Trans. Nonferrous Met. Soc. China 24(2014) 982-988

Effect of Si content on microstructure and properties of Si/Al composites

Wei-chen ZHAI1, Zhao-hui ZHANG1,2, Fu-chi WANG1,2, Xiang-bo SHEN1, Shu-kui LEE1,2, Lu WANG1,2

1. School of Materials Science and Engineering, Beijing Institute of Technology, Beijing 100081 China;

2. National Key Laboratory of Science and Technology on Materials under Shock and Impact, Beijing 100081, China

Received 6 March 2013; accepted 18 January 2014

Abstract: Si/Al composites with different Si contents for electronic packaging were prepared by spark plasma sintering (SPS) technique. Properties of the composites were investigated, including density, thermal conductivity, coefficient of thermal expansion and flexural strength. The effects of the Si content on microstructure and thermal and mechanical properties of the composites were studied. The results show that the Si/Al composites consist of Si and Al components and Al uniformly distributes among Si grains. The relative density of the Si/Al composites gradually increases with the decrease of Si content and reaches 98.0% when the Si content is 50%. The thermal conductivity, the coefficient of thermal expansion and the flexural strength of the composite all decrease with the increase of the Si content, and an optimal matching of them is obtained when the Si content is 60% (volume fraction).

Key words: spark plasma sintering; Si/Al composite; thermal conductivity; coefficient of thermal expansion; flexural strength

1 Introduction

The effects of packaging on circuit properties and reliability are particularly important when the integrated circuit has a rapid development. Generally, the requirements of the electronic packaging materials include a good thermal conductivity, a coefficient of thermal expansion similar to that of the semiconductor materials, a high strength and low density [1-3]. As a novel kind of electronic packaging material, the Si/Al composites have the thermal expansion coefficient similar to that of the semiconductor materials such as Si and GaAs, and good thermal conductivity. Therefore, the Si/Al composites have a broad application prospect [4]. For the Si/Al composites, the material properties can be adjusted by changing the Si content, so the properties of the Si/Al composites are adjustable and controllable.

Compared with the conventional sintering methods, the spark plasma sintering (SPS) has the characteristics of rapid heating rate and short sintering time, which can effectively prevent the grain from growth during the sintering process, thereby ensuring that the material has fine microstructure and excellent thermal and mechanical properties [5,6]. Based on the characteristics of SPS, the Si/Al composites with different Si contents (50%-70% in volume fraction) for electronic packaging were prepared in this work, their thermal and mechanical properties were measured, and the effects of Si content on the microstructure and properties of the composites were discussed.

2 Experimental

2.1 Starting powders

Al powders with a particle size of 10 μm and Si powders with a particle size of 44 μm were selected and mixed to obtain a powder mixture, wherein the purities of the Al powders and Si powders were 99.8% and 99.6%, respectively. The volume fractions of Si in the powder mixture were 50%, 55%, 60%, 65% and 70%, respectively. A planetary ball mill was used for mixing the powders at a rotary speed of 300 r/s for 30 min. The loss rate of the materials was lower than 10% during the mixing powder process.

