DOI: 10.11817/j.ysxb.1004.0609.2021-40016

钢/铝层状复合板的拉伸力学性能与界面失效过程

李小兵1, 2,蒋国民1,王 强1,张小立1,伊军英1,曲锦波2,杨才福3

(1. 江苏科技大学(张家港) 冶金与材料工程学院,苏州 215600;

2. 江苏省(沙钢)钢铁研究院 板带研究室,苏州 215625;

3. 钢铁研究总院 工程用钢研究所,北京 100081)

摘 要:采用准静态拉伸实验研究钢/铝复合板在1×10-4~1×10-2 s-1应变速率范围的拉伸力学性能与变形行为,通过扫描电镜表征分析复合界面的组织演变与失效机理。结果表明:钢/铝轧制复合界面生成厚度约8 μm、含有少量金属间化合物Fe2Al5和Fe4Al13的过渡层。复合板的强度与钢、铝层之间满足混合法则,界面具有强化作用但易产生微裂纹,界面断裂失效和基层应变硬化导致应力-应变曲线波动。高应变速率加载使界面层急剧断裂,曲线波动程度增大,但断口的界面分离程度减小。准静态拉伸过程,钢/铝界面最先萌生裂纹,层间附加应力引起界面裂纹长大并扩展至铝层内部,钢层随后颈缩导致复合板断裂失效。提高钢/铝界面的结合强度可以改善层状复合板的变形协调性和力学性能。

关键词:钢/铝复合板;拉伸试验;复合界面;断裂;力学性能

文章编号:1004-0609(2021)-08-2125-11 中图分类号:TB331 文献标志码:A

引文格式:李小兵, 蒋国民, 王 强, 等. 钢/铝层状复合板的拉伸力学性能与界面失效过程[J]. 中国有色金属学报, 2021, 31(8): 2125-2135. DOI: 10.11817/j.ysxb.1004.0609.2021-40016

LI Xiao-bing, JIANG Guo-min, WANG Qiang, et al. Mechanical properties and interface failure behavior of steel/Al laminated composite sheets during tensile test[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(8): 2125-2135. DOI: 10.11817/j.ysxb.1004.0609.2021-40016

碳钢/铝复合板是在碳钢基材表面覆盖一层铝或铝合金,层间界面形成牢固的冶金结合状态,兼具了钢、铝材的优异性能,是具有较高性价比的金属层状复合材料,广泛应用于机械、车辆、石油化工等领域[1-2]。目前,钢/铝复合板的制备技术研究已取得较大进步,轧制复合技术因其环境友好、自动化程度高、可连续化生产等优势,成为制备钢/铝层状复合材料的主要方法[3-5]。在轧制复合制备过程,钢/铝复合界面区域较易发生元素扩散,促进了基体层间的冶金结合,但界面区往往会形成一层具有不同成分及结构的过渡组织,对复合板的使役行为产生重要影响[6-7]。因此,需要对金属层状复合材料的组织演变规律和力学响应机制进行深入研究,为实现复合板力学性能的优化和调控提供精确模型。

科研人员针对金属层状复合板的制备技术与组织性能开展了系列研究,揭示了复合界面的组织演变规律。徐卫等[8]研究发现,采用爆炸焊接方法制备的钛/铝复合板具有波状界面,界面区存在少量金属间化合物和其他岛状夹杂物,导致复合板在后续轧制时沿界面产生周期性裂纹。刘兴海等[9]研究表明,在550 ℃以上温度范围热轧复合制备的钢/铝复合板会在层间界面区形成不连续的金属间化合物和微孔洞,制约了复合板的界面结合强度和弯曲成形性能。TALEBIAN等[10]研究发现,当退火温度高于500 ℃时,经过30 min保温处理就会造成钢/铝复合界面产生大量的金属间化合物和扩散孔洞,导致钢/铝界面的高脆性和断裂分离。

当前,界面问题正成为复合材料研究领域的热点,大量基础研究围绕着复合界面的结构演变与失效机制进行。刘肖婷[11]通过拉伸实验研究了IF钢/铝复合板的变形机制,裂纹首先在界面层萌生和扩展,当裂纹尖端应力达到铝层的强度极限时,铝层开始颈缩并产生裂纹,同时界面裂纹沿拉伸方向迅速扩展,随后IF钢单独伸长变形直至断裂。王传杰等[12]研究了Cu/Ni复合箔的界面变形行为,基体层间的力学性能差异导致Cu/Ni界面的微孔缺陷处最先萌生裂纹,当界面裂纹大量合并和纵向扩展时,基体层开始发生颈缩和断裂。皇涛等[13]通过扫描电镜表征研究了钛/铝复合板原位拉伸加载过程的损伤演化行为,裂纹在复合界面区的金属间化合物层中萌生、扩展和贯通,随后由界面区逐渐扩展至基体层,直至复合板完全断裂。刘帅洋等[14]研究了拉伸应变速率对铜/铝铸轧复合板力学性能的影响, 铜/铝层间的强结合界面使复合板各层产生协调变形,延缓了铝层过早颈缩行为的发生,复合板抗拉强度与断后伸长率随应变速率增大而提高。

为了预报和设计层状复合材料的力学性能,刘咏等[15-16]研究了粉末冶金加工制备的Ti-Ta金属层状结构材料的动态力学行为,试样破坏机制主要为裂纹桥联和局部层裂,加载过程表现出明显的应变速率强化、应变硬化及绝热软化特征,改进了的Johnson-Cook 本构模型能够较好地预测该材料的力学变形行为。刘宝玺等[17-18]研究表明,通过调控各材料的尺寸配比和结构参数,热轧制备的不锈钢/碳钢复合板可获得优异的强塑性和断裂韧性,界面状态和层厚尺寸对复合板的断裂韧性和伸长率产生重要影响。COHADES等[19]研究了金属层状复合材料的拉伸性能与各组分的应变硬化指数n、应变速率敏感系数m和强度K的关系,为层状复合材料结构设计提供了数据支撑。

