DOI:10.19476/j.ysxb.1004.0609.2017.12.16

铝含量对(Zr0.761Cu0.147Ni0.092)93-xAl7+x非晶合金的热稳定性及其力学性能的影响

张 为,寇生中,艾亚军,孙卫民,赵燕春,李春燕,李 广

(兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050)

摘 要:采用铜模吸铸法制备(Zr0.761Cu0.147Ni0.092)93-xAl7+x(x=0, 1, 2, 3, 5, 7 (摩尔分数, %))块体非晶合金,采用同步示差扫描量热仪(DSC)、万能试验机和显微硬度计测试各试样的过冷液相区、压缩塑性和显微硬度,利用X射线衍射(XRD)和扫描电镜(SEM)等手段对其微观结构和力学性能的关系进行分析。结果表明:随着Al含量的增加,(Zr0.761Cu0.147Ni0.092)93-xAl7+x非晶合金的玻璃转变温度Tg、初始晶化温度Tx均呈现增大的趋势,而过冷液相区ΔTx先增大后减小,在x=3时达到最大的94 K。合金塑性变形εp随着Al含量的增加先增大后减小,在x=3时达到最大值为15.82%;合金屈服强度σs和显微硬度HV都呈现增强的趋势,在x=7时取得最大值,分别为1713和4095 MPa。

关键词:锆基块体非晶合金;过冷液相区;塑性变形;显微硬度

文章编号:1004-0609(2017)-12-2527-08 中图分类号:TG139 文献标志码:A

Zr基非晶合金具有优异的力学性能,如高强度、高硬度、高耐磨性以及低弹性模量等,是非常具有优势的结构材料之一[1]。由于其具有较大的非晶形成能力,更是具有广阔的应用前景[2-6]。但是Zr基金属玻璃在室温变形时,往往发生灾难性的脆性断裂,从而制约了该材料在工程中的应用[7]。研究发现,采用复合化[8]、微合金化[9-10]和在非晶基体中预制缺陷[11]等方法可以改善非晶合金的室温塑性。近几年,发现高锆含量的Zr基非晶合金Zr-Cu-Ni-Al合金系由于具有玻璃形成能力高和一定的室温塑性等而被大量研 究[12-15]。LI等[16]通过铜模吸铸做出的Zr70Al8Cu13.5Ni8.5非晶合金2 mm试样室温塑性达到了72%。本文作者在前人研究的基础上进一步研究,发现铝含量对该合金体系的热稳定性和塑性变形有显著的影响,以(Zr0.761Cu0.147Ni0.092)92Al8非晶合金为研究基体,通过添加不同含量的Al元素,检测分析非晶合金的结构、热力学参数的变化、力学性能(塑性、屈服强度、显微硬度等),研究Al元素对Zr基非晶合金热稳定性和力学性能的影响。

1 实验

实验原料为纯度为Zr(99.99%)、Cu(99.99%)、A1(99.99%)、Ni(99.98%)(质量分数)的纯金属,配制成分为(Zr0.761Cu0.147Ni0.092)93-xAl7+x (x=0, 1, 2, 3, 5, 7(摩尔分数, %))的合金。实验采用悬浮熔炼铜模吸铸法制备试样。将称量好的原料60 g(各成分质量误差为±5 mg)一次加入坩埚,重熔3次使合金成分均匀后形成母合金。将母合金重熔并加热到功率8 kW下保温60 s,降至6 kW,在负压为0.03 MPa吸铸试样,形成直径3 mm、长度为50 mm的圆棒状试样。

按实验要求将圆棒试样在水冷金刚石切片机上切成分析试样:XRD试样高度3 mm、金相试样高度4 mm、压缩试样高度6 mm、显微硬度试样高度2 mm,其中金相、压缩以及显微硬度试样的两端面磨平,保证两端面平行并与中轴垂直。采用D8Advance型X射线衍射仪(Cu Kα)进行结构检测,XRD试验的扫描角度范围为20°~80°,步长为0.02°;用TA Q2000型DSC差示扫描量热议对玻璃转变温度和晶化温度进行检测,加热速率为20 K/min;用4XC-PC型金相显微镜进行金相观察;用WDW-100D型微机控制电子万能试验机进行压缩试验,压缩应变速率为1×10-4 s-1。用JSM-6700F型场发射扫描电镜观察试样断口形貌和组织结构。用HVT-1000A型显微硬度计进行显微硬度实验,加载载荷为0.5 N,作用时间为10 s,测试前用石蜡粘在样品台上。

