GH4169镍基高温合金热压缩变形行为和加工图

王迎1,潘清林1,张宇玮2,单群2,李晨1,李智凤1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 航天材料及工艺研究所,北京,100076)

摘要:在Gleeble-3500热模拟试验机上采用等温压缩试验研究GH4169合金的高温流变行为,获得GH4169合金在变形温度为850~1050 ℃、应变速率为0.1~50.0 s-1条件下的真应力-应变曲线,根据动态材料模型(DMM)建立GH4169合金的热加工图。研究结果表明:GH4169合金在实验条件下具有正的应变速率敏感性,流变应力随着应变速率的增大而增大,随变形温度的升高而减小,该合金的流变应力行为可用Arrhenius方程来描述。在变形温度为850~870 ℃、应变速率为7.4~50.0 s-1和变形温度为875~945 ℃、应变速率为0.1~2.7 s-1的2个区域内易产生流变失稳现象。GH4169合金安全热加工区域的变形温度在1 000~1 050 ℃之间、应变速率在0.10~0.34 s-1之间。

关键词:GH4169合金;流变应力;本构方程;加工图

中图分类号:TG146.1+5 文献标志码:A 文章编号:1672-7207(2014)11-3752-10

Hot deformation behavior and processing map of GH4169 superalloy

WANG Ying1, PAN Qinglin1, ZHANG Yuwei2, SHAN Qun2, LI Chen1, LI Zhifeng1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Aerospace Research Institute of Materials & Processing Technology, Beijing 100076, China)

Abstract: The hot deformation behavior of GH4169 alloy was investigated by hot compressive tests on Gleeble-3500 thermal simulation test machine at the temperature of 850-1 050 ℃ and strain rate of 0.1-50 s-1. The true stress-strain curves under different deformation conditions were obtained and the processing map was developed based on the dynamic material modeling (DMM). The results show that the flow stress is sensitive to the strain rate and the deforming temperature. The flow stress becomes higher with the increase of the strain rate at constant temperature and lower with the increase of the deformation temperature at constant strain rate, which can be described by a constitutive equation in the form of Arrhenius function. The flow instability regimes appear at two different regimes: at the temperature of 850-870 ℃ and the strain of 7.4-50 s-1, as well as at the temperature of 875-945 ℃ and the train rate of 0.1-2.7 s-1. The hot deformation of GH4169 alloy can be carried out safely in the region with temperature of 1 000-1 050 ℃ and strain rate of 0.10-0.34 s-1.

Key words: GH4169 alloy; flow stress; constitutive equation; processing map

镍基高温合金因具有较高的高温强度、良好的抗氧化性和抗热腐蚀性能、良好的疲劳性能、断裂韧性和塑性,并且可在600 ℃以上高温及一定应力作用下长期工作,从而广泛应用于航空航天发动机的各种高温部件[1-3]。在美国,镍基高温合金在航空航天发动机上的用量已占到总用量的85%[4]。高温合金GH4169是以γ″-Ni3Nb和γ′-Ni3(Al, Ti, Nb)相为主要强化相的沉淀强化型Ni-Cr-Fe合金,该合金在高温下具有高的强度、良好的焊接性能、抗疲劳性能和塑性,故常被应用于航空发动机的导向器、涡轮盘、耐高温紧固件,石油工业中的油气井及油气管道,核反应堆结构部件的高强度深冷结构元件,涉及航空、航天、能源、化工等多个领域[5-8]。镍基高温合金GH4169在热加工过程中存在着热变形抗力大、热加工温度范围窄等难题。因此,对此合金高温变形行为的系统研究,有助于实现批量生产高质量的GH4169镍基高温合金材料。合金热变形过程中的流变应力是表征材料塑性变形性能的一个最基本量,在实际变形过程中,合金的流变应力决定了变形时所需施加的载荷和所需消耗能量[9-10]。基于动态材料模型理论的加工图在研究材料的组织、性能和变形机制对加工工艺参数反应时非常有效,通过该加工图不仅能够预测不同变形条件下材料的塑性变形机制,为材料的热变形提供了最佳的变形工艺参数范围,而且还描绘了加工过程中应该避免的不稳定性流变区域,为避免热加工缺陷产生,节省工艺设计时间,获得组织性能优良且稳定一致的加工件提供了理论基础[11-12]。因此,本文作者在变形温度为850~1 050 ℃和应变速率为0.1~50.0 s-1条件下,通过对GH4169合金进行高温热压缩模拟实验,研究合金高温压缩变形时流变应力的变化规律,建立合金热变形 方程和基于动态材料模型的加工图,以便为GH4169合金热加工工艺参数的制定和优化提供理论依据。

