液相氧化法钒渣提钒研究及展望

来源期刊:中国有色金属学报(英文版)2014年第5期

论文作者:王中行 郑诗礼 王少娜 刘 彪 王大卫 杜 浩 张 懿

文章页码:1273 - 1288

关键词:钒渣;液相氧化;亚熔盐;熔盐;钒;铬;提取

Key words:vanadium slag; liquid oxidation; sub-molten salt; molten salt; vanadium; chromium; extraction

摘 要:针对从钒渣中提取钒、铬存在的问题,提出了一系列绿色液相氧化法,包括NaOH/KOH亚熔盐法和NaOH-NaNO3熔盐法。与传统钠化焙烧法工艺相比,新方法的操作温度由850 °C降低至200~400 °C,而钒、铬的提取率分别由75%和接近0提高至95%和90%,整个操作过程中无废气及毒渣排放。与焙烧法相比,新工艺在能耗、环境友好及矿物资源综合利用率方面显示出明显的优势,成为钒行业绿色化升级的有效替代方案。

Abstract: A series of innovative green metallurgical processes using novel reaction media including the NaOH/KOH sub-molten salt media and the NaOH-NaNO3 binary molten salt medium, for the extraction of vanadium and chromium from the vanadium slag have been developed. In comparison with the traditional sodium salt roasting technology, which operates at 850 °C, the operation temperatures of these new processes drop to 200-400 °C. Further, the extraction rates of vanadium and chromium utilizing the new approaches could reach 95% and 90%, respectively, significantly higher than those in the traditional roasting process, which are 75% and approximate zero, respectively. Besides, no hazardous gases and toxic tailings are discharged during the extraction process. Compared with the conventional roasting method, these new technologies show obvious advantages in terms of energy, environments, and the mineral resource utilization efficiency, providing an attractive alternative for the green technology upgrade of the vanadium production industries.

Trans. Nonferrous Met. Soc. China 24(2014) 1273-1288

Zhong-hang WANG1,2, Shi-li ZHENG1, Shao-na WANG1, Biao LIU1, Da-wei WANG1,3, Hao DU1, Yi ZHANG1

1. National Engineering Laboratory for Hydrometallurgical Cleaner Production Technology, Institute of Process Engineering, Chinese Academy of Sciences, Beijing 100190, China;

2. School of Chemistry and Chemical Engineering, University of Chinese Academy of Sciences, Beijing 100049, China;

3. School of Chemical and Environmental Engineering, China University of Mining and Technology (Beijing), Beijing 100083, China

Received 30 May 2013; accepted 10 September 2013

Abstract: A series of innovative green metallurgical processes using novel reaction media including the NaOH/KOH sub-molten salt media and the NaOH-NaNO3 binary molten salt medium, for the extraction of vanadium and chromium from the vanadium slag have been developed. In comparison with the traditional sodium salt roasting technology, which operates at 850 °C, the operation temperatures of these new processes drop to 200-400 °C. Further, the extraction rates of vanadium and chromium utilizing the new approaches could reach 95% and 90%, respectively, significantly higher than those in the traditional roasting process, which are 75% and approximate zero, respectively. Besides, no hazardous gases and toxic tailings are discharged during the extraction process. Compared with the conventional roasting method, these new technologies show obvious advantages in terms of energy, environments, and the mineral resource utilization efficiency, providing an attractive alternative for the green technology upgrade of the vanadium production industries.

Key words: vanadium slag; liquid oxidation; sub-molten salt; molten salt; vanadium; chromium; extraction

1 Introduction

Vanadium and its compounds are widely used in the fields of metallurgical industry, petrochemical industry, defense industry, electronic industry, paint and coatings industry, etc, due to their excellent mechanical [1], electrochemical [2], catalytic [3], magnetic [4], and other physicochemical properties [5]. Vanadium compounds originate mostly from primary sources such as ore feedstock, concentrates, metallurgical slags, and petroleum residues, among which vanadium-bearing slag is the most important source for vanadium production, accounting for about 60% of the vanadium production globally [6]. The vanadium slag which contains 12%-24% V2O5 is mainly obtained from the oxygen blowing of the molten pig iron via the shaking ladle process, hot metal ladle process, converter process, etc [6]. Sodium salt roasting is the most representative route for the extraction of vanadium from vanadium slag currently, and this process mainly consists of the following operation units: salt roasting, leaching and purification, precipitation, and V2O5-fusion [7].

It is well known that the salt roasting is the key stage in the whole vanadium extraction process, and the objective of such operation is to convert insoluble vanadium oxide into water-soluble sodium vanadate salts. During salt roasting, vanadium (III) in the vanadium slag is oxidized to sodium metavanadate in the presence of sodium reagents such as NaCl, Na2CO3, and Na2SO4, and such operation typically proceeds under oxidative environment in rotary kiln or multiple hearth furnace at high temperature (750-850 °C). Unfortunately, due to low vanadium conversion rate (only 65%-85%) of single roasting, multiple roasting processes are commonly applied, causing the consumption of extra amount of energy and resource [8]. Besides, during the oxidizing roasting, large quantity of aggressive gases such as Cl2, SO2, and HCl are emitted due to pyrolysis of sodium reagents. Moreover, chrome spinel, which is commonly associated in the vanadium slag, is much more stable than vanadium spinel in thermodynamic consideration, and thus cannot be oxidized effectively unless the operation temperature is increased to above 1150 °C. Consequently, chromium in the vanadium slag cannot be synchronously extracted using the typical sodium salt roasting method, producing hazardous chromium containing tailings, which leads to serious resource waste and environmental pollution.

In order to meet the more stringent environmental regulation and alleviate the resource deficiency, improved sodium salt roasting methods, such as roasting with composite sodium reagents [9], and new roasting methods, such as the lime roasting method [10], have been developed to improve the vanadium yield to nearly 90% and reduce the hazardous residue production. But the problems associated with high temperature salt roasting technologies including low overall resource utilization, high energy consumption, as well as the environmental pollution due to the formation of hexavalent residue remain unsolved.

Recently, based on principles of cleaner production and industrial ecology, novel processes named the sub-molten salt (SMS) technologies have been developed by ZHANG and coworkers from the Institute of Process Engineering, Chinese Academy of Sciences (IPE,CAS), in order to achieve the 3Rs (Reduce, Recycle and Reuse) objectives [11]. Compared with the traditional roasting methods, the operation temperatures in these new technologies drop from 850 °C to 200-400 °C, yet the extraction rate of vanadium and chromium could reach up to 95% and 90% after reacting for 5 h, respectively [12]. Besides, no hazardous gases and toxic tailings are discharged during the whole processes, showing attractive industrial application prospects.

However, systematic studies regarding the extraction of vanadium and chromium from vanadium slag using the sub-molten salt technologies have rarely been reported. Therefore, the main focus of this paper is to give a systematic analysis of different sub-molten salt technologies in treating vanadium slag. Firstly, the treatment of vanadium slag by the NaOH sub-molten salt method, the NaOH-NaNO3 binary molten salt method, and the KOH sub-molten salt method will be briefly introduced, and the merits and drawbacks of these processes will be discussed. Further, reaction mechanism using SMS to treat vanadium slag will be analyzed. And finally, future development of the SMS technologies for the vanadium slag processing will be proposed.

2 Sub-molten salt technology

2.1 Concept and application

The sub-molten salt (SMS) is an ionized solution with high alkali concentration, and is capable of providing reactive oxygen species (ROS) with high chemical reactivity. As an unconventional reaction medium, the SMS medium is characterized by high alkali concentration (usually above 50% (mass fraction)), high boiling point, high ionic strength, etc, showing superior physicochemical properties in reaction and separation [11].

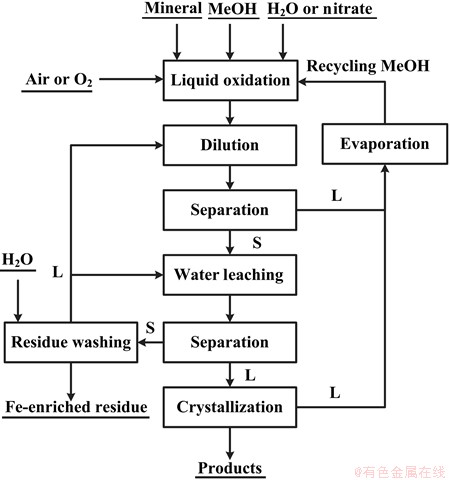

In the SMS approach, the mineral is treated with SMS medium under oxidative conditions using air, oxygen, or nitrate as the oxidant, as schematically presented in Fig. 1.

Fig. 1 Simplified flow sheet of typical SMS approach

After the liquid oxidation reaction, the reaction slurry is diluted and filtrated to separate the alkaline liquid and the mixture of Fe-enriched residue, the vanadate and the chromate, which can be further separated via water leaching, filtration and crystallization procedures. The diluted alkaline solution as well as the crystallization mother liquid is then evaporated to certain concentration and added into the reactor for recycling.