2 结果与讨论

2.1 Al含量变化对合金热稳定性的影响

2.1.1 Al含量变化对合金结构和热稳定性的影响

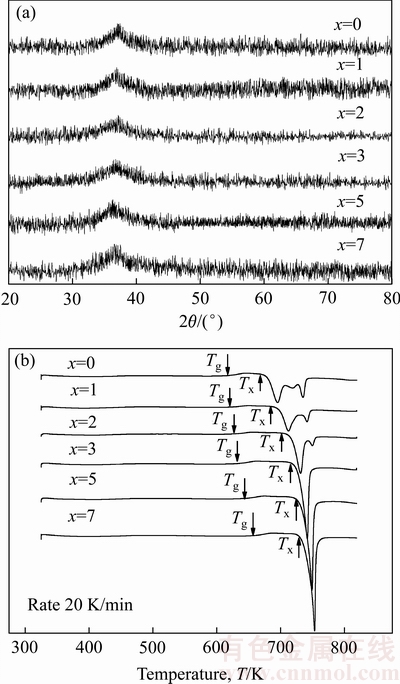

图1(a)所示为铸态(Zr0.761Cu0.147Ni0.092)93-xAl7+x (x=0, 1, 2, 3, 5, 7 (摩尔分数, %))合金试样的XRD谱。从图1(a)中可以看出,对于不同成分的试样在30°~45°范围内均为典型的馒头峰,说明这6种合金均为非晶结构。图1(b)所示为铸态(Zr0.761Cu0.147Ni0.092)93-xAl7+x (x=0, 1, 2, 3, 5, 7 (摩尔分数, %))合金试样的DSC曲线。每一条曲线都有一个明显的由于玻璃转变产生的吸热峰和紧随其后的1个(x=3,5,7)、2个(x=1,2)或者3个(x=0)由于晶化产生的放热峰。

图1 (Zr0.761Cu0.147Ni0.092)93-xAl7+x合金的XRD谱和DSC 曲线

Fig. 1 XRD patterns(a) and DSC curves(b) of (Zr0.761Cu0.147- Ni0.092)93-xAl7+x alloys

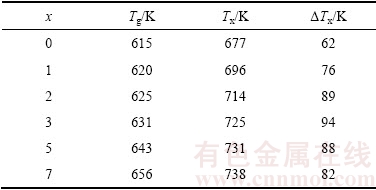

表1所列为相应的玻璃转变温度Tg、初始晶化温度Tx和过冷液相区温度区间ΔTx。从表1和图2可以看出,随着Al含量的增加,非晶合金的玻璃转变温度Tg从615 K上升到656 K,初始晶化温度Tx从677 K上升到738 K,过冷液相区ΔTx先增大后减小,且其在x=3时达到峰值为94 K,说明Al元素含量的增加使得Zr基非晶合金的热稳定性先提高后降低。而合金成分位于共晶点或共晶点附近是合金具有较好的热稳定性和大的非晶形成能力的必要条件[17]。这也从侧面说明x=3的合金具有较好的热稳定性。

表1 (Zr0.761Cu0.147Ni0.092)93-xAl7+x非晶合金的温度

Table 1 Temperature of fabricated (Zr0.761Cu0.147Ni0.092)93-xAl7+x amorphous alloys

图2 (Zr0.761Cu0.147Ni0.092)93-xAl7+x合金热力学曲线

Fig. 2 Thermodynamic curves of (Zr0.761Cu0.147Ni0.092)93-xAl7+x alloys

表1列出了相应的玻璃转变温度Tg、初始晶化温度Tx和过冷液相区温度区间ΔTx。从表1和图2可以看出,随着Al含量的增加,非晶合金的玻璃转变温度Tg从615 K上升到656 K,初始晶化温度Tx从677 K上升到738 K,过冷液相区ΔTx先增大后减小,且其在x=2时达到峰值为94 K。说明Al元素含量的增加使得Zr基非晶合金的热稳定性先提高后降低。

