DOI: 10.11817/j.issn.1672-7207.2019.07.006

矿渣-钢渣基胶凝材料固砷机理

鄢琪慧1, 2, 3,倪文1, 2, 3,高巍1, 2, 3,李云云1, 2, 3,张钰莹1, 2, 3

(1. 北京科技大学 土木与资源工程学院,北京,100083;

2. 金属矿山高效开采与安全教育部重点实验室,北京,100083;

3. 工业典型污染物资源化处理北京市重点实验室,北京,100083)

摘要:为降低广西某选矿厂铅锌矿尾砂对环境的危害,同时达到固废减量化、资源化的目的,以矿渣、钢渣为主要原料制备胶凝材料(metallurgical slag cementitious material,MSC),并与尾矿砂混合制备膏体充填料协同固化砷。研究结果表明:尾砂中As质量分数为0.11%,As原始浸出质量浓度为0.66 mg/L,经MSC固化后As浸出质量浓度为0.031 mg/L,固化率达95.3%;As可以通过类质同象替换进入C-S(A)-H凝胶或类沸石相中代替Si原子或Al原子的位置,  可与Mg(OH)2和Ca(OH)2反应生成溶解度较低的复盐沉淀,且砷可以被水化产物C-S(A)-H凝胶包裹、吸附,Na2SO4与Na3AsO4反应生成低溶解度复盐类沉淀,这些都是砷被稳定固化的机制。

可与Mg(OH)2和Ca(OH)2反应生成溶解度较低的复盐沉淀,且砷可以被水化产物C-S(A)-H凝胶包裹、吸附,Na2SO4与Na3AsO4反应生成低溶解度复盐类沉淀,这些都是砷被稳定固化的机制。

关键词:矿渣;钢渣;固化;砷;胶结充填

中图分类号:X751 文献标志码:A 文章编号:1672-7207(2019)07-1544-07

Mechanism for solidification of arsenic with blast furnace slag-steel slag based cementitious materials

YAN Qihui1, 2, 3, NI Wen1, 2, 3, GAO Wei1, 2, 3, LI Yunyun1, 2, 3, ZHANG Yuying1, 2, 3

(1. School of Civil and Resources Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Key Laboratory of High-efficient Mining and Safety of Metal Mines, Ministry of Education, Beijing 100083, China;

3. Key Laboratory of Resource-oriented Treatment of Industrial Pollutants, Beijing 100083, China)

Abstract: In order to reduce the environmental risk of lead and zinc tailings in a concentrator in Guangxi, and at the same time achieve the purpose of reducing and recycling solid waste, blast furnace slag and steel slag were used as the main raw materials to prepare cementitious materials (metallurgical slag cementitious material, MSC), and mixed with tailings to prepare paste backfilling materials, which could also immobilize arsenic. The results show that the arsenic in tailings is 0.11%. The leaching mass concentrations of arsenic is 0.66 mg/L. After metallurgical slag cementitious material’s solidification, the leaching mass concentrations of arsenic is 0.031 mg/L, and the curing efficiency is 95.3%. Arsenic atom can replace the aluminum atom or silicon atom which is in the structure of C-S(A)-H gel and zeolite-like phase,  can also react with Mg(OH)2 and Ca(OH)2 in formation of calcium arsenate with lower solubility, and arsenic can be adsorbed and encapsulated by C-S(A)-H gel, furthermore, Na2SO4 reacts with Na3AsO4 resulting in the formation of double salt precipitates with low solubility, which is all the mechanism for solidification of arsenic.

can also react with Mg(OH)2 and Ca(OH)2 in formation of calcium arsenate with lower solubility, and arsenic can be adsorbed and encapsulated by C-S(A)-H gel, furthermore, Na2SO4 reacts with Na3AsO4 resulting in the formation of double salt precipitates with low solubility, which is all the mechanism for solidification of arsenic.