钢/铝复合板具有层状结构和界面过渡组织,各部分的力学性能差异使复合板在加载过程产生复杂变形。目前,层状复合板的动态力学测试分析手段仍存在不足,对复合界面的微观变形机制与断裂失效机理研究不够透彻,因而无法做到精准调控复合板的显微组织与使役性能。本文作者以冷轧复合工艺制备的钢/铝层状复合板为研究对象,通过拉伸试验分析应变速率对复合板力学性能的影响,基于断口分析探讨复合界面在拉伸过程的组织演变规律,研究钢/铝层状复合板的断裂失效机理。

1 实验

实验原材料为Q235冷轧钢板和A1100纯铝板,厚度分别为1.0 mm、0.4 mm,用剪床裁成长度100 mm、宽度30 mm的条状试样。Q235钢的主要化学成分(质量分数,%)为C 0.16、Mn 0.50、Si 0.30、S 0.04、P 0.04、Fe余量,在程控电阻炉内进行完全退火处理,退火温度为900℃,保温1 h,然后放置于10%盐酸(体积分数)水溶液中浸泡24 h,再用丙酮和蒸馏水清洗后烘干。采用转速12000 r/min的钢丝刷和酒精去除钢板、铝板待复合面上的附着物,并获得具有一定粗糙度的硬化层。随后将钢板和铝板打磨过的表面贴合,以钢板为基材、铝板为复材组合成铝/钢/铝顺序的堆垛结构,用细铁丝固定两端后在室温条件下立即进行轧制复合。在直径为200 mm二辊可逆轧机上进行轧制实验,轧辊表面无润滑,轧制速度设定为2.7 m/min,单道次压下率为58%,轧制后钢、铝层间实现固态结合。随后,轧制试样在程控电阻炉内进行退火处理,消除加工硬化和残余应力,并改善钢/铝复合界面的结合强度。退火温度设定为450℃,保温时间1 h,温度精度为±2 ℃。

使用电火花线切割机在钢/铝复合板上取样进行表征分析测试,金相组织观察面为轧制横截面,拉伸力学试验样品沿着轧制方向制取,标距尺寸为40 mm×10 mm。钢/铝复合板的显微组织与拉伸断口形貌通过ZEISS Axio Scope A1光学金相显微镜和配备能谱分析仪(EDS)的JSM-6510LA扫描电镜(SEM)表征分析,金相腐蚀剂为4%(体积分数)硝酸酒精溶液。采用Ultima IV型X射线衍射仪(XRD)对钢、铝层沿复合界面剥离后的表面进行物相成分分析,用于确定钢/铝复合界面过渡组织的结构类型。

拉伸力学试验在UTM 5205X型电子万能试验机上进行,由计算机控制夹头的移动速度,分组设定为0.25、2.5、25 mm/min,对应名义应变速率为1.0×10-4、1.0×10-3、1.0×10-2 s-1,位移量由引伸计测定。在1.0×10-3 s-1拉伸应变速率条件下,将试样分别拉伸至不同变形阶段后立即卸载,进行取样镶嵌,沿着标距段纵向截面观察钢/铝界面的显微组织,分析钢/铝复合板在拉伸加载过程的变形行为与失效机理。

2 结果与分析

2.1 钢/铝复合板及其界面的组织结构

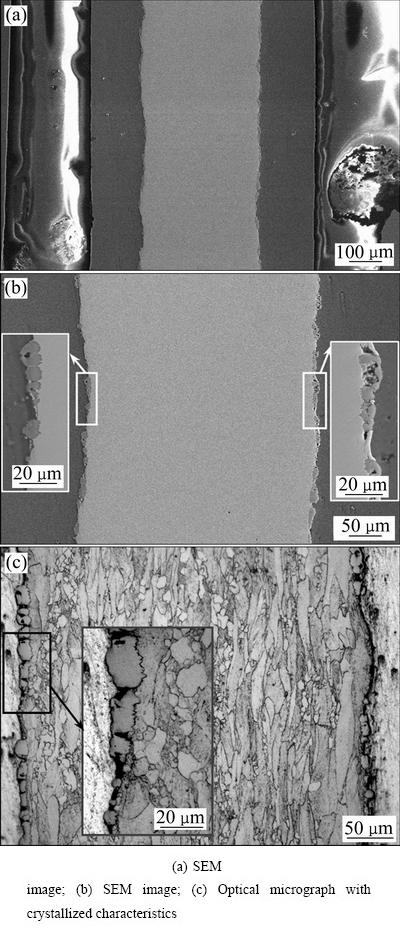

经轧制复合与退火处理制备的钢/铝层状复合板显微组织如图1所示。钢、铝基层之间形成紧密结合的界面,不存在缝隙、裂纹等结构缺陷。钢/铝复合界面区生成了一层厚度不均匀的过渡组织,其中局部位置含有少量微孔洞。

图1 钢/铝复合板及界面区的显微组织

Fig. 1 Micrographs of steel/Al composite sheet

由于钢、铝之间的成分组织及力学性能存在明显差异,轧制过程中各金属层间的塑性流动速率不同,使待复合接触面受到摩擦剪切应力作用,增强了层间界面区的物理交互反应和机械啮合程度。室温轧制复合过程需要较大的塑性变形程度,钢/铝层间界面伴随着剧烈塑性流动,形成大量空位、位错、剪切带等微观结构,并存储了高密度的畸变能,满足了界面区原子长程迁移和互扩散所需的热力学、动力学条件。钢、铝待复合面由于经过机械处理处于粗糙状态,导致界面区塑性变形在微观尺度范围内存在不均匀性,界面各处获得不同的变形组织和能量[4]。根据扩散机理可知,形变储能越高、成分梯度越大、扩散通道越多,扩散程度就越显著,因此原子在变形剧烈位置最先发生跨界面的长程扩散,导致钢/铝层间界面形成不等厚、非均匀分布的扩散产物[20]。

