文章编号:1004-0609(2008)08-1527-07

钨钛粉末的轴对称爆炸压实

张晓立1, 2,王金相1,贾宪振2,孙钦密2,刘家骢2

(1. 南京理工大学 瞬态物理国家重点实验室,南京 210094;

2. 南京理工大学 化工学院工程力学系,南京 210094)

摘 要:对钨钛粉末进行不同装药比的柱状爆炸压实实验,利用光学显微镜得到压实件轴线附近的显微照片;借助于LS-DYNA3D程序对爆炸压实过程进行数值模拟,给出试件中的压力云图、轴线上选定单元的压力时程曲线、中心截面选定节点的径向位移曲线。结合实验和数值模拟的结果分析装药比(E/M)对实验密度的影响及马赫孔的成因。结果表明:利用爆炸压实法可获得高密度(>98%理论密度)的试件;装药比是影响压实质量的重要参数,随着装药比的增大,试件密度呈增大的趋势,但装药比过大,会在压实件中产生马赫孔,致使压实质量下降。数值模拟预测结果与实验检测结果吻合良好。

关键词:钨钛粉末;爆炸压实;马赫孔;装药比;数值模拟

中图分类号:TG146.4 文献标识码:A

Axial symmetry explosive compaction of W-Ti powders

ZHANG Xiao-li1, 2, WANG Jin-xiang1, JIA Xian-zhen2, SUN Qin-mi2, LIU Jia-cong2

(1.State Key Laboratory of Transient Physics, NUST, Nanjing 210094, China;

2. Engineering Mechanics Department of Institute of Chemical Technology, NUST, Nanjing 210094, China)

Abstract: Axial symmetry explosive compaction was investigated for W-Ti powders at different mass ratios of explosive to mixed powders (E/M). The micrographs near the axis of the specimens were taken by the light microscope. Numerical simulation of explosive compaction was carried out to recur LS-DYNA3D program. Pressure cloud pictures of the set-up for explosive compaction, pressure time-history curve of the certain elements of the axis of the sample and the radial displacement of the certain nodes of the center cut of it were protracted. Influences of E/M on specimen density and the formation of mach-hole were analyzed. The results show that the specimens with high density over 98% (T. D) can be obtained by explosive compaction of powders. E/M is an important parameter that affects the specimen quality. With increasing E/M, the density of the specimens increases firstly, and then the mach-hole appears that debases the compact quality. The prediction results of numerical simulation show a good agreement with the experimental measurements.

Key words: tungsten-titanium powders; explosive compaction; mach-hole; mass ratio of explosive to mixed powders; numerical simulation

钨合金具有一系列优异的物理力学性能,如强度、硬度高,延展性、韧性好,热膨胀系数小,导电、导热性好,抗腐蚀和抗氧化性好,机加工和可焊性好 等[1]。在国防军工、航空航天、电子信息、能源、冶金和机械加工等领域具有十分广泛的用途,在国民经济中占有重要地位。传统的钨合金是以钨为基体,加入少量钛、镍、铁、铜等合金元素经模压成形和液相烧结而成[2],该工艺存在的主要问题是, 元素粉末的机械混合难以将各元素粉末混合得很均匀,易造成成分的不均匀性。另外液相烧结温度高,容易产生变形与晶粒粗化,这对产品的尺寸精度控制和合金性能非常 不利。

爆炸粉末压实是利用炸药爆轰产生的能量,以激波的形式作用于金属或非金属粉末,在瞬态、高温、高压下发生压实的一种材料加工或合成的新技术,是爆炸加工领域的第三代研究对象。作为一种高能率加工的新技术,爆炸粉末压实具有压实时间短(一般为几十微秒左右)、作用压力大(可达0.1~100 GPa)的特征。与常规压实方法[3?4]相比,有着其独特的优点:1) 具备高压性,可以烧结出近乎密实的材料;2) 具备快熔快冷性,有利于保持粉末的优异特性。爆炸压实可在瞬间产生一般机械装置不能达到的高压, 可使通常难于致密化的粉体达到很高的致密度[5?6]。由于爆炸压实在极短的时间(微秒量级)内完成的,因此复合界面几乎没有扩散或仅有程度很小(100 nm量级)的扩散,所以对机械合金化工艺制备的合金粉进行爆炸压实, 不仅可以克服两相偏析, 而且由于在极短时间内爆炸合成,晶粒来不及长大,可以保留机械合金化制得的纳米晶的初始特征[7?8]。除上述特点外,与一般爆炸加工技术一样,爆炸粉末压实还具备经济、设备简单的特点,正广泛地用于精细陶瓷[9]、金属间化合物[10?11]、金属基复合材料[12]、纳米块体[11?13]以及微晶、准晶、非晶等亚稳合金[14]的粉末压实研究中。