Key words: blast furnace slag; steel slag; solidification; arsenic; cemented backfilling

避免砷进入食物链是防治砷污染的关键[1],固化/稳定化方法消除砷的危害是目前较为有效的方式。水泥是常用的固化剂,常用于处理含砷废渣、尾矿等[2-4]。水泥固化砷的机理主要包括砷经沉淀反应生成Ca-As难溶盐,水泥水化产物对砷的吸附作用和物理包裹作用[5-7]。为了降低固砷胶凝材料中的水泥用量,大量文献报道了采用工业废渣部分替代水泥制备固砷胶凝材料的研究[8-9],而采用全固废制备“零”水泥含量的固砷胶凝材料的研究尚未见报道。本文作者以矿渣、钢渣、脱硫石膏为原料制备胶凝材料(MSC),并将其与含砷尾砂混合制备胶结充填料协同固化砷。矿渣中含有大量的活性硅(铝)氧四面体,钢渣中含有硅酸盐、铝酸盐、铁铝酸盐、游离氧化钙、游离氧化镁、RO相等氧化物类矿物,脱硫石膏的主要成分为CaSO4·2H2O。钢渣水化产生Ca(OH)2可以为体系提供Ca2+和OH-,OH-会破坏矿渣表面玻璃体的网络结构[10],使得其表面溶出大量铝氧四面体和硅氧四面体,这些活性的硅(铝)氧四面体与Ca2+和 等发生反应生成钙矾石、C-S(A)-H凝胶、类沸石相[11]等水化产物。砷可能参与水化反应生成难溶的砷酸盐[12],或者取代钙矾石中的S原子的位置[13],也有可能被水化产物包裹、吸附[14],不仅可提高钢渣、矿渣、脱硫石膏等大宗工业固体废弃物的利用率,而且能处理含重金属的尾砂,对尾砂中的砷进行有效的固化处理,降低其溶出性能,减小其对环境的危害性。

等发生反应生成钙矾石、C-S(A)-H凝胶、类沸石相[11]等水化产物。砷可能参与水化反应生成难溶的砷酸盐[12],或者取代钙矾石中的S原子的位置[13],也有可能被水化产物包裹、吸附[14],不仅可提高钢渣、矿渣、脱硫石膏等大宗工业固体废弃物的利用率,而且能处理含重金属的尾砂,对尾砂中的砷进行有效的固化处理,降低其溶出性能,减小其对环境的危害性。

1 试验原料

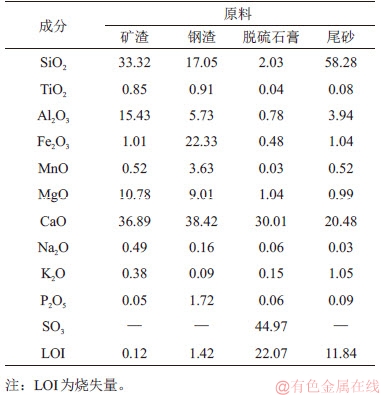

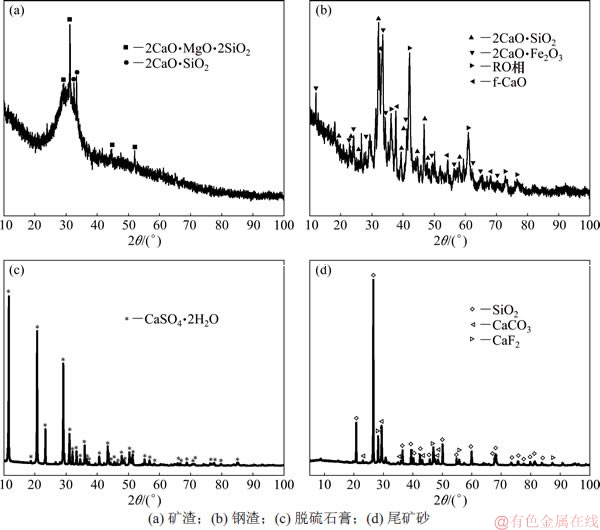

试验原料包括高炉炼铁产生的水淬矿渣、转炉钢渣、脱硫石膏、尾矿砂和外加剂。原料化学成分分析结果见表1,原料XRD分析结果见图1。

1) 矿渣粉磨至比表面积435 m2/kg备用。矿渣中除镁黄长石和硅酸二钙外无其他明显结晶相,主要为玻璃体。

2) 钢渣粉磨至比表面积444 m2/kg备用。钢渣中的主要物相有硅酸二钙、铁酸二钙、RO相、游离氧化钙。

3) 脱硫石膏粉磨至比表面积325 m2/kg备用。脱硫石膏中的主要物相为二水硫酸钙。

4) 尾矿砂。尾矿砂为广西某选矿厂铅锌矿尾矿,含砷0.11%,按HJ557—2009“固体废物浸出毒性浸出方法──水平振荡法”进行砷的毒性浸出试验,浸出液中砷的质量浓度为0.66 mg/L。尾砂中的主要成分有石英、方解石和萤石。

