文章编号:1004-0609(2015)04-0997-08

添加Al2O3对Ti3SiC2复合材料性能的影响

陈金学,尹洪峰,帅 航,田养利,袁蝴蝶

(西安建筑科技大学 材料与矿资学院,西安 710055)

摘 要:采用反应热压烧结法制备Ti3SiC2-Al2O3复合材料,研究热压温度和Al2O3含量对Ti3SiC2-Al2O3复合材料相组成、力学性能及抗氧化性能的影响。结果表明:采用反应热压烧结,可以在1450 ℃烧结得到致密度高、性能良好的Ti3SiC2-Al2O3复合材料。添加Al2O3可以起到第二相增强的作用,从而提高材料的强度。随着添加量的增加,复合材料的力学性能先提高后降低,当Al2O3添加量为20%(质量分数)时断裂韧性达最大值(7.10 MPa×m1/2),当Al2O3添加量为30%时抗弯强度达最大值(512 MPa)。Al2O3在高温下与TiO2反应生成具有耐高温和高抗热震性能的Al2TiO5,可以有效提高Ti3SiC2基复合材料高温抗氧化性能。

关键词:Ti3SiC2-Al2O3;复合材料;相组成;力学性能;抗氧化性能

中图分类号:TB333;TB34 文献标志码:A

Effect of Al2O3 addition on properties of Ti3SiC2 composites

CHEN Jin-xue, YIN Hong-feng, SHUAI Hang, TIAN Yang-li, YUAN Hu-die

(College of Materials and Mineral Resource, Xi’an University of Architecture and Technology, Xi’an 710055, China)

Abstract: Ti3SiC2-Al2O3 composites were prepared by reactive hot-pressed sintering. The effects of the Al2O3 content and hot pressing temperature on the phase constituent,mechanical properties and oxidation resistance property of Ti3SiC2-Al2O3 composites were investigated. The results show that the Ti3SiC2-Al2O3 composites with high density and good properties can be prepared by reactive hot-pressed sintering at 1450 ℃. The Al2O3 addition has the effect of the second phase strengthening which can improve the strength of the material. The mechanical properties of Ti3SiC2-Al2O3 composites increase firstly and then decrease with increasing Al2O3 content, the fracture toughness reaches the maximum value (7.10 MPa×m1/2) when the mass fraction of Al2O3 is 20%, and the bending strength reaches the maximum value (512 MPa) when the mass fraction of Al2O3 is 30%. Al2O3 reactes with TiO2 under high temperature, generating Al2TiO5 with high temperature resistance and high thermal shock resistance, which can effectively improve the oxidation resistance of Ti3SiC2 composites.

Key words: Ti3SiC2-Al2O3; composite; phase composition; mechanical property; oxidation resistance property

三元层状碳化物Ti3SiC2材料结合了金属和陶瓷的许多优良性能,它既具有金属的良好导电性、导热性能和易切削加工性,又具有陶瓷的高熔点、高化学稳定性、抗热震性等性能。众多的优良性能使Ti3SiC2可望在高温结构陶瓷、电极材料、可加工陶瓷材料、自润滑材料等领域得到广泛应用。然而,在氧化气氛下该材料抗氧化性在1000 ℃以上较差使其在高温条件下的使用受限。目前,研究者多采用复合材料来提高其综合性能,已研究的体系主要有:Ti3SiC2-SiC,Ti3SiC2-TiC以及Ti3SiC2-TaC [1-5]。

Al2O3是一种高熔点(2050 ℃)、高硬度、高强度、耐多种腐蚀介质作用的高温稳定性材料,被广泛用于高温工业,因为其热膨胀系数(7.71×10-6 ℃-1)与Ti3SiC2的热膨胀系数(9.1×10-6 ℃-1)非常接近,所以Al2O3对Ti3SiC2材料是一种较好的增强相。王红洁等[6]研究了Al2O3对Ti3SiC2-Al2O3复合材料性能及显微组织的影响,得出加入适量的Al2O3可以提高Ti3SiC2复合材料强度和断裂强度。CAI等[7]用热压反应法合成Ti3SiC2-Al2O3复合材料,研究了其室温相组成及力学性能。刘光明等[8]研究了Ti3SiC2抗高温氧化性能,得出单相Ti3SiC2在1100 ℃下抗氧化性较差。因此,本文作者研究制备了Al2O3增强Ti3SiC2基复合材料,从而实现在提高力学性能的同时,也提高其高温抗氧化性能的目的。为此,采用反应热压烧结法制备了Ti3SiC2-Al2O3复合材料,并对其致密度、显微组织、相组成、力学性能及抗氧化性能进行了研究。

