文章编号:1004-0609(2012)09-2500-08

矩形断面铜包铝复合材料的水平连铸直接复合成形

吴永福1,刘新华1,谢建新1,王连忠2,董晓文2

(1. 北京科技大学 材料先进制备技术教育部重点实验室,北京 100083;

2. 烟台孚信达双金属股份有限公司,烟台 264118)

摘 要:制备断面尺寸为50 mm×30 mm、铜包覆层厚度为3 mm的矩形断面铜包铝复合材料,研究结晶器长度、拉坯速度、芯管长度和一次冷却水流量对矩形断面铜包铝复合材料水平连铸直接复合成形过程的影响。结果表明:当连铸结晶器长度为150 mm、芯管长度为125 mm时,较为合理的拉坯速度范围为75~90 mm/min;当拉坯速度过慢时,铝液的填充不连续,导致芯部铝的收缩或冷隔等缺陷;当拉坯速度过快时,铜铝界面反应严重;当拉坯速度为75 mm/min 时,合理的一次冷却水流量为700 L/h,一次冷却水流量大于1 000 L/h导致铝液填充不连续,一次冷却水流量小于400 L/h则导致铜铝界面反应加剧。通过检测芯管出口位置处的石墨内衬温度变化可有效监控铝液的填充行为以及连铸过程的稳定性。

关键词:铜包铝;复合材料;矩形断面;水平连铸

中图分类号:TG249.7 文献标志码:A

Copper cladding aluminum composite materials with rectangle

section fabricated by horizontal core-filling continuous casting

WU Yong-fu1, LIU Xin-hua1, XIE Jian-xin1, WANG Lian-zhong2, DONG Xiao-wen2

(1. Key Laboratory for Advanced Materials Processing, Ministry of Education, University of Science and Technology

Beijing, Beijing 100083, China; 2. Yantai Fisend Bimetal Co., Ltd., Yantai 264118, China)

Abstract: Copper cladding aluminum (CCA) composite materials with the section dimensions of 50 mm×30 mm and the sheath thickness of 3 mm were fabricated by horizontal core-filling continuous casting (HCFC) technology. The effects of the crystallizer length, withdrawing speed, mandrel tube length and flux of the primary cooling water were studied. The results show that when the crystallizer length is 150 mm and the mandrel tube length is 125 mm, the rational withdrawing speed is 75-90 mm/min. Too low withdrawing speed leads to the discontinuous filling process of liquid aluminum, which causes shrinkage or cold shuts. Conversely, too high withdrawing speed results in serious interface reaction between copper and aluminum. At the withdrawing speed of 75 mm/min, the rational primary cooling water is 700 L/h. The flux of primary cooling water above 1 000 L/h leads to the discontinuous filling process of the liquid aluminum, but the flux of primary cooling water below 400 L/h leads to severe interface reaction. The filling behavior of the liquid aluminum and the stability of the continuous casting can be controlled by monitoring the temperature variation of the graphite mould at the position corresponding to the outset of the mandrel tube.

Key words: copper cladding aluminum; composite materials; rectangle section; horizontal continuous casting

基金项目:国家高技术研究发展计划资助项目(2009AA03Z532)

收稿日期:2011-08-12;修订日期:2011-11-09

通信作者:谢建新,教授,博士;电话:010-62332254;E-mail: jxxie@mater.ustb.edu.cn

铜包铝复合材料(CCA)以纯铝为芯体,外层包覆纯铜,兼具铜和铝的优点,并具有低密度、低成本和易钎焊等特点[1-2]。导体在传输交变电流时的“趋肤效应”[3],使得铜包铝复合材料在高频信号传输和大电流输送方面的应用前景广阔。铜包铝圆线已在通信电缆等领域获得了较广泛应用,而矩形断面的铜包铝电力扁排由于可替代现有纯铜扁排应用于母线槽、控制柜、高低压开关柜等行业,实现大规模以铝节铜,因此,日益受到人们的重视[4-6]。

