文章编号:1004-0609(2007)07-1119-05

微观组织对TA15 ELI钛合金损伤容限性能的影响

李士凯,惠松骁,叶文君,于 洋,熊柏青

(北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088)

摘 要:研究了TA15 ELI 钛合金43 mm厚板的等轴组织、双态组织和片层组织的室温拉伸性能、断裂韧性(KIC)以及疲劳裂纹扩展速率(da/dN)等损伤容限性能,通过金相显微镜观测了疲劳裂纹在各类组织中的扩展规律,讨论显微组织对该合金损伤容限性能的影响。结果表明:该合金等轴组织和双态组织的室温力学性能和疲劳裂纹扩展阻抗差别不大;相对等轴组织和双态组织而言,该合金片层组织在损失强度较小的前提下(Rm=992 MPa),合金断裂韧性提高,达到111 MPa?m1/2,同时该合金的疲劳裂纹扩展速率也大幅降低,其Paris公式拟合参数为:c=1.08×10-8,n=3.23,具有更好的损伤容限性能。

关键词:TA15 ELI钛合金;疲劳裂纹;扩展速率;断裂韧性;损伤容限

中图分类号:TG 146.23 文献标识码:A

Effects of microstructure on damage tolerance properties of ta15 eli titanium alloy

LI Shi-kai, HUI Song-xiao, YE Wen-jun, YU Yang, XIONG Bai-qing

(State Key Laboratory for Fabrication and Processing of Non-ferrous Metals,

General Research Institute for Non-ferrous Metals, Beijing 100088, China)

Abstract: The damage tolerance behavior of TA15 ELI alloy 43 mm plates with equiaxed, bi-model and lamellae microstructure were studied, including tensile properties, fracture toughness and fatigue crack propagation behavior. The effects of microstructure of TA15 ELI alloy on the damage tolerance were discussed. The results show that the equiaxed and bi-modal microstructures have the similar mechanical properties and fatigue crack propagation rate. The plate with lamellae microstructure has higher fracture toughness about 111 MPa?m1/2 and fatigue crack propagation resistance, and its strength lose is less compared with that of bi-modal microstructure, which indicates that the lamellar microstructure has better damage tolerance behavior.

Key words: TA15 ELI titanium alloy; fatigue crack propagation rate; fracture toughness; damage tolerance

随着人们认识的深化和断裂力学的发展,满足结构完整性要求的损伤容限设计准则已在民用和军用航空领域中得到广泛应用。结构损伤容限特性主要是指裂纹缓慢扩展特性和含裂纹结构剩余强度[1],裂纹缓慢扩展特性主要看裂纹扩展DK—da/dN曲线变化特性,结构剩余强度与材料断裂韧性有关。国外开发的具有高断裂韧性和低裂纹扩展速率的中强或高强损伤容限型钛合金已成功应用于民用和军用飞机的结构 件[2-5],该类合金主要为TC4 ELI和Ti-1023等[6-8]。目前国内在损伤容限型钛合金宽厚板的研制工作仍属空白。

TA15 ELI合金是在前苏联研制的TA15 (Ti-6Al- 2Zr-1Mo-1V)基础上,通过降低间隙元素(O、C、N、H等)方法获得的损伤容限型钛合金[9]。本文作者通过不同热处理制度获得3种TA15 ELI 合金43 mm厚板组织(等轴、双态组织和片层组织),主要研究微观组织对该合金损伤容限性能的影响,最终研究结果将为工厂实际大批量生产该类合金提供参考依据。