1 实验

以TiC粉末(粒度≤2.6 μm,纯度99.9%,北京兴荣源科技有限公司生产)、Ti粉末(粒度≤45 μm,纯度99.5%,宝鸡市赛特钛业有限公司生产)、Si粉末(粒度≤45 μm,纯度99.5%,中钢集团洛阳耐火材料研究院生产),Al2O3粉末(平均粒度7.0 μm,纯度99.5%,济源市鑫源陶瓷材料有限公司生产)为原料。将原料按摩尔比n(TiC):n(Si):n(Ti)=2:1.2:1配料,分别引入10%、20%、30%、40%、50%的Al2O3(质量分数),在行星式球磨机中以无水乙醇为分散介质湿混3 h,干燥后置于d 44 mm石墨磨具内进行热压烧结制备了Ti3SiC2基复合材料。升温速率为10 ℃/min,热压压力为25 MPa,保温时间为3 h,气氛条件为真空。氧化试样尺寸为7 mm×7 mm×10 mm,实验在高温炉中进行,待温度升至特定温度,放入试样,在空气气氛下恒温氧化20 h。

采用阿基米德法测试试样的显气孔率和体积密度。根据XRD结果,用绝热法公式计算了Ti3SiC2基复合材料中Ti3SiC2的相对含量(即试样中除去Al2O3后,Ti3SiC2在Ti3SiC2和TiC总质量中的质量分数)[9],如式(1)所示:

(1)

(1)

式中:wi为第i相的质量分数;Ii为第i相的衍射强度;Ki为第i相的参比强度;i=1, 2, 3, …。

试样物相组成采用DMAX-2400型转靶X-ray衍射仪(日本理学生产)测定。利用VEGA3 TESCAN型扫描电镜(捷克TESCAN有限公司生产)观察试样的显微结构。在DWD-5微机控制电子万能试验机(长春机械科学研究院有限公司生产)上测试弯曲强度和断裂韧性,采用三点弯曲法测定试样的弯曲强度,采用单边切口梁法测定试样的断裂韧性。力学性能测试每组有3根平行试样。

2 结果与讨论

2.1 热压温度对Ti3SiC2-20%Al2O3相组成及致密化程度的影响

图1所示为不同热压温度烧结后Ti3SiC2- 20%Al2O3试样的XRD谱。可见,主晶相为Ti3SiC2,次晶相是Al2O3,同时含有少量TiC;随着热压温度的升高,Ti3SiC2衍射峰的强度逐渐增强,当温度超过1500 ℃时,Ti3SiC2衍射峰的强度开始减弱,TiC衍射峰的强度逐渐增强,导致该现象的原因如下:1) 烧结温度高于1414 ℃以上时Si容易挥发而使样品中Si的含量减少,使反应物成的摩尔比不成比例,因而造成TiC的过量,使得反应进行的不够完全;2) 由于模具为石墨模具,会与试样中的Ti3SiC2发生如下反应[10-11]:

Ti3SiC2+C→3TiC+Si(g) (2)

反应(2)的进行将消耗试样的Ti3SiC2,还会生成一定量的TiC,同时还会促使Si的挥发,从而导致Si含量的不足,过量的TiC残留在最终组织中。

图1 不同热压温度烧结后试样的XRD谱

Fig. 1 XRD patterns of samples sintered at different hot pressing temperatures

表1所列为不同热压温度的Ti3SiC2-20%Al2O3复合材料体积密度和显气孔率。可见随着热压温度的增加,体积密度增大,对显气孔率影响不大且呈降低趋势。这主要是因为提高热压温度,有利于烧结,而且有利于金属Ti的塑性填充,使复合材料致密化程度得到提高。

表1 热压温度对Ti3SiC2-20%Al2O3复合材料致密化程度的影响

Table 1 Effect of hot pressing temperature on densification of Ti3SiC2-20%Al2O3 composites