与纯铝相比,碳钢具有较大的变形抗力,在室温固态压力复合过程塑性变形程度相对较低,并发生强烈的应变硬化行为,导致钢/铝层间反应程度受限,界面区无法获得完全致密的物理接触,残留了少量空隙,经过退火后在界面扩散区形成如图1(b)插图所示的微孔。结果表明,在金属压力复合过程中必须具有合适的材料性能与变形条件,增强金属在界面区的塑性流动能力和物理反应,才能有效满足层状金属固态结合所需的物质条件和能量要求。

图1(c)所示为钢/铝复合板的金相显微组织。钢层由变形带和少量再结晶晶粒组成,钢/铝界面含有不连续分布的过渡层组织,钢层紧邻界面区域的再结晶程度较低。钢/铝轧制复合界面存在大量晶格缺陷和畸变能,为退火处理时原子长程迁移提供了有利条件,促进了钢/铝界面区原子扩散,在层间原始接触面位置形成固溶体组织和金属间化合物[10]。在退火过程,钢层紧邻复合界面的区域受铝原子扩散影响形成了固溶体组织,而且该区的轧制变形储能和晶格缺陷大量消失,提高了铁素体再结晶形核的临界条件,从而推迟了再结晶行为的发生,造成钢侧界面区主要由带状变形晶粒组成。

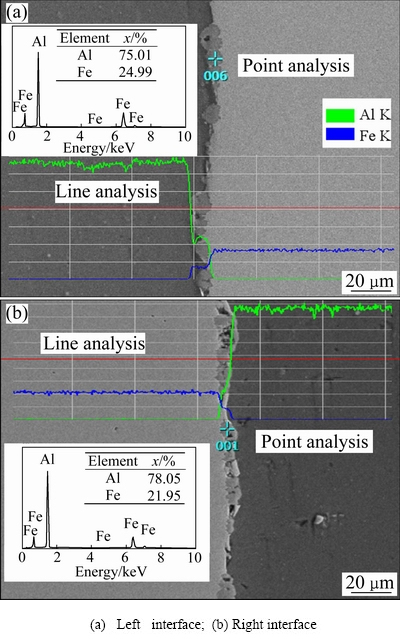

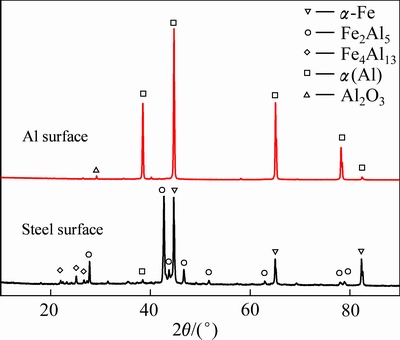

图2所示为钢/铝复合界面的EDS成分分析结果。Fe、Al原子跨界面进行长程扩散,界面生成厚度约8 μm的中间过渡层。线扫描成分曲线中存在一个Fe、Al摩尔分数相对不变的平台区,能谱分析Fe、Al摩尔比约为1:3,可以推测钢/铝层间界面区生成了某种化合物。沿着复合界面进行层间剥离,然后分别对钢层、铝层表面的物相成分进行XRD测试,结果如图3所示,界面扩散反应生成了金属间化合物Fe2Al5、Fe4Al13相。剥离后的界面化合物主要存在于钢层表面,这与界面断裂失效行为有关,将在下文结合力学试验结果进行分析。

退火过程中,钢/铝界面区的原子之间发生反应,生成金属间化合物及其他中间相。根据Fe-Al系金属间化合物的物性参数可知,当反应温度介于300~1500 K时,除FeAl相之外,Fe3Al、FeAl2、FeAl3、Fe4Al13、Fe2Al5的吉布斯自由能DG均为负值且依次降低,Fe2Al5的吉布斯自由能DG接近-500 kJ/mol,在化合物生成过程具有较强的反应自发性,因此,钢/铝界面最容易形成富铝的Fe2Al5相[21]。随着退火时间延长,Fe、Al原子继续扩散并与Fe2Al5反应产生Fe4Al13相。退火处理使界面区的Fe、Al原子之间形成大量金属键,增强了钢/铝层间的冶金结合,有利于提高复合板的力学性能。

图2 钢/铝复合界面的SEM像与EDS分析结果

Fig. 2 SEM images and EDS analysis results of interface zone of steel/Al composite sheet

图3 沿复合界面剥离后钢、铝表层的XRD谱

Fig. 3 XRD patterns of steel and aluminum surface after peeling along bonding interface of composite sheet

2.2 应变速率对复合板拉伸力学性能的影响

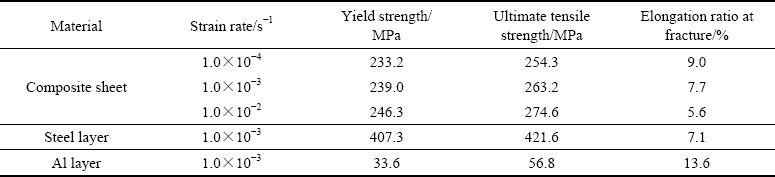

钢/铝复合板在不同应变速率加载条件下的拉伸强度与塑性列于表1中,拉伸应力-应变曲线如图4所示。当应变速率从1.0×10-4 s-1增至1.0×10-2 s-1时,复合板的屈服强度由233.2 MPa增至246.3 MPa,抗拉强度由254.3 MPa提高到274.6 MPa,而复合板断后伸长率明显下降。金属材料在拉伸过程存在应变速率强化现象[22],高应变速率拉伸时钢、铝层发生强化,使钢/铝复合板的强度值升高,塑性下降。