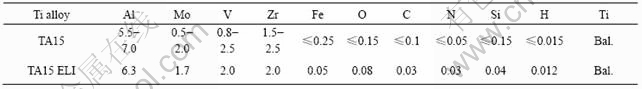

1 实验

TA15合金与TA15ELI合金的化学成分如表1所示。与传统TA15合金相比,TA15 ELI合金主要是降低了间隙元素C、N和O的含量,因为它们与钛形成固溶体后,使钛的晶格发生畸变,c轴增加量大于a轴增加量,导致轴比c/a增大,滑移系减少,阻碍了位错运动,尽管这将提高合金的强度,却大大损害了合金的疲劳裂纹扩展性能[10-11]。金相法测得该合金相变点为(960±5) ℃。实验选用TA15ELI钛合金43 mm厚板,先经过α+β两相区热加工,空冷(AC)至室温,随后分别采用940 ℃保温2 h((α+β)区上部退火)和990 ℃保温1 h(β区退火)热处理,空冷至室温,为了消除加工残余应力,所有试样又经过700℃保温8 h,空冷至室温。为了进行对比研究,实验中进行了800 ℃,2 h、AC((α+β)区下部退火)热处理。在室温和实验室环境下,分别测得拉伸、断裂韧性、冲击和疲劳裂纹扩展速率性能。采用HF、HNO3和H2O(体积比2?10?88)混合腐蚀济侵蚀10 s后,在Axiovert 200 MAT光学显微镜下观察金相组织和疲劳裂纹扩展通道。

2 结果及讨论

2.1 显微组织

图1所示为经不同条件处理后TA15 ELI合金43mm厚板的微观组织。800 ℃处于TA15 ELI合金(α+β)相区下部,空冷后获得了等轴组织(图1(a)),等轴α相平均直径约为30 μm。940 ℃处于(α+β)两相区上部,空冷后获得的组织中等轴α相所占比例约为43%,可以认为是双态组织[12](图1(b)),平均直径约16.2 μm,β转变组织中α板条呈交织或集束状分布,板条厚度约2~4 μm。990 ℃已进入β相区,保温1 h后空冷,获得片层组织(图1(c)),初始β晶粒尺寸约为665 μm,晶界α相宽度约为2 μm,β晶粒内部的α片层厚约 3 μm,部分α相在同一位向并行排列,呈现α集束形

图1 经不同条件处理后TA15 ELI合金43 mm厚板的微观组织

Fig.1 Microstructures of TA15 ELI alloy 43mm plate after different treatments: (a) 800 ℃, 2 h, AC; (b) 940 ℃, 2 h, AC+700 ℃, 8 h, FC; (c) 990 ℃, 1 h, AC+700 ℃, 8 h, FC

貌,宽约80 μm。

2.2 力学性能

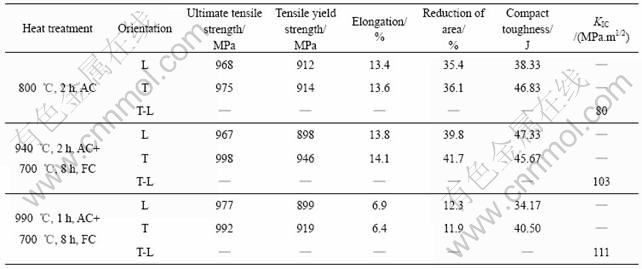

表2所列为TA15 ELI合金不同组织的力学性能测试结果。同一热处理制度下,沿轧制方向(L向)合金

表1 TA15钛合金与TA15 ELI合金成分对比

Table 1 Comparison of element content of commercial grade and ELI grade of TA15 (mass fraction, %)

表2 不同热处理后TA15 ELI合金43 mm厚板的力学性能

Table 2 Mechanical properties of TA15 ELI alloy 43 mm plates after different heat treatment

的强度要比横向(T向)低20 MPa左右,这是由于轧制过程中出现加工织构,而热处理很难消除这种织 构[13]。3种热处理制度对合金强度影响不大,双态组织和等轴组织的塑性和冲击值要明显高于片层组织,但等轴组织的断裂韧性低于双态组织,片层组织的断裂韧性最高。