国外KECSKES[15]等采用热爆炸压实的方法得到了钨钛合金,本文作者将钨钛粉末组成合金体系,并采用爆炸压实的方法对其进行了压实。采用叠加原理对钨钛混合粉末参数进行计算,并在此基础上借助于LS-DYNA有限元程序对压实过程进行三维数值模拟,从理论上分析应力波动及马赫孔的成因。

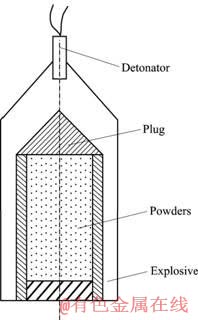

1 钨钛粉末的爆炸压实实验

实验装置采取单管接触爆炸压实装置,如图1所示,将待压实的钨粉和钛粉混合后装在低碳钢包套内,采用4组不同壁厚的包套,每组两个试件,整个装置放置在拍实的沙堆平面上,炸药采用2号岩石硝铵炸药,引爆后即获得爆炸压实试件。根据实验要求设计相关的炸药参数,粉末粒径,装药比(炸药质量与粉末的质量的比值,E/M)等参数。

图1 粉末单管爆炸压实装置

Fig.1 Columned set-up for explosive compaction of powders

1.1 粉末制取

将钨粉和钛粉按70︰30的质量比混合,使用XQM?2L变频行星式球磨机充分混合,这个过程持续20 h,以获得均匀一致的混合粉末并改善粉末的不规则形状。粒径小于75 mm,钛粉粒度分布为正态分 布[16],而钨粉及钨钛混合粉末的粒度分布接近对数正态分布,钨钛粉末的纯度均达到99.9%以上。

1.2 实验参数

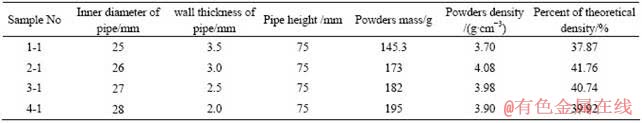

实验的各项参数如表1和表2所列。

表1实验装置及粉末参数

Table 1 Parameters of set-up and powders for experiments

表2 爆炸压实装药参数及压实后试件密度

Table 2 Charge parameters of explosive consolidation and the density of the samples

1.3 实验结果及分析

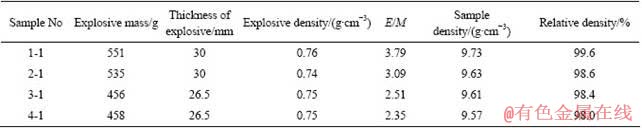

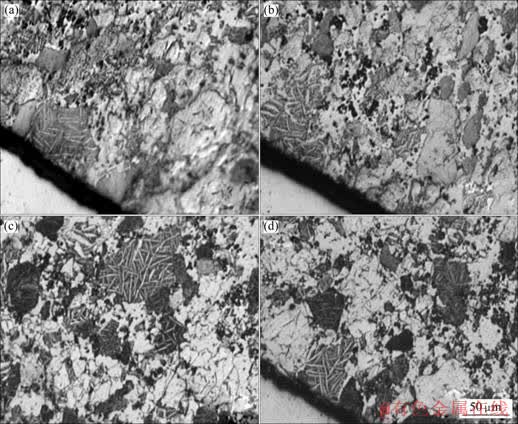

图2所示为压实件边缘附近的显微照片。由图可见,试件中钨钛粉末颗粒分布均匀,致密度均较高。将爆炸压实后的试件截取中间部分进行分析。应用阿基米德法测得4组试件的密度,均在9.50 g/cm3以上,占理论密度的98%以上,说明适当控制爆炸参数,可以使压实试件的密度接近理论密度值。图3所示为对应的压实件轴线附近的显微照片。由图3可知,随着装药比E/M的增大,马赫孔有增大的趋势,试件4-1装药比最小且无马赫孔。