2.2 热压温度对Ti3SiC2-20%Al2O3力学性能的影响

图2所示为不同热压温度对的Ti3SiC2-20%Al2O3复合材料的弯曲强度和断裂韧性的影响。由图2可见,随着热压温度的提高,复合材料力学性能的整体趋势为先升高后下降。当温度到达1450 ℃时,弯曲强度和断裂韧性的值最大,分别可达到491 MPa和7.10 MPa×m1/2。图3所示为不同热压温度下Ti3SiC2- 20%Al2O3试样的断口形貌,同时结合图4所示的EDS谱可知,主晶相为层状结构的Ti3SiC2晶粒,粒状颗粒主要为Al2O3相,同时含有一部分与Ti3SiC2伴生的TiC颗粒,TiC小晶粒镶嵌在层状结构Ti3SiC2中。当热压温度低于1400 ℃时,层状Ti3SiC2晶粒较少,粒状颗粒相对较多;随着热压温度的升高,层状Ti3SiC2晶粒明显增多且晶粒尺寸逐渐增大,相互穿错搭接,能有效缓解应力应变,同时由于致密度也随之增大,所以热压温度能有效提高该复合材料的力学性能。但当热压温度超过1500 ℃时,由图3(f)可以看出,层状的Ti3SiC2数量相对降低,这在一定程度上降低了层状Ti3SiC2缓解应力的能力,使其性能不提高反而降低。因此,在1450 ℃烧结可以得到性能良好的Ti3SiC2- Al2O3复合材料。

图2 热压温度对Al2O3/Ti3SiC2复合材料力学性能的影响

Fig. 2 Effect of hot pressing temperature on mechanical properties of Ti3SiC2-Al2O3 composites

图3 不同热压温度下Ti3SiC2-20%Al2O3试样断口形貌

Fig. 3 Fracture morphologies of Ti3SiC2-20%Al2O3 at different temperatures

图4 1450 ℃热压的Ti3SiC2-20%Al2O3试样不同位置的EDS谱

Fig. 4 EDS patterns of Ti3SiC2-20%Al2O3 pressed at 1450 ℃ at different positions

2.3 Al2O3添加量对Ti3SiC2-Al2O3相组成及致密化程度的影响

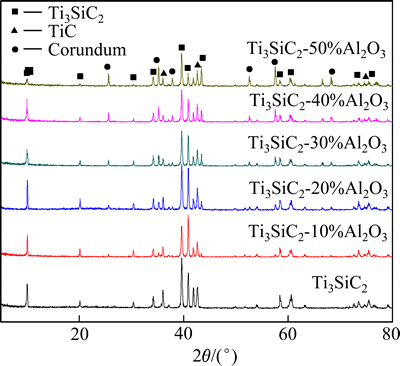

图5所示为在1450 ℃烧结温度下,不同Al2O3添加量的Ti3SiC2-Al2O3复合材料的XRD谱,由图5可见,主晶相是Ti3SiC2和Al2O3,也存在少量的TiC杂质相。当Al2O3添加量为10%~30%(质量分数),随着Al2O3添加量的增加,Ti3SiC2衍射峰的强度逐渐增强,TiC峰值逐渐降低;当Al2O3添加量超过30%后,Ti3SiC2衍射峰的强度开始减弱,TiC衍射峰的强度开始增强;表2所列为不同Al2O3添加量的Ti3SiC2-Al2O3复合材料性能参数。由表2可知,在添加Al2O3后,Ti3SiC2的相对含量增加,说明Al2O3的添加能促进主晶相Ti3SiC2的生成。衍射结果也表明了添加的Al2O3不参与反应,并与Ti3SiC2有很好的化学相容性。

图5 Ti3SiC2-Al2O3复合材料的XRD谱

Fig. 5 XRD patterns of Ti3SiC2-Al2O3 composites

表2 不同Al2O3添加量的Ti3SiC2-Al2O3复合材料性能参数

Table 2 Properties parameters of Ti3SiC2-Al2O3 composites with different Al2O3 contents

由表2还可以看出,纯Ti3SiC2试样的体积密度高于理论密度,这是由杂质相TiC的存在所致,其密度(4.93 g/cm3)高于Ti3SiC2密度(4.53 g/cm3)。随着Al2O3添加量的增加,试样的体积密度降低,这是由Ti3SiC2密度较高、Al2O3密度(3.98 g/cm3)较低所致。而气孔率影响不大呈上升趋势,这主要是由于Al2O3的存在,一定程度上阻碍了Ti、Si与TiC的化学反应进程,同时降低Ti的塑性填充能力,影响致密化程度,造成气孔率增加。