Different from those in the traditional roasting technologies, reactions which occur in the SMS medium are pseudo-homogeneous, and the mass transfer efficiency is much higher in comparison with that in the roasting process. Besides, fundamental study suggests that in the molten or SMS medium, mineral could be oxidized by oxygen, air, nitrate, as well as the reactive oxygen species (ROS), which could be obtained via the pyrolysis of hydroxyl or nitrate ions and the oxygen reduction reaction (ORR) process [8,13,14]. The ROS could cause mineral lattice distortion and cause catalytic oxidation of metal suboxides in the ore. All these characteristics mentioned above contribute to the high reaction efficiency of LO approaches in comparison with the roasting methods. For example, in the KOH sub-molten salt medium (75% KOH aqueous solution), the chromite can be efficiently decomposed at 300 °C [15]. Based on such a technology, a 10000 t scale pilot plant has been built, and the operation results demonstrated that the chromium yield could reach more than 99%. Further, the amount of chromium- containing residue produced in the new process was only one-fifth in comparison with that produced in the traditional roasting process, significantly elevating the environmental burden [16]. Till now, the SMS technology has been successfully applied to the treatment of amphoteric ores to extract valuable metal resources including Cr, Al, Ti, Nb, Ta, etc [11,12,16-19].

In view of the foregoing, it is clear that the application of SMS technologies for the processing of amphoteric metal resources has been proven to be feasible and attractive. Similar strategy has also been utilized to treat vanadium slag using the SMS media, and has also been proven to be very efficient and attractive. Vanadium and chromium can be effectively extracted from vanadium slag synchronously under relatively moderate reaction conditions, and detailed analysis will be addressed later in this paper.

2.2 Fundamental research on sub-molten salt technology

2.2.1 Physicochemical properties of KOH and NaOH SMS media

As an unconventional chemical medium, the physicochemical properties of the SMS media cannot be obtained accurately utilizing the traditional analytical technique and classic electrolyte models, resulting in only sporadic basic physicochemical data of the SMS media being reported. While accurate and reliable basic physicochemical properties are crucial for understanding the reaction mechanisms and principles of the SMS technology. In this regard, various physicochemical properties of the SMS medium (mainly refers to the highly concentrated sodium hydroxide and potassium hydroxide solutions) have been summarized by combining experimental measurements [20,21], theoretical calculation [22,23], and computer modeling [24,25], as discussed in the following sections.

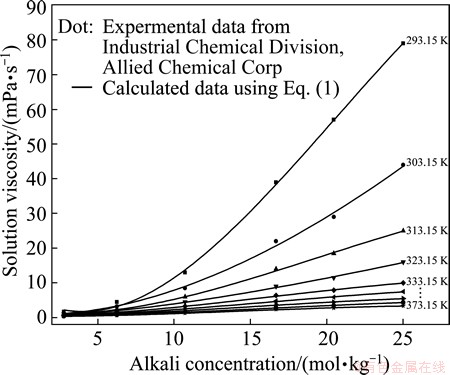

1) Solution viscosity

The viscosity of the concentrated alkaline solutions is the foremost property that has a prominent influence on the oxidation procedure in the SMS methods. Over the past decades, variations of alkaline viscosity with temperature and solution concentration have been studied extensively [26,27], and some of the results are summarized and presented in Figs. 2 and 3.

Fig. 2 Viscosity variation of KOH solution with solution concentration

Fig. 3 Viscosity variation of NaOH solution with solution concentration

Further, a large number of empirical and semi- empirical models have been developed for calculating or correlating the solution viscosity [28-30]. It is found that the improved Jones-Dole relative viscosity model (Eq. (1)), developed by ABDULAGATOV et al [31] showed better performance in correlating and predicting the viscosity of the SMS media.

(1)

(1)

where η and ηw are the viscosities of the electrolyte solution and pure solvent (at the same temperature and pressure), respectively; A, B, D, and F are the viscosity coefficients; and c is the molar concentration of the electrolyte.

It can be seen that the alkaline viscosity increases monotonically with the increasing of solution concentration in both KOH and NaOH solutions. This phenomenon is mainly due to the enhancement of solute-solvent and solute-solute structural interactions as the alkali concentration increases, and such structural interactions include high terms of the long-range columbic forces, high term hydrodynamic effect, and interactions arising from changes in solute-solvent interactions with concentration (Dc2 and Fc2.5 terms in Eq. (1)).

Further, the variation of solution viscosity with the alkali concentration in NaOH solutions is much more significant in comparison with that in equivalent KOH solutions. The more significant increase of solution viscosity in NaOH solutions is mainly due to the radius difference between potassium ion and sodium ion. Previous viscosity measurements, spectroscopic analysis, thermodynamic considerations, and flotation tests have revealed that ions of small size interact strongly with water molecules, and form electrostatically stabilized hydrophilic hydration shells [32]. With the increase of ion radius, the local electric fields on the ion surface decrease significantly, and the orienting force between the ions and water is weakened. Hence, as the size of ion increases, the dominating electrostatic hydrophilic hydration of small ions is gradually replaced by hydrophobic hydration of large ions where hydrogen- bonded water molecules form a large disordered cage surrounding the ions. In another word, as the size of ion increases, the radius of the primary hydration shell becomes larger, and the hydration shell becomes more fragile and breakable, resulting in the damage of the water hydrogen bonding network and the decrease of B-coefficient value in Eq. (1). For example, the B-coefficient values of potassium ion and sodium ion in aqueous solution at 298.15 K are +0.086 and -0.007, respectively [33]. And it might be inferred that other viscosity coefficients in Eq. (1) will show similar variation with the change of ion radius (requires further validation). Thus, the viscosity of NaOH solution is larger in comparison with that of the equivalent KOH solution. And the difference of solution viscosity in KOH and NaOH solutions becomes more significant as the solution becomes more concentrated, as illustrated by Eq. (2).

(2)

(2)

where Δηr is the difference of relative solution viscosity between KOH and NaOH solutions; ΔA, ΔB, ΔD, and ΔF are the difference of viscosity coefficients in Eq. (1), respectively.

It can be seen that, Δηr increases dramatically with the increase of alkali concentration, and the viscosity of NaOH solutions is more sensitive to the alkali concentration variations in comparison with that of KOH solutions. Further, it can be clearly inferred that the mass transfer efficiency in KOH solutions is much higher in comparison with that in the equivalent NaOH solutions, and detailed analysis will be addressed in the subsequent sections in this paper regarding the important influence of the solution viscosity on the mass transfer.

2) Activity and osmotic coefficient

Accurate and reliable activity and osmotic coefficients are essential for the thermodynamic equilibrium calculations, providing theoretical foundations for the quantitative evaluation of chemical reactions and phase separations which occur in the SMS media. A large number of activity and osmotic coefficients of NaOH and KOH solutions have been reported [34-36]. PABALAN and PITZER [37] used the osmotic coefficients of NaOH solutions, calculated from critically evaluated literature data on vapor pressures, to fit the Pitzer equations, and obtained ion-interaction parameters as a function of temperature and pressure. These parameters allow the calculation of osmotic and activity coefficients of 0-10 mol NaOH solutions in the temperature range of 0-350 °C and saturation pressure to about 400 bar. Using the vapor pressures of aqueous NaOH solutions, CAMPBELL and BHATNAGAR [35] calculated the osmotic and activity coefficients of NaOH in water from 150 to 250 °C in the concentration range of 0.32-3.7 mol/L. Using the Pitzer-Debye-Huckel model as the long-range excess Gibbs energy contribution, and a new expression based on the local composition concept as the short-range excess Gibbs energy contribution, ZAFARANI-MOATTAR and MAJDAN-CEGINCARA [38] developed a new NRF-modified-NRTL local composition model for the representation of the excess Gibbs energy of the electrolyte solutions. The model was applied to correlating the mean ionic activity coefficients and osmotic coefficients of NaOH (0-29 mol/L) and KOH (0-20 mol/L) solutions at 25 °C. The fitting quality of the new model has been favorably compared with the electrolyte NRTL, Wilson, modified NRTL, NRTL–NRF, NRF– Wilson, UNIQUAC–NRF, Pitzer and TCPC models.

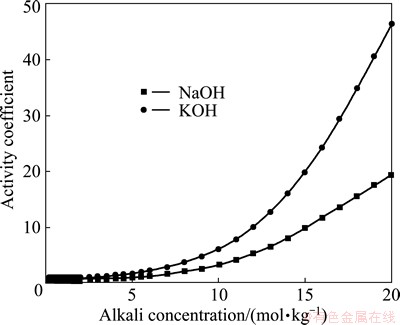

Figure 4 presents the comparison of activity coefficients of NaOH and KOH aqueous solutions at 298.15 K [36].

Fig. 4 Comparison of activity coefficients of NaOH and KOH aqueous solutions at 298.15 K (Data are taken from Ref. [36])

It can be seen that due to the increase of excess Gibbs energy (Gex) of the solution arsing from the enhancement of ion-water and ion-ion structural interactions with the increase of alkali concentration, as described by the Pitzer theory [39] (Eq. (3)), the activity coefficients increase monotonically with the alkali concentration increasing.

(3)

(3)

where Gex, R, T, m i are the excess Gibbs energy, the universal gas constant, the thermodynamic temperature, and the molality of solute i, respectively; λij and μijk are the two-ion and three-ion interaction parameters, respectively.

It is observed that the Gex increases with the solution concentration increasing due to the enhancement of multi-ion interactions, resulting in the increase of the activity. Besides, the activity coefficient of KOH solution is substantially higher than that of equivalent NaOH solution. This might be caused by the significant differences in ion-ion and ion-water interactions originated from the radius difference between the potassium ion and the sodium ion, as discussed above.