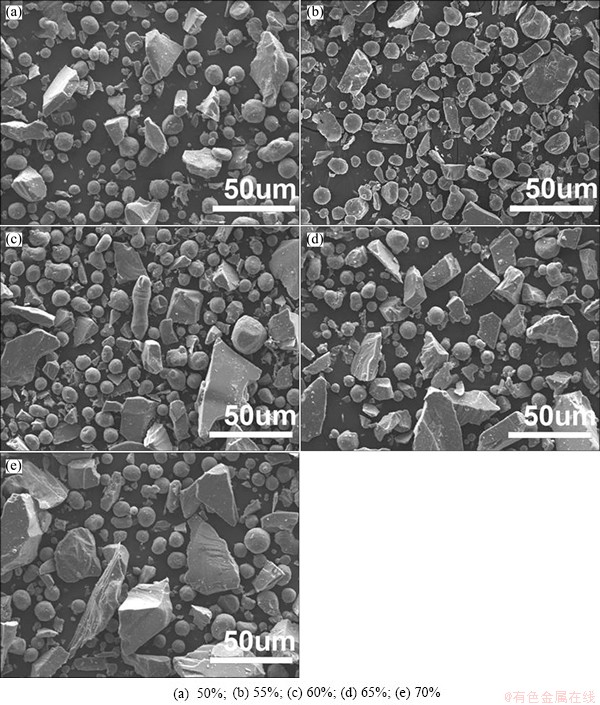

Figure 1 shows the SEM images of the powder mixtures with different Si contents, wherein Al particle was spherical and Si particle had an irregular shape. Moreover, Fig. 1 shows that Si and Al particles were mixed more uniformly. The powder mixture was firstly treated by rotary evaporation for 40 min in a water bath with temperature of 85 °C at a rotating speed of 45 r/min in a 1 Pa vacuum chamber; then it was taken out and dried in an oven for 24 h.

Fig. 1 SEM images of powder mixtures containing various Si contents

2.2 Sintering parameters

DR.SINTER type SPS-3.20 equipment (Sojitz Machinery Corporation, Tokyo, Japan) with a pulse duration of 3.3 ms and a current on-off ratio of 12:2 was used in this procedure. The mixtures were sintered in a 0.5 Pa vacuum chamber, using a cylindrical graphite die ( as performed using a pressing die with a diameter Sanye Carbon Group, Beijing, China). The external diameter, internal diameter and height of the die were 90, 40 and 80 mm, respectively. A graphite felt was used as thermal insulation. The temperature was examined by the thermocouple. The specimens were sintered at temperature of 550 °C with a heating rate of 100 °C/min for 5 min of holding time. The applied compressive pressure level was 50 MPa. Uniaxial pressure was gradually applied up to 50 MPa within the first minute at the final sintering temperature and maintained at 50 MPa during the remaining 4 min.

2.3 Characterization tests

The sintered samples were processed into the test samples with different dimensions using a wire cutting method. The density of the material was measured by the Archimedes method. The phase identification was evaluated by X-ray diffraction (XRD) analysis (X' Pert PRO MPD, PANalytical B.V., Netherlands) using Cu Kα radiation. Microstructure investigation of the as-sintered composites was carried out by scanning electron microscope (SEM, Hitachi S-4800N, Hitachi, Japan). Flexural strength was evaluated by three-point bending method using an Instron instrument, and the dimensions of the specimen were 3 mm×4 mm×22 mm with a span of 15 mm. The thermal conductivity was measured by the TC-7000 laser thermal constant analyzer. The coefficient of thermal expansion of the composite was measured by NETZSCH DIL 402C thermal dilatometer.

3 Results and analysis

3.1 XRD analysis

Figure 2 shows the XRD patterns of the Si/Al composites with different Si contents. It can be seen that the composites prepared by SPS comprised Si and Al two phases, and no reaction compound was found, which indicated that there were no chemical reactions between Si and Al during the sintering process. In addition, no impurity was detected in the composites, which was beneficial from the unique surface cleaning effect of the SPS technique [7]. During the sintering process, the high pulse current excited the powder grains to partially discharge on their surfaces, which increased the local temperature, promoted the melting of the local surface, and peeled off the substances on the surface. Further, the sputtering of the plasma generated by the discharge and the discharge impulse could remove the oxides and adsorbed gases on the surface. Meanwhile, high-vacuum sintering ensured that the material could not be oxidized at high temperatures [8], so that the natural states of the raw materials were maintained, which caused the properties of the composite to be excellent and controllable.

Fig. 2 XRD patterns of Si/Al composites containing various Si contents

3.2 Microstructure of composite

Figure 3 shows the metallographic structure of the Si/Al composites with different Si contents. It can be seen that all Si/Al composites were sintered densely, and the composites had a continuously-connected network structure. Because the melting points of Al and Si are 660 °C and 1420 °C [9], respectively, the densification of the composites composed of Si and Al is difficult to be achieved by the common sintering methods, therefore more pores are generated in the composites, which adversely affect the material properties [10,11]. However, when the SPS is used, owing to its unique discharge effect, each particle could generate joule heat uniformly so that the particle surfaces are activated. Then most of the Al particles are melted and the Al liquid could flow freely under the action of the pressure to fill the Si gaps, which promotes the densification of the material.