1 实验材料及方法

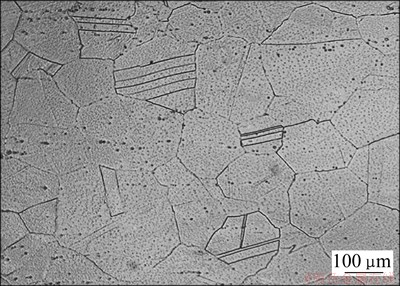

实验用镍基高温合金GH4169的成分(质量分数)为:Cr 17.0%~21.0%,Ni 50.0%~55.0%,Nb 4.75%~ 5.50%,Mo 2.80%~3.30%,Al 0.20%~0.65%,Ti 0.65%~ 1.55%,余为Fe。实验用合金经挤压后加工成直径×长度为6 mm×10 mm的圆柱形压缩试样,其金相显微组织如图1所示。从图1可以看出:合金晶粒呈无畸变的等轴多边形,粒径比较均匀,晶界比较平直,且分布着大量孪晶。热压缩试验在Gleeble-3500热模拟机上进行。通过其自动控制系统在预设的温度和应变速率下进行恒温、恒应变速率压缩。为减小试样与压头之间的摩擦,在压缩试样两端分别加工厚度为0.2 mm的凹槽以填充润滑剂(75%石墨+20%机油+5%硝酸三甲苯脂,质量分数)。实验应变速率为0.1,1.0,10.0和50.0 s-1,变形温度为850,900,950,1 000和1 050 ℃,真应变为0.5。压缩试验结束后立即对试样进行水淬处理,以保留合金压缩结束时的变形组织。采用POLYVER-MET金相显微镜对不同变形条件下的典型组织进行观察,实验所采用的浸蚀剂溶液为5 g CuCl2+100 mL HCl+100 mL C2H5OH。

图1 GH4169合金经挤压后的显微组织

Fig. 1 Microstructure of GH4169 alloy after extrusion

2 实验结果及分析

2.1 合金真应力-真应变曲线

图2所示为GH4169合金在不同变形条件下等温热压缩的真应力-真应变曲线。由图2可见:流变应力随着变形程度的增加而增加到某一峰值,然后逐渐下降到一稳态值,这种应力应变曲线变化趋势符合低层错能金属的流变特征,表明在热变形过程中发生了动态再结晶。在同一应变速率下,流变应力随变形温度的升高而下降;在同一变形温度下,流变应力随应变速率增加而升高,当应力达到峰值后,流变应力随应变量的增大而呈现逐渐降低的趋势。这是因为随着应变速率的增加,单位时间内产生的位错密度增加,位错运动受阻,位错攀移及位错反应等引起的软化速率也相对降低,硬化增强,使合金的临界切应力升高,导致流变应力增大。

从图2还可以看出:当材料在应变速率为1.0 s-1和10.0 s-1下变形时,流变应力达到峰值应力后,流变曲线出现锯齿状的流变特征(图2(b)~(c))。这主要是由于动态再结晶以及高温下晶粒的迅速长大引起的软化和已再结晶的晶粒又重新变形引起的硬化交替进行造成的。图2(d)中流变曲线在应变量较低时很不规则,这可能是因为应变速率较高(50.0 s-1),可能会有裂纹产生,但是若有裂纹出现也会在短时间内焊合,故曲线表现出不规则的现象[13]。

GH4169合金在热压缩变形中出现了明显的动态回复与动态再结晶现象,在变形初始阶段,随着应变的增加位错密度不断增加,此时位错交滑移引起的软化不足以补偿位错密度增加引起的硬化,从而流变应力上升很快。因此,在峰值应力之前加工硬化占主导地位。当应变量继续增加时,位错密度不断提高,超过一定的形变量后变形储存能成为再结晶的驱动力,变形过程中动态再结晶引起的软化作用逐渐起到决定性作用,当加工硬化速率与动态软化速率平衡时,流变应力达到峰值。随动态再结晶的进行,软化速率大于硬化速率,应力逐渐下降。

图2 GH4169合金不同应变速率下的真应力-真应变曲线

Fig. 2 True stress-strain curves of GH4169 alloy at different strain rates

2.2 合金热压缩变形流变本构方程

金属材料在高温热变形过程中,流变应力是影响材料成型过程中非常重要的因素,对不同热加工数据的研究表明,σ, 和T之间在不同的应力水平下满足不同的关系。在低应力水平和高应力水平下,流变应力与应变速率的关系分别可用指数关系和幂指数关系描述[14-15],即

和T之间在不同的应力水平下满足不同的关系。在低应力水平和高应力水平下,流变应力与应变速率的关系分别可用指数关系和幂指数关系描述[14-15],即

低应力水平( <0.8)时:

<0.8)时:

(1)

(1)

高应力水平( >1.2)时:

>1.2)时:

(2)

(2)

式中:A1,A2,n1和β均为与温度无关的常数;R为气体常数;T为变形温度;Q为变形激活能,它反映材料热变形的难易程度,是材料热变形过程中重要的力学性能参数。以上关系描述了应变硬化和动态软化之间的动态平衡,它与稳态蠕变对应的关系相似。综合考虑方程(1)和(2)的局限性,可采用包含变形激活能Q和温度T的双曲正弦形式修正的Arrhenius关系来描述这种热激活稳态变形行为[16],即:

(3)

(3)