片层组织的断裂韧性较高的原因主要如下:1) 由于晶界α的存在,使得晶间断裂比例减小;2) 在片层组织中,裂纹往往沿α/β界面扩展,因各个α集束取向不同,使裂纹扩展至集束边界后,继续扩展受到另一位向α集束的阻碍而被迫改变方向或分枝[14]。这样裂纹扩展遇到不同位向的α集束时,常改变方向,使裂纹路径曲折,增加了分枝及裂纹总长度,从而使断裂时吸收的能量变大,提高了合金的断裂韧性。在双态组织中含有较多的β转变组织,使得其断裂韧性高于完全等轴组织。在拉伸时,α/β界面上容易产生空洞,使片层组织中的空洞在较低应变下,即可达到临界尺寸,表现为其塑性低于双态组织的塑性。

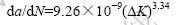

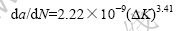

2.3 裂纹扩展速率

在应力比为0.1,加载频率为10 Hz时,TA15 ELI合金3种组织的?K—da/dN关系曲线如图2所示,按Paris公式拟合结果分别如下:

等轴组织

双态组织

片层组织

由图2所示的拟合结果可知,在Paris区的(裂纹扩展第二阶段)片层组织较等轴组织和双态组织具有更高的疲劳裂纹扩展抗力,而疲劳裂纹在等轴组织和双态组织中扩展时差别不大。

疲劳裂纹在TA15 ELI合金各种组织中的扩展路径如图3所示。对于双态组织,在单向拉应力作下,裂纹扩展一般不会穿过初生等轴α相而是绕过,裂纹主要在基体β转变组织中扩展。而在循环交变载荷作用下,与单向拉伸时不同,疲劳裂纹基本沿水平方向扩展,遇到初生α相时,裂纹可以直接穿过初生α相向前扩展,疲劳裂纹扩展路径如图3(a)所示。对于等

图2 TA15 ELI合金3种组织在Paris区疲劳裂纹扩展数据比较

Fig.2 Comparison of fatigue crack propagation of bi-model, fully equiaxed and lamellae microstructures of TA15 ELI alloy in Paris field

图3 疲劳裂纹在TA15 ELI合金3种组织中的扩展路径

Fig.3 Comparison of fatigue crack propagation path in bi-model(a), equiaxed(b) and lamellae microstructure(c) of TA15 ELI alloy

轴组织也出现类似现象,结果如图3(b)所示。Peters和Lutjering[15]认为,疲劳裂纹能否穿过等轴α相,除与应力水平、应力方向有关外,还取决于β转变组织和等轴α相的强度。由于α相稳定元素(Al和O等)在等轴α相内富集,这不仅强化了等轴α相,而且也弱化了β转变组织基体的强度,使得等轴α相的强度高于β转变组织的。对于片层组织,疲劳裂纹扩展路径比较曲折,主要以垂直和平行于片状α相的长轴方向扩展。Jin和Mall[16]在研究Ti6Al2Sn4Zr2Mo0.1Si合金时,也发现了类似情况。由于α相和β相之间存在着Burgers关系,滑移可以顺利地穿过,但由于这种组织中有不同位向分布的α集束存在,阻碍滑移穿过,降低了滑移长度,使得裂纹扩展路径比较曲折[17-18]。

3 结论

1) TA15 ELI合金厚板等轴组织、双态组织和片层组织强度相差不大,前两者的塑性优于片层组织,但等轴组织的断裂韧性低于双态组织的,片层组织获得最高的断裂韧性。

2) 该合金片层组织抵抗疲劳裂纹扩展性能优于双态组织和等轴组织。疲劳裂纹在双态组织中有部分路径穿过等轴α相,其余主要穿过β转变组织和沿等轴α相界面扩展,路径比较平直。疲劳裂纹在片层组织中扩展时,路径曲折,主要以平行或垂直于α片长轴方向扩展。总体上讲,片层组织相对等轴组织和双态组织具有更好的损伤容限性能。

REFERENCES

[1] 曹春晓. 选材判据的变化与高损伤容限钛合金的发展[J]. 金属学报, 2002, 38(增1): 4-11.