图2 4组试件边缘附近显微照片

Fig.2 Micrographs near brim of four samples: (a) Sample 1-1; (b) Sample 2-1; (c) Sample 3-1; (d) Sample 4-1;

随着装药比的增大,试件密度呈增大的趋势,而压实的质量有下降的趋势,因此应优化爆炸参数,兼顾压实件的质量和密度。

2 爆炸压实过程数值模拟

2.1 参数确定

使用LS-DYNA3D对爆炸压实实验进行数值模拟。炸药的材料模型选用*MAT_HIGH_EXPLOSIVE_ BURN,状态方程采用*EOS_JWL,具体参数如表3[17]所列。

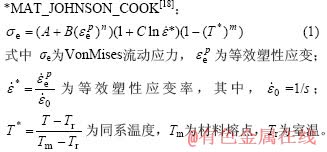

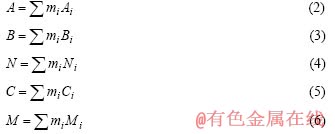

钨钛粉末的材料模型采用能够描述应变率效应和温度效应的Johnson-Cook本构模型,即

图3 4组试件轴线附近显微照片

Fig.3 Micrographs near axis of four samples: (a) Sample 1-1; (b) Sample 2-1; (c) Sample 3-1; (d) Sample 4-1

表3 2号岩石硝铵炸药JWL状态方程中的参数

Table 3 Parameters for JWL equation state of 2# ammonium nitrate

本实验中粉末为混合粉末,分别查阅钨粉[19]及钛粉[20]的Johnson-Cook本构参数,利用叠加原理,得到混合粉末的Johnson-Cook本构参数,即

由公式(2)~(6)得到A=283.6 MPa,B=833.2 MPa,N=0.109,C=0.042,M=0.45。

状态方程采用LS-DYNA中*EOS_TABULATED_ COMPACTION列表式压实模型,材料压力定义为

(7)

(7)

式中 εV是体应变,εV=ln(V/V0),V是材料的比容(材料密度的倒数),V0是材料的初始比容。式(7)在应用时一般采用以下简化形式[20?21]:p=C(εV),即关键字卡片中γ=0,初始内能E0=0,初始比容V0=1.0。另需填入10组对应的εV和C(εV),由此定义材料的p?V的关系。上述参数来自文献[22?23],单位制采用g?cm?μs。

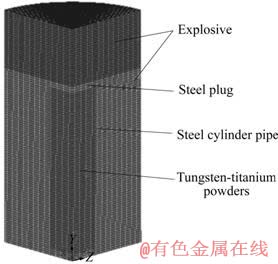

2.2 数值模拟

建立的有限元模型如图4所示,由于锥形塞对爆炸压实实验影响很小[18],因而对压实装置进行了简化,并考虑到计算量,建立爆炸压实装置的四分之一有限元模型,施加对称边界。该模型包括炸药、上端塞、钨钛粉末及钢筒4个部分,采用Lagrange接触算法,定义了各部分之间的相互接触。接触采用*CONTACT_SLIDING_ONLY_PENALTY。

图4 钨钛粉末爆炸烧结的有限元模型

Fig.4 FEM for explosive consolidation of mixed tungsten- titanium powders

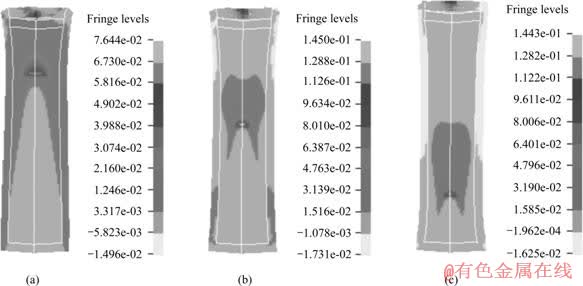

炸药分为两部分,一部分位于粉末顶部,为实心圆柱装药,另一部分包裹在钢筒周围,为空心圆柱装药,采用点起爆方式,起爆点位于实心圆柱顶面圆心,炸药起爆后,在实心圆柱炸药中形成爆轰波,当其传播到两部分炸药分界面时,空心圆柱炸药起爆,在钢筒侧壁形成滑移爆轰。图5所示为试件1-1爆炸压实装置中的压力云图,其中图5(a)~(c)所示分别为起爆后12、28和45 μs时刻装置中的压力分布,直观地再现了试件中爆轰波的传播过程。