其中:A,n和 均是材料常数,

均是材料常数, ,β和应力指数n1之间满足

,β和应力指数n1之间满足 。在低应力和高应力条件下,式(3)分别简化为式(1)和式(2),所以它可以在整个应力范围内较好地描述常规热加工过程的流变应力变化规律。

。在低应力和高应力条件下,式(3)分别简化为式(1)和式(2),所以它可以在整个应力范围内较好地描述常规热加工过程的流变应力变化规律。

高温塑性变形存在热激活过程,应变速率和温度对流变应力的影响可用Zener-Hollomon参数Z表示,

(4)

(4)

其物理意义是温度补偿的变形速率因子。由式(4)得,

(5)

(5)

根据双曲正弦函数的反函数公式:

(6)

(6)

在热变形过程中,高温合金流变应力 主要取决于变形温度和应变速率,因此可将流变应力

主要取决于变形温度和应变速率,因此可将流变应力 表述成Z参数的函数,即

表述成Z参数的函数,即

(7)

(7)

由此可知,若知道A,Q,n和 等材料参数,则可求得任意变形条件下的流变应力。本文采用双曲正弦函数关系对GH4169合金的流变应力进行描述。

等材料参数,则可求得任意变形条件下的流变应力。本文采用双曲正弦函数关系对GH4169合金的流变应力进行描述。

假定在一定的温度下,变形激活能Q为常数,对式(1)和(2)两边取对数有:

(8)

(8)

(9)

(9)

其中: ;

; 。

。

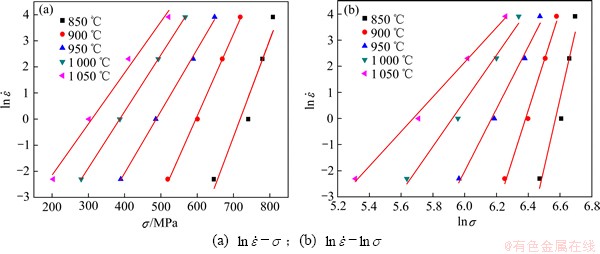

大量研究结果表明:峰值应力和稳态流变应力满足一定的线性关系,且峰值应力和稳态流变应力都能较好地用Z参数函数形式来描述。对工业应用而言,

获得峰值应力与温度及应变速率的关系更为重要。取不同条件下的峰值应力为流变应力,绘制出 -

- 和

和 -

- 关系图,并分别进行线性回归,如图3所示。从图3可以看出:

关系图,并分别进行线性回归,如图3所示。从图3可以看出: 与

与 和

和 与

与 线性关系均十分明显。根据式(8)和(9),取图3(a)中各直线斜率的平均值,得到n1=14.617 98;取图3(b)中各直线斜率的平均值,得到β=0.026 73 MPa-1,则

线性关系均十分明显。根据式(8)和(9),取图3(a)中各直线斜率的平均值,得到n1=14.617 98;取图3(b)中各直线斜率的平均值,得到β=0.026 73 MPa-1,则 0.001 828 MPa-1。

0.001 828 MPa-1。

对式(3)两边取自然对数,整理可得:

(10)

(10)

其中: 。

。

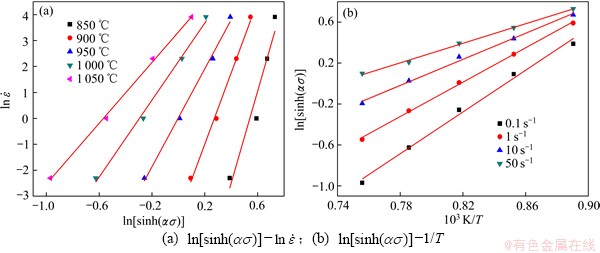

=0.001 828 MPa-1,以

=0.001 828 MPa-1,以 和

和 为坐标作图,并进行线性回归,如图4(a)所示。从图4(a)可以看出:

为坐标作图,并进行线性回归,如图4(a)所示。从图4(a)可以看出: 与

与 之间的线性关系明显。这说明GH4169合金流变应力与应变速率之间的关系可以用双曲正弦函数修正的Arrhenius关系很好地加以描述,这为通过控制应变速率来控制热加工的应力水平和力学参数提供了理论依据。

之间的线性关系明显。这说明GH4169合金流变应力与应变速率之间的关系可以用双曲正弦函数修正的Arrhenius关系很好地加以描述,这为通过控制应变速率来控制热加工的应力水平和力学参数提供了理论依据。

对式(4)两边取自然对数,并假定在恒应变速率条件下变形时,一定温度范围内Q保持不变,可得:

(11)

(11)

式中: ;

; 。

。

以 和1 000/T为坐标作图,进行线性回归,如图4(b)所示。可见:在相同应变速率下,

和1 000/T为坐标作图,进行线性回归,如图4(b)所示。可见:在相同应变速率下, 和1 000/T呈线性关系。

和1 000/T呈线性关系。

考虑温度对变形激活能的影响,对式(4)求偏微分得:

图3 峰值应力与应变速率的关系

Fig. 3 Relationship between peak stress and strain rate

图4  与

与 以及

以及 与1/T的关系

与1/T的关系

Fig.4 Relationship of  with

with  and

and  with 1/T

with 1/T

(12)

(12)

其中:n为一定温度下 关系的斜率,即图4(a)中各直线斜率的平均值,其值为10.821 9;S为应变速率一定的条件下

关系的斜率,即图4(a)中各直线斜率的平均值,其值为10.821 9;S为应变速率一定的条件下 -(1/T)关系的斜率,即图4(b)中各直线斜率的平均值,其值为7.427 6。将n和S代入式(12)即可求出变形激活能Q=668.29 kJ/mol。

-(1/T)关系的斜率,即图4(b)中各直线斜率的平均值,其值为7.427 6。将n和S代入式(12)即可求出变形激活能Q=668.29 kJ/mol。

对式(4)两边取对数还可得:

(13)

(13)

将Q值和变形条件代入式(4)求出Z值。绘制 -

- 关系图并进行线性拟合,如图5所示。其线性关系表明:GH4169合金高温变形流动应力应变行为可以用Z参数描述,即该合金的高温塑性变形受热激活控制。由式(13)可知:图5中直线的斜率即为应力指数n,而其截距为lnA。由拟合结果可得,应力指数n=9.786 2,由

关系图并进行线性拟合,如图5所示。其线性关系表明:GH4169合金高温变形流动应力应变行为可以用Z参数描述,即该合金的高温塑性变形受热激活控制。由式(13)可知:图5中直线的斜率即为应力指数n,而其截距为lnA。由拟合结果可得,应力指数n=9.786 2,由 =65.996 3,可以求得材料常数A=4.59×1028 s-1。

=65.996 3,可以求得材料常数A=4.59×1028 s-1。

将A,Q,n和 等材料常数代入式(3),得GH4169合金用双曲正弦函数修正的Arrhenius关系表示的流变应力方程为:

等材料常数代入式(3),得GH4169合金用双曲正弦函数修正的Arrhenius关系表示的流变应力方程为:

(14)

(14)

将以上所求材料常数代入式(5),即可得到GH4145合金用Z参数表达的流变应力方程:

(15)

(15)

其中: 。

。

图5 Z参数与流变应力的关系

Fig. 5 Relationship between Z parameter and flow stress

2.3 合金热变形参数对其显微组织的影响

2.3.1 变形温度对合金的影响

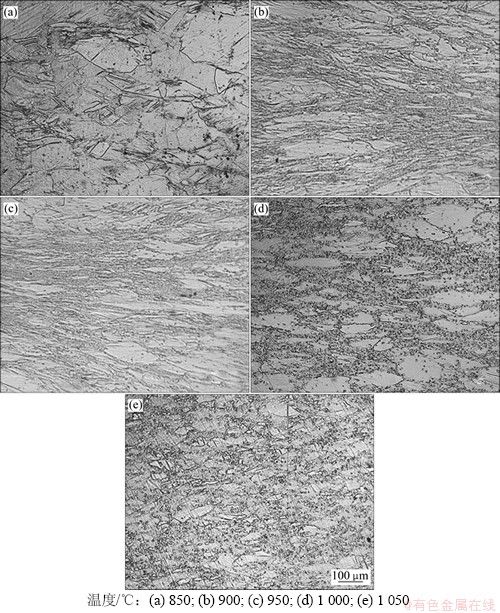

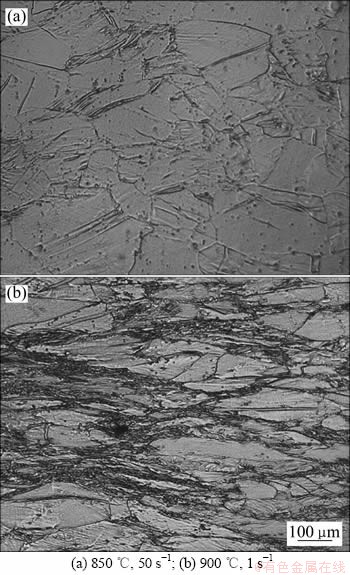

GH4169合金在同一应变速率不同温度下的显微组织如图6所示。GH4169合金在850 ℃下变形,较粗大的原始晶粒发生畸变,被严重拉长,晶界也呈现不规则弯曲的形态,并未观察到沿原始晶界有明显的动态再结晶晶粒形成(图6(a))。当变形温度为900 ℃时,合金大部分发生动态再结晶,新生的细小等轴晶与具有锯齿形边界的原始晶粒形成链状结构(图6(b))。950 ℃时合金中再结晶晶粒进一步增多,且变形大晶粒与动态再结晶小晶粒混杂在一起形成了链状结构(图6(c))。当温度升高到1 000 ℃时,动态再结晶晶粒增多,晶粒尺寸也有所长大,如图6(d)所示。变形温度为1 050 ℃时,合金的动态再结晶程度相比变形温度1 000 ℃时没有很明显的变化,仍然存在一些变形的粗大晶粒(图6(e))。