5) 外加剂。外加剂包括北京慕湖外加剂有限公司生产的PC减水剂。

表1 原料的化学成分(质量分数)

Table 1 Chemical components of raw material %

图1 原料XRD分析结果

Fig. 1 XRD patterns of raw materials

2 试验方法

2.1 充填料试样的制备

将矿渣、钢渣和脱硫石膏按表2所示比例配制成MSC,按胶砂质量比(即MSC与铅锌矿尾砂质量之比)1:4添加尾矿砂,按料浆质量分数(MSC和铅锌矿尾砂总质量占充填料总质量的比例)81%添加水,添加1%(占MSC质量的比例)减水剂制成充填料浆。为模拟广西某地下高温矿井大体积充填的实际环境,试样的养护条件如下:覆膜温度为40 °C,湿度为90%。拆模后,在相同条件下继续养护,测量其3,7和28 d的抗压强度及砷的浸出质量浓度。抗压强度的测定参考GB/T 17671-1999“水泥胶砂强度检验方法(ISO法)”。按照HJ557—2009“固体废物浸出毒性浸出方法──水平振荡法”进行砷的毒性浸出试验,釆用电感耦合等离子-原子发射光谱法(ICP-AES),测定浸出液中砷的质量浓度。

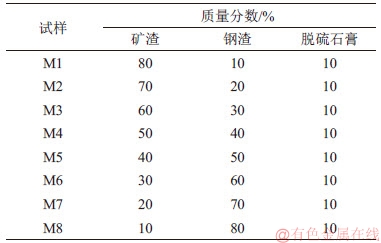

表2 MSC配比试验方案

Table 2 Mixed ratio of metallurgical slag cementitious materials

2.2 净浆试样的制备

为研究MSC固砷的机理,避免尾矿砂对分析结果的影响,做净浆固砷试验。用分析纯Na3AsO4·12H2O代替含砷尾矿砂, 掺入量为MSC总质量的5%,矿渣、钢渣和脱硫石膏的质量分数分别为60%,30%和10%,水胶比为0.4,制备净浆固化体。同时将不含砷的空白样作为对照组,养护条件与充填料浆固化体的一致。

掺入量为MSC总质量的5%,矿渣、钢渣和脱硫石膏的质量分数分别为60%,30%和10%,水胶比为0.4,制备净浆固化体。同时将不含砷的空白样作为对照组,养护条件与充填料浆固化体的一致。

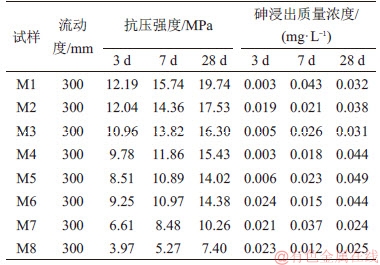

表3 充填料试样流动度、硬化体抗压强度和砷浸出质量浓度分析结果

Table 3 Test results of fluidity, compressive strength and leaching concentration of arsenic of samples

3 实验结果分析与讨论

表3所示为充填料试样流动度、硬化体抗压强度和砷浸出质量浓度分析结果。膏体充填一般设定坍落度为150~250 mm[15],流动度达250 mm基本可以实现自流输送。各组试样流动度均能满足自流输送要求。随着钢渣掺量的增加,充填料硬化体抗压强度有减小的趋势。当MSC配比为M1时,充填料硬化体养护至28 d时抗压强度最高,为19.74 MPa;当MSC配比为M7时,充填料硬化体养护至28 d时砷浸出质量浓度较低,为0.024 mg/L,与原尾矿砷浸出质量浓度(0.66 mg/L)相比,固化率达到96.4%。综合考虑固化体强度和砷浸出质量浓度,选择M3组配比进行净浆试验(即矿渣、钢渣、脱硫石膏的质量分数分别为60%,30%和10%)。净浆试样避免了尾矿砂的影响,有助于讨论矿渣-钢渣基胶凝材料固化 的机制。

的机制。

4 固砷机理研究

4.1 XRD分析

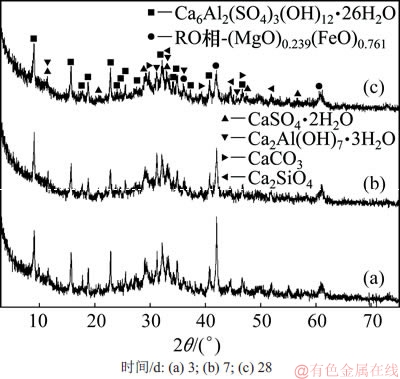

图2所示为MSC空白样XRD图谱。从图2可以看出:MSC水化产物有钙矾石、水化铝酸钙、方解石,还有未反应完的石膏、RO相和硅酸二钙。水化产物C-S-H凝胶由于结晶性不强,故XRD图谱中未分析出。随着养护时间的增加,作为激发剂的脱硫石膏的量减少,钙矾石的生成量逐渐增多,C2S逐渐水化成C-S-H凝胶,进一步填充胶结网络的空隙。