3) Oxygen solubility and diffusion coefficient

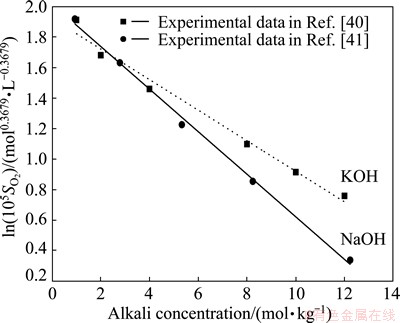

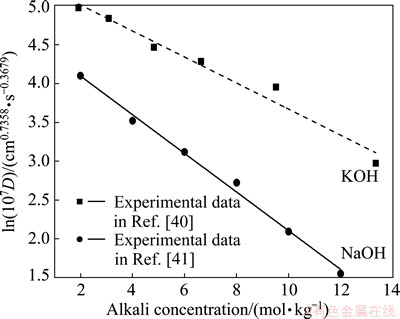

As the main oxidative reagent in the typical SMS media, the behavior of oxygen plays an important role in the oxidation reactions. Dissolved oxygen molecules are capable of oxidizing the metal suboxides directly. On the other hand, fundamental studies have suggested that the reactive oxygen species (ROS) obtained from oxygen reduction reaction (ORR) in SMS media could facilitate the oxidation of the metal suboxides, which will be discussed in detail below. Regardless of the reaction mechanisms, the efficiency of the oxidation reactions in the SMS media is mainly determined by the oxygen solubility and transfer properties (such as diffusion coefficient). The solubility and diffusion coefficient of oxygen in NaOH and KOH solutions are presented in Figs. 5 and 6 [40-42], respectively.

It is clear that with the increase of alkali concentration, the solubility of oxygen decreases significantly due to the salting-out effect, as discribed by Eq. (4) [43].

(4)

(4)

The ratio of the oxygen solubility in pure water (S0) and aqueous solution (S) is equal to the activity coefficient of the dissolved oxygen (γO2) at a given molality (m), and ks is the salting coefficient. The subscripts O, c, and a in the right terms of Eq. (4) represent the oxygen, cation, and anion, respectively; λ and ζ are the interaction parameters of oxygen-ion and oxygen-anion-cation, respectively.

Fig. 5 Comparison of oxygen solubility in KOH (298 K) and NaOH (296 K) solutions

Fig. 6 Comparison of oxygen diffusion coefficient in KOH (298 K) and NaOH (296 K) solutions

In view of the previous discussion, with the increase of solution concentration, the ion-ion and ion-water interactions in the solution become stronger, and the salting out effect is thus more significant. Consequently, the solubility of oxygen decreases dramatically with the increase of alkali concentration. And the solubility of oxygen in KOH solutions is 1.5-2 times higher than that in equivalent NaOH solutions (ignoring the little temperature difference in Fig. 5), which could be explained by the fact that K+ is a much larger cation, and interacts much weakly with surrounding water molecuels in the solutions. Such weak interaction is in favor of the formation of a disturbed hydrogen bonding network, allowing nopolar oxygen moleucles to accommodate in the solutions. In contract, Na+ is a typical water structure making cation, and can hdyrogen bond strongely with water molecules. Therefore, the hydrogen bonding network in NaOH solutions are much stronger, inhibiting the disslution of nonpolar oxygen molecules.

In addition, the oxygen diffusion coefficient also reduces with the increase of alkali concentraction due to the increase of solution viscosity. Besides, as mentioned above, in comparison with the KOH solutions, the viscosity of NaOH solution is more senstive to the variation of alkali concentrtions, resulting in dramatic decrease of the oxygen diffusion coefficient in the NaOH solutions with the increase of the solution concentraction.

Because of the important impact of oxygen solubility and diffusion in the alkaline medium on the oxdation reactions which occur in the SMS medium, it could be inferred that the oxdation reactions in the KOH sub-molten salt medium will be much more favorible in comparison with that in the NaOH sub-molten salt medium due to the better oxygen dissolution and mass transfer capacities.

2.2.2 Reactivity of NaOH and KOH SMS media

According to the previous studies, the sub-molten salt medium is a good carrier of reactive oxygen species, which could be obtained from the pyrolysis of hydroxyl ions and the oxygen reduction reaction (ORR) process. The ROS can cause mineral lattice distortion and catalytic oxidation of the metal suboxides, resulting in efficiently oxidative decomposition of mineral particles in the SMS media. Thus, the understanding of the formation, the existence states, and the reaction mechanism of ROS in the SMS media is of significant importance to understand the mechanisms and the principles of the oxidative decomposition of mineral particles, providing theoretical foundations for the optimization of the SMS technologies.

1) Formation and existence state of ROS in the SMS medium

The formation of ROS in highly concentrated MeOH (Me represents Na or K) solutions under anaerobic conditions was studied by ELUARD and  [44] and CHONG et al [45], and they found that oxygen anions could be obtained from the pyrolysis of hydroxyl ions at high temperature (Reaction (5)). Further oxidization of oxygen anions could lead to the formation of superoxide ions and peroxide ions (Reactions (6) and (7)), which was confirmed by JIN et al [14] in their electrochemical study of ROS in the KOH sub-molten salt medium under argon atmosphere.

[44] and CHONG et al [45], and they found that oxygen anions could be obtained from the pyrolysis of hydroxyl ions at high temperature (Reaction (5)). Further oxidization of oxygen anions could lead to the formation of superoxide ions and peroxide ions (Reactions (6) and (7)), which was confirmed by JIN et al [14] in their electrochemical study of ROS in the KOH sub-molten salt medium under argon atmosphere.

(5)

(5)

(6)

(6)

(7)

(7)

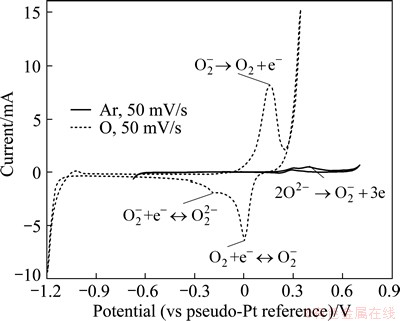

Further, the ROS could be obtained from the oxygen reduction reactions [41,46,47]. SONG et al [48] produced stable superoxide ions via a reversible one-electron oxygen reduction reaction in a 1 mol/L NaOH aqueous solution using a graphite electrode modified by Co(II) HFPC. And stable superoxide ions were also observed in the SMS media by JIN et al [15], as presented in Fig. 7.

Fig. 7 Comparison of CV curves in 85% Ar and O2 saturated KOH SMS media at 320 °C

In fact, the oxygen reduction peak current (the formation of superoxide ion via the one-electron oxygen reduction reaction at ca. 0 V) is more than 40 times larger than the oxidation peak current (the formation of superoxide ion via oxidizing of oxygen anions) in the equivalent solutions under anaerobic conditions, suggesting that the ORR is the major origin of ROS in the SMS media.

It should be noted that the formation and existence of ROS are largely dependent on the media properties, including the alkali concentration, the mass transfer capacity, and the alkali metal cation species. According to ZHANG et al [41] and ZHAO et al [49], the ORR could happen via “series” 4e reduction process in basic solutions, during which oxygen was firstly reduced to superoxide anion (Reation (8)), followed by further reduction to hydrogen peroxide anions as the intermediate and hydroxyl ions as the final product (Reacitons (9) and (10)).

(8)

(8)

(9)

(9)

(10)

(10)

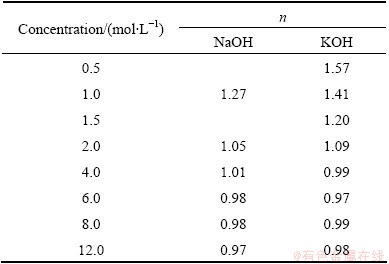

It was suggested that Reactions (9) and (10) would be gradually inhibited as the alkali concentration increases, which was confirmed by JIN et al [14] by calculating the election transfer number (n) of ORR in NaOH and KOH solutions within the concentration range of 0.5 to 12 mol/L as presented in Table 1.

Table 1 Electron transfer number (n) of ORR in NaOH and KOH solutions at 298 K

It is obvious that the electron transfer number (n) transits from 2 in dilute solutions to 1 in concentrated solutions in both NaOH and KOH solutions, suggesting that the ORR process shifts from 2e reduction to 1e reduction and the lifetime of superoxide intermediate is extended with the increase of alkali concentration.

Besides, the macro-kinetics study of ORR in alkaline solutions has shown that the electrochemical reduction of oxygen in NaOH and KOH aqueous solutions is attributed to a quasi-reversible diffusion- controlled reaction [14], which is mainly controlled by the oxygen diffusion in the alkaline media. And as the major reactant of the ORR, the solubility of oxygen in alkaline solutions appears to be another main factor in ORR kinetics apart from the oxygen diffusivity.