2.1.2 热稳定性与热力学参数相关性分析

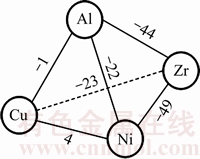

Al含量的改变导致合金热稳定性产生变化,进而改变了合金的非晶形成能力。图3所示为(Zr0.761Cu0.147- Ni0.092)93-xAl7+x(x=0, 1, 2, 3, 5, 7 (摩尔分数, %))合金各个组元混合焓之间的相互关系。混合焓ΔHmix 表示组元混合时能量的变化,是非晶合金的重要热力学参数。

(1)

(1)

式中:Ωij=4ΔHij,ΔHij为第i种和第j种元素的混合焓;ci为第i种元素的摩尔浓度。非晶合金热稳定性不仅与混合焓有关系,还与合金组元的种类、数量相关。非晶合金中另一个非常重要的热力学参数混合熵ΔSmix是一个表征混合系统状态无序度的物理量,其与合金的成分、原子半径等有很大关系。液体的混合熵越大,说明其结构的无序程度就越高,其在快速冷却过程中原子的重新排列也就越难发生而容易形成非晶。

图 3 Zr-Cu-Ni-Al合金元素之间混合焓的关系

Fig. 3 Relationship between heat of mixing (ΔHmix) for atomic pairs of Zr-Cu- Ni-Al alloys (Unit: kJ/mol)

图3中的Zr-Cu-Ni系合金中,除了Cu与Ni之间有一个较大的正混合焓ΔHCu-Ni=4 kJ/mol,其余均为负混合焓(ΔHZr-Cu=-23 kJ/mol,ΔHZr-Ni=-49 kJ/mol)[18]。图3中添加元素Al对Zr-Cu-Ni系合金元素全为负混合焓(ΔHAl-Zr=-44 kJ/mol,ΔHAl-Cu=-1 kJ/mol,ΔHAl-Ni= -22 kJ/mol)。则通过式(2)可得[19]:

ΔSmix可以通过计算得到[20]:

(2)

(2)

式中:R是理想气体常数;ci是第i个组元的摩尔浓度;Φi是第i个组元的原子体积分数。

用原子半径代替原子体积分数,可得

(3)

(3)

式中:ri是第i个组元的原子半径,Zr、Cu、Ni、Al对应的原子半径分别为1.60、1.28、1.24、1.43  。XIA等[21]通过定义抑制原子重新排列的能力ε,来表征非晶合金的热稳定性和非晶形成能力,通过统计得出当ε越接近0.25时,Zr基非晶合金热稳定性越好。其中

。XIA等[21]通过定义抑制原子重新排列的能力ε,来表征非晶合金的热稳定性和非晶形成能力,通过统计得出当ε越接近0.25时,Zr基非晶合金热稳定性越好。其中

(4)

(4)

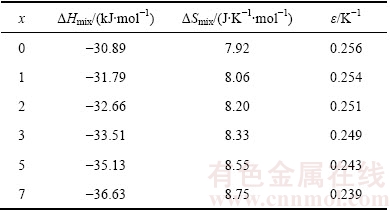

通过式(1)、(3)、(4)计算可得如表2所示热力学参数。通过表2可知,Al元素的添加使得整个Zr-Cu-Ni-Al系非晶合金的混合焓变得更负,混合熵值逐渐增大。而ε逐渐减小,在x为2和3时最接近于0.25,表明在这两个成分中,合金热稳定性较好,这与实验测得的数据基本相符。说明合金的混合熵和混合的比值可以一定程度上对合金的热稳定性进行预判,从而可以根据合金的这两个参数设计具有较好热稳定性的非晶合金。

表2 (Zr0.761Cu0.147Ni0.092)93-xAl7+x非晶合金热力学参数

Table 2 Thermodynamic properties of typical (Zr0.761Cu0.147- Ni0.092)93-xAl7+x amorphous alloys

