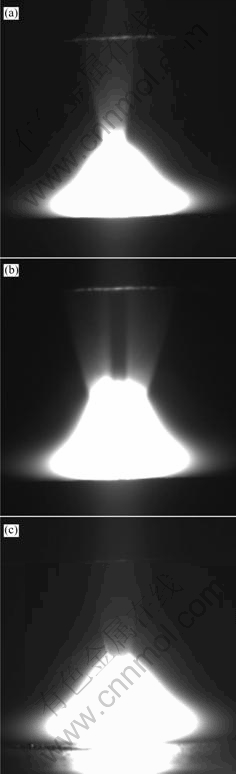

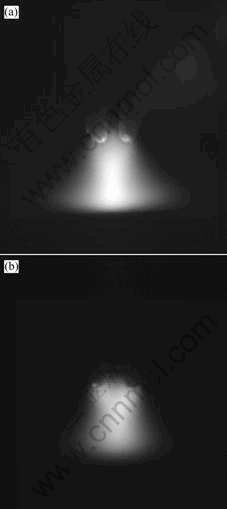

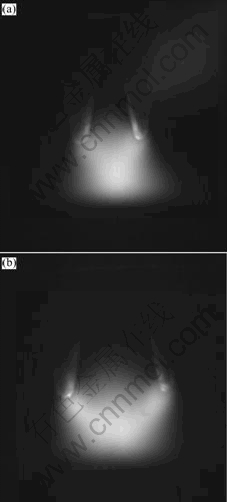

Fig.2 shows the comparison between single arc and coupling arc. Fig.3 shows the coupling arc shapes at different welding currents. Fig.4 shows the arc shapes under different tungsten distances.

From the above figures, the followings can be seen:

1) These two arcs pull each other due to the Lorentz force, and become a big arc, seen in Fig.2.

2) The coupling arc is no longer axis-symmetry like single arc, the cross section of coupling arc is ellipse, its short axis is the direction of two tungsten array, seen from the comparison of Figs.2(b) and (c).

3) The brightest zone of welding arc is where the current density is the biggest, and the temperature is the highest[13]. It can be seen from Fig.3 and Fig.4 that due to the attraction force, the brightest zone of every arc is offset to its tungsten axis, two bright lines make up a triangle zone.

4) The pull force between two arcs can be expressed as formula (1)[14]:

(1)

(1)

where F is the pull force, I1 and I2 are arc currents, L is the distance of two tungsten, k is a constant.

The pull force increases with the increase of arc current and the decrease of the distance of two arcs, which can be seen in Fig.3 and Fig.4.

4 Measure and analysis of pressure of coupling arc

4.1 Arc pressure measuring system

The static small hole method[15] was applied to measure the pressure of the coupling arc. The developed measuring system is shown in Fig.5. The anode of the arc was a water-cooled copper plate which was fixed up on a three dimensional coordinate instrument. The anode could move in three dimensions at the precision of 0.001 mm. The diameter of hole used to measure on the anode plate was 0.5 mm. The arc pressure on the hole was led to pressure sensor by a pipe. The pressure sensor transferred the arc pressure into voltage signal inputted to computer to process. The precision of the pressure measuring system was 1 Pa.

4.2 Measuring and analysis of arc pressure

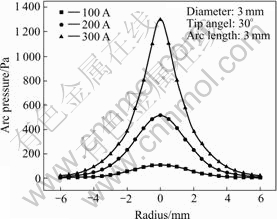

Fig.6 and Fig.7 show the measured single arc and coupling arc pressure curves. The followings can be seen.

1) For single arc, arc pressure increases quickly with the increase of welding current in accordance with the hyperbolical curve[16]. At high current, the arc pressure is too excessive.

Fig.2 Shape comparison between single arc and coupling arc: (a) Single arc; (b) Coupling arc; (c) Coupling arc

2) Arc pressure of coupling arc is kept at low level even under high current zone.

3) The covered area of coupling arc is larger than single arc. The pressure gradation of coupling arc at radial direction is smaller than single arc.

Fig.3 Inner shape comparison of coupling arc under different welding current: (a) 100 A+100 A; (b) 50 A+50 A

5 Static voltage-ampere characteristic of coupling arc

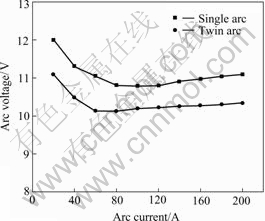

Fig.8 shows the static voltage-ampere characteristic of single arc and coupling arc. For coupling arc, the x-axis current value is the current through one tungsten electrode. It can be seen that at the same current, the arc voltage of coupling arc is lower than single arc.

6 Welding experiment

One way to improve the welding efficiency is to increase the welding current, but for traditional TIG welding, the arc pressure becomes very excessive at high current, it induces a big cave in weld pool, and the welding process becomes unstable, the welding flaws, such as undercut, underfill and cutting, are easy to exist, the weld quality drops. So there is a limit to improve welding efficiency by using high current in traditional TIG welding.