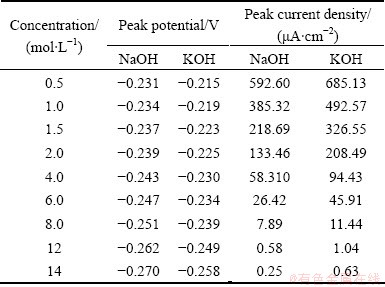

Though similar variation of the electron transfer number with alkali concentration and similar kinetic characteristics are observed in both NaOH and KOH solutions, due to the impact of alkali metal cations, significant differences of the ORR process in KOH and NaOH solutions exist in both thermodynamics and kinetics consideration as presented in Table 2 [14].

Table 2 Comparison of ORR behavior in NaOH and KOH solutions ranging from 0.5 to 14 mol/L at 298 K (scan rate 100 mV/s)

It is clearly seen from Table 2 that the peak potential of ORR in KOH solution is more positive and the peak current density is larger in comparison with that in equivalent NaOH solution, indicating that potassium cation is more favorable for the ORR process in both thermodynamic and kinetic considerations in comparison with the sodium cation. The above-mentioned observation is possibly because the radius of potassium ion is larger than that of sodium ion, causing the much smaller potassium ion surface charge density and much weaker interaction among the potassium ion, water, and hydroxyl ion. Thus, compared with the equivalent NaOH solution, the KOH solution has lower viscosity, higher solution activity, and greater oxygen dissolution capacity, more favorable for the formation and stable existence of ROS, as discussed above.

2) Mineral dissociation

As mentioned in the previous sections, the ROS plays an important role in the mineral dissociation. SUN et al [13] studied the oxidative decomposition of chromite ore in KOH-KNO2 binary sub-molten salt system, and their work indicated that oxygen dissolved into the medium could be converted to ROS, such as O, O2- and  , causing catalytic oxidation of Cr(III). FEI et al [50] and HANSARD et al [51] reported that superoxide ions played an important role in the oxidation of As(III) and Mn(II). SEIGNEUR and CONSTANTINOU [52] proposed that trace metals could react rapidly with free radicals and ions such as

, causing catalytic oxidation of Cr(III). FEI et al [50] and HANSARD et al [51] reported that superoxide ions played an important role in the oxidation of As(III) and Mn(II). SEIGNEUR and CONSTANTINOU [52] proposed that trace metals could react rapidly with free radicals and ions such as  ,

,  , OH·. JIN et al [53] studied the oxidation mechanisms of the trivalent chromium in the alkaline medium in the presence of oxygen, and their results showed that the oxidation process would be greatly enhanced due to the formation of ROS in highly concentrated alkaline solutions. SUN et al [13] and LIU et al [8] studied the mechanisms of the decomposition of chromite ore and vanadium slag in NaOH-NaNO3 binary molten salt systems, respectively. According to their studies, the nitrate acted as the oxygen provider. The active oxygen atoms could be released from nitrate through the pyrolysis process, and the oxygen atoms can further react with negative oxygen ions in the NaOH molten salt medium (obtained from the pyrolysis of hydroxyl ions) to form ROS with high chemical oxidation reactivity, such as the superoxide anion and peroxy ions.

, OH·. JIN et al [53] studied the oxidation mechanisms of the trivalent chromium in the alkaline medium in the presence of oxygen, and their results showed that the oxidation process would be greatly enhanced due to the formation of ROS in highly concentrated alkaline solutions. SUN et al [13] and LIU et al [8] studied the mechanisms of the decomposition of chromite ore and vanadium slag in NaOH-NaNO3 binary molten salt systems, respectively. According to their studies, the nitrate acted as the oxygen provider. The active oxygen atoms could be released from nitrate through the pyrolysis process, and the oxygen atoms can further react with negative oxygen ions in the NaOH molten salt medium (obtained from the pyrolysis of hydroxyl ions) to form ROS with high chemical oxidation reactivity, such as the superoxide anion and peroxy ions.

All the mineral dissociation studies jointly suggest that the existence of large amount of ROS and the excellent mass transfer properties are the key to the efficient decomposition of amphoteric metal mineral in the SMS media. And in combination with the comparison of the physicochemical properties and the formation and existence of ROS in the NaOH and KOH sub-molten salt media, it can be found that the KOH SMS media has lower viscosity, higher solution activity, and greater oxygen dissolution capacity in comparison with the equivalent NaOH SMS media. In this regard, the KOH SMS is expected to be more favorable for the formation and stabilization of ROS as well as the mass transfer, contributing to the higher reactivity of KOH sub-molten salt medium. Further, it can be inferred that the decomposition of vanadium slag in the KOH SMS media will be much more favorable and efficient in comparison with that in the equivalent NaOH SMS media. And the comparison of KOH and NaOH SMS reactivity in decomposing and oxidizing vanadium slag will be discussed in detail in the following sections.

3 Processing of vanadium slag with SMS technology

3.1 Mineralogy analysis of vanadium slag

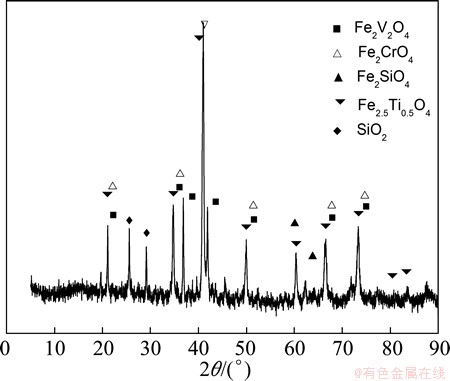

The mineralogy analysis and structural characterization of vanadium slag obtained from Chengde Iron and Steel Group Co., Ltd., Hebei, China, were carried out using an inductively coupled plasma optical emission spectrometer (ICP-OES), X-ray diffraction analyzer (XRD) and scanning electronic microscope (SEM).

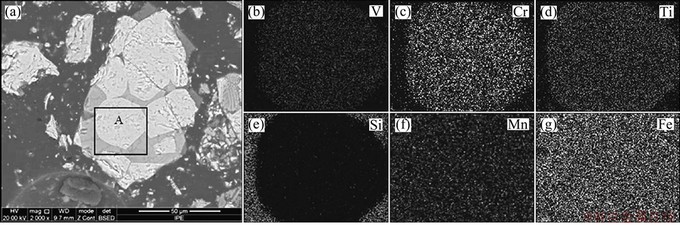

Figures 8 and 9 illustrate the XRD pattern and SEM image of typical vanadium slag particle.

Fig. 8 XRD pattern of vanadium slag

It is concluded that the vanadium slag mainly consists of spinel (FeO·V2O3, FeO·Cr2O3, and MnV2O4), quartz (SiO2), and fayalite (Fe2SiO4). And two obvious phases could be observed from the back scattered electron image (Fig. 9(a)) of a typical vanadium slag particle. To identify the chemical composition of the two phases, further examination of the element distribution of section A in Fig. 9 was carried out using EDX, as illustrated in Figs. 9(b)-(g). It is found that V, Cr, Ti, Mn, and Fe mainly present in the bright section as spinel namely (Fe,Mn)(V,Cr,Ti,Mn)2O4, and Si mainly presents in the gray section as quartz (SiO2) and fayalite (Fe2SiO4). Furthermore, it is clear that the spinel particles are randomly dispersed in the fayalite phase, suggesting that the fayalite phase should be decomposed before the vanadium and chromium spinel is oxidized [8].

3.2 Processing of vanadium slag with SMS technology

The flow sheet of a typical process to treat vanadium slag using the SMS technology is described in Fig. 2. And the process mainly consists of the following operation units: the reactants mixing, the SMS oxidation reaction, dilution, and solid-liquid separation.

Fig. 9 SEM image and element mappings of vanadium slag

3.2.1 NaOH sub-molten method

In the NaOH SMS medium, due to the high alkalinity, fayalite and quartz can readily react with NaOH and O2 according to the reactions described as following:

Fe2SiO4+(1/2)O2=Fe2O3+SiO2 (11)

SiO2+2NaOH=Na2SiO3+H2O (12)

Followed by the dissolution of fayalite and quartz, vanadium and chromium spinels are exposed to the reaction medium for further reactions. In the presence of oxygen, the vanadium and chromium spinel will be rapidly decomposed and oxidized to produce water- soluble salts of vanadate and chromium as follows:

FeO·V2O3+6NaOH+(5/4)O2=(1/2)Fe2O3+3H2O+2Na3VO4 (13)

FeO·Cr2O3+4NaOH+(7/4)O2=(1/2)Fe2O3+2H2O+2Na2CrO4 (14)

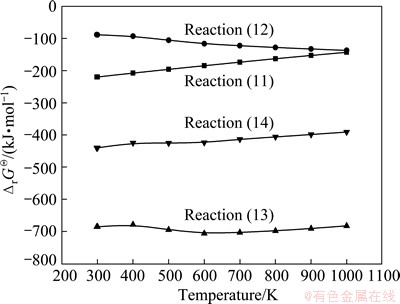

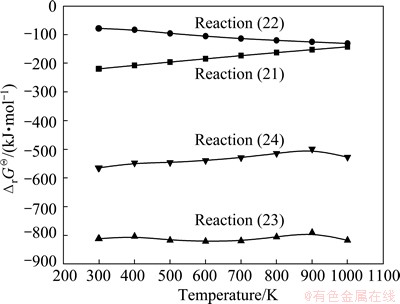

Utilizing the standard Gibbs energy data taken from the related references [54], the changes of the standard Gibbs energies (ΔrGΘ) for Reactions (11) to (14) were calculated at different temperatures, as shown in Fig. 10.