铜包铝复合材料制备技术的研究和开发较为活跃,迄今已发展了多种铜包铝圆线制备工艺,包括包覆焊接法[7-8]、轧制压接法[9-10]和静液挤压法[11-12]等,但这些工艺存在流程较长和成材率较低等问题,且难以制备电力扁排类具有较大断面尺寸的产品。

水平连铸直接复合成形(HCFC)是谢建新等[13]开发的制备铜包铝复合材料的新工艺,具有流程短、效率高及复合界面可达到冶金结合等优点,为制备铜包铝电力扁排等异形断面复合导体提供了新的途径。在前期研究工作中,采用该新工艺已制备了性能良好的d 30 mm铜包铝圆形棒坯[14],并结合轧制、拉拔等加工方法制备了高性能铜包铝复合电力扁排[15-16]。由于圆坯具有复合模具结构简单、温度场易于控制等特点,采用HCFC工艺最适合于制备圆形断面复合棒坯,但从后续扁排类产品的加工成形考虑,与圆形断面坯料相比,矩形断面坯料具有后续加工过程更简便、变形应力状态更均匀、加工后平直度更易调控等特点。然而,非圆形断面坯料由于断面不具备中心对称性的特点,在水平连铸直接复合成形时的传热过程更为复杂,对制备工艺控制的要求更高。

为此,本文作者研究矩形断面铜包铝复合材料的水平连铸成形过程,以截面宽度为50 mm、厚度为30 mm、铜包覆层厚度为3 mm的矩形断面铜包铝复合材料为对象,分析结晶器长度(L)、拉坯速度(v)、一次冷却水流量(Q1)和芯管长度(L2)等工艺参数对矩形断面铜包铝水平连铸成形过程的影响。

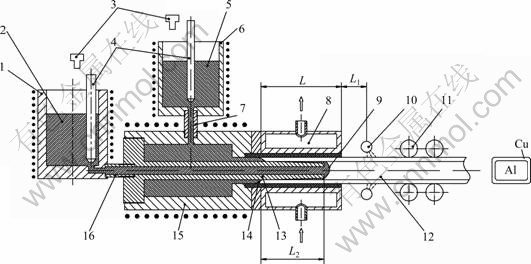

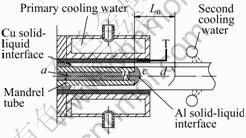

1 实验

矩形断面铜包铝复合材料的水平连铸直接复合成形工艺原理如图1所示。其工艺过程如下:复合连铸开始时,铜液在位于结晶器内的矩形芯棒和矩形铸模之间先凝固形成矩形铜管,并通过牵引机构连续引出。矩形芯棒带有导流孔(以下简称芯管),在连铸铜管的同时,将铝液通过芯管充入铜管中,通过结晶器的一次冷却和喷水二次冷却作用,控制铝的凝固过程以及铜铝之间的界面反应,从而连续拉铸铜包铝复合矩形坯。连铸过程中铜液、铝液和复合模具的温度由控温装置进行控制。

纯铜(T2)和纯铝(L2)分别采用感应电炉和电阻炉进行熔化,复合模具采用感应加热。实验时复合模具保温温度(tc)、铜液温度(tCu)和铝液温度(tAl)保持恒定,分别改变结晶器长度(L)、芯管长度(L2)、拉坯速度(v)和一次冷却水流量(Q1)等参数,研究各参数对矩形断面铜包铝复合材料水平连铸直接复合成形过程的影响。所制备的矩形断面铜包铝复合材料的规格为50mm×30 mm×3 mm。采用线切割将复合铸坯沿连铸方向(纵向)和垂直于连铸方向(横向)剖切,观察其内部宏观形貌。

图1 矩形断面铜包铝水平连铸直接复合成形工艺原理图

Fig. 1 Schematic diagram of HCFC processing principle for fabricating CCA composite materials with rectangle section: 1—Molten aluminum holding furnace; 2—Liquid aluminum; 3—Thermal couple; 4—Stopper; 5—Liquid copper; 6—Molten copper holding furnace; 7—Runner; 8—Crystallizer; 9—Solidification front of liquid aluminum; 10—Secondary cooler; 11—Pinch rolls; 12—Composite casting rod; 13—Mandrel tube; 14—Solidification front of liquid copper; 15—Composite mold; 16—Runner; L—Length of crystallizer; L1—Distance between second cooling water and outlet of crystallizer; L2—Length of mandrel tube