图2 MSC空白样XRD图谱

Fig. 2 XRD patterns of metallurgical slag cementitious material

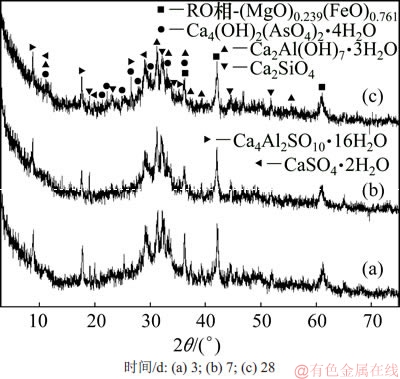

图3所示为MSC固As(V)试样XRD图谱。从图3可以看出:MSC固As(V)试样水化产物有水化铝酸钙、水化硫铝酸钙、四水合碱式砷酸钙(Ca4(OH)2(AsO4)2·4H2O),还有原料中未反应完全的RO相、硅酸二钙和二水石膏。与空白样不同的是,掺入含As(V)药剂后试样中未检测到钙矾石。根据SATISH[16]的研究,钙矾石表面吸附的砷酸根离子浓度若超出其可吸附能力,砷酸根离子会更倾向于与钙离子反应生成砷酸钙类沉淀,使得钙矾石的结构被破坏。掺入含As(V)药剂的试样中检测出了砷酸钙类化合物,即 Ca4(OH)2(AsO4)2·4H2O,与前人的研究结论相吻合。根据朱义年等[17]的研究结果,Ca4(OH)2(AsO4)2·4H2O溶度积为10-27.49,溶解度较低。

图3 MSC固As(V)试样XRD图谱

Fig. 3 XRD patterns of metallurgical slag cementitious material with As(V)

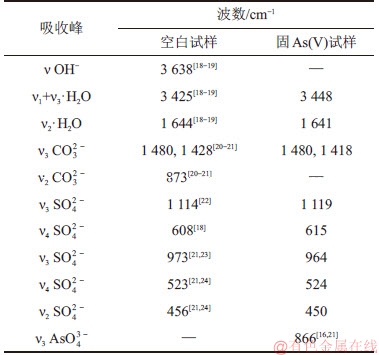

表4 IR分析图谱中各吸收峰分析结果

Table 4 Analysis results of each absorption peak in IR spectra

综上所述, 与MSC体系中的Ca2+和OH-发生反应生成溶解度极低的四水合碱式砷酸钙,从而被稳定固化。同时,由于

与MSC体系中的Ca2+和OH-发生反应生成溶解度极低的四水合碱式砷酸钙,从而被稳定固化。同时,由于 的大量存在,影响了MSC体系中钙矾石的生成。

的大量存在,影响了MSC体系中钙矾石的生成。

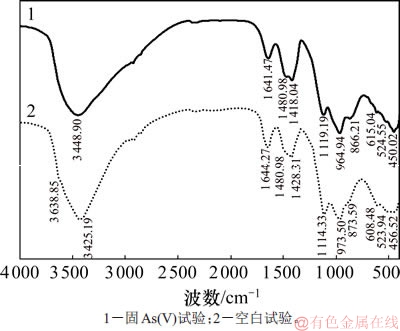

4.2 IR分析

表4所示为IR分析图谱中各吸收峰分析结果,图4所示为MSC固As(V)试样和空白试样28 d龄期的IR图谱。从表4和图4可知:固As(V)试样中不含OH-的特征峰,说明 的存在会消耗大量的OH-,

的存在会消耗大量的OH-, 与OH-和Ca2+发生反应,这与XRD分析结果吻合。1 110 cm-1附近为

与OH-和Ca2+发生反应,这与XRD分析结果吻合。1 110 cm-1附近为 非对称伸缩振动的特征峰,固As(V)试样的此峰较空白样发生了偏移,因为固As(V)试样中未生成钙矾石而是其他水化硫铝酸钙矿物。MSC空白试样中ν3