Fig. 10 Ellingham diagram of oxidation reactions in NaOH SMS medium

It is observed that the changes of standard Gibbs energies of Reactions (11) to (14) are all negative within the given temperature ranging from 300 to 1000 K, indicating that all these reactions are thermodynamically feasible. And for the spinel oxidation reactions which occur in the sub-molten salt media (typically 400-700 K), the changes of standard Gibbs energies become more negative with the increase of temperature, suggesting that high temperature is more favorable for the spinel oxidation. Further, it is found that the oxidation of chromium spinel is less favorable in thermodynamic consideration than the vanadium spinel, suggesting that more harsh conditions are required for the effective dissolution of chromium spinel.

The effect of temperature on extraction of vanadium from vanadium slag was investigated under other conditions controlled to be alkali-to-ore ratio 6:1, alkali concentration 80% (mass fraciton), oxygen flow 1.0 L/min, stirring speed 700 r/min, and ore particle size <200 mesh. The extraction rate of vanadium at different temperatures is presented in Fig. 11.

From Fig. 11, it is observed that at temperatures lower than 180 °C, the extraction rate of vanadium is less than 50% after reacting for 2 h, whereas at 210 °C the value is approximately 90%, demonstrating that the increase of temperature can significantly accelerate the decomposition of vanadium spinel. This is because increasing the temperature will not only enhance the oxidation reactions from the thermodynamic point of view (as shown in Fig. 10), but also strengthen the mass transfer by reducing the medium viscosity as discussed in the previous section (see Fig. 2 for further information).

Fig. 11 Effect of temperature on vanadium extraction in NaOH SMS medium

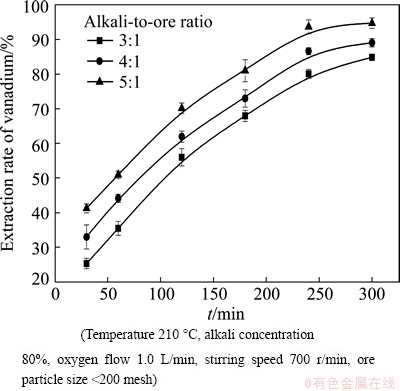

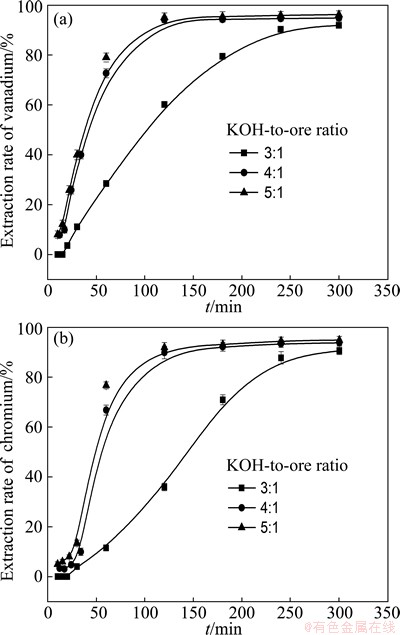

Besides the reaction temperature, the alkali-to-ore ratio also has great impact on vanadium extraction, as presented in Fig. 12. The result demonstrates that the extraction rate of vanadium increases with the increase of the alkali-to-ore ratios from 3:1 to 5:1, which is attributed to the fact that the increase of alkali-to-ore ratios decreases the medium viscosity, favoring the mass transfer of oxygen and ore particles.

Fig. 12 Effect of alkali-to-ore ratio on vanadium extraction in NaOH SMS medium

In addition, the reaction kinetics analysis shows that the initial stage of the oxidative decomposition of vanadium spinel can be well interpreted by the shrinking core model under interfacial chemical reaction control. And the apparent activation energy for vanadium is 63.13 kJ/mol.

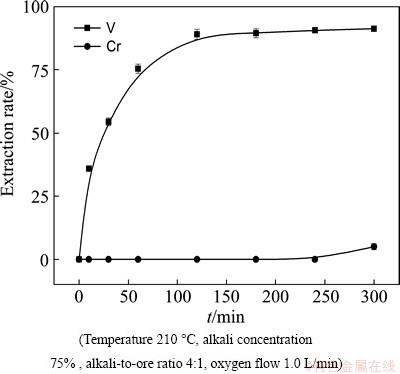

Unfortunately, the chromium in vanadium slag, which exist as the ferrochrome spinel, cannot be effectively extracted using the existing NaOH SMS method. Figure 13 illustrates the comparison of the extraction rates of vanadium and chromium from the vanadium slag using the above NaOH SMS method. It is obvious that the extraction rate of chromium is less than 5% after reacting for 300 min, whereas the value of vanadium extraction rate is approximately 90%. This phenomenon is explained by the fact that the chromium spinel is thermodynamically much more stable in comparison with the vanadium spinel, requiring much more harsh conditions in order to be effectively dissolved.

Fig. 13 Comparison of extraction of vanadium/chromium in NaOH SMS medium

3.2.2 NaOH-NaNO3 binary molten salt method

To achieve the simultaneous extraction of vanadium and chromium from the vanadium slag, NaNO3 was introduced to the vanadium slag decomposition process in NaOH molten medium. Due to the strong oxidizability and instability at high temperatures, NaNO3 would give direct or indirect oxidation on the metal suboxides in the vanadium slag as shown below (besides Reactions (11) to (14)).

FeO·V2O3+6NaOH+NaNO3=(1/2)Fe2O3+3H2O+2Na3VO4+NaNO2 (15)

FeO·Cr2O3+4NaOH+(7/2)NaNO3=(1/2)Fe2O3+2H2O+2Na2CrO4+(7/2)NaNO2 (16)

NaNO3=NaNO2+(1/2)O2 (17)

Figure 14 illustrates the Ellingham diagram of oxidation reactions and NaNO3 pyrolysis in the NaOH-NaNO3 binary molten salt medium.

Fig. 14 Ellingham diagram of oxidation reactions and NaNO3 pyrolysis in NaOH-NaNO3 binary molten salt medium

It can be seen from Fig. 14 that all these oxidation reactions are thermodynamically feasible, and the oxidation of vanadium spinel is much more favorable in comparison with the chromium spinel in thermodynamics. Further, active oxygen atoms could be released from NaNO3 through the pyrolysis process (Reaction (18)). And these released oxygen atom could react with the negative oxygen ions in the NaOH molten salt medium (obtained from the pyrolysis of hydroxyl ions) to form ROS with high chemical oxidation such as the superoxide anion and peroxy ions (Reactions (19) and (20)).

NaNO3→NaNO2+O (18)

O2-+O→ (19)

(19)

+O2→

+O2→ (20)

(20)

Figure 15 presents the effect of reaction temperature on the extraction of vanadium and chromium from vanadium slag in the NaOH-NaNO3 binary molten salt medium.

It is observed that at temperatures higher than 375 °C, the extraction rates of vanadium and chromium are approximately 90% and 80% after reacting for 1 h, respectively, whereas at 325 °C, the values are less than 55% and 50%, respectively. This is because high temperature is more favorable for the oxidation decompositions of spinels in both thermodynamics and kinetics aspects, as discussed in previous sections. Besides, high temperature is necessary to the pyrolysis of nitrate, namely, the nitrate is easily decomposed under high temperatures (higher than 375 °C), resulting in the increase of the ROS content in the medium, which helps to enhance the medium reactivity and accelerate the decomposition of the vanadium slag. While, the extraction rates of vanadium and chromium become independent of temperature when the reaction temperature is higher than 425 °C, suggesting that at high reaction temperatures, the mineral decomposition process is no longer controlled by the chemical reaction stage. And this is confirmed by the kinetic study of the decomposition of vanadium slag in the NaOH-NaNO3 binary molten salt medium. According to the kinetic and mechanism study, the mass transfer in the residue layer, which consists of iron, titanium and manganese oxides, is the rate-determining step during the oxidation reaction, and the apparent activation energies of vanadium and chromium extraction are calculated to be 98.02 kJ/mol and 102.90 kJ/mol, respectively. And further study shows that NaOH is believed to provide basic media and facilitate the dissolution of acidic oxides (such as SiO2) during the reactions. In addition, NaOH functions to intensify the decomposition of NaNO3 to NaNO2, while inhibits the further decomposition of NaNO2 to NO, NO2, etc. Further, NaNO3 can be regenerated by oxidation of NaNO2 in the presence of oxygen at high temperature, and apparent activation energy for the oxidation of NaNO2 is calculated to be 105.5 kJ/mol at the temperature ranging from 350 to 450 °C.

Fig. 15 Effect of reaction temperature on vanadium (a) and chromium (b) extraction in NaOH-NaNO3 binary molten salt medium

While it should be noted that even though vanadium and chromium can be extracted simultaneously using NaOH-NaNO3 binary molten salt media, some problems are created due to the introduction of NaNO3. First and foremost, the subsequent crystallization of the vanadium and chromium compounds becomes much more complex due to the introduction of new chemical reagents. Besides, NaNO3 cannot achieve efficient pyrolysis unless at high reaction temperatures (higher than 375 °C in this method), leading to huge energy consumption. Last but not the least, the oxidation of nitrite to nitrate can only be realized at elevated temperatures (higher than 350 °C), and the oxidation efficiency increases with reaction temperature [9]. Therefore, in order to achieve fully recycle of NaNO3 in the reaction system, prolonged reaction time (2 to 3 times longer than that required for vanadium slag fully decomposition) is required, consuming large amount of energy.