2.2 Al含量变化对非晶合金力学性能的影响

2.2.1 Al含量对非晶合金压缩塑性和显微硬度的影响

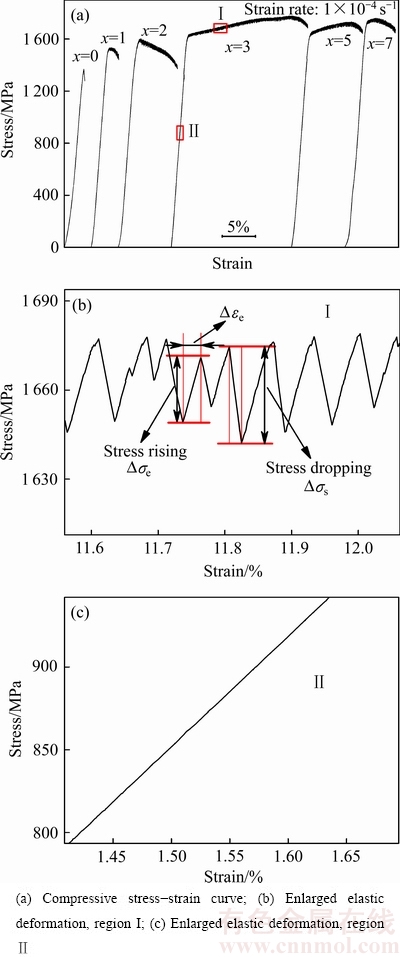

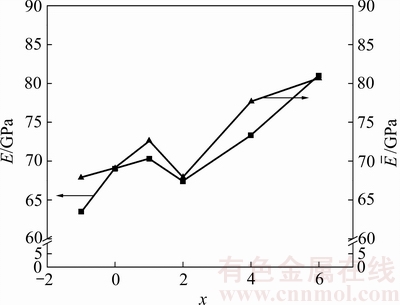

图4所示为(Zr0.761Cu0.147Ni0.092)93-xAl7+x (x=0, 1, 2, 3, 5, 7 (摩尔分数, %))合金试样室温下的压缩应力-应变曲线和不同应变区域的局部放大图。通过调整Al含量实现Zr-Cu-Ni-Al非晶合金的成分变化。合金试样通过XRD和DSC检测可以确定为非晶结构。

通过对比非晶合金的压缩曲线,所有合金均是先经过弹性变形然后发生屈服,产生一定程度的塑性变形,发生断裂,且部分成分表现出较好的塑性变形。表2列出了相应的力学性能参数,包括弹性模量E,屈服强度σs、塑性变形εp和显微硬度HV,其中显微硬度由硬度计从试样边缘向心部每隔0.5 mm打点后取平均值得到。结果表明,随着Al含量的增加,弹性模量E、屈服强度σs和显微硬度HV整体呈现上升的趋势,最大分别达到了81 GPa、1713 MPa和4095 MPa,但x=3时,弹性模量出现反常,减小为67 GPa。塑性变形能力却由于成分的不同而表现出巨大的差异,Al含量的增加使得塑性变形εp先增大后减小,在x=3时合金塑性变形最大,达到15.82%,表现出了很好的塑性。说明非晶合金的塑性变形能力与其成分存在密切的关系。

图4 (Zr0.761Cu0.147Ni0.092)93-xAl7+x合金压缩应力-应变曲线及区域Ⅰ锯齿放大图

Fig. 4 Compressive stress-strain curves of (Zr0.761Cu0.147- Ni0.092)93-xAl7+x alloys and enlarged serrations in regions

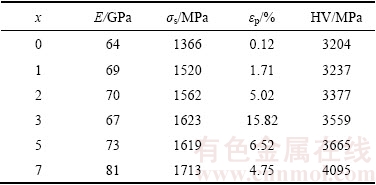

表3 (Zr0.761Cu0.147Ni0.092)93-xAl7+x 合金力学性能

Table 3 Mechanical properties of (Zr0.761Cu0.147Ni0.092)93-xAl7+x alloys

2.2.2 Al含量变化对非晶合金锯齿流变的影响

通过对比图4(b)和(c)可以看出,合金两个不同的变形阶段变形机理完全不同。曲线的塑性变形部分有很多的锯齿组成,这些锯齿是由弹性加载的应力上升部分和剪切带滑移产生的应力下降的部分组成。通过定义应力降幅(Stress dropping)和应力增幅(Stress rising)可以考察锯齿流变随塑性变形量的变化产生的变化,如图4(b)所示,分别用Δσs和Δσe表示。应力增幅所需应变为Δεe。

图5所示为(Zr0.761Cu0.147Ni0.092)93-xAl7+x (x=1, 2, 3, 5, 7 (摩尔分数, %))合金塑性变形阶段锯齿流变产生的应力降幅Δσs与塑性变形的散点分布图。插图为不同成分应力降幅(N)出现频数的分布图。由于x=0合金的塑性很小,只有很少的锯齿,并没有明显的锯齿流变行为,故没有列出;而x=1时,由于塑性变形小于2%,所以只取1%的变形量作为研究,其余则均取2%。图5中(a)~(e)分别对应x为1, 2, 3, 5, 7 (摩尔分数, %)。