由图1及表1结果分析可知,复合板的拉伸强度 与各单层金属强度之间基本满足式(1)所示的混合法则[17]:

与各单层金属强度之间基本满足式(1)所示的混合法则[17]:

(1)

(1)

式中:x表示单层金属在复合板中的厚度占比。复合板的屈服强度、抗拉强度与式(1)计算值相比均略有偏大,表明冶金结合界面有利于钢、铝层之间产生协同变形,改善了复合板的强度性能。然而,复合板的断后伸长率与单层金属之间不满足线性关系,尚未获得准确的关系模型。

在拉伸加载初期,复合板发生弹性变形,由于碳钢和纯铝的弹性模量及泊松比差异较大,铝层率先在板厚方向发生减薄,造成钢/铝层间结合区形成附加拉应力和弹性畸变场[12]。继续加载时,铝层开始出现屈服和大量位错运动,使钢/铝界面形成位错塞积和应力集中,再加上界面区弹性变形引起的附加应力,诱发了微裂纹在钢/铝界面层快速萌生,界面区的弹性应力得到释放。当复合板屈服进入塑性变形阶段后,钢、铝层形成的大量位错难以跨越层间界面区进行滑移运动,界面过渡层组织中钉扎和塞积了大量形变位错,界面层的位错强化效应使复合板的拉伸强度增加。

表1 不同应变速率时复合板及单层金属的拉伸性能

Table 1 Tensile properties of composite sheet and individual layer at different strain rates

图4 不同拉伸速率下钢/铝复合板与基层金属的工程应力-应变曲线

Fig. 4 Engineering stress-strain curves of steel/Al composite sheets and individual layer at different tensile rates

图4插图显示,在复合板屈服之后的变形过程,拉伸应力-应变曲线存在波动现象。应变速率越高,曲线波动现象越显著,波动阶段的总应变量越小。分析认为,钢/铝复合界面的结构特征导致在拉伸加载过程容易产生裂纹,导致复合板变形抗力稍有下降,应力-应变曲线出现降低趋势,复合板产生一种“软化”现象。然而,裂纹尖端在界面层扩展时被金属层和冶金结合界面所阻碍,界面裂纹的长大行为受到限制[23]。另一方面,钢、铝层的应变硬化效应使复合板变形抗力提高,表现出“硬化”特征,从而造成拉伸应力-应变曲线在塑性变形初期出现波动现象。

应变速率较低时,塑性变形初期位错的增殖及运动行为较平缓,位错对复合界面的影响较低,界面扩散层存在较少的应力集中和微裂纹,复合板产生“软化”效应不明显。同时,各基层金属的应变硬化程度不高,复合板在塑性伸长过程的“软化”与“硬化”行为基本平衡,应力-应变曲线的波动程度较小。当拉伸载荷增加到一定程度,铝层开始进入局部颈缩变形阶段,诱发钢/铝界面断裂分层,复合板塑性伸长过程的界面“软化”效应达到极限状态。此后,各单层金属的形变强化行为对复合板拉伸性能的影响占主导,应力-应变曲线逐渐上升,直至复合板发生颈缩。

在高应变速率拉伸过程,钢、铝层受到应变速率强化效应的影响,复合板的变形抗力得到明显提升。然而,较高的加载应力导致界面层过快产生裂纹并沿界面急剧扩展,复合板抵抗拉伸载荷的能力下降,使应力-应变曲线形成波动现象。由于钢/铝界面层在局部区域严重断裂,界面对复合板力学性能的影响迅速减弱,后续变形过程复合板性能主要取决于钢、铝单层金属,因而,屈服之后发生的应力-应变曲线波动阶段很快结束。

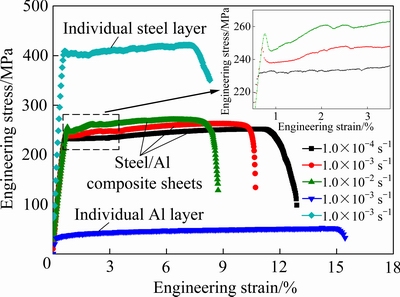

图5所示为钢/铝复合板拉伸断口的SEM像,反映了拉伸速率对复合板变形行为的影响。由于碳钢的应变速率强化效应较显著,当拉伸速率提高时,钢层强度提高,塑性下降,断口表面韧窝数量和尺寸均有所减少[22],分别如图5(a)、(c)和(e)所示。随着塑性应变量的增加,钢、铝层的应变硬化程度不相同,二者的力学性能差异逐渐扩大,沿拉伸轴向的伸长变形程度不一致,对层间结合界面产生破坏作用[13]。铝层因变形抗力较低而率先颈缩和断裂,钢层的伸长变形受铝层约束程度逐渐减小,避免了层间复合界面受附加应力的持续破坏。

图5 不同应变速率时钢/铝复合板拉伸断口的SEM像

Fig. 5 SEM images of tensile fracture of steel/Al composite sheets at different strain rates

如上所述,拉伸应变速率越高,界面层局部断裂越早发生,界面强化作用越弱,钢、铝层间的变形独立性越大。因此,如图5(b)、(d)和(f)所示,钢/铝界面的断裂分离程度逐渐减弱,钢、铝层的塑性伸长量差异增大。

钢/铝界面层含有脆性的金属间化合物Fe2Al5和Fe4Al13相,低应变速率加载时,在拉应力作用下产生垂直于拉伸轴向的微裂纹。界面层与铝层的流动性差异较大,容易诱发应力集中,导致界面裂纹集中在铝层与界面层之间扩展[24]。此外,界面层的金属间化合物在拉应力作用下将会发生破碎,如图5(b)上部插图所示。

