铜阳极泥碱性加压氧化浸出渣的硫酸浸出过程

刘伟锋1, 2,刘又年1,杨天足2,陈霖2,张杜超2,王安2

(1. 中南大学 化学化工学院 湖南 长沙,410083;

2. 中南大学 冶金与环境学院,湖南 长沙,410083)

摘要:针对铜阳极泥碱性加压氧化浸出渣开展硫酸浸出过程研究,考察硫酸浓度、温度、时间、液固比、搅拌速度和氧化方式等因素对浸出渣渣率和金属浸出率的影响。研究结果表明:金属浸出率随硫酸浓度的增加而提高,银的溶解尤为明显;硫酸浸出渣中未溶解的铜主要以单质存在,采用空气氧化方式可以提高铜的浸出率;在最佳条件即硫酸浓度为2.7 mol/L,温度为85 ℃,液固比为5:1,时间为2 h,空气压力为0.1~0.2 MPa和搅拌速度为300 r/min下,硫酸浸出渣率为60.0%,Cu和Te的浸出率分别为97.65%和77.53%,Ag和Sb的浸出率分别为8.95%和2.0%。

关键词:阳极泥;碱性加压氧化浸出;硫酸浸出;铜

中图分类号:TF111 文献标志码:A 文章编号:1672-7207(2013)06-2192-08

Sulfuric acid leaching of residue from copper anode slime pretreated by alkaline oxidative pressure leaching

LIU Weifeng1, 2, LIU Younian1, YANG Tianzu2, CHEN Lin2, ZHANG Duchao2, WANG An2

(1. School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China;

2. School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: The process of sulfuric acid leaching was adopted to treat the residue from copper anode slime pretreated by alkaline pressure oxidation leaching. The effects of many factors such as sulfuric acid concentration, temperature, time, liquid-solid ratio, stirring speed and oxidation type in sulfuric acid leaching on residue yield and leaching ratio were investigated. The results show that leaching ratios of copper, tellurium and silver increase with the increase of the concentration of sulfuric acid, especially for the leaching ratio of silver. The phase of undissolved copper in the leaching residue exists mainly in the elemental, and the leaching ratio of copper can be enhanced with air. The optimum conditions of sulfuric acid leaching are determined. Under the optimum conditions of the sulfuric acid concentration 2.7 mol/L, temperature 85 ℃, liquid-solid ratio 5:1, time 2 h, stirring speed 300 r/min and air pressure 0.1~0.2 MPa, the residue yield is 60%. The leaching rates of copper, tellurium, silver and nickel are 97.65%, 77.53%, 8.95% and 5.85%, respectively.

Key words: anode slime; alkaline oxidative pressure leaching; sulfuric acid leaching; copper

铜阳极泥是粗铜电解精炼的副产物,主要含有Cu,Pb,Se,Te,As,Sb,Bi,Au,Ag和铂族金属等有价元素,是提取稀贵金属的重要原料[1-2]。铜阳极泥首先经预处理过程脱除不利于后续工序进行的稀散金属Se,Te和贱金属Cu,然后用火法熔炼或湿法溶解的方法富集并产出贵金属合金或粉末,最后精炼产出贵金属产品,这些处理过程环环相扣,构成一个完整的铜阳极泥处理工艺[2-3],而预处理过程是决定铜阳极泥处理工艺最重要的环节。有关铜阳极泥预处理方法的研究很多[2, 4-5],目前广泛用于工业实践的只有加压氧化酸浸法[3, 6]和硫酸盐化焙烧法[7]以及个别的选矿富集法[4]等,而铜阳极泥预处理方法的研究则主要集中在这些方法的精细化过程控制、减少设备腐蚀和提高金属回收率等方面[8-11],但是,这些方法依然存在金属回收率较低、设备腐蚀和环境污染等问题,因此,开发合理和有效的预处理方法尤为迫切。借鉴相似领域的研究经验[12-15],本文作者采用碱性加压氧化法预处理铜阳极泥,即铜阳极泥经过碱性加压氧化浸出过程脱除Se和As,同时实现Cu和Te等金属的转型,然后,用硫酸溶解碱性浸出渣中的Cu和Te,碱性加压氧化浸出过程Se和As的浸出率可以达到99.0%以上,实现稀散金属的高效脱除与相互分离以及贵金属富集的多重目的[16]。本研究以碱性加压氧化浸出渣为原料,研究碱性浸出渣硫酸浸出过程中Cu,Te,Sb和Ag等金属的溶解行为。