Figure 3 also shows that the pores in the composite increased with the increase of the Si content, which was mainly due to the fact that Al was melted under the combined action of the temperature and pressure and filtered into the gaps and interfaces of the Si particles during the sintering process. Under the condition that the particle sizes kept constant, the more the Si content was, the more the pores formed among the Si particles were, and even closed pores were formed. Under the action of capillary effect, the resistance for Al entering into the Si gaps increased, therefore the porosity of the composite increased and the density decreased. Because the stress concentration could be formed in the pores, the pores became the cradle of microcracks. Subsequently, the cracks grew and finally caused the fracture of the composite. So, the pores had adverse effects on the thermal and mechanical properties of the material. Thus, when the Si/Al composite was prepared, the Si content should be rationally controlled in order to obtain a fine microstructure and reduce defects, therefore more excellent comprehensive properties of the composite were obtained.

Fig. 3 Metallographical structures of Si/Al composites with different Si contents

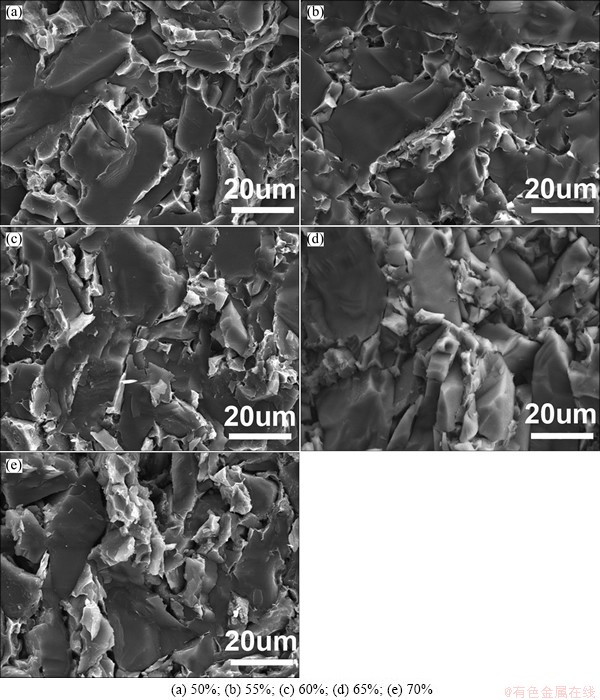

Fig. 4 SEM images showing fracture morphologies of Si/Al composites with different Si contents

Figure 4 shows the facture morphologies of the Si/Al composites with different Si contents. It can be seen that the Si/Al composites mainly had three fracture modes including the cleavage fracture of Si grains, the ductile tearing of Al phase and the interface separation between the Si grains and Al phase. With the increase of Si content, the proportion of the cleavage fracture of the Si grains on the fracture surface of the composite gradually increased, whereas the proportion of the ductile tearing of Al phase and the interface separation between the Si grains and Al phase gradually decreased. The cleavage fracture of the Si grains belongs to the brittle fracture, so the increase of the Si content in the composite would cause the decrease of the mechanical properties.

3.3 Performance test of composite

3.3.1 Density

The theoretical density (ρtheore) of the composite was calculated according to the following formula [12]:

ρtheore=ρSiVSi+ρAlVAl

where ρi is the density of component i (i=Si or Al), ρSi=2.34 g/cm3, ρAl=2.70 g/cm3; Vi is the volume fraction of component i (i=Si or Al).

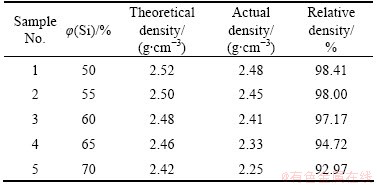

Table 1 lists the densities of the Si/Al composites with different Si contents. It can be seen that the densities of the composites decrease with the increase of the Si contents, which is consistent with the result of the metallographic structure observation of the composites. In addition, Table 1 shows that the Si/Al composites have lower densities and could be used for the packaging of the aviation components [13].