非对称伸缩振动的特征峰,固As(V)试样的此峰较空白样发生了偏移,因为固As(V)试样中未生成钙矾石而是其他水化硫铝酸钙矿物。MSC空白试样中ν3  和ν2

和ν2  的特征吸收峰在973 cm-1和456 cm-1处,而固As(V)试样中为波峰在964 cm-1和450 cm-1处,掺入

的特征吸收峰在973 cm-1和456 cm-1处,而固As(V)试样中为波峰在964 cm-1和450 cm-1处,掺入 使得

使得 的特征峰均向低波数方向偏移,说明

的特征峰均向低波数方向偏移,说明 的存在影响了硅酸盐的结构,波数减小,说明Si─O键的键能减小。由于向体系中加入Na3AsO4,

的存在影响了硅酸盐的结构,波数减小,说明Si─O键的键能减小。由于向体系中加入Na3AsO4, 倾向于与Ca2+反应生成溶解度较低的复盐,使得进入硅酸盐体系的阳离子发生变化,水化硅酸盐产物中Na+增多,Ca2+减少,有利于类沸石相(具有3个以上桥氧结构的非晶态硅(铝)网络体)的形成[25-27],Si─O键的键能减小可能是因为生成了类沸石相。

倾向于与Ca2+反应生成溶解度较低的复盐,使得进入硅酸盐体系的阳离子发生变化,水化硅酸盐产物中Na+增多,Ca2+减少,有利于类沸石相(具有3个以上桥氧结构的非晶态硅(铝)网络体)的形成[25-27],Si─O键的键能减小可能是因为生成了类沸石相。

图4 MSC试样28 d龄期IR图谱

Fig.4 IR spectra of metallurgical slag cementitious material for 28 d

综上所述, 与Ca2+和OH-反应生成溶解度较低的复盐,使得MSC水化反应体系中Ca2+数量减少,进入硅氧网络中起到平衡电荷作用的Ca2+被Na+取代,有助于MSC体系中类沸石相的产生。类沸石相中存在很多孔洞和孔道,有助于吸附As,且As可以取代类沸石相中的Al或Si原子的位置。这是由于As,Al和Si原子共价半径相近(As 0.119 nm,Al 0.121 nm,Si 0.111 nm[28]),并且都可以与氧形成四面体结构的阴离子,使得As可与C-S(A)-H凝胶或类沸石相中的Al和Si发生类质同象替换[29]。

与Ca2+和OH-反应生成溶解度较低的复盐,使得MSC水化反应体系中Ca2+数量减少,进入硅氧网络中起到平衡电荷作用的Ca2+被Na+取代,有助于MSC体系中类沸石相的产生。类沸石相中存在很多孔洞和孔道,有助于吸附As,且As可以取代类沸石相中的Al或Si原子的位置。这是由于As,Al和Si原子共价半径相近(As 0.119 nm,Al 0.121 nm,Si 0.111 nm[28]),并且都可以与氧形成四面体结构的阴离子,使得As可与C-S(A)-H凝胶或类沸石相中的Al和Si发生类质同象替换[29]。