图6 GH4169合金应变速率为10 s-1时不同温度下变形后的显微组织

Fig. 6 Microstructure of GH4169alloy deformed at different temperatures with strain rate of 10 s-1

动态再结晶是一个新晶粒形核和核心长大的过程。当温度升高时,合金中原子热振动和扩散速率增加,位错的滑移、攀移、交滑移比低温时更容易,动态再结晶的形核率增加,同时,晶界迁移能力增强,因此,温度的升高可以促进动态再结晶的发生。当变形温度继续升高时,细小的等轴晶粒就会有所长大[17-18]。

2.3.2 应变速率对合金显微组织的影响

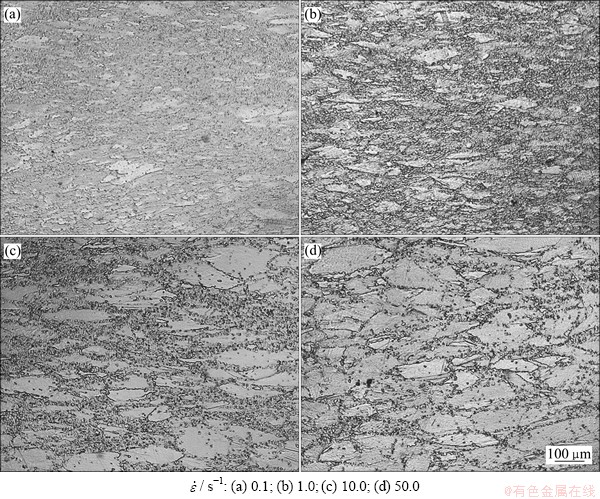

图7所示为变形温度为1 000 ℃时GH4169合金的金相组织。当变形温度一定时,随着应变速率的增大,合金的动态再结晶的程度降低。当应变速率低至0.1 s-1时,动态再结晶趋于完全,再结晶晶粒尺寸较细小(图7(a))。同时再结晶晶粒尺寸随着应变速率的减小也逐渐增大,当应变速率降为1.0 s-1时再结晶晶粒数量明显较少,如图7(b)所示。当应变速率为10.0 s-1和50.0 s-1时,只有很少量的动态再结晶晶粒在原始晶粒附近出现,仍保留大量经严重变形而被拉长的晶粒(图7(c)~(d))。这是因为应变速率低时亚结构容易形成,并迅速地通过动态再结晶形核及长大释放变形储能;当应变速率增大时,亚结构不能充分发展,动态再结晶难以形核;而且在很大的应变速率下变形比较剧烈,新生的动态再结晶晶粒发生畸变,从而产生位错,降低再结晶核心与形变晶粒间的应变梯度,因此再结晶晶粒的长大也不明显。

图7 GH4169高温合金在1 000 ℃不同应变速率下的金相组织

Fig. 7 Microstructure of GH4169 alloy at 1 000 ℃ at different strain rates

2.4 合金热加工图的建立

2.4.1 加工图理论

在不同的变形温度与应变速率下,加工图能反映材料在热变形时内部微观组织的变化,且能够评估材料的可加工性。Prasad等[19]提出可以采用动态材料模型(dynamic matreials model, DMM)来描述材料的变形行为。该模型的基本原理是:将热变形的加工件看作是一个能量耗散体,在塑性变形过程中,加工件会将外界输入的总能量P以2种方式消耗:一是加工件发生塑性变形所需要的能量,用G表示;二是加工件变形过程中微观组织演化所消耗的能量,用J表示。总能量P可表示为:

(16)

(16)

材料在一定应力条件下的应变速率敏感指数m可表示为:

(17)

(17)

流变应力可表示为:

(18)

(18)

则耗散协量J可表示为:

(19)

(19)

其中:0<m≤1。当m=1时,材料处于理想耗散状态,耗散协量J达到最大值,即J=Jmax= 。对于非线性耗散,可用功率耗散效率

。对于非线性耗散,可用功率耗散效率 来反映材料的功率耗散特征,即

来反映材料的功率耗散特征,即

(20)

(20)

功率耗散效率 随变形温度和应变速率的变化图就构成了该材料的功率耗散图。一般来说,

随变形温度和应变速率的变化图就构成了该材料的功率耗散图。一般来说, 越高的区域,材料在此条件下的加工性能就越好。但是在变形失稳区

越高的区域,材料在此条件下的加工性能就越好。但是在变形失稳区 也可能很高,所以要先确定材料的变形失稳区。

也可能很高,所以要先确定材料的变形失稳区。

将不可逆热力学的极大值原理应用于大应变塑性变形中[20],当

<

< (21)

(21)

时,材料会出现变形失稳,D是耗散函数。按照动态材料模型原理,D等于协变量J,由此推导出材料发生变形失稳的判据为:

<0 (22)

<0 (22)

参数 是变形温度和应变速率的函数,在能量耗散图上为负值的区域为变形失稳区,该图称为变形失稳图。将失稳图叠加于功率耗散图上就构成了材料的热加工图。根据加工图可以确定材料加工的流变失稳区和安全区。在材料的安全加工区,