Table 1 Density of Si/Al composites with various Si contents

3.3.2 Thermal conductivity

As one of the main performance indices of the electronic packaging materials, the thermal conductivity decides whether the packaging material could effectively dissipate the heat generated by the chips and semiconductors when they are working, which could ensure that the operating states of the circuit are stable or do not fail at high temperatures. So, the electronic packaging material should have higher thermal conductivities [14,15].

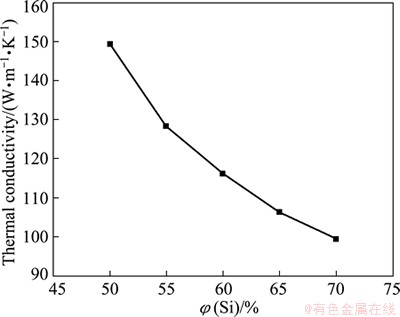

Figure 5 shows thermal conductivity curve of the Si/Al composites with different Si contents. It can be seen that the thermal conductivities of the Si/Al composites gradually decreased with the increase of the Si content mainly because the thermal conductivities of single crystal Si and Al were 148 W/(m·K) and 237 W/(m·K) [16], respectively. Therefore, the thermal conductivities of the Si/Al composites decreased with the increase of the Si content. In addition, the densities of the Si/Al composites decreased with the increase of the Si content, which also led to the decrease of the thermal conductivities of the composites.

Fig. 5 Relation curve of thermal conductivities of Si/Al composites with Si content

3.3.3 Coefficient of thermal expansion

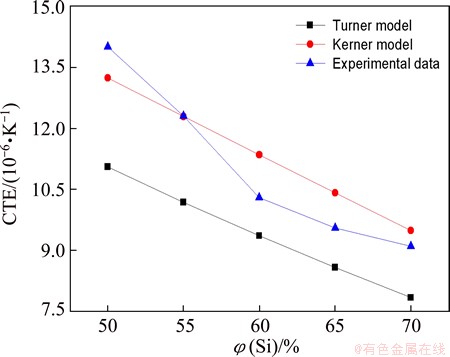

The thermal expansion performance is very important physical characteristics of the electronic packaging materials, and the coefficient of thermal expansion (CTE) is one of the indices for evaluating the thermal expansion performance [17,18]. The coefficient of thermal expansion was theoretically calculated by applying Turner model and Kerner model, respectively; and then a comparative analysis between the calculated and the experimental values was performed.

The coefficient of thermal expansion was theoretically calculated by Turner model. The assumed conditions of the Turner model are within the temperature range. There is no stress existing in the internal part of the material and a uniform plastic deformation is required for the matrix; there are no changes of internal cracks of the material and the pores. The model is shown as follows [19]:

, i=1, 2

, i=1, 2

where αc is the coefficient of thermal expansion of the composite; αi is the coefficient of thermal expansion of phase i; φi is the volume fraction of of the phase i; Ki is the bulk modulus of the phase i.

The coefficient of thermal expansion was calculated by Kerner model. The reinforcement phase is spherical granular and is uniformly enclosed by the matrix. The model is shown as follows [20]:

where Gl is the shear modulus of the matrix.

Figure 6 shows the relation curves of the calculated and experimental thermal expansion coefficients of Si/Al composites with Si content. It can be seen that the thermal expansion coefficients of the Si/Al composites gradually decreased with the increase of the volume fraction of Si because the coefficient of thermal expansion of Si (4.1×10-6 K-1) was far less than that of Al (23.6×10-6 K-1) [21]. Therefore, the coefficients of thermal expansion of the Si/Al composites gradually decreased with the increase of the Si content.

Fig. 6 Relation curves of thermal expansion coefficients of Si/Al composites with Si content

The Si/Al composite with Si content of 60% prepared by SPS technique had the coefficient of thermal expansion of 9.8×10-6 K-1, which was lower than that of the Si/Al composites with the same component prepared by spray deposition method and conventional powder metallurgy method [22], and was similar to that of the materials used as the semiconductor. Moreover, the residual stress generated by the different thermal expansions among the materials was effectively reduced due to the uniform microstructure of the composites prepared by SPS process. In addition, The Si/Al composite with 60% Si has a high thermal conductivity of 116.5 W/(m·K). Hence, the Si/Al composite with 60% Si prepared by SPS is more suitable to be used as the electronic packaging material due to the high thermal conductivity and low thermal expansion coefficient. Figure 6 also shows that the calculated values obtained by Kerner model were more close to the experimental values and could predict the experimental values better.