Fig.4 Inner shape comparison of coupling arc under different cathode distances: (a) 4 mm; (b) 6 mm

Fig.5 Measuring system of T-TIG arc pressure

From the above research, the arc pressure of twin-tungsten TIG welding was kept at low level even under very high current. The welding process was stable at high current. This merit widened the range of used welding current. So the developed twin-tungsten TIG welding was specially suitable in high-current-high-speed

Fig.6 Arc pressure of single electrode

Fig.7 Arc pressure distribution of coupling arc

Fig.8 Static volt-ampere characteristic of coupling arc and single arc

welding of thin plate, high deposition rate welding of thick plate, and high efficiency bead-on-plate welding.

To prove the high efficiency of the new welding method, the following thin plate welding experiment was designed. Material of workpiece was Q235, and the thickness was 2 mm. The distance of two tungsten electrodes was set at 2 mm. Welding current was 150 A+ 150 A, welding speed was 600 mm/min. Fig.9 and Fig.10 separately show the welding results using single tungsten TIG and twin-tungsten TIG. The weld of single tungsten TIG has the flaw of undercut, at the end of seam cutting appears. However, the weld of twin-tungsten TIG is very good.

Fig.9 Welded workpiece with traditional TIG at high welding current

Fig.10 Welded workpiece with twin-tungsten TIG at high welding current

This experiment proves that twin-tungsten TIG welding can realize high-current-high-speed welding to improve welding efficiency.

7 Conclusions

1) The research proves that the twin-tungsten TIG welding is a new welding method that realizes to improve welding efficiency without sacrificing the advantages of the traditional TIG welding.

2) Due to Lorentz force, the twin-tungsten TIG arc becomes a big arc, the arc is no longer axis-symmetry like single arc, the cross section of coupling arc is ellipse.

3) Arc pressure of the twin-tungsten TIG welding is very low even at high current, which is a very important merit.

4) Due to low arc pressure, the twin-tungsten TIG welding realizes stable high-speed welding at high welding current.

References

[1] WANG Y L, DAI H, CHEN H. Role and development of modern welding engineering in manufacture industry [J]. Electric Welding Machine, 2004, 34(11): 1-5.

[2] GAO H M, WU L. How to increase welding productivity [J]. Welding and Joining, 2000(2): 6-10.

[3] YANG C L, LIN S B. Arc Welding Base [M]. Harbin: Harbin Institute of Technology Press, 2003.

[4] LANCASTER J F. The Physics of Welding [M]. Tokyo: Japan Welding Society, 1990.

[5] SYKES I, DIGIACOMO J. Principle and application of submerged arc welding with hot wire addition [J]. Welding Journal, 1995, 74(7): 53-56.

[6] YANG C L, LIN S B, LIU F Y.  Research on the mechanism of penetration increase by flux in A-TIG welding [J]. Journal of Materials Science and Technology, 2003, 19: 225s-227s.

Research on the mechanism of penetration increase by flux in A-TIG welding [J]. Journal of Materials Science and Technology, 2003, 19: 225s-227s.

[7] GAO Hong-ming, WU Lin, DONG Hong-gang. Penetration mechanism of aluminum alloy in double-sided GTAW process [J]. Trans Nonferrous Met Soc China, 2005, 15(2): 35-38.

[8] YAMADA K. Practical application of high efficiency twin-arc TIG welding method (SEDAR-TIG) for PCLNG storage tank [J]. IIW Doc XII-1669-01, 2004. 101-110.

[9] NISHIMURA K. Development of high efficient twin-arc TIG welding method [J]. IIW Doc XI-783-03, 2001. 78-87.

[10] KAZUO H, AKIRA O, MICHIO I. Effects of helium gas on arc characteristic in gas tungsten arc welding [J]. Transactions of National Research Institute for Metals, 1986, 28(2): 139-145.

[11] FUJII H, SUMI Y, TANAKA M. Effects of welding current, arc length and shielding gas flow rate on arc pressure Trends in welding research [A]. ASM Proceedings of the International Conference: Trends in Welding Research [C]. Phoenix, AZ, United States: ASM International, 2002, 404-407.

[12] SHCHETININAV I. Dependence of the distribution of arc pressure on welding process [J]. Welding Production, 1981, 28(4): 1-2.

[13] XU C M, GAO H M, WU L. Application of monochromatic image method in arc plasma diagnostics [J]. IEEE Transaction on Plasma Science, 2005, 33(2): 304-305.

[14] HU P X. College Physics Handbook [M]. Shanghai: Shanghai Jiaotong University Press, 1999.

[15] JIA C S, XIAO K M, YIN X Q. The plasma flow force of welding arc [J]. Journal of Xi’an Jiaotong University, 1994, 28(1): 23-28.

[16] FAN H G, SHI Y W. Numerical simulation of the arc pressure in gas tungsten arc welding [J]. Journal of Materials Processing Technology, 1996, 61: 302-308.

(Edited by LI Xiang-qun)

Corresponding author: ZHANG Guang-jun; Tel/Fax: +86-451-86415537; E-mail: zhanggj@hit.edu.cn