从图5中可以看出,塑性较差的x为1和7的应力降幅随着变形的增加呈现波动中上升的趋势。而应力降幅的增大表明锯齿的出现越来越困难,需要更大的能量才能产生,而这也使得试样断裂的几率显著增加。塑性较好(εp>5%)的x为2、3和5的合金随着变形的增加都呈现了较为稳定的应力降幅,波动范围较小。图5的插图中,不同成分应力降幅分布的情况也有所不同。随着Al含量的增加,试样的主要应力降幅先增大后减小,从30~40 MPa增加至40~50 MPa后再降至20~30 MPa,在x=3处达到最大。

图5 (Zr0.761Cu0.147Ni0.092)93-xAl7+x合金应力降 幅-应变散点图(插图是不同应力降幅分布图)

Fig. 5 Stress dropping-strain scatter diagram of (Zr0.761Cu0.147Ni0.092)93-xAl7+x alloys (Insert is histogram of different stress dropping in number)

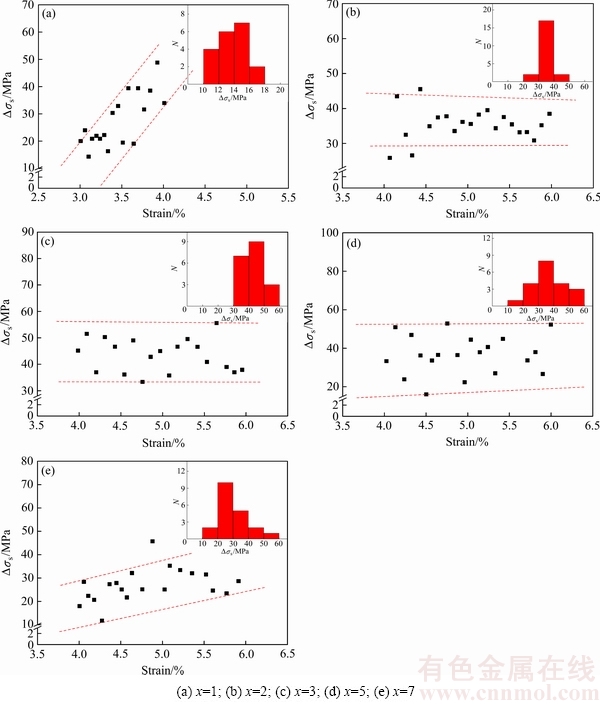

通过对应力增幅Δσe的统计计算发现,每一个锯齿上的应力增幅不论其大小,应力增幅与产生应力增幅所用的变形的比值,也就是其弹性模量基本保持不变。

对这些比值计算后取平均值,本研究定义为

(5)

(5)

式中:Δσei和Δεei和分别为第i个锯齿的应力增幅和应力增幅所需的应变。

图6所示为(Zr0.761Cu0.147Ni0.092)93-xAl7+x (x=0, 1, 2, 3, 5, 7 (摩尔分数, %))非晶合金弹性模量E的曲线与塑性变形阶段应力增幅的平均弹性模量 。从图6中可以看出,合金弹性变形阶段的弹性模量和塑性阶段的变化趋势基本一致。表明合金的塑性变形实质上就是合金试样自身的弹性变形和剪切带的滑移综合作用的效果,弹性变形由于试样的剪切带滑移而消失,剪切带的宽度就是一个锯齿的变形量。因而可以通过观察合金试样的剪切带形貌来判断合金的塑性好坏。

。从图6中可以看出,合金弹性变形阶段的弹性模量和塑性阶段的变化趋势基本一致。表明合金的塑性变形实质上就是合金试样自身的弹性变形和剪切带的滑移综合作用的效果,弹性变形由于试样的剪切带滑移而消失,剪切带的宽度就是一个锯齿的变形量。因而可以通过观察合金试样的剪切带形貌来判断合金的塑性好坏。