3.3.4 Flexural strength

Besides the good thermal and physical properties, good mechanical properties are required for the electronic packaging material to support and protect the chips.

Figure 7 shows the relation curve of the flexural strengths of the Si/Al composites with Si content. It can be seen that the flexural strength of the Si/Al composites decreased with the increase of the Si content, which was due to the following two aspects. First, in the Si/Al composites, the cleavage fracture strength of Si grains was lower, therefore the flexural strength of the Si/Al composites decreased with the increase of the Si content. Second, the relative density of the Si/Al composites decreased with the increase of the Si content, which also induced that the flexural strength of the Si/Al composites decreased with the increase of the Si content.

Fig. 7 Relation curve of flexural strengths of Si/Al composites with Si content

4 Conclusions

1) Si/Al composites were prepared by spark plasma sintering (SPS) technique. The prepared composites comprised Si and Al two components and Al uniformly distributed among Si grains. There were no chemical reactions between Si and Al. When SPS was preceding, the locally high temperature generated by the particle discharge could melt Al, and the molten Al could filter into the gaps of Si particles to promote the densification of the composites.

2) The density of the Si/Al composites increased with the decrease of the Si content. When the Si content was 50%, the relative density of the Si/Al composite reached 98.41%.

3) The thermal conductivity, the coefficient of thermal expansion and the flexural strength of the composites all decreased with the increase of the Si content, and an optimal matching among them was obtained when the Si content was 60%.

References

[1] GERMAN R M, HENS K F, JOHNSON J L. Powder metallurgy processing of thermal management materials for microelectronic applications [J]. International Journal of Powder Metallurgy, 1994, 30(2): 205-214.

[2] CHIEN C W, LEE S L, LIN J C. Processing and properties of high volume fraction Al/Si composites [J]. Materials Science and Technology, 2003, 19(13): 1231-1234.

[3] TIAN Chong, CHEN Gui-yun, YANG Lin, ZHAO Jiu-zhou, ZHANG Yong-chang. Study of novel 70%Si-Al alloy for electronic packaging prepared by the spray deposition technique [J]. Powder Metallurgy Technology, 2005, 23(2): 108-111.

[4] XIU Zi-yang, CHEN Guo-qing, WANG Xiao-feng, WU Gao-hui, LIU Yan-mei, YANG Wen-peng. Microstructure and performance of Al-Si alloy with high Si content by high temperature diffusion treatment [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(11): 2134-2138.

[5] BAI Ling, GE Chang-chun, SHEN Wei-ping. Spark plasma sintering technology [J]. Powder Metallurgy Technology, 2007, 25(3): 217-223.

[6] LUO Yong-ming, LI Shu-qin, PAN Wei, LI Liu. Fabrication and mechanical evaluation of SiC-TiC nanocomposites by SPS [J]. Materials Letters, 2004, 58(1-2): 150-153.

[7] MA Yao, ZHOU Zhang-jian, YAO Wei-zhi, SONG Shu-xiang, GE Chang-chun. Research progress in preparing metal materials by spark plasma sintering [J]. Materials Review, 2008, 22(7): 60-64. (in Chinese)

[8] WANG Song, XIE Ming, ZHANG Ji-ming, YANG You-cai, LIU Man-men, CHEN Yong-tai, WANG Sai-bei. Development of spark plasma sintering technology [J]. Precious Metals, 2012, 33(3): 73-77. (in Chinese)

[9] HUANG Qiang, GU Yuan-ming. Status and prospects of matrix composites for electronic packaging [J]. Electronics & Packaging, 2003, 3(2): 23-26. (in Chinese)

[10] LI Yan-xia, LIU Jun-you, LIU Guo-quan, JIA Qi-jin. Microstructure and properties of Al-65vol%Si alloy fabricated by a process of liquid and solid separation [J]. Transactions of Materials and Heat Treatment, 2012, 33(3): 40-45. (in Chinese)