2 结果与讨论

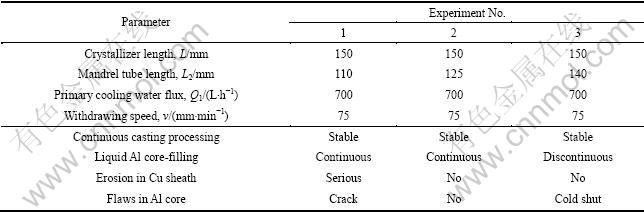

2.1 结晶器长度的影响

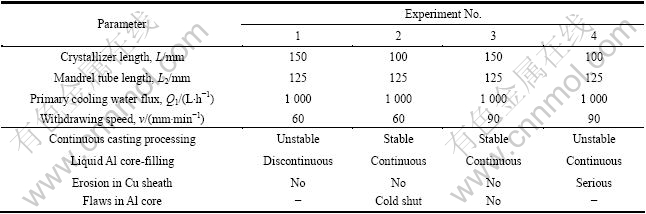

结晶器使铜液先凝固成包覆层铜管,并对充填进入铜管的铝液进行一次冷却,与二次冷却水配合,控制铝芯的凝固,实现复合铸坯的成形。由于结晶器既对铜层的凝固有直接影响,也对芯部铝的凝固有影响,因此,结晶器长度(图1中的L)是一个重要参数。在圆断面铜包铝复合材料连铸成形研究结果[14]和前期实验研究的基础上,确定了较为合理的金属液温度和复合模具保温温度等基本工艺参数:铜液温度(tCu) 1 240 ℃、铝液温度(tAl)750 ℃、复合腔保温温度(tc) 1 150 ℃、二次冷却水流量(Q2)100 L/h、二次冷却水距离(L1)30 mm。固定这些工艺参数不变,在60和90 mm/min两种拉坯速度下研究两种不同结晶器长度(100和150 mm)对水平连铸过程的影响,以确定可实现稳定连铸成形的基本条件。不同工艺条件下的实验结果如表1所列,两种可实现稳定连铸条件下(表1中实验序号2和3)所制备的矩形铜包铝复合材料横、纵截面的宏观形貌如图2所示。

图2 不同结晶器长度下所制备的矩形铜包铝复合材料横、纵断面的宏观形貌

Fig. 2 Transverse ((a), (c)) and longitudinal ((b), (d)) section morphologies of CCA composite materials fabricated at different crystallizer lengths: (a), (b)L=150 mm, v= 90 mm/min; (c), (d)L=100 mm, v=60 mm/min

由表1可知,采用长度为150 mm的结晶器,当拉坯速度为90 mm/min 时,可实现稳定连铸且铝液填充较好,如图2(a)和(b)所示;但当拉坯速度为60 mm/min时则出现由于冷却强度过大而导致的“拉坯冻住”现象。这表明,当结晶器长度为150 mm时,需要配以较高的拉坯速度才能使铝芯的固液界面处于芯管出口之外,从而使铝液可以连续充填到包覆铜管中。当结晶器长度为100 mm、拉坯速度为60 mm/min 时可实现稳定的连铸,但铝芯存在少量铸造缺陷,如图2(c)和(d)所示;而当拉坯速度增加至90 mm/min 时,由于结晶器的一次冷却不够,导致铝液将铜层熔穿。这表明,当结晶器较短时,需配以较低的拉坯速度才能使铝芯的固液界面位置和界面反应程度都得到较好的控制。

表1 结晶器长度连铸过程及铸坯质量的影响

Table 1 Effect of crystallizer length on continuous casting process and quality of CCA rods