是变形温度和应变速率的函数,在能量耗散图上为负值的区域为变形失稳区,该图称为变形失稳图。将失稳图叠加于功率耗散图上就构成了材料的热加工图。根据加工图可以确定材料加工的流变失稳区和安全区。在材料的安全加工区, 越大,表明材料在此区域内可加工性就越好[21]。

越大,表明材料在此区域内可加工性就越好[21]。

2.4.2 合金热加工图及分析

采用三次样条函数拟合 与

与 的关系,按式(17)计算m,再按式(15)计算功率耗散效率

的关系,按式(17)计算m,再按式(15)计算功率耗散效率 ,

, 随温度和应变速率的变化就构成了功率耗散图。按式(22)计算

随温度和应变速率的变化就构成了功率耗散图。按式(22)计算 ,参数

,参数 小于0的区域为非稳态流动区域,以变形温度(T)和应变速率(

小于0的区域为非稳态流动区域,以变形温度(T)和应变速率( )为变量的

)为变量的 构成了失稳图。将功率耗散图和失稳图叠加在一起,就构成了真应变(

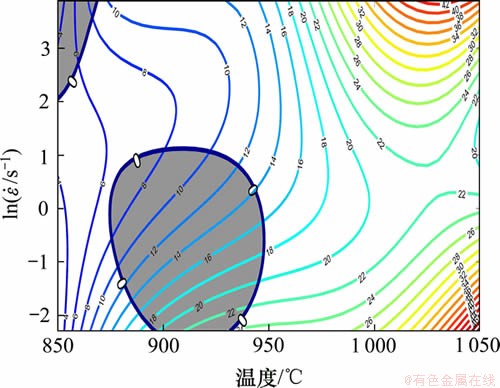

构成了失稳图。将功率耗散图和失稳图叠加在一起,就构成了真应变( )为0.5所对应的DMM加工图,如图8所示,图中等值线上的数字表示功率耗散系数,从低温区到高温区,功率耗散效率有增大的趋势,这种变化与合金不同的高温变形机制有关,由于变形温度的升高,使得位错间相互销毁和重组区域完全,促进亚晶形核生长,导致合金动态再结晶程度增大。一般认为功率耗散系数越高,热加工性能越好。从图8还可以看出:加工图包含2个功率耗散效率较大的区域。区域Ⅰ,功率耗散效率

)为0.5所对应的DMM加工图,如图8所示,图中等值线上的数字表示功率耗散系数,从低温区到高温区,功率耗散效率有增大的趋势,这种变化与合金不同的高温变形机制有关,由于变形温度的升高,使得位错间相互销毁和重组区域完全,促进亚晶形核生长,导致合金动态再结晶程度增大。一般认为功率耗散系数越高,热加工性能越好。从图8还可以看出:加工图包含2个功率耗散效率较大的区域。区域Ⅰ,功率耗散效率 为28%~42%,该区域主要集中在变形温度为985~1 050 ℃,应变速率为10.0~50.0 s-1。该区域的晶粒呈细小的颗粒状,为典型的动态再结晶区域,如图6(d)~(e)所示。区域Ⅱ,功率耗散效率

为28%~42%,该区域主要集中在变形温度为985~1 050 ℃,应变速率为10.0~50.0 s-1。该区域的晶粒呈细小的颗粒状,为典型的动态再结晶区域,如图6(d)~(e)所示。区域Ⅱ,功率耗散效率 为26%~50%,该区域主要集中在变形温度为1 000~1 050 ℃,应变速率为0.1~0.34 s-1。该区域也为动态再结晶区域,如图7(a)所示,相比区域Ⅰ,因为应变速率较低,有充分的时间来实现大角度的迁移,容易发生动态再结晶,故再结晶数量明显增加。

为26%~50%,该区域主要集中在变形温度为1 000~1 050 ℃,应变速率为0.1~0.34 s-1。该区域也为动态再结晶区域,如图7(a)所示,相比区域Ⅰ,因为应变速率较低,有充分的时间来实现大角度的迁移,容易发生动态再结晶,故再结晶数量明显增加。

图8 GH4169合金在应变为0.5时的加工图

Fig. 8 Processing map for GH4169 alloy at strain of 0.5

图8中阴影部分表示失稳区域,如果合金在失稳区域内所对应的工艺参数下进行塑形反应,可能会出现对微观组织不利的各种缺陷。图8中存在2个失稳区域,第1个区域是变形温度为850~870 ℃,应变速率为7.4~50.0 s-1。此变形条件下的金相组织如图6(a)和图9(a)所示,基体都为大块不规则的变形组织,变形晶粒很不均匀。第2个失稳区域相对较大一些,主要集中在变形温度为875~945 ℃,应变速率为0.1~2.7 s-1。通过对该区域内变形试样的金相组织观察,发现了局部剪切带的存在,如图9(b)所示。由于剪切变形的大部分能量以热能形式耗散在局部塑形流动带上,故其失稳区的 较低,GH4169高温合金在此条件下变形,出现的局部塑形流动对于其加工时非常危险的。因此,在实际选择热加工参数时应尽量避免这些区域。相比其他镍基高温合金,GH4169高温合金的热变形特征随着应变速率的增加,展现出反常的关系,主要原因可能是即使在一个较高的应变下晶界滑动相对减弱和动态再结晶过程也相对较迅速[22]。