3.2.3 KOH sub-molten salt method

To simultaneously extract vanadium and chromium from the vanadium slag without introducing new components, the KOH sub-molten salt medium is chosen as the reaction medium, due to its superior physicochemical properties in oxygen dissolution, mass transfer, etc. In the KOH sub-molten medium in the presence of oxidation gases, the vanadium slag may be decomposed through the following reactions.

Fe2SiO4+(1/2)O2=Fe2O3+SiO2 (21)

SiO2+2KOH=K2SiO3+H2O (22)

FeO·V2O3+6KOH+(5/4)O2=(1/2)Fe2O3+3H2O+2K3VO4 (23)

FeO·Cr2O3+4KOH+(7/4)O2=(1/2)Fe2O3+2H2O+2K2CrO4 (24)

Figure 16 illustrates the changes of standard Gibbs free energy for Reactions (21) to (24).

Fig. 16 Ellingham diagram of oxidation reactions in KOH SMS medium

Similar to those in the NaOH sub-molten salt medium, all these oxidation reactions which occur in the KOH sub-molten salt medium are thermodynamically feasible, with better thermodynamic trends. And the oxidation of chromium spinel is much more difficult than the vanadium spinel in thermodynamics.

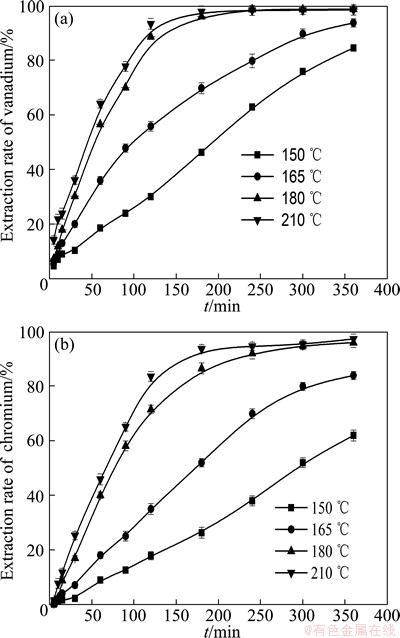

Figures 17 and 18 summarize the effect of temperature (150 to 210 °C) and alkali-to-ore ratio (3:1 to 5:1) on the extraction of vanadium and chromium.

Fig. 17 Effect of temperature on vanadium (a) and chromium (b) extraction in KOH molten salt medium

The results demonstrate that the extraction rates of vanadium and chromium synchronously increase with the increase of temperature and alkali-to-ore ratio from 150 to 180 °C and 3:1 to 4;1, respectively, possibly due to the decrease of medium viscosity and the increase of transfer efficiency of reactants as discussed previously. And similar to those in the NaOH-NaNO3 binary molten salt medium, the extraction rates of vanadium and chromium become independent of temperature and alkali-to-ore ratio when the reaction temperature and alkali-to-ore ratio are higher than 180 °C and 4:1, respectively. This is because at such conditions, the chemical reaction step is no longer the bottleneck of the mineral decomposition. In another word, the chemical reaction stage is not the rate-determining step when the reaction temperature and alkali-to-ore ratio are higher than 180 °C and 4:1, respectively. And under the optimal reaction conditions of temperature 180 °C, initial alkali-to-ore mass ratio 4:1, stirring speed 700 r/min, and gas flow 1.0 L/min, the extraction rates of vanadium and chromium can reach up to 95% and 90% respectively, after reacting for 300 min.

Besides, according to the kinetics study, the oxidation reactions which occur in the KOH sub-molten salt medium are mainly controlled by internal diffusion (mass diffusion in the solid product layer) rather than interfacial chemical reaction. And the apparent activation energies of vanadium and chromium extraction are calculated to be 40.54 kJ/mol and 50.27 kJ/mol, respectively, much lower than those in the NaOH sub-molten salt medium. This is because compared with the equivalent NaOH sub-molten salt medium, the KOH sub-molten salt medium has lower viscosity, higher solution activity, and larger oxygen solubility, in favor of the formation and stabilization of the reactive oxygen species, as well as mass transfer. All the characteristics mentioned above contribute to the higher reactivity of KOH sub-molten salt medium in comparison with the NaOH sub-molten salt medium, resulting in the effective and synchronous extraction of vanadium and chromium.

Fig. 18 Effect of KOH-to-ore ratio on vanadium (a) and chromium (b) extraction in KOH molten salt medium

3.3 Discussion

Compared with the traditional roasting methods, all the three liquid oxidation technologies discussed above are capable of achieving effective extraction of vanadium and chromium (except the NaOH sub-molten salt method) simultaneously under relatively moderate reaction conditions. While, it is observed that the kinetics and mechanisms of the three technologies exhibit obvious difference due to the difference of medium physicochemical properties. In this regard, the comparison of thermodynamics and kinetics of the three liquid oxidation technologies is carried out.

3.3.1 Thermodynamic comparison

It is observed from Figs. 10, 14 and 16 that the alkali cation has significant impact on the oxidation of spinels in thermodynamics. Compared with those in the NaOH sub-molten salt medium and the NaOH-NaNO3 binary molten salt medium, the changes of the standard Gibbs free energies of the spinel oxidation reactions which occur in the KOH sub-molten salt medium are much more negative, suggesting better reaction tendency.

3.3.2 Kinetic comparison

According to the mechanism and kinetic study of the oxidative decomposition of vanadium slag in the MeOH (Me presents Na or K) sub-molten salt media or NaOH-NaNO3 molten salt media, the ROS plays a crucial role in oxidizing the vanadium and chromium spinels. Thus, the formation and existence of ROS in the reaction media are critical to the decomposition of vanadium slag.

In the MeOH SMS media, the superoxide ion is the major species of ROS, which is mainly obtained via the single-electron oxygen reduction process. And the macro-kinetic study of ORR in the MeOH aqueous solutions demonstrates that the ORR process is attributed to a quasi-reversible diffusion-controlled reaction, which is mainly controlled by the oxygen diffusion in the alkaline media. The alkali concentration, the oxygen solubility, and the alkali metal cation species also have significant impact on the formation and existence of ROS. According to the comparison of physicochemical properties of the NaOH and KOH aqueous solutions, it can be seen that in comparison with the equivalent NaOH solution, the KOH solution has lower viscosity, higher solution activity, and greater dissolved oxygen capacity, which are in favor of the formation and existence of the reactive oxygen species and mass transfer. All the characteristics mentioned above are believed to contribute to the higher reactivity of KOH sub-molten salt medium in comparison with the NaOH sub-molten salt medium, resulting in the effective and synchronous extraction of vanadium and chromium in KOH SMS medium. While in the NaOH sub-salt medium, the chromium can hardly be effectively extracted, as mentioned in the previous sections.

Unlike that in the SMS medium, in the NaOH-NaNO3 binary molten salt medium, the ROS mainly exists in the form of oxygen atom, which is primarily obtained from the pyrolysis of the nitrate. And this process is heavily dependent on the reaction temperature (higher than 375 °C). The NaOH-NaNO3 molten salt medium exhibits strong oxidation capacity due to large amount of highly oxidative oxygen atoms and high reaction temperature, ensuring the rapid and complete oxidation of spinels.

In summary, due to the existence of large amount of stable ROS in the media and the excellent mass transfer properties, vanadium and chromium can be synchronously extracted from the vanadium slag using either the KOH sub-molten salt medium or the NaOH-NaNO3 binary molten salt medium. While in the NaOH sub-molten salt medium, because of the bad mass transfer and oxygen dissolution properties, only vanadium can be extracted.

4 Prospect

In view of the foregoing description, it can be seen that these new liquid approaches can achieve much more effective extraction of vanadium and chromium simultaneously under relatively moderate reaction conditions, showing obvious advantages in terms of energy, environment, and the mineral resource utilization efficiency and providing an attractive alternative for the green technology upgrade of the vanadium production industries. While, it also should be noted that due to the recycle of alkali in the typical liquid process (as shown in Fig. 1), large amount of dilute alkaline solutions need to be concentrated via evaporation, causing significant energy consumption as well as equipment erosion. Therefore, tremendous improvements are required for the current liquid approaches, to meet the industrialization needs. And according to the mechanism and kinetic study of the oxidation decomposition of vanadium slag in the sub-molten salt medium, the reactive oxygen species play a key role in oxidizing the vanadium and chromium spinel, and the oxidation process is mainly controlled by diffusion of the reactants. Thus, taking measures that can promote the formation of reactive oxygen species and that can enhance the mass transfer of ROS and other reactants in the sub-molten salt media can further optimize the current sub-molten salt technologies. Based on the principles mentioned above, the existing sub-molten technologies can be further optimized from the following aspects.