2.2.3 断口形貌与宏观压缩塑性的关系

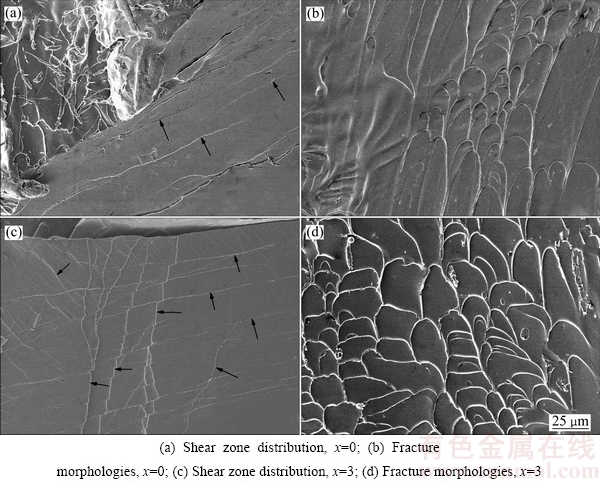

图7所示为(Zr0.761Cu0.147Ni0.092)93-xAl7+x(x=0, 3 (摩尔分数, %))合金试样的断口形貌的SEM像。选择塑性最好的x=3的试样和塑性较差的x=0的试样对其断口进行对比分析。通常块体非晶合金的塑性行为主要受变形过程中形成的剪切带控制,其塑性变形大小与剪切带的密度及分布状态密切相关[22]。图7中(a)和(c)分别为x=0和x=3两种非晶合金压缩断口侧面剪切带的分布情况。在x=3的非晶合金断面中,可以观察到高密度剪切带的形成。一次剪切带与二次剪切带之间彼此相互交割,同时剪切带的分支清晰可见。而x=0的非晶合金中剪切带的密度明显低于x=3非晶合金的,且只有较少的一次剪切带,并未有明显的二次剪切带。对于具有较高塑性变形能力的非晶合金,具有高密度剪切带是至关重要的。高密度的剪切带可以防止应力集中而发展成裂纹,从而有效阻止断裂的传播,最终合金表现出较好的塑性,这也是x=3非晶合金具有较大塑性变形能力的原因。图7(b)和(d)所示为x=0与x=3非晶合金压缩断口形貌的SEM像,样品断面上典型的脉络纹体现了断裂过程中的局部粘性流动。脉络纹的成因被认为是由大量临近断口的剪切带在剪切应力的作用下层层撕裂后留下的痕迹[22]。因此,脉络纹可作为块体金属玻璃塑性的标志,即断口表面上脉状花样的多少与块体非晶合金塑性的大小有关。通常脉络纹越致密,非晶合金的塑性越好[23-24]。在实验中观察到x=3断口表面脉状纹络呈现更加致密且规则排列的趋势,与其较高的塑性相对应。相对x=3的非晶合金而言,x=1的非晶合金脉络纹较少,塑性较差,塑性只有0.12%。

图6 (Zr0.761Cu0.147Ni0.092)93-xAl7+x合金的弹性模量

Fig. 6 Elastic modulus of (Zr0.761Cu0.147Ni0.092)93-xAl7+x alloys

3 结论

图7 (Zr0.761Cu0.147Ni0.092)93-xAl7+x (x=0, 3)合金试样的压缩断口形貌

Fig. 7 Fracture morphologies of (Zr0.761Cu0.147Ni0.092)93-xAl7+x (x=0, 3) alloys

1) 通过Al元素的添加,得到了大尺寸的具有较好塑性的(Zr0.761Cu0.147Ni0.092)92Al10合金,塑性变形εp=15.82%,且此成分具有较好的热稳定性,过冷液相区温度达到了94 K。

2) 随着Al含量的增加,合金过冷液相区ΔTx先增大后减小。混合焓ΔHmix逐渐减小而混合熵ΔSmix逐渐增大,后者与前者的比值越接近0.25,合金的热稳定性越好。

3) Al的添加有利于提高Zr-Cu-Ni-Al非晶合金的屈服强度和显微硬度,(Zr0.761Cu0.147Ni0.092)86Al14合金的屈服强度σs和显微硬度HV均达到最大,分别为1713 MPa和4095 MPa。

4) 应力-应变曲线中锯齿流变行为的产生是合金具有塑性的表现,而锯齿流变中随着应变的增加应力降幅Δσs较小的波动是合金具有较好塑性的保证。

REFERENCES

[1] 黄劲松, 刘 咏, 陈仕奇, 刘祖铭, 黄伯云. 锆基非晶合金的研究进展与应用[J]. 中国有色金属学报, 2003, 13(6): 1321-1332.