结晶器的作用一是实现包覆铜管凝固,二是当铝液充填到包覆铜管中时对复合铸坯进行一次冷却。因此,当结晶器较短时,一方面包覆铜管在结晶器内受到的冷却距离较短,所以,在铝液充填到包覆铜管中时两者复合部位的铜管温度较高,铜铝发生界面反应的程度增加;另一方面结晶器对铝液充填到铜管时的一次冷却能力也较低。两个方面的共同作用,使得结晶器较短时如果拉坯速度较快容易发生过度界面反应甚至铜层熔穿。图2(a)和(b)结果表明,采用长度为150 mm的结晶器进行连铸时,有利于获得更高的拉坯速度(90 mm/min)。因此,结晶器长度为150 mm较为合理。

2.2 拉坯速度的影响

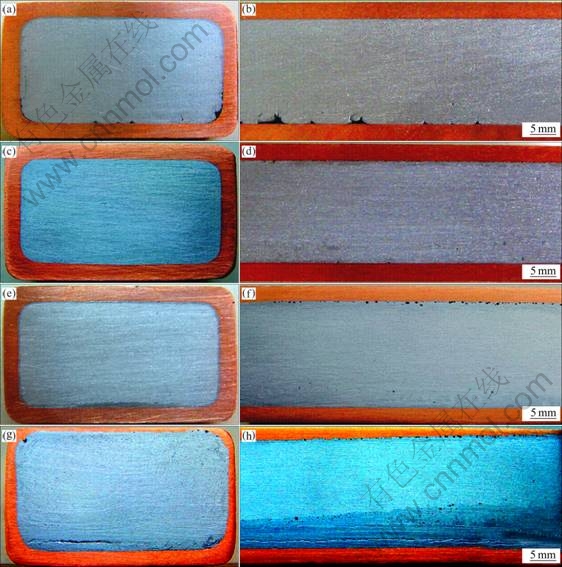

当平均拉坯速度在60~105 mm/min的范围内时,拉坯速度对矩形铜包铝复合材料水平连铸过程的影响如表2所列,所制备的矩形铜包铝复合材料的横、纵截面形貌如图3所示。

如图3(a)和(b)所示,当拉坯速度为60 mm/min时,铝的下部有少量冷隔,说明铝的填充过程不连续;当拉坯速度为75~90 mm/min时,矩形断面铜包铝复合材料的水平连铸过程稳定,芯部铝无明显缺陷,如图3(c)~(f)所示;当拉坯速度达到105 mm/min时,上部的铜包覆层与铝的界面反应严重,铜层被严重熔蚀,甚至导致上部铜层熔穿,如图3(g)和(h)所示。同时,由于被熔蚀的铜与铝生成高密度的富铜脆性金属间化合物,凝固时沉积到铝芯下部,在铸造应力或牵引辊的压力下形成裂纹。综合上述结果可以看出,随着拉坯速度的增大,铝液填充过程从不连续转变为连续,但拉坯速度的进一步增大,包覆层与铝芯接触温度升高,会导致界面反应加剧。在本实验条件下,较适宜的拉坯速度范围为75~90 mm/min。

图3 不同拉坯速度下所制备的矩形铜包铝复合材料横、纵断面的宏观形貌

Fig. 3 Transverse ((a), (c), (e), (g)) and longitudinal ((b), (d), (f), (h)) section morphologies of CCA fabricated at different withdrawing speeds: (a), (b) v=60 mm/min; (c), (d) v=75 mm/min; (e), (f) v=90 mm/min; (g), (h) v=105 mm/min

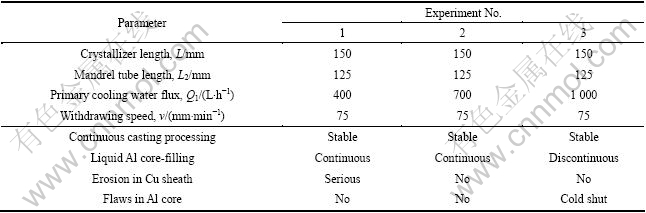

2.3 芯管长度的影响

芯管长度对矩形铜包铝复合材料水平连铸过程的影响如表3所列;所制备的矩形铜包铝复合材料的横、纵截面形貌如图4所示。

图4 不同芯管长度条件下所制备矩形铜包铝复合材料横、纵断面的宏观形貌

Fig. 4 Transverse ((a), (c), (e)) and longitudinal ((b), (d), (f)) section morphologies of CCA fabricated at different mandrel tube lengths: (a), (b) L2=110 mm; (c), (d) L2=125 mm; (e), (f) L2=140 mm