2.4 Al2O3添加量对Ti3SiC2-Al2O3复合材料力学性能的影响

图6所示为Al2O3添加量对Ti3SiC2-Al2O3复合材料力学性能的影响,由图6可见,添加Al2O3可以起到第二相增强的作用,使材料的强度得到提高,随着材料中Al2O3添加量的增加,弯曲强度和断裂韧性都表现为先提高后降低。当Al2O3添加量为20%时,断裂韧性达到最大值(7.10 MPa×m1/2),而Al2O3添加量为30%时,弯曲强度达到最大值(512 MPa)。当Al2O3添加量超过30%时,试样的力学性能呈现下将趋势。图7所示为Ti3SiC2-Al2O3复合材料断口形貌图,灰色层

状结构为Ti3SiC2,黑色颗粒状为Al2O3。当Al2O3添加量为10%~30%时,外加Al2O3弥散地分布在基体中,与Ti3SiC2有良好的相容性,且与Ti3SiC2交错桥接生长,起到弥散强化的作用,能有效提高复合材料的力学性能。但当Al2O3添加量超过40%时,层状Ti3SiC2颗粒明显减少。当Al2O3添加量为50%时,几乎没有层状Ti3SiC2颗粒,以小颗粒为主,导致力学性能不提高反而降低。一方面,添加Al2O3的量过高,会造成Al2O3颗粒产生偏聚,使局部产生缺陷或显微结构不均匀,影响增强效果;另一方面,在文献[12]中,研究认为层状Ti3SiC2晶粒可以通过扭折、片层间断裂及拔出缓解应力集中,提高试样的力学性能。当Al2O3添加量过高时,层状Ti3SiC2的量相对降低,从而使层状Ti3SiC2缓解应力集中的作用降低,试样强度降低。因此,为了改善Ti3SiC2材料的力学性能,Al2O3添加量不宜超过30%,以免影响该材料力学性能。

图6 Al2O3添加量对Ti3SiC2-Al2O3复合材料力学性能的影响

Fig. 6 Effect of Al2O3 content on mechanical properties of Ti3SiC2-Al2O3 composites

图7 不同Al2O3添加量的Ti3SiC2-Al2O3复合材料断口形貌

Fig. 7 Fracture morphologies of Ti3SiC2-Al2O3 composites with different Al2O3 contents

2.5 Al2O3添加量对Ti3SiC2-30%Al2O3抗氧化性能的影响

图8所示为不同Al2O3添加量的各试样在1100~1500 ℃下氧化20 h后的质量增加百分比。由图8看出,随着氧化温度逐渐升高,试样的质量增加逐渐增大,即氧化温度升高,氧化速率增大,试样的质量增加量增大,试样被氧化的部分越多。当氧化温度超过1200 ℃时,添加Al2O3的试样的质量增加低于纯Ti3SiC2试样的,Al2O3添加量越高,氧化增加越低,且温度越高,这种现象就愈明显。所以Ti3SiC2-Al2O3试样的抗氧化性能优于纯Ti3SiC2试样。

图8 不同Al2O3添加量的Ti3SiC2-Al2O3在不同温度下氧化 20 h后的质量增加曲线

Fig. 8 Mass gain curves of Ti3SiC2-Al2O3 with different Al2O3 contents oxidized at different temperature for 20 h

图9所示为Ti3SiC2-30%Al2O3复合材料在1100~ 1500 ℃氧化20 h后试样的XRD谱。随着氧化温度升高,氧化后试样中Ti3SiC2含量逐渐降低,氧化产物主要为TiO2(金红石型),同时伴随着Al2O3和少量的杂质TiC残留,Ti3SiC2和Al2O3峰强值随温度的升高而降低,至1500 ℃时衍射峰消失,表明试样完全氧化;在1300 ℃氧化试样的EDS谱中出现Al2TiO5和石英衍射峰,Al2TiO5是Al2O3和TiO2在高温下反应生成新相,是一种耐高温、高抗热震性的材料,本身具有较高的熔点,对抗氧化具有很大贡献[13-14]。因此,添加Al2O3可以有效提高Ti3SiC2基复合材料高温抗氧化性能。

图9 Ti3SiC2-30%Al2O3试样在不同温度下氧化20 h后的XRD谱

Fig. 9 XRD patterns of Ti3SiC2-30%Al2O3 oxidized at different oxidation temperatures for 20 h