由于界面裂纹主要沿界面过渡层与铝基层之间扩展,造成大量界面扩散产物黏附在钢层表面,形成如图5(a)上部插图所示的凸起状颗粒。由图5(c)上部插图可知,铝层表面存在少量颗粒物,经EDS分析发现主要含Fe、Al成分,可推断为残留在铝层断口的金属间化合物。钢、铝层的断口形貌特征与XRD物相分析结果相一致,明确了复合界面断裂失效位置与扩展路径,界面产物对复合板拉伸行为具有重要影响。

2.3 复合板拉伸过程的界面演变与失效机理

钢/铝复合板具有层状结构和宏观相界面,在复合界面的影响下表现出特殊的拉伸力学行为与响应机制。图6~8所示分别为钢/铝复合板在应变速率为1.0×10-3 s-1时拉伸至不同变形阶段所观察的显微组织,用于分析准静态加载时钢/铝层状复合板的界面演变过程和断裂失效机理。

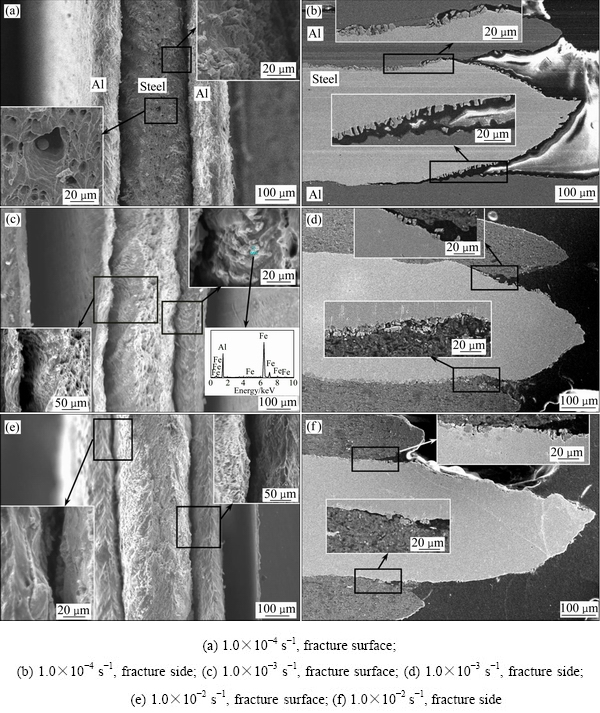

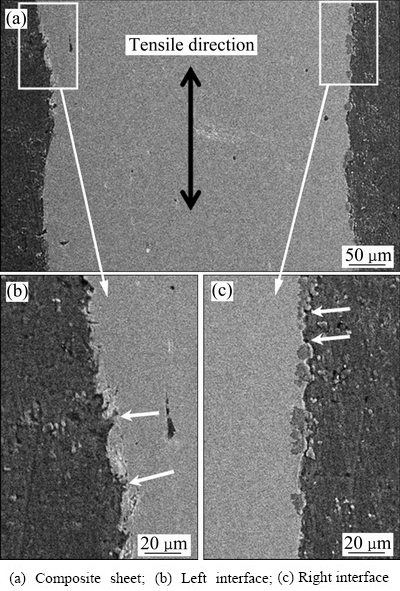

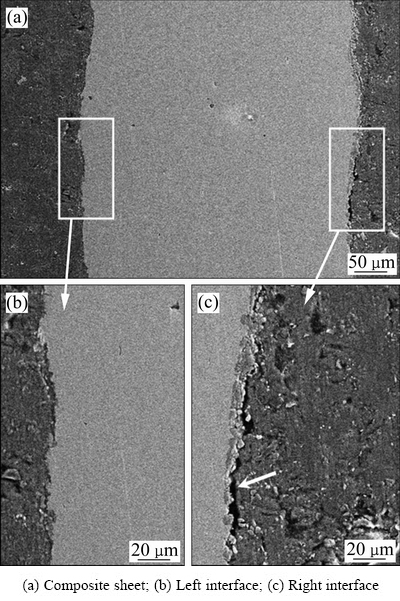

由图6可知,当复合板发生屈服时,钢/铝界面的显微组织无明显变化,金属层间整体上仍保持良好结合,在图6(b)、(c)中箭头所示的界面层局部位置形成少量微孔洞。在复合板拉伸加载过程,钢、铝层先后进入屈服状态,存在塑性变形不同步现象,层间不协调变形造成复合界面承受附加拉应力和剪应力。在轧制复合时,钢/铝界面的组织性能具有一定程度的不均匀性。在界面扩散程度较低的位置以及界面出现金属间化合物的位置,各层之间存在较大的组织突变,基层金属伸长变形产生的附加应力容易诱发钢/铝界面萌生微裂纹。由于复合板刚进入屈服阶段,塑性变形程度很小,钢/铝界面层中的裂纹仍处于萌生状态,尚未发生长大。