4.3 SEM-EDS分析

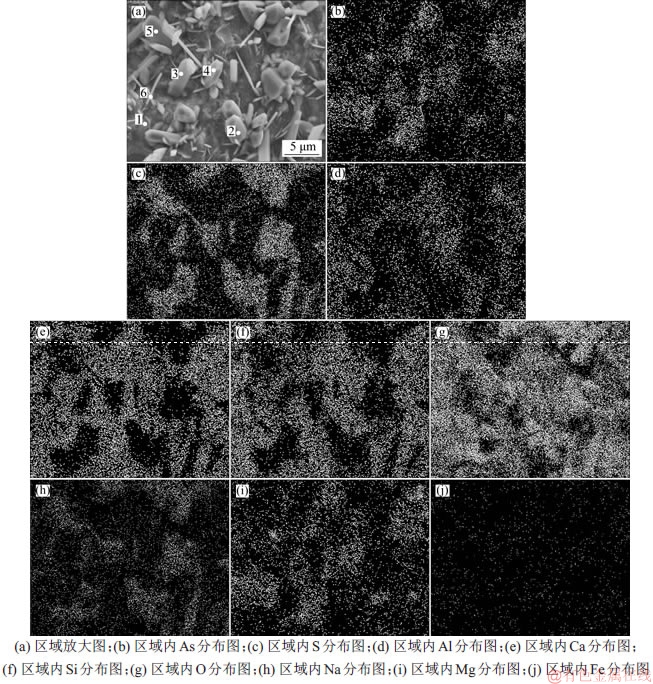

图5所示为MSC固As(V)试样SEM-EDS分析结果,图5(a)所示为MSC固As(V)试样硬化体某区域放大图片,图5(b)~5(j)所示为该区域各元素分布图。从图5可以看出:Ca,Al和Si等元素的密度变化规律几乎相同,再结合表5中1号点的成分分析结果,重合的区域基本可以确定为水化产物C-S(A)-H凝胶或类沸石相。As主要分布在Ca,Al和Si元素重合的区域,可能是通过类质同象替换进入凝胶或类沸石相的结构中代替Si原子的位置,另外,被凝胶吸附包裹以及与体系中的Ca(OH)2反应生成砷酸钙沉淀之后被吸附包裹在凝胶中都可能成为As被固化的机制。Na和S元素的密度变化规律较接近,结合表5中5号点分析结果可知,图5(a)中2,3,4和5号点均为Na2SO4,即图5(a)中的棒状物质。这些区域有少部分As(3号点检测出少量As,可能是Na2SO4与Na3AsO4的复盐类矿物(如砷钠明矾石等)。图5(a)中6号点的成分分析结果表明:这些细长的棒状物质可能是钙矾石,但分析结果中Si和Na含量也不低,可能是由于棒状物质直径太小,分析时电子束也打到了周围的其他物质。6号点检测到含量较高的As,但无法确定As具体存在的位置。

图5 MSC固As(V)试样SEM-EDS分析结果

Fig. 5 SEM-EDS analysis result of metallurgical slag cementitious material with As(V)

表5 图5(a)中各点成分分析结果

Table 5 Component analysis result of point in Fig. 5(a)

综上所述,As主要分布在C-S(A)-H凝胶和类沸石相中,还有少部分As存在于Na2SO4与Na3AsO4形成的复盐类矿物中。

5 结论

1) 利用工业冶炼渣制备胶凝材料代替水泥,并与尾矿砂混合制备膏体充填材料。当矿渣、钢渣和脱硫石膏掺量分别为60%,30%和10%,胶砂质量比为1:4,减水剂添加量为1%,料浆质量分数为81%时,充填料试样流动度为300 mm,满足自流输送的要求。养护至28 d,充填料试样硬化体抗压强度为16.30 MPa,满足一般矿山对充填体的强度要求。砷浸出质量浓度为0.031 mg/L,与原尾矿砷的浸出质量浓度(0.66 mg/L)相比,固化率达到95.3%。

2) MSC固As(V)的机理包括:As进入C-S(A)-H凝胶或类沸石相中代替硅原子的位置从而被稳定固化;Ca(OH)2及Mg(OH)2与 发生反应生成含砷复盐沉淀;As被水化产物C-S(A)-H凝胶包裹、吸附;Na2SO4与Na3AsO4反应生成低溶解度含砷复盐类沉淀。

发生反应生成含砷复盐沉淀;As被水化产物C-S(A)-H凝胶包裹、吸附;Na2SO4与Na3AsO4反应生成低溶解度含砷复盐类沉淀。

3) MSC代替水泥做胶结剂能有效降低胶结剂成本,同时能大量利用堆存的工业废物,具有较高的经济价值和环境意义。MSC还可用于固化重金属,对于Pb2+和Cd2+等二价重金属有很好的固化效果,对砷的固化效果有待提高,其长期固化性能需进一步研究。

参考文献:

[1] 熊如意, 宋卫锋. 环境砷污染及其治理技术发展趋势[J]. 广东化工, 2007, 34(11): 92-94.

XIONG Ruyi, SONG Weifeng. Arsenic pollution in environment and its trend of treated technology[J]. Guangdong Chemical Industry, 2007, 34(11): 92-94.

[2] 赵萌, 宁平. 含砷污泥的固化处理[J]. 昆明理工大学学报(理工版), 2003, 28(5):100-104.

ZHAO Meng, NING Ping. Treatment of arsenical sludge solidification[J]. Journal of Kunming University of Science and Technology (Science and Technology), 2003, 28(5):100-104.

[3] 汪吉章, 庞敏晖, 李善茂, 等.含砷飞灰固化处理及浸出毒性试验研究[J].化学工程师, 2009, 23(5): 37-39, 50.