图10所示为Ti3SiC2-30%Al2O3复合材料氧化20 h后表面形貌。由图10可见,当氧化温度为1100~1300 ℃时,氧化表面形成较大尺寸的短柱状TiO2晶粒,这是氧化物晶粒向外择优生长的结果。晶粒晶界清晰,棱角分明,晶粒尺寸随温度的升高而增大,但在晶粒与晶粒之间大量间隙,O原子易通过间隙进入基体进一步氧化。当氧化温度超过1400 ℃时,TiO2晶粒细化,在TiO2晶粒的周围明显有液相的产生,很好的包覆着TiO2晶粒,有效地填补晶间间隙,阻止O原子的进一步向里扩散,提高Ti3SiC2-Al2O3复合材料的高温抗氧化性能。试样表面出现穿晶裂纹,这是因为在氧化冷却过程中,Al2TiO5的热膨胀系数(2.0×10-6 ℃-1)比TiO2的热膨胀系数(9×10-6 ℃-1)小所致[15]。图11和12所示为在1300 ℃氧化后的截面形貌和能谱,在区域D主要含Al、Ti和O元素,按元素质量比计算,该物质主要是Al2TiO5相和TiO2相;区域E主要含TiO2相;在区域D有一定量的Si元素,而在区域E消失,这是由于Si元素以SiO的形式向外扩散,在氧化层外层的富氧区生成SiO2,而外层Al2TiO5可以固溶SiO2,导致在区域E没有Si元素[16]。区域含有大量的O、Ti和C元素,这是由于O原子进一步向内部扩散,与一部分基体发生反应生成的TiO2,及部分未氧化的基体相存在,同时可能还有一定量Si的氧化物存在。

图10 Ti3SiC2-30%Al2O3复合材料氧化20 h后表面形貌

Fig. 10 Surface morphologies of Ti3SiC2-30%Al2O3 samples oxidized at different temperatures for 20 h

图11 1300 ℃氧化后Ti3SiC2-30%Al2O3的截面形貌

Fig. 11 Sectional morphology of Ti3SiC2-30%Al2O3 samples oxidized at 1300 ℃ for 20 h

3 结论

1) 采用反应热压烧结,可以在1450 ℃烧结得到致密度高、性能良好的Ti3SiC2-Al2O3复合材料。

2) 随着Al2O3添加量的增加,复合材料的力学性能呈先提高后降低,当Al2O3添加量为20%时,断裂韧性达到最大值(7.10 MPa×m1/2),当Al2O3添加量为30%时,抗弯强度达到最大值(512 MPa)。

图12 1300 ℃氧化后Ti3SiC2-30%Al2O3试样不同区域氧化层的EDS谱

Fig. 12 EDS patterns of Ti3SiC2-30%Al2O3 sample oxidized at 1300 ℃ in different areas

3) 添加的Al2O3在高温下和Ti3SiC2反应生成抗氧化性更好的Al2TiO5,可以有效提高Ti3SiC2基复合材料抗氧化性能。

REFERENCES

[1] LUO Y M, ZHENG Z M, MEI X N, XU C H. Growth mechanism of Ti3SiC2 single crystals by in situ reaction of poly carbosilane and metal titanium with CaF2 additive[J]. Journal of Crystal Growth, 2008, 310(14): 3372-3375.

[2] 李世波, 成来飞, 王 东, 张立同. 层状Ti3SiC2陶瓷的组织结构及力学性能[J]. 复合材料学报, 2002, 19(6): 20-24.

LI Shi-Bo, CHENG Lai-Fei, WANG Dong, ZHANG Li-Tong. Microstructure and mechanical properties of Ti3SiC2 ceramics[J]. Acta Materiae Compositae Sinica, 2002, 19(6): 20-24.

[3] 熊进辉, 黄继华, 张 华, 赵兴科, 林国标. Cf/SiC复合材料与Ti合金的Ag-Cu-Ti-TiC复合钎焊[J]. 中国有色金属学报.2009, 19(6): 1038-1043.

XIONG Jin-hui, HUANG Ji-hua, ZHANG Hua, ZHAO Xing-ke, LIN Guo-biao. Brazing of Cf/SiC composite to Ti alloy using Ag-Cu-Ti-TiC composite filler materials[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(6): 1038-1043.

[4] LI S B, XIE J X, ZHANG L T. Mechanical properties and oxidation resistance of Ti3SiC2/SiC composite synthesized by in situ displacement reaction of Si and TiC[J]. Materials Letters, 2003, 57(20): 3048-3056.