HUANG Jin-song, LIU Yong, CHEN Shi-qi, LIU Zu-ming, HUANG Bai-yun. Progress and application of Zr-based amorphous alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1321-1332.

[2] Inoue A. Stabilization of metallic supercooled liquid and bulk amorphous alloys ☆[J]. Acta Materialia, 2000, 48(1): 279-306.

[3] WU H, IAN BAKER, LIU Y, WU X L. Dry sliding tribological behavior of Zr-based bulk metallic glass[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(3): 585-589.

[4] Zhang Q S, Zhang W, Inoue A. Ni-free Zr-Fe-Al-Cu bulk metallic glasses with high glass-forming ability[J]. Scripta Materialia, 2009, 61(3): 241-244.

[5] 袁小鹏, 寇生中, 赵燕春, 李春燕, 于 朋, 蒲永亮, 徐 娇. Cu46Zr44Al5Nb5块体非晶合金的晶化行为研究[J]. 稀有金属, 2013(5): 738-743.

YUAN Xiao-peng, KOU Sheng-zhong, ZHAO Yan-chun,YU Peng, PU Yong-liang, XU Jiao. Crystallization behavior of Cu46ZrAl5Nb5 bulk amorphous alloy[J]. Chinese Journal of Rare Metals,2013(5):738-743.

[6] GELLER J S. The boy genius report: iPhone 5S to feature indestructible liquid metal case[EB/OL]. [2013-07-17]. http://bgr.com/2013/07/17/apple-iphone-5s-case-launch-liquidmetal/.

[7] Cai A H, Ding D W, AN W K, Zhou G J, Luo Y. Transition of plasticity and fracture mode of Zr-Al-Ni-Cu bulk metallic glasses with network structures[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(8): 2617-2623.

[8] Hofmann D C, Suh J Y, Wiest A, Duan G, Lind M L. Designing metallic glass matrix composites with high toughness and tensile ductility[J]. Nature, 2008, 451(7182): 1085-1089.

[9] Chen L Y, Fu Z D, Zhang G Q, Hao X P, Jiang Q K. New class of plastic bulk metallic glass[J]. Physical Review Letters, 2008, 100(7): 652-663.

[10] Tan Z, Xue Y F, Cheng X W, ZHANG L, CHEN W W, WANG L, ZHANG H F, FU H M. Effect of element fitting on composition optimization of Al-Cu-Ti amorphous alloy by mechanical alloying[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(10): 3348-3353.

[11] Jiang F, He L, Zhong M B, Han Z H, Zhao Q. Orientation effect of pre-introduced shear bands in a bulk-metallic glass on its “work-ductilising”[J]. Materials Science & Engineering A, 2008, 496(1): 285-290.

[12] Kumar G, Ohkubo T, Mukai T, Hono K. Plasticity and microstructure of Zr-Cu-Al bulk metallic glasses[J]. Scripta Materialia, 2007, 57(2): 173-176.

[13] Kim Y C, Lee J C, Cha P R, AHN J p, Fleury E. Enhanced glass forming ability and mechanical properties of new Cu-based bulk metallic glasses[J]. Materials Science & Engineering A, 2006, 437(2): 248-253.

[14] XU H W, DU Y L, DENG Y. Effect of minor-addition of Fe on structural and mechanical properties of CuZrAl bulk metallic glass[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(5): 1123-1126.

[15] Li Y H, Zhang W, Dong C, Qiang J B, Fukuhara M, Makino A, Inoue A. Effects of Ni addition on the glass-forming ability, mechanical properties and corrosion resistance of Zr-Cu-Al bulk metallic glasses[J]. Materials Science & Engineering A, 2011, 528(29/30): 8551-8556.

[16] Li Y H, Zhang W, Dong C, Qiang J B, Yubuta K, Makino A, Inoue A. Unusual compressive plasticity of a centimeter-diameter Zr-based bulk metallic glass with high Zr content[J]. Journal of Alloys & Compounds, 2010, 504(8): S2-S5.

[17] 宁向梅, 黄金亮, 贾淑果, 殷 镖, 张兴渊. Al对Mg-Cu-Y合金非晶形成能力及热稳定性的影响[J]. 中国有色金属学报, 2013, 23(7): 1805-1811.