1 实验

1.1 实验原料

实验原料为国内某厂铜阳极泥经过碱性加压氧化浸出后的浸出渣,碱性加压氧化浸出过程实验条件:NaOH浓度为2.0 mol/L、温度为200 ℃、氧分压为0.7 MPa、时间为3 h、液固比为5:1、填充比为0.8和搅拌速度为1 000 r/min,碱性浸出渣率为76.0%,As和Se的浸出率都达到99.0%以上,Cu,Ag和Te的浸出率为0,Pb和Sb的浸出率小于3.0%[17]。铜阳极泥和碱性加压氧化浸出渣的化学成分如表1所示。

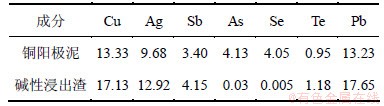

表1 铜阳极泥碱性加压浸出渣化学成分(质量分数)

Table 1 Chemical composition of copper anode slime and alkaline leaching residue %

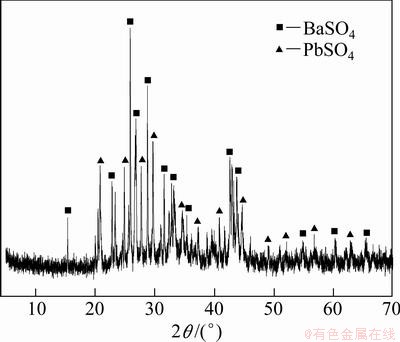

为了确定碱性加压氧化浸出渣主要成分的赋存状态,对铜阳极泥和碱性加压氧化浸出渣分别进行X线衍射分析,结果如图1和图2所示。

对比图1和图2可以看出:由于铜阳极泥中大多数元素没有完整晶型,所以,只能检测出硫酸铅和硫酸钡物相,而碱性加压氧化浸出渣中,只有硫酸钡与单质银2个物相,硫酸铅物相消失。这说明在碱性加压氧化浸出过程中,硫酸铅物相发生了转化,而硫酸钡物相没有转化。

图1 铜阳极泥XRD图谱

Fig. 1 XRD pattern of Cu anode slime

图2 碱性加压浸出渣的XRD图谱

Fig. 2 XRD pattern of alkaline leaching residue

1.2 实验方法

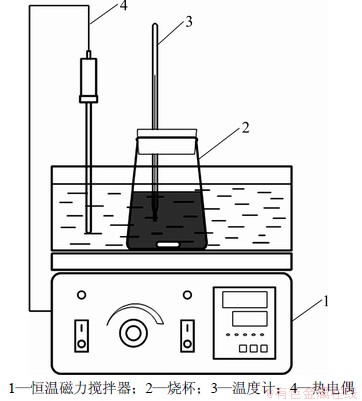

碱性浸出渣的硫酸浸出实验在配置有250 mL缩口烧杯的恒温磁力搅拌器中进行,实验装置示意见图3。首先配制浓度和体积一定的硫酸溶液,然后,启动磁力搅拌器并设定水浴温度,待烧杯内温度和水浴温度相同时,缓慢加入一定重量的碱性加压浸出渣并开始计时,实验结束后,采用真空抽滤方式过滤,浸出液量取体积,浸出渣用热水洗涤后烘干并称质量。Cu,Ag,Sb和Te等元素的含量依次用碘量法、硫氰酸钾滴定法、硫酸铈滴定法和重铬酸钾滴定法测定。

1.3 化学反应

铜阳极泥碱性加压氧化浸出渣的硫酸浸出过程主要发生的化学反应如下:

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

在硫酸浸出过程中,主要发生氧化物与硫酸的中和反应,其中Cu和Te溶解进入溶液,Pb和Ag的形态转化后进入浸出渣,少量Sb和Sn等溶解。

图3 溶液中金属回收实验装置示意图

Fig. 3 Experiment schematic diagram of sulfuric acid leaching

2 结果与讨论

2.1 硫酸浓度的影响

2.1.1 硫酸浓度对硫酸浸出过程的影响

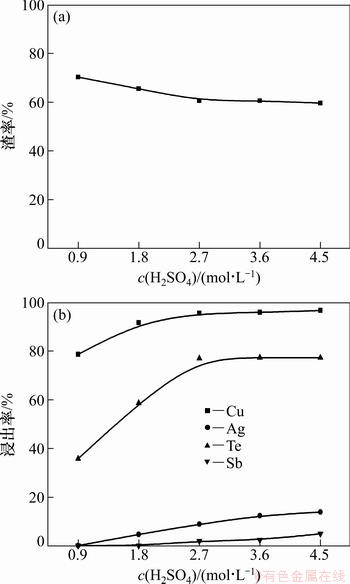

初始条件:碱性浸出渣质量为20 g,液固比为5:1、时间为2 h,温度为85 ℃和搅拌速度为400 r/min。在此条件下,考察硫酸浓度对硫酸浸出过程各金属浸出率的影响,结果见图4。