较低,GH4169高温合金在此条件下变形,出现的局部塑形流动对于其加工时非常危险的。因此,在实际选择热加工参数时应尽量避免这些区域。相比其他镍基高温合金,GH4169高温合金的热变形特征随着应变速率的增加,展现出反常的关系,主要原因可能是即使在一个较高的应变下晶界滑动相对减弱和动态再结晶过程也相对较迅速[22]。

图9 流变失稳条件下样品的显微组织

Fig. 9 Optical microstructures of samples after hot deformation under different conditions

研究表明[23-24],功率耗散效率越高,越容易发生动态再结晶,动态再结晶可导致流变软化并形成稳态流变,有利于材料的热变形。从图8可以看出:存在2个功率耗散效率较高的区域,一个低应变速率区和一个高应变速率区。考虑到低应变速率区的动态再结晶更趋于完全、均匀。且高应变速率下,界面滑移所产生的应力集中没有足够的时间通过扩散等途径来释放,容易造成合金变形的不均匀。综合考虑这些因素,1 000~1 050 ℃的变形温度和0.10~0.34 s-1的应变速率为实验合金的最佳热加工工艺参数。

3 结论

1) GH4169合金高温压缩变形真应力-真应变曲线具有动态回复和动态再结晶现象,流变应力经历了过渡变形和稳态变形2个阶段。应变速率一定时,流变应力随变形温度的升高而降低;变形温度一定时,流变应力随应变速率的增加而增大。

2) 合金的变形激活能为668.29 kJ/mol,流变应力、变形温度和应变速率之间的关系可用双曲正弦形式的本构方程来描述:

3) 随着变形温度的升高,功率耗散效率有增大的趋势。且合金的热加工图中存在2个失稳区:第1个区域是变形温度为850~870 ℃,应变速率为7.4~50.0 s-1;第2个区域是变形温度为875~945 ℃,应变速率为0.1~2.7 s-1,失稳原因是合金局部发生了塑形流动,使得合金的显微组织极其的不均匀。

4) 结合热加工图及微观组织观察结果,1 000~1 050 ℃的变形温度和0.10~0.34 s-1的应变速率为GH4169高温合金的最佳热加工参数区。

参考文献:

[1] 李爱兰, 曾燮榕, 曹腊梅, 等. 航空发动机高温材料的研究现状[J]. 材料导报, 2003, 17(2): 26-28.

LI Ailan, ZENG Xierong, CAO Lamei, et al. Current status of research on high temperature materials for advances aircraft engines[J]. Materials Review, 2003, 17(2): 26-28.

[2] 师昌绪, 仲增墉. 中国高温合金40年[J]. 金属学报, 1997, 33(1): 1-8.

SHI Changxu, ZHONG Zengyong. Forty years of superalloy R & D in China[J]. Acta Metallurgica Sinica, 1997, 33(1): 1-8.

[3] 谢锡善. 我国高温材料的应用与发展[J]. 机械工程材料, 2004, 28(1): 2-8.

XIE Xishan. The development and application of high temperature materials in China[J]. Materials for Mechanical Engineering, 2004, 28(1): 2-8.

[4] Campbell C E, Boettinger W J, Kattner U R. Development of a diffusion mobility database for Ni-base superalloys[J]. Acta Materialia, 2002, 50(4): 775-792.

[5] 李晨, 李淼泉, 王柯. 固溶处理GH4169 合金的高温变形行为[J]. 航空学报, 2010, 31(2): 360-375.

LI Chen, LI Miaoquan, WANG Ke. Deformation behavior of nickel based superalloy GH4169 through solution treatment[J]. Acta Aeronautica et Astronautica Sinica, 2010, 31(2): 360-375.

[6] Li M Q, Ju W B, Lin Y Y, et al. Deformation behaviour of GH4169 nickel based superalloy in isothermal compression[J]. Materials Science and Technology, 2008, 24(10): 1195-1198.

[7] WU Xiaowei, Chandel R S, LI Hang, et al. Induction brazing of Inconel 718 to Inconel X-750 using Ni-Cr-Si-B amorphous foil[J]. Journal of Materials Processing Technology, 2000, 104: 34-43.

[8] 谢锡善, 董建新, 付书红, 等. γ''和γ'相强化的Ni-Fe基高温合金GH4169的研究与发展[J]. 金属学报, 2010, 46(11): 1289-1302.

XIE Xishan, DONG Jianxin, FU Shuhong, et al. Research and development of γ'' and γ' strengthened Ni-Fe base superalloy GH4169[J]. Acta Metallurgica Sinica, 2010, 46(11): 1289-1302.