[5] ZHANG Y, ZHOU Y C, LI Y Y. Solid-liquid synthesis of Ti3SiC2 particulate by fluctuation procedure[J]. Scripta Materialia, 2003, 49: 249-253.

[6] 王红洁, 金志浩, MIYAMOTO Y. Al2O3对Ti3SiC2/Al2O3复合材料性能及显微结构的影响[J]. 稀有金属材料. 2004, 33(1): 40-43.

WANG Hong-jie, JIN Zhi-hao, MIYAMOTO Y. Effect of Al2O3 on the mechanical properties and microstructure of Ti3SiC2/Al2O3 composite[J]. Rare Metal Materials and Engineering, 2004, 33(1): 40-43.

[7] CAI Y Z, YIN H F, PAN L Q, CHEN P J, SUN G L. Microstructures and mechanical properties of Ti3SiC2/TiC–Al2O3 composites synthesized by reactive hot pressing[J]. Materials Science and Engineering A, 2013, 571: 137-143.

[8] 刘光明, 李美栓, 张亚明, 周延春. Ti3SiC2表面渗硅涂层的抗高温氧化性能[J]. 中国有色金属学报, 2002, 12(8): 629-633.

LIU Guang-ming, LI Mei-shuan, ZHANG Ya-ming, ZHOU Yan-chun. Oxidation performances of silicide coatings on Ti3SiC2-based ceramic[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(8): 629-633.

[9] ZHU J F, YE L, HE L H. Effect of Al2O3 on the microstructure and mechanical properties of Ti3SiC2/Al2O3 in situ composites synthesized by reactive hot pressing[J]. Ceramics International, 2012, 38(7): 5475-5479.

[10] SUN Z, ZHOU Y, LI M. Oxidation behavior of Ti3SiC2-based ceramic at 900-1300 ℃ in air[J]. Corrosion Science, 2001, 43(6): 1095-1109.

[11] 尹洪峰, 杨祎诺. TaC/Ti3SiC2复合材料的制备与性能[J]. 复合材料学报, 2014, 31(5): 987-992.

YIN Hong-feng,YANG Yi-nuo. Preparation and properties of TaC/Ti3SiC2 composites[J]. Acta Materiae Compositae Sinica, 2014, 31(5): 987-992.

[12] 倪东惠, 谭文昌, 郑军君, 罗汇果, 李元元. Si 含量对放电等离子烧结制备(1-x)Ti3SiC2+xSiC复合材料的影响[J]. 中国有色金属学报, 2011, 12(6): 1279-1284.

NI Dong-hui, TAN Wen-chang, ZHENG Jun-jun, LUO Hui-guo, LI Yuan-yuan. Influence of Si content on (1-x)Ti3SiC2+xSiC composites prepared by spark plasma sintering[J]. The Chinese Journal of Nonferrous Metals, 2011, 12(6): 1279-1284.

[13] RADOVIC M, BARSOUM M W, EL-RAGHY T, WIEDERHORN S M, LUECKE W E. Effect of temperature, strain rate and grain size on the mechanical response of Ti3SiC2 in tension[J]. Acta Materialia, 2002, 50(6): 1297-1306.

[14] BROUM M W, EI-RAGHY T, OGBUJI L U J T. Oxidation of Ti3SiC2 in air[J]. Journal of the Electrochemical Society, 1997, 144: 2508-2516.

[15] 李立鑫, 柳学全, 丁存光, 李 一, 李 楠, 李金普, 李发长. Cr3C2-Ni-Ti3SiC2新型减摩复合材料的高温摩擦学行为[J]. 中国有色金属学报, 2014, 24(2): 425-431.

LI Li-xin, LIU Xue-quan, DING Cun-guang, LI Yi, LI Nan, LI Jin-pu, LI Fa-chang. High temperature tribology behavior of new anti-friction/composites Cr3C2-Ni-Ti3SiC2[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(2): 425-431.

[16] 董红英, 李树杰, 贺跃辉. 用Ti3SiC2粉料连接反应烧结SiC陶瓷[J]. 中国有色金属学报, 2005, 15(7): 1051-1056.

DONG Hong-ying, LI Shu-jie, HE Yue-hui. Joining of reaction bonded SiC ceramic using Ti3SiC2 powder as filler[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 1051-1056.

(编辑 王 超)

基金项目:国家自然科学基金青年基金资助项目(51302206)

收稿日期:2014-09-01;修订日期:2014-12-29

通信作者:尹洪峰,教授,博士;电话:13909185139;E-mail: yinhf01@163.com