4.1 Flow field enhancement

In the traditional sodium salt roasting method, the roasting process is a typical gas-solid reaction, which is governed by the bad mass transfer efficiency of the oxidizing gas, such as oxygen. While, the oxidation process in the sub-molten salt technology is pseudo- homogeneous liquid phase reaction, and the mass transfer is significantly enhanced, leading to the efficient decomposition of vanadium slag in the sub-molten salt medium. It also should be noted that, according to the kinetic study of the decomposition of the vanadium slag in the NaOH and KOH sub-molten salt media, the oxidation process is still mainly controlled by the diffusion of reactants, suggesting that the mass transfer performance in the sub-molten salt medium could be further enhanced by enhancing the agitation, reducing the medium viscosity, etc. It is believed that the oxidation process will be more efficient and the reaction conditions can be further optimized with the enhancement of mass transfer performance.

4.2 Pressure field enhancement

As an important reactant, oxygen plays a vital role in the oxidation decomposition of vanadium slag. The content of the dissolved oxygen and the diffusion performance of oxygen are two main factors that affect the oxidation reaction kinetics. Under external pressure, the amount of the dissolved oxygen and the oxygen transfer performance will both be improved significantly, making the decomposition of vanadium slag more rapid and efficient.

4.3 Electrochemical enhancement

Reactive oxygen species can be obtained from the electrochemical oxygen reduction reactions under moderate conditions with the introduction of the electrochemical field. In particular, in the sub-molten salt medium, large amount of the reactive oxygen species, such as the superoxide ion, the peroxy ion, with high oxidation capability, can be formed and exist stably by controlling the appropriate slot voltage. Thus, the reactivity of the sub-molten salt medium could be highly enhanced by the electrochemical field, making it possible for the efficient decomposition of vanadium slag at more moderate conditions.

4.4 Chemical enhancement

Regardless of the problems created, the introduction of nitrate into the NaOH molten salt medium for treating the vanadium slag has been proven to be feasible and effective. Thus, it is reasonable to believe that the formation and stabilization of the ROS in the SMS media can be achieved under more moderate conditions by selecting the appropriate additives, making the decomposition of vanadium slag more rapid and efficient.

5 Conclusions

1) A series of innovative green metallurgical processes using novel reaction media including the NaOH sub-molten salt medium, the KOH sub-molten salt medium, and the NaOH-NaNO3 binary molten salt medium for the extraction of vanadium and chromium from the vanadium slag have been developed. These technologies could achieve much higher extraction rates of vanadium and chromium with much less energy consumption and environmental pollution in comparison with the current roasting methods.

2) Due to the existence of large amount of stable ROS in the media and the excellent mass transfer properties, vanadium and chromium can be synchronously extracted from the vanadium slag using either the KOH sub-molten salt medium or the NaOH-NaNO3 binary molten salt medium. While in the NaOH sub-molten salt medium, because of the bad mass transfer and oxygen dissolution, only vanadium can be extracted.

3) According to the mechanism and kinetic study of the oxidation decomposition of vanadium slag in the sub-molten salt medium, the reactive oxygen species play a key role in oxidizing the vanadium and chromium spinels, and the oxidation process is mainly controlled by the diffusion of the reactants. Thus, the existing sub-molten salt technologies can be further optimized by taking measures that can promote the formation of reactive oxygen species and enhance the mass transfer of ROS and other reactants in the sub-molten salt medium, such as flow field enhancement, press field enhancement, electrochemical enhancement, and chemical enhancement.

Acknowledgements

The authors acknowledge Dr. Jin WEI for the discussion on the study of the formation and existence of ROS in the alkaline medium.

References

[1] ABBASI S M, SHOKUHFAR A. Improvement of mechanical properties of Cr-Ni-Mo-Cu-Ti stainless steel with addition of vanadium [J]. Journal of Iron and Steel Research, International, 2007, 14(6): 74-78.

[2] VERNARDOU D, PATERAKIS P, DROSOS H, SPANAKIS E, POVEY I M, PEMBLE M E, KOUDOUMAS E, KATSARAKIS N. A study of the electrochemical performance of vanadium oxide thin films grown by atmospheric pressure chemical vapour deposition [J]. Solar Energy Materials and Solar Cells, 2011, 95(10): 2842-2847.

[3] MAURYA M R, BISHT M, AVECILLA F. Synthesis, characterization and catalytic activities of vanadium complexes containing ONN donor ligand derived from 2-aminoethylpyridine [J]. Journal of Molecular Catalysis A: Chemical, 2011, 344(1-2): 18-27.

[4] SALETA M E, CURIALE J, TROIANI H E, RIBEIRO GUEVARA S,  R D, MALTA M, TORRESI R M. Magnetic characterization of vanadium oxide/polyaniline nanotubes [J]. Applied Surface Science, 2007, 254(1): 371-374.

R D, MALTA M, TORRESI R M. Magnetic characterization of vanadium oxide/polyaniline nanotubes [J]. Applied Surface Science, 2007, 254(1): 371-374.

[5] BOUDIN S, GUESDON A, LECLAIRE A, BOREL M M. Review on vanadium phosphates with mono and divalent metallic cations: Syntheses, structural relationships and classification, properties [J]. International Journal of Inorganic Materials, 2000, 2(6): 561-579.

[6] MOSKALYK R R, ALFANTAZI A M. Processing of vanadium: A review [J]. Minerals Engineering, 2003, 16(9): 793-805.

[7] YE G. Recovery of vanadium from LD slag, a state of the art report: Part 1—Facts and metallurgy of vanadium [R]. Stjarnholm, 2006.

[8] LIU B, DU H, WANG S N, ZHANG Y, ZHENG S L, LI L J, CHEN D H. A novel method to extract vanadium and chromium from vanadium slag using molten NaOH-NaNO3 binary system [J]. AIChE Journal, 2012, 59(2): 541-552.

[9] CHEN T J, ZHANG Y M, SONG S X. Improved extraction of vanadium from a Chinese vanadium-bearing stone coal using a modified roast-leach process [J]. Asia-Pacific Journal of Chemical Engineering, 2010, 5(5): 778-784.

[10] LI C H, ZHOU X Y, WANG H, ZHANG T K, LI J, OU X, JIANG X D. Effect of oxidation on vanadium extraction from stone coal with calcified roasting [J]. Journal of Central South University: Science and Technology, 2011, 42(1): 7-10. (in Chinese)

[11] ZHENG S, DU H, ZHANG Y, CHEN D, BAI R. Efficient and cleaner technology of vanadium extraction from vanadium slag by sub-molten salt method [J]. Iron Steel Vanadium Titanium, 2012, 33(1): 15-19. (in Chinese)

[12] LIU H B, LIU B, LI L J, ZHENG S L, DU H, WANG S N, CHEN D H, QI J, ZHANG Y. Novel methods to extract vanadium from vanadium slag by liquid oxidation technology [J]. Advanced Materials Research, 2011, 396-398: 1786-1793.

[13] SUN Z, ZHANG Y, ZHENG S L, ZHANG Y. A new method of potassium chromate production from chromite and KOH-KNO3- H2O binary submolten salt system [J]. AIChE Journal, 2009, 55(10): 2646-2656.

[14] JIN W, DU H, ZHENG S, XU H, ZHANG Y. Comparison of the oxygen reduction reaction between NaOH and KOH solutions on a Pt electrode: The electrolyte-dependent effect [J]. Journal of Physical Chemistry B, 2010, 114(19): 6542-6548.

[15] XU H B, ZHANG Y, LI Z H, ZHENG S L, WANG Z K, QI T, LI H Q. Development of a new cleaner production process for producing chromic oxide from chromite ore [J]. Journal of Cleaner Production, 2006, 14(2): 211-219.

[16] ZHENG S, ZHANG Y, LI Z, QI T, LI H, XU H. Green metallurgical processing of chromite [J]. Hydrometallurgy, 2006, 82(3-4): 157-163.

[17] XU H B, ZHENG S L, ZHANG Y, LI Z H, WANG Z K. Oxidative leaching of a Vietnamese chromite ore in highly concentrated potassium hydroxide aqueous solution at 300 °C and atmospheric pressure [J]. Minerals Engineering, 2005, 18(5): 527-535.

[18] ZHOU H, ZHENG S, ZHANG Y. Leaching of a low-grade niobium–tantalum ore by highly concentrated caustic potash solution [J]. Hydrometallurgy, 2005, 80(1-2): 83-89.

[19] LIU Y, QI T, CHU J, TONG Q, ZHANG Y. Decomposition of ilmenite by concentrated KOH solution under atmospheric pressure [J]. International Journal of Mineral Processing, 2006, 81(2): 79-84.

[20] JIN W, ZHENG S, DU H, XU H, WANG S, ZHANG Y. Phase diagrams for the ternary Na2O-Al2O3-H2O system at 150 and 180 °C [J]. Journal of Chemical & Engineering Data, 2010, 55(7): 2470-2473.

[21] JIN W, ZHENG S, DU H, XU H, ZHANG Y. Isopiestic study of the Na2CrO4-H2O system at 353.15 K: Prediction of the solubility of Na2CrO4 in aqueous NaOH solutions [J]. Industrial & Engineering Chemistry Research, 2010, 49(17): 8244-8247.

[22] BEN  L, GROS J B, DUSSAP C G. Activity coefficients of concentrated strong and weak electrolytes by a hydration equilibrium and group contribution model [J]. Fluid Phase Equilibria, 2010, 289(1): 40-48.

L, GROS J B, DUSSAP C G. Activity coefficients of concentrated strong and weak electrolytes by a hydration equilibrium and group contribution model [J]. Fluid Phase Equilibria, 2010, 289(1): 40-48.