[9] Wang Y, Shao W Z, Zhen L, et al. Flow behavior and microstructures of superalloy 718 during high temperature deformation[J]. Materials Science and Engineering A, 2008, 497: 479-486.

[10] Ning Y Q, Fu M W, Chen X. Hot deformation behavior of GH4169 superalloy associated with stick δ phase dissolution during isothermal compression process[J]. Materials Science and Engineering A, 2012, 540: 164-173.

[11] Prasad Y V R K, Seshacharyulu T. Modelling of hot deformation for microstructural control[J]. International Materials Reviews, 1998, 43(6): 243-258.

[12] 吴凯, 刘国权, 胡本芙, 等. 新型镍基粉末高温合金的热变形行为[J]. 稀有金属材料与工程, 2011, 40(4): 645-649.

WU Kai, LIU Guoquan, HU Benfu, et al. Hot deformation behavior of a new type nickel-based P/M superalloy[J]. Rare Metal Materials and Engineering, 2011, 40(4): 645-649.

[13] 王宏伟, 易丹青, 王斌, 等. Mg-6.3Zn-0.7Zr-0.9Y-0.3Nd镁合金的高温塑性变形行为的热压缩模拟[J]. 中国有色金属学报, 2010, 20(3): 378-384.

WANG Hongwei, YI Danqing, WANG Bin, et al. Hot compressive deformation simulation of Mg-6.3Zn-0.7Zr-0.9Y- 0.3Nd magnesium alloy at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 378-384.

[14] Mcqueen H J, Ryan N D. Constitutive analysis in hot working[J]. Materials Science and Engineering A, 2002, 322: 43-63.

[15] 蔡大勇, 熊良银, 孙贵东, 等. GH708高温合金热变形行为[J]. 稀有金属材料与工程, 2006, 35(zl): 144-147.

CAI Dayong, XIONG Liangyin, SUN Guidong, et al. Study on the hot deformation behaviour of superalloy GH708[J]. Rare Metal Materials and Engineering, 2006, 35(zl): 144-147.

[16] Shi H, Mclaren A J, Sellars C M, et al. Constitutive equations for high temperature flow stress of aluminum alloys[J]. Materials Science and Technology, 1997, 13(3): 210-216.

[17] XU Yulai, YANG Caixiong, XIAO Xueshan, et al. Evolution of microstructure and mechanical properties of Ti modified superalloy Nimonic 80 A[J]. Materials Science and Engineering A, 2011, 530: 315-326.

[18] WANG Zhongtang, ZHANG Shihong, CHENG Ming, et al. Kinematics and dynamics model of GH4169 alloy for thermal deformation[J]. Journal of Iron and Steel Research, International, 2010, 17(7): 75-78.

[19] Prasad Y V R K, Sasidhara S. Hot working guide: A compendium of processing maps[M]. Ohio: ASM International, Materials Park, 1997: 451-493.

[20] 戚延龄, 夏长清, 王志辉, 等. Ti62421s 钛合金的热变形行为及加工图[J]. 中南大学学报(自然科学版), 2012, 43(5): 1662-1671.

QI Yanling, XIA Changqing, WANG Zhihui, et al. Deformation behavior and processing map of high temperature deformation of Ti62421s alloy[J]. Journal of Central South University (Science and Technology), 2012, 43(5): 1662-1671.

[21] 胡加瑞, 肖来荣, 蔡一湘, 等. TiC 颗粒增强钛基复合材料的热变形行为及加工图[J]. 中南大学学报(自然科学版), 2012, 43(5): 1672-1677.

HU Jiarui, XIAO Lairong, CAI Yixiang, et al. Hot deformation and processing map of titanium matrix composites reinforced by TiC particulates[J]. Journal of Central South University (Science and Technology), 2012, 43(5): 1672-1677.

[22] KANG Fuwei, ZHANG Guoqing, LI Zhou, et al. Hot deformation of spray formed nickel-base superalloy using processing maps[J]. Transaction of Nonferrous Metals Society of China, 2008, 18: 531-535.

[23] 冯菲, 曾卫东, 朱艳春, 等. 铸态TC21钛合金高温热变形行为及加工图[J]. 稀有金属材料与工程, 2012, 41(2): 251-255.

FENG Fei, ZENG Weidong, ZHU Yanchun, et al. Hot deformation behavior and processing map of as-cast TC21 alloy[J]. Rare Metal Materials and Engineering, 2012, 41(2): 251-255.

[24] SUI Fengli, XU Lixia, CHEN Liqing, et al. Processing map for hot working of Inconel 718 alloy[J]. Journal of Materials Processing Technology, 2011, 211: 433-440.

(编辑 赵俊)

收稿日期:2013-11-20;修回日期:2014-02-13

基金项目(Foundation item):国防科工委军品配套研制资助项目(115-2-948) (Project(115-2-948) supported by the Commission of Science, Technology and Industry for National Defence)

通信作者:潘清林(1964-),男,湖北孝感人,教授,博士生导师,从事铝合金及镍基高温合金的研究;电话:0731-88830933;E-mail: pql@csu.edu.cn