CAO Chun-xiao. Change of material selection criterion and development of high damage-tolerance titanium alloy[J]. Acta Metallurgica Sinica, 2002, 38(S1): 4-11.

[2] Swift T. Damage tolerance capability[J]. International Journal of Fatigue, 1994, 16(1): 75-96.

[3] Jarfall L. Verification of the damage tolerance of a fighter air craft[J]. Fatigue, 1994, 16: 67-74.

[4] AMS 4905C. Titanium alloy, damage-tolerant grade plate 6Al-4V beta annealed[S].

[5] Duret N. Titanium for damage tolerance application on A380[C]//Lutjering G, Albrecht J. The 10th conference on titanium. Hamburg: TMS, 2003: 2667-2671.

[6] Shankar P S, Ravichandran K S. Fatigue behavior of titanium alloys[M]. Chicago: TMS, 1998: 135.

[7] Yoder G R, Cooley L A, Boyer R R. Microstructure fracture toughness and fatigue crack growth rate in titanium alloys[M]. ATMS-AIME Marriott, 1987: 209.

[8] Niinomi M, Akahori T, Fukunaga K I, Eylon D. Fatigue behavior of titanium alloys[M]. Chicago: TMS, 1998: 307.

[9] 熊柏青,惠松骁. 损伤容限钛合金研究进展[J]. 稀有金属材料与工程, 2005, 34: 130-133.

XIONG Bai-qing, HUI Song-xiao. Progress in study of damage tolerant titanium alloys[J]. Rare Metal Materials and Engineering, 2005, 34: 130-133.

[10] 李兴无,刘瑞民,沙爱学,储俊鹏,张旺峰,马济民. 显微组织对TA15合金疲劳性能的影响[J]. 金属学报,2002,38:280-281.

LI Xing-wu, LIU Rui-min, SHA Ai-xue, CHU Jun-peng, ZHANG Wang-feng, MA Ji-min. Effect of microstructure on fatigue properties of TA15 alloy[J]. Acta Metallurgica Sinica, 2002, 38: 280-281.

[11] Vanghan F, Elengkinsop A, Holl A. The effect of oxygen content on the mechanical properties of an α+β titanium alloy Ti-4Al-2Sn-4Mo-0.5Si (IMI550)[C]//Kimura H, Izumi O. The 4th conference on titanium. Kyoto: TMS, 1980: 1645-1651.

[12] 张宝昌. 有色金属及其热处理[M]. 西安: 西北工业大学出版社,1993: 107.

ZHANG Bao-chang. Heat-treatments of non-ferrous metals[M]. Xi’an: Northwest Poly Technical University Press, 1993: 107.

[13] Lutjering G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys[J]. Mater Sci Eng A, 1998, A243: 32-35.

[14] Hall A. Fatigue crack initiation in alpha-beta titanium alloys[J]. Int J Fatigue, 1997, 19: S23-37.

[15] Peters O, Lutjering G. Comparison of the fatigue and fracture of α+β and β titanium alloys[J]. Metall Mater Trans A, 2001, A32: 2805-2818.

[16] Jin O, Mall S. Effects of microstructure on short crack growth behavior of Ti-6Al-2Sn-4Zr-2Mo-0.1Si alloy[J]. Mater Sci Eng A, 2003, A359: 356-367.

[17] Suri S, Viswanathan B, Neeraj T, Hou D H, Mills M J. Room temperature deformation and mechanisms of slip transmission in oriented single-colony crystals of an α/β titanium[J]. Acta Materialia, 1999, 47: 1019-1034.

[18] Savage F, Tatalovich J, Zupan M, Hemker K J, Mills M J. Deformation mechanisms and microtensile behavior of single colony Ti-6242Si[J]. Mater Sci Eng A, 2001, A319/321: 398-403.

(编辑 龙怀中)

收稿日期:2006-07-18;修订日期:2007-03-29

通讯作者:李士凯,博士研究生;电话:010-82241161-223; E-mail: lsk786150@163.com