上述结果表明,芯管长度显著影响铜包铝复合材料连铸过程铝液的流动行为以及界面反应状况。由图4(c)和(d)可以看出,当芯管长度L2为125 mm时,铝液的填充效果良好,无冷隔和裂纹等宏观铸造缺陷。当芯管长度太短时,由于铝液与铜管接触时的温度均较高,上部铜层与芯部铝的界面反应较剧烈,导致铜包覆层的明显侵蚀,如图4(a)和(b)所示;而当芯管长度过长时,铝芯受冷却程度大,固液界面移至芯管出口以内,铝液的填充变得不连续,导致芯部铝产生明显的冷隔,如图4(e)和(f)所示。因此,在本实验条件下,适宜的芯管长度为125 mm。

表2 拉坯速度对连铸过程及铸坯质量的影响

Table 2 Effect of withdrawing speed on continuous casting process and quality of CCA rods

表3 芯管长度对连铸过程及铸坯质量的影响

Table 3 Effect of mandrel tube length on continuous casting process and quality of CCA rods

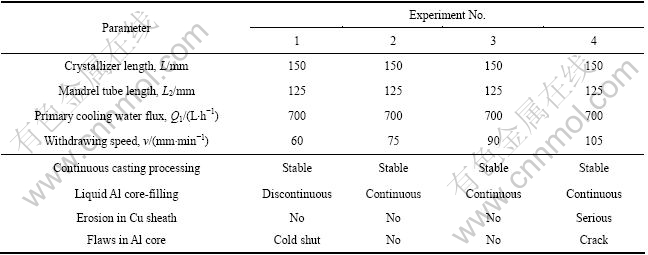

2.4 一次冷却水流量的影响

一次冷却水流量对矩形铜包铝复合材料水平连铸过程的影响如表4所列。当一次冷却水流量较低时(如Q1=400 L/h),先凝固的铜包覆层温度较高,使得铝液流出芯管与之接触的界面反应较为明显,导致包覆层被部分熔蚀、厚度不均匀,所制备的铜包铝复合材料的横、纵截面的宏观形貌与图4(a)和(b)相似。增大一次冷却水流量(如Q1=700 L/h)可以抑制界面反应,获得包覆层均匀、铝芯连续、无宏观铸造缺陷的铜包铝铸坯,所制备的铜包铝复合材料的横、纵截面的宏观形貌与图4(c)和(d)相似。但当一次冷却水流量达到 1 000 L/h时,铝液的填充开始不连续,芯部铝出现冷隔,所制备的铜包铝复合材料的横、纵截面的宏观形貌与图4(e)和(f)相似。因此,在本实验条件下适宜的一次冷却水流量为700 L/h。

表4 一次冷却水流量对连铸过程及铸坯质量的影响

Table 4 Effect of primary cooling water flux on continuous casting process and quality of CCA rods