[11] WANG Xiao-feng, PENG Chao-qun, XIU Zi-yang, WU Gao-hui. Evolution of silicon phase configuration and Si-Al interface of Sip/Al composites [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(3): 477-482. (in Chinese)

[12] YI Xiao-su, DU Shan-yi, ZHANG Li-tong. Handbook of composites [M]. Beijing: Chemical Industry Press, 2007: 492-493. (in Chinese)

[13] YANG Ben, JIANG Yang, DING Xia-nan, ZHONG Hong-mei, LI Xiang-peng. Hot-pressing synthesis and characterization of Al-50%Si alloy electronic packaging materials [J]. Powder Metallurgy Industry, 2012, 22(5): 24-27. (in Chinese)

[14] WEI Yang-guang, XIONG Bai-qing, ZHANG Yong-an, LIU Hong-wei, WANG Feng, ZHU Bao-hong. Property measurements on spray formed Si-Al alloys [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(2): 368-372.

[15] KIYOSHI M, KANRYU I, YASUYUKI A, TORU N, MASAMI S, MOTOHIRO T, TAKASHI T. Processing of Al/SiC composites in continuous solid-liquid co-existent state by SPS and their thermal properties [J]. Composites Part B, 2012, 43(4): 2012-2019.

[16] VINCENT C, SILVAIN J F. Effect of porosity on the thermal conductivity of copper processed by powder metallurgy [J]. Journal of Physics and Chemistry of Solids, 2012, 73(3): 499-504.

[17] CHEN Guo-qin, XIU Zi-yang, YANG Wen-shu, JIANG Long-tao. Effect of thermal-cooling cycle treatment on thermal expansion behavior of particulate reinforced aluminum matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(11): 2143-2147.

[18] WU Gao-hui, ZHANG Qiang-jiang, LONG Tao. Fundamental study of SiC/Al composites in electronic packaging applications [J]. Electronic components & materials, 2003, 22(6): 27-31. (in Chinese)

[19] TURNER P S. Thermal expansion stresses in reinforced plastics [J]. J Res Natl Bur Stand, 1946, 37: 239-250.

[20] KERNER E H. The elastic and thermo-elastic properties of composite media [J]. Process Phys Soc B, 1956, 69(24): 808-813.

[21] ZHU Xiao-min, YU Jia-kang, WANG Xin-yu. Microstructure and properties of Al/Si/SiC composites for electronic packaging [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(7): 1686-1692.

[22] YANG Pei-yong, FENG Xi, ZHENG Zi-qiao, LI Shi-chen, CAI Chang. PM process of Si-Al electronic packing materials [J]. Chinese Journal of Rare Metals, 2004, 28(1): 160-165. (in Chinese).

Si含量对Si/Al复合材料组织及性能的影响

翟蔚宸1,张朝晖1,2,王富耻1,2,神祥博1,李树奎1,2,王 鲁1,2

1. 北京理工大学 材料学院,北京 100081;

2. 冲击环境材料技术国家级重点实验室,北京100081

摘 要:采用放电等离子烧结(SPS)技术制备不同Si含量的电子封装用Si/Al复合材料,测试复合材料的性能,包括密度、热导率、热膨胀系数及弯曲强度;进行成分及断口分析,研究Si含量对Si/Al复合材料微观组织及热、力学性能的影响规律。结果表明:Si/Al复合材料由Si、Al组成,Al均匀分布于Si晶粒之间;随着Si含量的降低,Si/Al复合材料的相对密度不断增大,当Si含量为50%(体积分数)时,复合材料的相对密度达到98.0%;复合材料的热导率、热膨胀系数及弯曲强度均随着Si含量的增加而减小,当Si含量为60%(体积分数)时,复合材料具有最佳的热导率、热膨胀系数及强度匹配。

关键词:放电等离子烧结;Si/Al复合材料;热导率;热膨胀系数;弯曲强度

(Edited by Xiang-qun LI)

Foundation item: Project (51374039) supported by the National Natural Science Foundation of China; Project (613135) supported by National Security Basic Research Program of China

Corresponding author: Zhao-hui ZHANG; Tel: +86-10-68912709; E-mail: zhang@bit.edu.cn

DOI: 10.1016/S1003-6326(14)63152-6