[23] MAY P M. Improved thermodynamic calculations for concentrated mixed electrolyte systems including ion pairing (or the absence of it) [J]. Marine Chemistry, 2006, 99(1-4): 62-69.

[24]  M, BARTCZAK W M. Structural and dynamical properties of concentrated aqueous NaOH solutions: A computer simulation study [J]. Computers & Chemistry, 2000, 24(3-4): 459-468.

M, BARTCZAK W M. Structural and dynamical properties of concentrated aqueous NaOH solutions: A computer simulation study [J]. Computers & Chemistry, 2000, 24(3-4): 459-468.

[25] GERING K L. Prediction of electrolyte viscosity for aqueous and non-aqueous systems: Results from a molecular model based on ion solvation and a chemical physics framework [J]. Electrochimica Acta, 2006, 51(15): 3125-3138.

[26] MASHOVET V P, PUCHKOV L V, SARGAEV P M, FEDOROV M K. Viscosity of solutions of lithim, sodium and potassium hydroxides up to 275 degrees. 2 [J]. Zhurnal Prikladnoi Khimii, 1973, 46(5): 992-996.

[27] GUO Y J, XU H B, GUO F, ZHENG S L, ZHANG Y. Density and viscosity of aqueous solution of K2CrO4/KOH mixed electrolytes [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(s1): s32-s36.

[28] HU Y F. Prediction of viscosity of mixed electrolyte solutions based on the eyring's absolute rate theory and the equations of patwardhan and kumar [J]. Chemical Engineering Science, 2004, 59(12): 2457-2464.

[29] WANG P, ANDERKO A, YOUNG R D. Modeling viscosity of concentrated and mixed-solvent electrolyte systems [J]. Fluid Phase Equilibria, 2004, 226(0): 71-82.

[30] ROBELIN C, CHARTRAND P. A viscosity model for the (NaF+AlF3+CaF2+Al2O3) electrolyte [J]. The Journal of Chemical Thermodynamics, 2011, 43(5): 764-774.

[31] ABDULAGATOV I M, ZEINALOVA A, AZIZOV N D. Viscosity of aqueous Na2SO4 solutions at temperatures from 298 to 573 K and at pressures up to 40 MPa [J]. Fluid Phase Equilibria, 2005, 227(1): 57-70.

[32] DU H, RASAIAH J C, MILLER J D. Structural and dynamic properties of concentrated alkali halide solutions: A molecular dynamics simulation study [J]. Journal of Physical Chemistry B, 2007, 111(1): 209-217.

[33] STOKES R H, MILLS R. Viscosity of electrolytes and related properties [M]. Oxford: Pergamon Press, 1965.

[34] ALLY M R, BRAUNSTEIN J. Activity coefficients in concentrated electrolytes: A comparison of the brunauer-emmett-teller (BET) model with experimental values [J]. Fluid Phase Equilibria, 1996, 120(1-2): 131-141.

[35] CAMPBELL A N, BHATNAGAR O N. Osmotic and activity coefficients of sodium hydroxide in water from 150 to 250 °C [J]. Journal of Chemical & Engineering Data, 1984, 29(2): 166-168.

[36] HAMER W J, WU Y C. Osmotic coefficients and mean activity coefficients of uni-univalent electrolytes in water at 25 °C [J]. Journal of Physical and Chemical Reference Data, 1972, 1(4): 1047-1100.

[37] PABALAN R T, PITZER K S. Thermodynamics of NaOH(aq) in hydrothermal solutions [J]. Geochimica et Cosmochimica Acta, 1987, 51(4): 829-837.

[38] ZAFARANI-MOATTAR M T, MAJDAN-CEGINCARA R. New local composition model for modeling of thermodynamic and transport properties of binary aqueous electrolyte solutions [J]. Calphad, 2011, 35(1): 109-132.

[39] PITZER K S. Thermodynamics of electrolytes. I: Theoretical basis and general equations [J]. The Journal of Physical Chemistry, 1973, 77(2): 268-277.

[40] SHOOR S K, WALKER R D, GUBBINS K E. Salting out of nonpolar gases in aqueous potassium hydroxide solutions [J]. The Journal of Physical Chemistry, 1969, 73(2): 312-317.

[41] ZHANG C, FAN F R F, BARD A J. Electrochemistry of oxygen in concentrated NaOH solutions: Solubility, diffusion coefficients, and superoxide formation [J]. Journal of the American Chemical Society, 2008, 131(1): 177-181.

[42] THAM M J, WALKER R D, GUBBINS K E. Diffusion of oxygen and hydrogen in aqueous potassium hydroxide solutions [J]. The Journal of Physical Chemistry, 1970, 74(8): 1747-1751.

[43] MILLERO F J, HUANG F, LAFERIERE A L. The solubility of oxygen in the major sea salts and their mixtures at 25 °C [J]. Geochimica et Cosmochimica Acta, 2002, 66(13): 2349-2359.

[44] ELUARD A,  B. Behavior of lead(II) ions in the NaOH+KOH eutectic melt [J]. Journal of Electroanalytical Chemistry and Interfacial Electrochemistry, 1971, 30(2): 323-326.

B. Behavior of lead(II) ions in the NaOH+KOH eutectic melt [J]. Journal of Electroanalytical Chemistry and Interfacial Electrochemistry, 1971, 30(2): 323-326.

[45] CHONG N S, SUEN N T, CHOU T L, TANG H Y. Electrocrystallization and characterization of polymorphic forms of barium metaplumbate [J]. Crystal Growth & Design, 2008, 8(5): 1779-1782.

[46] CHOI Y K, CHJO K H, PARK S M, DODDAPANENI N. Oxygen reduction at Co(II) 2-disalophen modified carbon electrodes [J]. Journal of the Electrochemical Society, 1995, 142(12): 4107-4112.

[47] CHEVALET J, ROUELLE F, GIERST L, LAMBERT J P. Electrogeneration and some properties of the superoxide ion in aqueous solutions [J]. Journal of Electroanalytical Chemistry and Interfacial Electrochemistry, 1972, 39(1): 201-216.

[48] SONG C, ZHANG L, ZHANG J. Reversible one-electron electro-reduction of O2 to produce a stable superoxide catalyzed by adsorbed Co(II) hexadecafluoro-phthalocyanine in aqueous alkaline solution [J]. Journal of Electroanalytical Chemistry, 2006, 587(2): 293-298.

[49] ZHAO Z, RUSH J D, HOLCMAN J, BIELSKI B H J. The oxidation of chromium(III) by hydroxyl radical in alkaline solution. A stopped-flow and pre-mix pulse radiolysis study [J]. Radiation Physics and Chemistry, 1995, 45(2): 257-263.

[50] FEI H, LENG W, LI X, CHENG X, XU Y, ZHANG J, CAO C. Photocatalytic oxidation of arsenite over TiO2: Is superoxide the main oxidant in normal air-saturated aqueous solutions? [J]. Environmental Science & Technology, 2011, 45(10): 4532-4539.

[51] HANSARD S P, EASTER H D, VOELKER B M. Rapid reaction of nanomolar Mn(II) with superoxide radical in seawater and simulated freshwater [J]. Environmental Science & Technology, 2011, 45(7): 2811-2817.

[52] SEIGNEUR C, CONSTANTINOU E. Chemical kinetic mechanism for atmospheric chromium [J]. Environmental Science & Technology, 1995, 29(1): 222-231.

[53] JIN W, MOATS M S, ZHENG S, DU H, ZHANG Y, MILLER J D. Indirect electrochemical Cr(III) oxidation in KOH solutions at an Au electrode: The role of oxygen reduction reaction [J]. The Journal of Physical Chemistry B, 2012, 116(25): 7531-7537.

[54] BARIN I. The thermochemical data of pure substance [M]. VCH, 1989.

王中行1,2,郑诗礼1,王少娜1,刘 彪1,王大卫1,3,杜 浩1,张 懿1

1. 中国科学院 过程工程研究所,湿法冶金清洁生产技术国家工程实验室,北京 100190;

2. 中国科学院大学 化学与化学工程学院,北京 100049;

3. 中国矿业大学(北京) 化学与环境工程学院,北京 100083

摘 要:针对从钒渣中提取钒、铬存在的问题,提出了一系列绿色液相氧化法,包括NaOH/KOH亚熔盐法和NaOH-NaNO3熔盐法。与传统钠化焙烧法工艺相比,新方法的操作温度由850 °C降低至200~400 °C,而钒、铬的提取率分别由75%和接近0提高至95%和90%,整个操作过程中无废气及毒渣排放。与焙烧法相比,新工艺在能耗、环境友好及矿物资源综合利用率方面显示出明显的优势,成为钒行业绿色化升级的有效替代方案。

关键词:钒渣;液相氧化;亚熔盐;熔盐;钒;铬;提取

(Edited by Sai-qian YUAN)

Foundation item: Project (2013CB632605) supported by the National Basic Research Program of China; Projects (51274178, 51090382) supported by the National Natural Science Foundation of China; Project (KGCX2-EW-215) supported by the Key Deployment Program of Chinese Academy of Sciences

Corresponding author: Hao DU; Tel: +86-10-82544856; E-mail: duhao121@hotmail.com

DOI: 10.1016/S1003-6326(14)63189-7