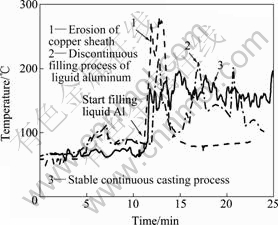

2.5 工艺条件对水平连铸过程稳定性的影响及监控

在矩形断面铜包铝复合材料水平连铸过程中,铝的固液界面位置对连铸过程的稳定性起决定性作用。如图5所示,根据铝的固液界面与芯管出口的相对位置L0,可将水平连铸过程分为如下3种典型情形:拉坯冻住、连铸过程稳定、铜层熔穿。在结晶器出口处的石墨内衬上布置热电偶(如图5中T所示),实验测得的3种不同连铸状态下的结晶器出口处的温度—时间曲线分别如图6中曲线1~3所示。当铝固液界面位于芯管以外的较长距离位置时(图5中的位置d),则铝液与铜包覆层之间的接触温度高、接触时间较长,导致铜铝在界面处发生过度反应,严重时可将铜层熔穿,其温度—时间曲线如图6中曲线1所示,其特征是充铝后温度迅速升高直至铜层被熔穿后铝液漏出,测温点的温度迅速下降。当由于冷却强度过高而使得铝固液界面位于芯管以内时(图5中的位置b),则铝的充填过程变得不连续,在温度—时间曲线上表现为较大幅度的波动,甚至连铸过程由于拉坯阻力过大而终止(图5中的位置a),如图6中曲线2所示。当铝固液界面位于芯管出口附近时,如图5中的位置c,连铸过程稳定,在温度—时间曲线上表现为较小幅度的波动,如图6中曲线3所示,其波动幅度在20 ℃以内,所制备的铜包铝矩形坯的宏观形貌如图3(c)和(d)所示。由图6中曲线1~3可知,温度—时间曲线的变化情况可以反映内部铝液的填充行为,据此可判断水平连铸过程的状态。因此,曲线3所对应的连铸过程是实验所希望得到的稳定状态。当所测温度出现不稳定情形(曲线1或2)时,可通过在线适当调整一次冷却水或拉坯速度等参数使连铸过程趋于稳定状态,制备出合格的复合铸坯。即通过在芯管出口处的石墨内衬布置热电偶,检测温度随时间的变化情况,有效监测铜包铝水平连铸过程的稳定状态,并进行适当调整。

图5 铜包铝复合材料水平连铸时4种典型的铝固液界面位置示意图

Fig. 5 Schematic diagram of four typical solid-liquid interface positions of aluminum in horizontal continuous casting process of CCA

图6 不同连铸状态下矩形断面铜包铝复合材料水平连铸结晶器出口处的温度—时间曲线

Fig. 6 Temperature—time curves at outlet of crystallizer in horizontal continuous casting process of CCA under different continuous casting conditions: 1—Erosion of copper sheath; 2—Discontinuous filling process of liquid aluminum; 3—Stable continuous casting process

3 结论

1) 50 mm×30 mm×3 mm矩形断面铜包铝复合材料水平连铸适宜的结晶器长度为150 mm,适宜的芯管长度为125 mm。与长度为100 mm的结晶器相比,较长的结晶器可以获得更快的拉坯速度和更高效率。

2) 较为适宜的拉坯速度范围为75~90 mm/min。当拉坯速度过慢时,铝液的填充不连续,导致芯部铝产生冷隔等缺陷;当拉坯速度过快时,铜铝界面会发生严重反应。

3) 当拉坯速度为75 mm/min时,适宜的一次冷却水流量约为700 L/h。一次冷却水大于1 000 L/h 导致铝液填充不连续,一次冷却水小于400 L/h 则导致铜铝界面反应加剧。

4) 在本实验条件下,矩形铜包铝复合材料水平连铸的合理工艺参数如下:铜液温度1 240 ℃、铝液温度750 ℃、复合腔保温温度1 150 ℃、结晶器长度 150 mm、芯管长度125 mm、拉坯速度75 mm/min、一冷水流量700 L/h、二冷水总流量100 L/h、二冷水距离30 mm。

5) 在芯管出口处石墨内衬布置热电偶,可有效监测铜包铝水平连铸过程的稳定性,并依此进行适当的参数调整。

REFERENCES

[1] PERRARD W. Strategies for optimizing cable design and performance through the use of bimetallic wire [J]. Wire Journal International, 2001, 34(7): 154-159.

[2] 谢世坤, 陈京平, 万建新, 郑慧玲. 双金属铜包铝线的制备工艺与力学性能 [J]. 材料导报, 2008, 22(5): 83-85.

XIE Shi-kun, CHEN Jing-ping, WAN Jian-xin, ZHENG Hui-ling. Manufacture process and mechanical performance of CCA bimetal wire [J]. Materials Review, 2008, 22(5): 83-85.

[3] TEARE B R, WEBB J R. Skin effect in bimetallic conductors [J]. Transactions of the American Institute of Electrical Engineers, 1943, 62(6): 297-302.