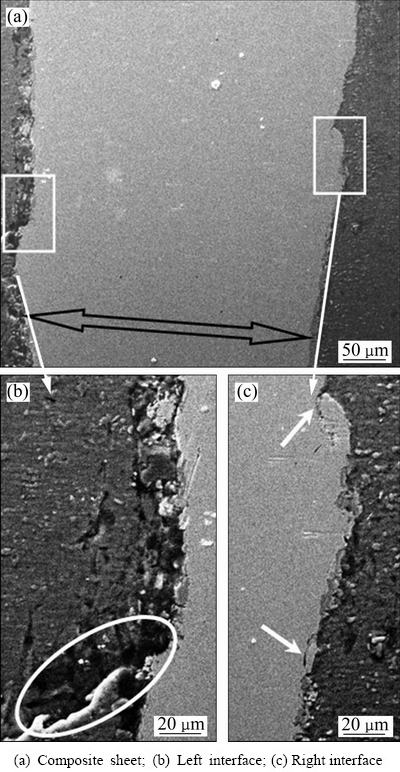

图7所示为钢/铝复合板拉伸至强度极限时的SEM像。此时,钢、铝层内部尚未生成裂纹,而层间复合界面在局部位置形成了沿拉伸轴向分布的贯通式裂纹,界面过渡层与铝层之间发生断裂分离,如图7(c)箭头所示。此外,钢层外侧的铝复层发生颈缩的位置具有随机性,在图7(b)、(c)所示左、右两个界面区域表现出不对称的断裂特征。

钢/铝复合板刚进入塑性变形阶段时,界面层横向裂纹尖端的应力集中程度达不到基层强度值,界面裂纹难以扩展至基层内部。随着各基层金属明显被拉长,各层厚度减小并对界面结合层产生附加拉应力,促使界面层的初始横向裂纹扩展路径偏转至钢/铝界面平面内继续扩展。由于各基层在拉伸方向的塑性变形不协调,在钢、铝层间界面区形成了附加剪切应力,导致结合界面的断裂抗力下降,界面与基体层之间逐渐开裂分离。

图6 钢/铝复合板拉伸至屈服时的SEM像

Fig. 6 SEM images of steel/Al composite sheet stretched to yield stage

图7 钢/铝复合板拉伸至强度极限时的SEM像

Fig. 7 SEM images of steel/Al composite sheet stretched to ultimate strength

根据图4所示应力-应变曲线可知,复合板达到抗拉强度极限时,铝层已发生明显颈缩,钢/铝界面的局部区域在应力作用下严重分离失效[12]。当复合板达到强度极限时钢层尚未发生颈缩变形,钢/铝界面开裂程度主要受铝层颈缩的影响,贯通式裂纹只存在于复合界面对应于铝层发生颈缩集中变形的区域。由于钢/铝界面结合状态被破坏,削弱了该区域内复合板的变形抗力,从而导致作为承载主体的钢层也在相同区域产生颈缩变形。

图8所示为钢/铝复合板产生明显颈缩但未断裂时的显微组织。由图8可知,钢层在黑色箭头标记的位置出现厚度减薄现象,钢/铝界面明显断裂破碎,基层金属靠近界面的位置形成了少量裂纹。

复合板颈缩时,铝层厚度已大幅减小,靠近铝层颈缩位置的界面层在附加拉应力和剪切力作用下发生断裂失效,形成碎片化的界面过渡组织[23]。复合板承受的流动应力已超过铝层断裂强度,界面区裂纹沿着与拉伸轴成45°方向的路径扩展到铝层内部,如图8(b)所示。在复合板局部颈缩过程,当钢/铝界面的结合强度较大时,裂纹在层间界面区的扩展行为受阻,随后发生偏转进入基层金属靠近界面的区域继续扩展[15],如图8(c)箭头所示,裂纹路径与界面基本平行。

图8 钢/铝复合板拉伸至明显颈缩时的SEM像

Fig. 8 SEM images of steel/Al composite sheet stretched to necking stage

钢层表面经过机械磨抛处理后形成粗糙的硬化层,在轧制复合时粗糙凸起处获得较大的塑性变形,与铝层表面紧密接触并形成良好的冶金结合,使层间界面具有较高的连接强度。此外,钢/铝层间界面在微观尺度上保留了粗糙特征,界面局部位置具有起伏状组织,在拉伸加载过程容易产生应力集中。在复合界面区,钢、铝层沿厚度方向的塑性变形具有梯度特征,扩散退火处理使临近界面的区域形成不均匀晶粒组织和复杂相结构。当复合板颈缩变形时,界面附加拉应力和剪应力造成钢层近界面区产生微裂纹,裂纹继续扩展诱发钢层断裂,最终导致钢/铝复合板整体断裂。

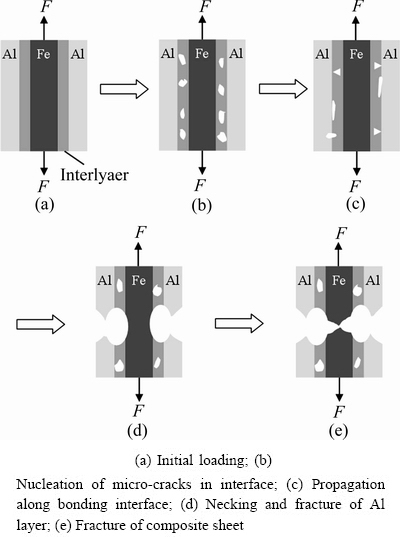

通过分析断口显微组织,明确了钢/铝复合板在准静态拉伸加载过程的变形行为与断裂机制。为了清晰反映界面层与复合板拉伸性能的关系,绘制了准静态拉伸加载时复合板断裂失效过程的示意图,如图9所示。研究表明,通过调控各单层金属及层间结合界面的组织性能,可以优化金属层状复合板的力学性能。

图9 钢/铝复合板拉伸变形过程示意图

Fig. 9 Schematic diagram showing tensile deformation process of steel/Al composite sheet

3 结论

1) 钢/铝冷轧复合板的界面区生成了不连续分布的扩散过渡层,最大厚度约8 μm,层内含有少量金属间化合物Fe2Al5和Fe4Al13相。钢/铝界面原子扩散行为抑制了再结晶晶粒的形核和长大,钢层紧邻复合界面区域的再结晶过程滞后于钢层内部。