WANG Jizhang, PANG Minhui, LI Shanmao, et al. Experimental study on solidification and leaching toxicity test of arsenic-containing fly ashes[J]. Chemical Engineer, 2009, 23(5): 37-39, 50.

[4] AKHTER H, CARTLEDGE F K, ROY A, et al. Solidification/stabilization of arsenic salts: effects of long cure times[J]. Journal of Hazardous Materials, 1997, 52(2/3): 247-264.

[5] CHOI W H, LEE S R, PARK J Y. Cement based solidification/stabilization of arsenic-contaminated mine tailings[J]. Waste Management, 2009, 29(5): 1766-1771.

[6] VANDECASTEELE C, DUTR V, GEYSEN D, et al. Solidification/stabilisation of arsenic bearing fly ash from the metallurgical industry: immobilisation mechanism of arsenic[J]. Waste Management, 2002, 22(2): 143-146.

V, GEYSEN D, et al. Solidification/stabilisation of arsenic bearing fly ash from the metallurgical industry: immobilisation mechanism of arsenic[J]. Waste Management, 2002, 22(2): 143-146.

[7] 姚燕, 王昕, 颜碧兰, 等.水泥水化产物结构及其对重金属离子固化研究进展[J].硅酸盐通报, 2012, 31(5):1138-1144.

YAO Yan, WANG Xin, YAN Bilan, et al. The research on heavy metal ions curing and its influence on the cement hydration process[J]. Bulletin of the Chinese Ceramic Society, 2012, 31(5):1138-1144.

[8] 陆占清, 朱丽苹, 张良勤, 等.含砷酸泥固化方法研究[J].水泥技术, 2012(6): 25-28.

LU Zhanqing, ZHU Liping, ZHANG Liangqin, et al. Solidification research of the arsenic acid mud[J]. Cement Technology, 2012(6): 25-28.

[9] 朱宏伟, 夏举佩, 周新涛, 等.矿渣基胶凝材料固化硫砷渣的研究[J].硅酸盐通报, 2014, 33(4): 874-879.

ZHU Hongwei, XIA Jupei, ZHOU Xintao, et al. Study on solidifying arsenic sulfide residue by slag cementitious material[J]. Bulletin of the Chinese Ceramic Society, 2014, 33(4):874-879.

[10] 彭小芹, 刘朝, 李三, 等.碱激发钢渣-矿渣胶凝材料凝结硬化性能研究[J].湖南大学学报: 自然科学版, 2015, 42(6): 47-52.

PENG Xiaoqin, LIU Chao, LI San, et al. Research on the setting and hardening performance of alkali-activated steel slag-slag based cementitious materials[J]. Journal of Hunan University(Natural Sciences), 2015, 42(6): 47-52.

[11] FRANTI EK

EK  , TOM

, TOM

J, LUBOM

J, LUBOM R K. Geopolymer materials based on fly ash[J]. Ceramics-Silikáty, 2005, 49(3):195-204.

R K. Geopolymer materials based on fly ash[J]. Ceramics-Silikáty, 2005, 49(3):195-204.

[12] LIU Degang, MIN Xiaobo, KE Yong, et al. Co-treatment of flotation waste, neutralization sludge, and arsenic-containing gypsum sludge from copper smelting: solidification/stabilization of arsenic and heavy metals with minimal cement clinker[J]. Environmental Science and Pollution Research, 2018, 25(8): 7600-7607.

[13] WANG Weixing, SHAO Yan, HOU Haobo, et al. Synthesis and thermodynamic properties of arsenate and sulfate-arsenate ettringite structure phases[J]. Plos One, 2017, 12(7): 1-14.

[14] LI Jiangshan, WANG Lei, CUI Jinli, et al. Effects of low-alkalinity binders on stabilization/solidification of geogenic As-containing soils: Spectroscopic investigation and leaching tests[J]. Science of the Total Environment, 2018, 631/632: 1486-1494.

[15] 王洪江, 吴爱祥, 陈进, 等.全尾砂-水淬渣膏状物料可泵性指标优化[J].采矿技术, 2007, 7(3): 15-21.

WANG Hongjiang, WU Aixiang, CHEN Jing, et al. Optimization of pumpability of full tailings-water granulated slag paste materials[J]. Mining Technology, 2007, 7(3): 15-21.

[16] SATISH C B M. Oxyanion-mineral surface interactions in alkaline environments: AsO4 and CrO4 sorption and desorption in ettringite[D]. Columbus: The Ohio State University. School of Graduate, 1995: 72-77.