图5 爆炸压实装置中的压力云图

Fig.5 Pictures of pressure distribution in set-up of explosive consolidation: (a) 12 μs; (b) 28 μs; (c) 45 μs

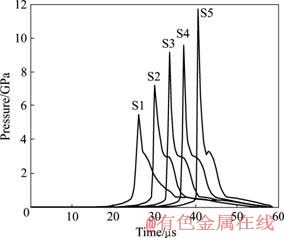

图6所示为试件1-1轴心不同位置处的压力时程曲线。在钨钛粉末中心轴线上从上至下依次等间距 (1 cm)选取5个单元S1、S2、S3、S4和S5,由曲线可以看出,S1~S5的压力峰值逐渐增加,S1的压力峰值为5.5 GPa,S5的压力峰值增至11.7 GPa。

图6 试件1-1的轴心处选定单元的压力—时程曲线

Fig.6 Pressure—time-history curves of certain elements near axis for sample 1-1

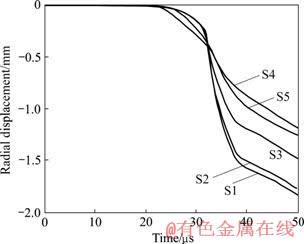

图7所示为试件1-1中心截面选定节点的径向位移。在试件1-1的中心截面,沿半径方向,从圆心到圆上,先密后疏依次选取节点S1、S2、S3、S4和S5,由曲线明显可以看出,各点位移依次增大,S1的位移最大,为?1.6 mm,这说明该试件的马赫孔半径即为1.6 mm,同理得到试件2-1、3-1和4-1的马赫孔半径大小分别为1.10、0.36和0.001 mm,数值模拟与实验结果吻合良好。

图7 试件1-1中心截面选定节点的径向位移

Fig.7 Radial displacement of certain nodes of center cut of sample 1-1

3 马赫孔成因分析

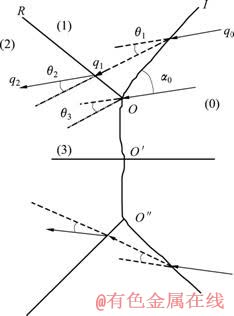

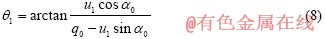

一般认为,粉末爆炸压实中产生的马赫孔是对称斜入射冲击波在轴线上发生马赫反射所形成的。马赫杆是过度压缩的强激波,图8所示为马赫反射示意图,物质从0区经过两次压缩到达2区,当入射波阵面与对称轴夹角大于临界角时,出现脱体激波,入射波阵面I与反射波阵面R的交点O’上移到O,形成具有强间断面的马赫波OO’。O点位入射波、反射波和马赫波的交点,即三波点,OO”为马赫杆[18]。OO’是一曲面,它上面的各点切线与刚性壁面的夹角在α0和90?之间,在O点处波阵面与刚性壁面夹角为α0,在O处波阵面与刚性壁面垂直。当激波以恒定速度在粉体中传播时,入射波成圆锥形,碰撞夹角为通过爆轰波入射求得的2倍的入射角偏转角,假定为2α1,而实际情况是激波在衰减与柱面的会聚作用下以2α0相碰,二者并不一定相等。激波过强时,就会形成马赫孔,这时2α0>2α1。对于爆炸压实来说,如何避免马赫杆是我们所关心的问题。入射激波的折转角θ1过大是发生马赫碰撞的主要原因,而由公式:

图8 激波的马赫反射

Fig.8 Mach reflect of shock wave

可知控制θ1就需要控制入射波速q0和入射角α0。对于特定的炸药,选择合适的装药比(E/M)是调节α0大小的有效手段。对于一定质量的粉末而言,装药量过大,激波的会聚作用增强,将导致α0过大,发生马赫碰撞,产生马赫孔;过小则导致压制不完全[22]。

由上文分析可知,E/M是决定压制是否均匀的主要因素,而E/M值的确定,主要通过实验的方法。本研究通过数值模拟的方法成功地得到了马赫孔随装药比的变化趋势,因此在今后的研究中,通过实验并辅以数值模拟的方法可以更为有效地确定合理的装药比,为得到高质量的压实体提供有价值的参考依据。

4 结论

1) 根据混合粉末各组分的质量比,利用叠加原理,得到混合粉末的本构参数,可较为准确地实现对混合粉末爆炸压实的数值模拟。

2) 装药比是影响压实质量的重要参数,装药比过小会引起压制件致密度不够,随着装药比的增大,试件密度呈增大的趋势,但装药比过大,会在压实件中产生马赫孔,使压实质量下降。因此应合理选择该参数,兼顾烧结件的质量和密度。

3) 对混合粉末爆炸压实的数值模拟研究方法是一次探索,通过与实验结果对比分析,表明其对实际的爆炸压实实验具有较好的预测,将为得到高密度且无马赫孔的高质量压实件提供重要的参考依据。

REFERENCES

[1] 赵慕岳, 范景莲, 王伏生. 我国钨基高密度合金的发展现状与展望[J]. 中国钨业, 1999, 14(5/6): 38?42.

ZHAO Mu-yue, FAN Jing-lian, WANG Fu-sheng. Present development and prospect of high-density tungsten-based alloy in our courtry[J]. China Tungsten Industry, 1999, 14(5/6): 38?42.

[2] 叶途明, 易健宏, 李丽娅. 高比重钨合金研究的新进展[J]. 材料导报, 2003, 17(12): 15?18.

YE Tu-ming, YI Jian-hong, LI Li-ya. New advance in study of tungsten heavy alloys[J]. Materials Review, 2003, 17(12): 15?18.

[3] 王志法, 姜国胜, 刘正春. 钨的超高压成型与低温烧结[J]. 稀有金属材料与工程, 1998, 27(5): 290?293.

WANG Zhi-fa, Jiang GUO-sheng, LIU Zheng-chun. Ultrapressure forming and low-temperature sintering of tungsten [J]. Rare Metal Materials and Engineering, 1998, 27(5): 290?293.

[4] 陈飞雄, 强劲熙, 贾佐诚. 热等静压法制取复合硬质合金轧辊[J]. 稀有金属材料与工程, 1998, 27(3): 177?181.

CHEN Fei-xiong, QIANG Jin-xi, JIA Zuo-cheng. Study of a composite hard metal-roller made by HIP diffusion bonding[J]. Rare Metal Materials and Engineering, 1998, 27(3): 177?181.

[5] BLAZYNSKI T Z. Explosive welding, forming and compaction [M]. Essex, England: Applied Science Publisher Ltd, 1983: 9.

[6] 郑子樵, 李益民, 梁叔全. 爆炸固结加自蔓延高温合成Ti/ Al2O3梯度功能材料[J]. 中国有色金属学报, 1996, 6(4): 73?77.

ZHENG Zi-qiao, LI YI-min, LIANG Shu-quan. Functional gradient materials Ti/ Al2O3 prepared by explosive compaction plus SHS method[J]. The Chinese Journal of Nonferrous Metals, 1996, 6(4): 73?77.

[7] HUANG S, MASHIMO T. Preparation of Fe-W system metastable alloy bulk body by mechanical alloying and shock compression[J]. Journal of Materials Processing and Technology, 1999, 85(1/3): 135?137.

[8] 李金平, 罗守靖, 纪 松. 爆炸烧结CuCr触头材料的性能[J]. 中国有色金属学报, 2001, 11(S1): 98?101.

LI Jin-ping, LUO Shou-jing, JI Song. Characteristics of CuCr contact materials made by explosive sintering[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(S1): 98?101.