2) 钢/铝复合板与基层金属之间满足强度混合法则,复合界面发挥了强化作用。拉伸过程钢、铝层间的不协调变形造成界面附加应力和微裂纹,界面层断裂失效和各基层应变硬化综合导致应力-应变曲线波动。高应变速率加载造成界面层急剧断裂,减弱基层变形的相互影响,钢/铝复合板拉伸曲线波动程度增大,但断口中的界面分离程度减小。

3) 准静态拉伸过程,钢/铝复合板的界面过渡层最先萌生横向裂纹,随后铝层颈缩,横向裂纹转至过渡层与铝层之间扩展合并。然后,裂纹扩展至铝层中,钢层开始颈缩,最终导致复合板断裂失效。具有较高结合强度的界面能够阻碍裂纹沿界面扩展,有利于提高复合板的变形协调性和力学性能。

REFERENCES

[1] 田广民, 李选明, 赵永庆, 等. 层状金属复合材料加工技术研究现状[J]. 中国材料进展, 2013, 32(11): 696-701.

TIAN Guang-min, LI Xuan-ming, ZHAO Yong-qing, et al. Research status of processing technology of laminated metal composite[J]. Materials China, 2013, 32(11): 696-701.

[2] MANESH H D, KARIMI T A. Bond strength and formability of an aluminum-clad steel sheet[J]. Journal of Alloys and Compounds, 2003, 361(1/2): 138-143.

[3] CHEN Gang, LI Jin-tao, XU Guang-ming. Bonding process and interfacial reaction in horizontal twin-roll casting of steel/aluminum clad sheet[J]. Journal of Materials Processing Technology, 2017, 246: 1-12.

[4] 王春阳, 姜雁斌, 谢建新, 等. 嵌入式铝/钢带材轧制复合铝层和钢层厚度的变化规律[J]. 中国有色金属学报, 2017, 27(4): 766-775.

WANG Chun-yang, JIANG Yan-bin, XIE Jian-xin, et al. Thickness variation of aluminum layer-steel layer of embedded aluminum-steel composite strip during cold roll bonding[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(4): 766-775.

[5] 黄海涛, 王 辉. 钢铝双金属复合板的轧制及其界面分析[J]. 热加工工艺, 2019, 48(11): 57-61.

HUANG Hai-tao, WANG Hui. Rolling and interface analysis of steel-aluminum bimetallic composite sheets[J]. Hot Working Technology, 2019, 48(11): 57-61.

[6] 黄华贵, 赵 阳, 王 超, 等. 界面涂层对厚规格热轧钢/铝复合板界面结构与力学性能的影响[J]. 机械工程学报, 2019, 55(14): 30-36.

HUANG Hua-gui, ZHAO Yang, WANG Chao, et al. Influence of plasma spraying on interfacial microstructure and mechanical property of thick steel/aluminum laminated plate by hot rolling[J]. Journal of Mechanical Engineering, 2019, 55(14): 30-36.

[7] YANG Yan-chao, ZHANG Fan-yong, HE Ji-ning, et al. Microstructure, growth kinetics and mechanical properties of interface layer for roll bonded aluminum-steel clad sheet annealed under argon gas protection[J]. Vacuum, 2018, 151: 189-196.

[8] 徐 卫, 朱 明, 郭胜利, 等. 钛-铝复合板界面组织及其对加工性能的影响[J]. 稀有金属, 2011, 35(3): 342-348.

XU Wei, ZHU Ming, GUO Sheng-li, et al. Interfaces of titanium-aluminum clad sheet and affecting to processing performance[J]. Chinese Journal of Rare Metals, 2011, 35(3): 342-348.

[9] 刘兴海, 张焜禹, 董 丽, 等. 热轧工艺对钢/铝复合板抗弯变形性能的影响[J]. 热加工工艺, 2015, 44(17): 50-53.

LIU Xing-hai, ZHANG Kun-yu, DONG Li, et al. Effects of hot rolling on bending-resistance deformability of steel/Al laminated plates[J]. Hot Working Technology, 2015, 44(17): 50-53.

[10] TALEBIAN M, ALIZADEH M. Manufacturing Al/steel multilayered composite by accumulative roll bonding and the effects of subsequent annealing on the microstructural and mechanical characteristics[J]. Materials Science and Engineering A, 2014, 590: 186-193.

[11] 刘肖婷. 层状IF steel-Al复合板的制备与变形机制的研 究[D]. 哈尔滨: 哈尔滨工业大学, 2015.

LIU Xiao-ting. Study on fabrication and deformation mechanism of IF steel-Al laminated composite sheets[D]. Harbin: Harbin Institute of Technology, 2015.

[12] WANG Chuan-jie, WANG Hai-yang, GENG Fang-fang, et al. Interactive effects of microstructure and interface on tensile deformation behaviors of Cu/Ni clad foils[J]. Materials Science and Engineering A, 2018, 714: 14-24.

[13] 皇 涛, 王 锟, 陈拂晓, 等. 钛-铝层状复合板冷塑性变形过程损伤演化行为[J]. 河南科技大学学报(自然科学版), 2019, 40(6): 8-12.

HUANG Tao, WANG Kun, CHEN Fu-xiao, et al. Damage evolution behavior of Ti-Al laminated composite plate in cold-plastic deformation process[J]. Journal of Henan University of Science and Technology (Natural Science), 2019, 40(6): 8-12.

[14] 刘帅洋, 王爱琴, 田捍卫, 等. 不同应变速率下铜/铝层状复合材料的拉伸变形行为[J]. 材料热处理学报, 2018, 39(10): 8-14.

LIU Shuai-yang, WANG Ai-qin, TIAN Han-wei, et al. Tensile deformation behavior of Cu/Al laminated composites at different strain rates[J]. Transactions of Materials and Heat Treatment, 2018, 39(10): 8-14.