[17] 朱义年, 张华, 梁延鹏, 等.砷酸钙化合物的溶解度及其稳定性随pH值的变化[J].环境科学学报, 2005, 25(12): 1652-1660.

ZHU Yinian, ZHANG Hua, LIANG Yanpeng, et al. Dependence of solubility and stability of calcium arsenates on pH value[J]. Acta Scientiae Circumstantiae, 2005, 25(12):1652-1660.

[18] 江虹.红外分析在水泥化学中的应用[J].贵州化工, 2001, 26(4): 30-31, 51.

JIANG Hong. Application of Infrared spectroscopy analysis in cement chemistry[J]. Guizhou Chemical Industry, 2001, 26(4):30-31, 51.

[19] VILLA C, PECINA E T, TORRES R, et al. Geopolymer synthesis using alkaline activation of natural zeolite[J]. Construction and Building Materials, 2010, 24(11): 2084-2090.

[20] 杨南如, 岳文海.无机非金属材料图谱手册[M]. 武汉: 武汉工业大学出版社, 2000: 337.

YANG Nanru, YUE Wenhai. The handbook of inorganic metalloid materials atlas[M]. Wuhan: Wuhan University of Technology Press, 2000: 337.

[21] MOLLAH M, KESMEZ M, COCKE D. An X-ray diffraction (XRD) and Fourier transform infrared spectroscopic (FT-IR) investigation of the long-term effect on the solidification/stabilization (S/S) of arsenic(V) in Portland cement type-V[J]. Science of the Total Environment, 2004, 325(1/2/3): 255-262.

[22] 阎爱云, 倪文, 黄晓燕, 等. 矿渣-钢渣基胶结剂固化-稳定化含铅尾砂[J].金属矿山, 2016(8): 180-184.

YAN Aiyun, NI Wen, HUANG Xiaoyan, et al. Solidification-stabilization of tailings containing lead by slag-steel slag system cement[J]. Metal Mine, 2016(8): 180-184.

[23] CETINTAS R, SOYER-UZUN S. Relations between structural characteristics and compressive strength in volcanic ash based one-part geopolymer systems[J]. Journal of Building Engineering, 2018, 20: 130-136.

[24] FERN NDEZ-JIM

NDEZ-JIM NEZ A, PALOMO A. Composition and microstructure of alkali activated fly ash binder: Effect of the activator[J]. Cement and Concrete Research, 2005, 35(10): 1984-1992.

NEZ A, PALOMO A. Composition and microstructure of alkali activated fly ash binder: Effect of the activator[J]. Cement and Concrete Research, 2005, 35(10): 1984-1992.

[25] 贾屹海. Na-粉煤灰地质聚合物制备与性能研究[D].北京: 中国矿业大学化工学院, 2009: 12-17.

JIA Yihai. Synthesis and characterization of fly-ash-based Na-geopolymer[D]. Beijing: China University of Mining and Technology. School of Chemical Engineering and Technology, 2009: 12-17.

[26] ALONSO S, PALOMO A. Calorimetric study of alkaline activation of calcium hydroxide-metakaolin solid mixtures[J]. Cement and Concrete Research, 2001, 31(1): 25-30.

[27] YIP C K, LUKEY G C, VAN DEVENTER J S J. The coexistence of geopolymeric gel and calcium silicate hydrate at the early stage of alkaline activation[J]. Cement and Concrete Research, 2005, 35(9): 1688-1697.

[28] BEATRIZ C, VER NICA G, ANA E P P, et al. Covalent radii revisited[J]. Dalton Trans, 2008(15), 2832-2838.

NICA G, ANA E P P, et al. Covalent radii revisited[J]. Dalton Trans, 2008(15), 2832-2838.

[29] 陶志超, 周新涛, 罗中秋, 等.含砷废渣水泥固化/稳定化技术研究进展[J].材料导报, 2016, 30(9): 132-136.

TAO Zhichao, ZHOU Xintao, LUO Zhongqiu, et al. Progress on the solidification/immobilization of arsenic-bearing waste cement[J]. Materials Review, 2016, 30(9): 132-136.

(编辑 杨幼平)

收稿日期: 2018 -09 -20; 修回日期: 2018 -11 -29

基金项目(Foundation item):国家自然科学基金资助项目(51504014)(Project(51504014) supported by the National Natural Science Foundation of China)

通信作者:倪文,博士,教授,从事矿物材料、保温耐火材料和固体废弃物资源化研究;E-mail: niwen@ces.ustb.edu.cn