[9] 张越举, 李晓杰, 闫鸿浩. 预热爆炸压实烧结纳米ITO陶瓷粉末[J]. 稀有金属材料与工程, 2007, 36(9): 1681?1684.

ZHANG Yue-jü, LI Xiao-jie, YAN Hong-hao. ITO nanopowders by pre-heat explosive consolidation sintering[J]. Rare Metal Materials and Engineering. 2007, 36(9): 1681?1684.

[10] 李晓杰, 赵 铮, 曲艳东. 爆炸烧结制备CuCr合金[J]. 爆炸与冲击, 2005, 25(3): 251?254.

LI Xiao-jie, ZHAO Zheng, QU Yan-dong. Producing CuCr alloy by explosive sintering[J]. Explosion and Shock Waves, 2005, 25(3): 251?254.

[11] 李晓杰, 王占磊, 谢兴华. WC/Al_2O_3颗粒增强Cu基复合材料爆炸粉末烧结实验研究[J]. 爆炸与冲击, 2006, 26(4): 356?360.

LI Xiao-jie, WANG Zhan-lei, XIE Xing-hua. Experimental study on explosive compaction of WC/Al_2O_3/Cu powders[J]. Explosion and Shock Waves, 2006, 26(4): 356?360.

[12] SIVAKUMAR K, BHAT T B, RAMAKRISHNAN P. Effect of process parameters on the densification of 2024Al-20vol.% SiCp composites fabricated by explosive compaction[J]. Journal of Materials Processing and Technology, 1998, 73(1/3): 268?275.

[13] TANIMOTO H, PASQUINI L, PRUMMER R. Self-diffusion and magnetic properties in explosive densified nanocrystalline Fe[J]. Scripta Materials, 2000, 42(10): 961?966.

[14] SHAO Bing-huang, LIU Zhi-yue, ZHANG Xiao-ti. Explosive consolidation of amorphous cobalt-based alloys[J]. Journal of Materials Processing and Technology, 1999, 85(1/3): 121?124.

[15] KECSKESA LASZLO J, HALL IAN W. Microstructural effects in hot-explosively-consolidated W-Ti alloys[J]. Journal of Materials Processing and Technology, 1999, 94(3): 247?260.

[16] 陆厚根. 粉体技术导论[M]. 上海: 同济大学出版社, 1998: 25.

LU Hou-gen. Introduction of powder technology[M]. Shanghai: Tongji University Press, 1998: 25.

[17] 王建民, 朱 锡, 刘润泉. 爆炸焊接三维数值模拟[J]. 焊接学报, 2007, 28(5): 109?112.

WANG Jian-min, ZHU Xi, LIU Run-quan. Three dimensional numerical simulation for explosive welding[J]. Transaction of the China Welding Institution, 2007, 28(5): 109?112.

[18] 赵 铮. 颗粒增强铜基复合材料的爆炸压实和数值模拟研究[D]. 大连: 大连理工大学, 2007: 61?86.

ZHAO Zheng. Research on explosive compaction and numerical simulation of particle reinforced copper matrix composites[D]. Dalian: Dalian University of Technology, 2007: 61?86.

[19] LENNON A M, RAMESH K T. The thermoviscoplastic response of polycrystalline tungsten in compression[J]. Materials Science and Engineering A, 2000, 276: 9?21.

[20] STANLEY P M. LASL shock Hugoniot data[M]. Los Angeles: University of California Press, 1980: 127.

[21] BOADE R R. Compression of porous copper by shock waves[J]. Journal of Applied Physics, 1986, 59(6): 1962?1967.

[22] 孙钦密. 混合粉末的爆炸烧结技术研究[D]. 南京: 南京理工大学, 2006: 31?32.

[23] SUN Qin-mi. The research of explosive consolidation technology of mixed-powder[D]. Master dissertation of Nanjing: Nanjing University of Science and Technology, 2006: 31?32.

基金项目:国防应用基础研究计划资助项目(A2620061131);“十一五”兵器预研支撑基金资助项目(62301110510);南京市科技计划资助项目(200704019)

通讯作者:王金相,讲师,博士;电话:025-84315276;E-mail: wjx@mail.njust.edu.cn

(编辑 何学锋)