[15] 李 谋, 刘 咏, 刘 彬, 等. 仿生结构Ti-Ta金属-金属复合材料的动态力学行为[J]. 中国有色金属学报, 2020, 30(8): 1818-1827.

LI Mou, LIU Yong, LIU Bin, et al. Dynamic behavior of biomimic structure Ti-Ta metal-metal composite[J]. The Chinese Journal of Nonferrous Metals, 2020, 30(8): 1818-1827.

[16] 徐圣航, 周承商, 刘 咏. 金属-金属层状结构复合材料研究进展[J]. 中国有色金属学报, 2019, 29(6): 1125-1143.

XU Sheng-hang, ZHOU Cheng-shang, LIU Yong. Research progress in metal-metal laminated structural composites[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(6): 1125-1143.

[17] 张博洋, 李泽斌, 刘宝玺. 层状金属复合材料断裂和增韧机理的研究进展[J]. 河北工业大学学报, 2020, 49(4): 1-11.

ZHANG Bo-yang, LI Ze-bin, LIU Bao-xi. Current research on fracture and toughening mechanisms of laminated metal composites[J]. Journal of Hebei University of Technology, 2020, 49(4): 1-11.

[18] LIU B X, AN Q, YIN F X, et al. Interface formation and bonding mechanisms of hot-rolled stainless steel clad plate[J]. Journal of Materials Science, 2019, 54, 11357-11377.

[19] COHADES A, CETIN A, MORTENSEN A. Designing laminated metal composites for tensile ductility[J]. Materials & Design, 2015, 66: 412-420.

[20] 邱然锋, 李久勇, 贺玉刚, 等. 铝合金/低碳钢点焊界面反应物生长机制[J]. 中国有色金属学报, 2017, 27(6): 1176-1181.

QIU Ran-feng, LI Jiu-yong, HE Yu-gang, et al. Growth mechanism of reactants at spot welding interface between aluminum alloy and low carbon steel[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(6): 1176-1181.

[21] 黄健康, 何翠翠, 石 玗, 等. 铝/钢异种金属焊接接头界面Al-Fe金属间化合物生成及其热力学分析[J]. 吉林大学学报(工学版), 2014, 44(4): 1037-1041.

HUANG Jian-kang, HE Cui-cui, SHI Yu, et al. Thermodynamic analysis of Al-Fe intermetallic compounds formed by dissimilar joining of aluminum and galvanized steel[J]. Journal of Jilin University (Engineering and Technology Edition), 2014, 44(4):1037-1041.

[22] HUH H, AHN K, LIM J H, et al. Evaluation of dynamic hardening models for BCC, FCC, and HCP metals at a wide range of strain rates[J]. Journal of Materials Processing Technology, 2014, 214(7): 1326-1340.

[23] ZHAO S, DHARANI L R, LIANG X. Analysis of damage in laminated architectural glazing subjected to blast loading[J]. Advances in Structural Engineering, 2008, 11(1): 129-134.

[24] 王世宏, 罗小兵, 苏 航, 等. 热处理温度对铝钢复合板界面组织和性能的影响[J]. 钢铁研究学报, 2019, 31(10): 937-945.

WANG Shi-hong, LUO Xiao-bing, SU Hang, et al. Effect of heat treatment temperature on interfacial microstructures and bonding properties of Al-steel clad plate[J]. Journal of Iron and Steel Research, 2019, 31(10): 937-945.

Mechanical properties and interface failure behavior of steel/Al laminated composite sheets during tensile test

LI Xiao-bing1, 2, JIANG Guo-min1, WANG Qiang1, ZHANG Xiao-li1, YI Jun-ying1, QU Jin-bo2, YANG Cai-fu3

(1. School of Metallurgy and Materials Engineering,

Jiangsu University of Science and Technology (Zhangjiagang), Suzhou 215600, China;

2. Department of Plate and Strip, Jiangsu (Shagang) Institute of Research of Iron and Steel, Suzhou 215625, China;

3. Department of Structural Steels, Central Iron and Steel Research Institute, Beijing 100081, China)

Abstract: The tensile tests of steel/aluminum composite sheet were conducted at strain rate ranging from 1×10-4 s-1 to 1×10-2 s-1. It was aimed to study the deformation behavior and failure mechanism. The results show that a transition layer with thickness of about 8 μm and a few of intermetallic compounds Fe2Al5 and Fe4Al13 phases forms at the steel/aluminum roll-bonded interface. The strength of the composite sheet satisfies the mixing rule with the individual layers. The interface plays an important role in the strengthening of composite sheet. However, the bonding interface is prone to fracture due to microstructural defects. The failure of the interface and the strain hardening of the individual layer cause the stress-strain curve to fluctuate. High strain rate loading leads to the sharp break of interface layer and the obvious fluctuation of tensile curve. During the quasi-static tensile process, the cracks firstly initiate in the steel/aluminum interface, and the additional stress between the layers causes the cracks to grow and expands into aluminum layer. The steel layer subsequently necks and causes the composite sheet to fracture. By increasing the bonding strength of steel/aluminum interface, the deformation coordination and mechanical properties of the composite sheets can be improved.

Key words: steel/aluminum composite sheet; tensile test; bonding interface; fracture; mechanical properties

Foundation item: Project(51801080) supported by the National Natural Science Foundation of China; Project (2017JKDQN05) supported by the Youth Innovation in Jiangsu University of Science and Technology, China

Received date: 2020-08-11; Accepted date: 2021-01-22

Corresponding author: LI Xiao-bing; Tel: +86-512-56731518; E-mail: lxbing2009@126.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51801080);江苏科技大学青年科技创新项目(2017JKDQN05)

收稿日期:2020-08-11;修订日期:2021-01-22

通信作者:李小兵,副教授,博士;电话:0512-56731518;E-mail:lxbing2009@126.com