[4] 黄崇祺. 论中国电缆工业的以铝节铜[J]. 电线电缆, 2008(6): 1-3.

HUANG Chong-qi. On the copper saving with aluminium in the Chinese cable industry [J]. Electric Wire and Cable, 2008(6): 1-3.

[5] 罗奕兵, 刘新华, 谢建新. 矩形截面铜包铝导电排的导电性能及断面形状结构的影响[J]. 北京科技大学学报, 2009, 30(10): 1292-1297.

LUO Yi-bing , LIU Xin-hua, XIE Jian-xin. Effects of sectional form and configuration on the conductivity of copper cladding aluminum bars with a rectangle section [J]. Journal of University of Science and Technology Beijing, 2009, 30(10): 1292-1297.

[6] GIBSON A. Emerging applications for copper-clad steel and aluminum wire [J]. Wire Journal International, 2008, 41(2): 142-148.

[7] 吴云忠, 马永庆, 刘世永, 张 洋. 包复焊接铜包铝线加工工艺与固相结合机理研究[J]. 焊接, 2006(4): 40-42.

WU Yun-zhong, MA Yong-qing, LIU Shi-yong, ZHANG Yang. Machining procedure and solid state bonding mechanism of clad process welding copper clad aluminum wire [J]. Welding and Joining, 2006(4): 40-42.

[8] 吴云忠, 马永庆, 张 洋, 刘世永. 铜包铝线材室温拉变形后的显微组织和力学性能[J]. 中国有色金属学报, 2006, 16(12): 2066-2070.

WU Yun-zhong, MA Yong-qing, ZHANG Yang, LIU Shi-yong. Microstructure and mechanical properties of copper clad aluminum wire by drawing at room temperature [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(12): 2066-2070.

[9] PAUL A. Method of metal cladding: USA, US3408727 [P]. 1968-11-05.

[10] NAKASUJl K, MASUDA K, HAYASHI C. Development of manufacturing progress of clad bar by rotary rolling [J]. Iron and Steel Institute of Japan (ISIJ International), 1997, 7(9): 899-905.

[11] RHEE K Y, HAN W Y, PARK H J, KIM S S. Fabrication of aluminum/copper clad composite using hot hydrostatic extrusion process and its material characteristics [J]. Materials Science and Engineering A, 2004, 384(1/2): 70-76.

[12] 胡 捷. 铜包铝复合线材静液挤压加工工艺研究[J]. 新技术新工艺, 2001(9): 27-28.

HU Jie. The study to produce copper fold aluminum composite wire by hydraulic extrusion [J]. New Technology and New Process, 2001(9): 27-28.

[13] 谢建新, 刘新华, 刘雪峰, 苏亚军. 一种包复材料水平连铸直接复合成形设备与工艺: 中国, ZL200610112817. 3 [P]. 2008-04-02.

XIE Jian-xin, LIU Xin-hua, LIU Xue-feng, SU Ya-jun. Horizontal continuous direct composite cast forming equipment and technology of a cladding materials: China, ZL200610112817. 3 [P]. 2008-04-02.

[14] SU Y J, LIU X H, HUANG H Y, WU C J, LIU X F, XIE J X. Effects of processing parameters on the fabrication of copper cladding aluminum rods by horizontal core-filling continuous casting [J]. Metallurgical and Materials Transactions B, 2010, 42(1): 104-113.

[15] 罗奕兵. 铜包铝复合导电扁排及成形加工研究[D]. 北京: 北京科技大学, 2009: 61-100.

LUO Yi-bing. Study on copper cladding aluminum composite conductive flat bar and formation [D]. Beijing: University of Science and Technology Beijing, 2009: 61-100.

[16] 罗奕兵, 刘新华, 谢建新. 铜包铝复合棒材平辊轧制宽展变形行为 [J]. 中国有色金属学报, 2009, 19(11): 1976-1981.

LUO Yi-bing, LIU Xin-hua, XIE Jian-xin. Lateral spreading deformation behavior in flat rolling of copper cladding aluminum composite rods [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(11): 1976-1981.

(编辑 陈卫萍)