NING Xiang-mei, HUANG Jin-liang, JIA Shu-guo, YIN Biao, ZHANG Xing-yuan. Effect of Al on glass forming ability and thermal stability of Mg-Cu-Y alloys[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1805-1811.

[18] Takeuchi A, Inoue A. Calculations of mixing enthalpy and mismatch entropy for ternary amorphous alloys[J]. Materials Transactions, 2000, 41(11): 1372-1378.

[19] Takeuchi A, Inoue A. Quantitative evaluation of critical cooling rate for metallic glasses[J]. Materials Science & Engineering A, 2001, 304/306: 446-451.

[20] Jiang Q, Chi B Q, Li J C. A valence electron concentration criterion for glass-formation ability of metallic liquids[J]. Applied Physics Letters, 2003, 82(18): 2984-2986.

[21] Xia M, Zhang S, Ma C, Li J. Evaluation of glass-forming ability for metallic glasses based on order-disorder competition[J]. Applied Physics Letters, 2006, 89(9): 091917-1-091917-3.

[22] Lee J Y, Han K H, Park J M, Chattopadhyay K, Kim W T, Kim D H. Deformation and evolution of shear bands under compressive loading in bulk metallic glasses[J]. Acta Materialia, 2006, 54(19): 5271-5279.

[23] 孙民, 柳 林, 王敬丰, 刘 兵. Nb对Zr基块体非晶合金热稳定性、非晶形成能力及机械性能的影响[J]. 金属学报, 2005, 41(5): 534-538.

SUN Ming, LIU Lin, WANG Jing-feng, LIU Bing. Effects of Nb on the thermal stability, glass forming ability and mechanical properties of Zr-based bulk amorphous alloys[J]. .Acta Metallurgica Sinica, 2005,41(5): 534-538.

[24] LIU G Q, KOU S Z, LI C Y, ZHAO Y C, SUO H L. Effect of minor Fe addition on glass forming ability and mechanical properties of Zr_(55)Al_(10)Ni_5Cu_(30) bulk metallic glass[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(3): 590-595.

Effects of Al content on thermal stability and mechanical properties of (Zr0.761Cu0.147Ni0.092)93-xAl7+x amorphous alloy

ZHANG Wei, KOU Sheng-zhong, AI Ya-jun, SUN Wei-min, ZHAO Yan-chun, LI Chun-yan, LI Guang

(State Key Laboratory of Advanced Processing and Recycling of Non-ferrous Metals, Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: (Zr0.761Cu0.147Ni0.092)93-xAl7+x bulk amorphous alloys with x of 0, 1, 2, 3, 5, 7 (mole fraction, %) were prepared by copper mold casting method. The differential scanning calorimeter (DSC), universal testing machine and micro-hardness tester were employed to detect the supercooled liquid region, mechanical properties and microhardness of the samples, respectively. Furthermore, the relationship between microstructures and mechanical properties of the BMGs was analyzed by X-ray diffraction (XRD) and scanning electron microscope (SEM). The results show that, with the addition of the content of Al, the glass transition temperature Tg and initial crystallization temperature Tx of (Zr0.761Cu0.147Ni0.092)93-xAl7+x (x=0, 1, 2, 3, 5, 7 (mole fraction, %)) amorphous alloys increase. But the supercooled liquid region ΔTx of amorphous alloys firstly increases and then decreases, and it reaches 94 K which is best in the supercooled liquid region ΔTx of the alloys when x=3. The plastic deformation increases first and then decreases with the Al content increasing and the plastic deformation reaches the highest value of 15.82% while x is 3. Along with the increase of the content of Al, the yield strength σs and microhardness HV of the alloy have an enhanced trend, and both of them reach the highest value of 1713 and 4095 MPa while x is 7.

Key words: Zr-based bulk amorphous alloy; supercooled liquid region; plastic deformation; microhardness

Foundation item: Projects(51571105, 51661017, 51661016) supported by the National Natural Science Foundation of China; Project(1606RJYA312) supported by the Natural Science Foundation of Gansu Province, China

Received date: 2016-09-27; Accepted date: 2017-03-01

Corresponding author: KOU Sheng-zhong; Tel: +86-931-2604664; E-mail: kousz@lut.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51571105,51661017,51661016);甘肃省自然科学基金资助项目(1606RJYA312)

收稿日期:2016-09-27;修订日期:2017-03-01

通信作者:寇生中,教授,博士;电话:0931-2604664;E-mail: kousz@lut.cn