从图4(a)可以看出:随着硫酸浓度的增加,硫酸浸出过程的渣率逐渐降低,当c(H2SO4)≥2.7 mol/L时,渣率保持在60%左右。从图4(b)图可以看出:Cu,Ag,Te和Sb的浸出率随硫酸浓度的增加逐渐增加,与渣率的变化刚好相反;当c(H2SO4)≥2.7 mol/L时,Cu,Te和Sb的浸出率基本不变,分别保持在96.0%,77.0%和4.0%;Ag的浸出率也随着硫酸浓度的增加逐渐增加,主要原因是生成了可溶性的AgHSO4,发生的反应如下:

(5)

(5)

图4 H2SO4浓度对碱性浸出渣硫酸浸出过程的影响

Fig. 4 Effect of H2SO4 concentration on sulfuric acid leaching

2.1.2 硫酸溶液中银平衡浓度的计算

为了查明硫酸溶液中银的溶解行为,有必要计算硫酸溶液中银浓度(c(Ag+)T)与硫酸浓度(c(H2SO4))和氢离子浓度(c(H+))的关系,由于没有其他反应发生,所以溶液中的游离银浓度(c(Ag+))就等于总银浓度(c(Ag+)T)。

当硫酸溶液中银的溶解与沉淀达到平衡时,存在以下2种离子平衡:

(1) 硫酸溶液中,银可能生成Ag2SO4的沉淀。

(6)

(6)

(2) SO42-的加质子平衡。在硫酸溶液中,SO42-会与H+反应生成HSO4-,而随着溶液中pH值的变化,SO42-的浓度(c(SO42-))和HSO4-的浓度(c(HSO4-))均会发生变化,溶液中的总硫酸根浓度c(SO42-)T可表示为:

(7)

(7)

(8)

(8)

其中:K1H为硫酸根离子的加质子常数。

由式(7)和式(8)可以计算溶液中的游离硫酸根c(SO42-)浓度为

(9)

(9)

将式(9)代入式(6),可以得出:

(10)

(10)

其中:温度298 K下硫酸根离子的加质子常数K1H=102,Ag2SO4的溶度积Ksp=1.2×10-5。

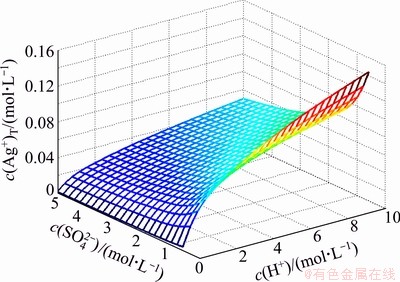

根据式(10)绘制了温度298 K,c(SO42-)T=0~5 mol/L,c(H+)=0~8 mol/L条件下,硫酸溶液中c(Ag+)与c(SO42-)T和c(H+)的关系曲面图,结果见图5。

由图5可以看出:随着硫酸溶液中氢离子浓度(c(H+))的增加,溶液中银总浓度c(Ag+)T逐渐增加,随着硫酸根总浓度(c(SO42-)T)的增加,溶液中银总浓度c(Ag+)T逐渐降低。

图5 硫酸溶液中c(Ag+)T与c(SO42-)T和c(H+)的关系曲面图

Fig. 5 Dissolution equilibrium curved surface of c(SO42-)T and c(H+) on c(Ag+)T

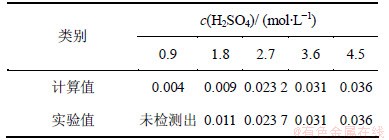

根据图5可以计算出不同c(SO42-)T和c(H+)下的硫酸溶液中溶解的银浓度c(Ag+)T,计算值与实验值对比见表2。

表2 硫酸溶液中c(Ag+)T的计算值与实验值对照表

Table 2 Calculation and experiment value of c(Ag+)T in solution mol/L

从表2可以看出:随着硫酸浓度的增加,溶液中银浓度逐渐升高,溶液中银总浓度的计算值与实验值吻合程度也越好,说明在高硫酸浓度的条件下,硫酸溶液越接近理想溶液。而溶液中银在c(H2SO4)=0.9 mol/L时,银浓度的理论计算值为0.004 mol/L,而实际溶液中未检测出银。原因主要是硫酸浓度低时,溶液的c(H+)浓度很低,银已经生成氢氧化物或氧化物等沉淀完全进入硫酸浸出渣中,此时,溶液中的总银浓度不能用式(10)计算。

根据以上研究结果,为了提高碱性浸出渣中Cu和Te的浸出率,尽可能减少Ag的溶解,选择硫酸浓度2.7 mol/L比较合适。

2.2 液固比的影响

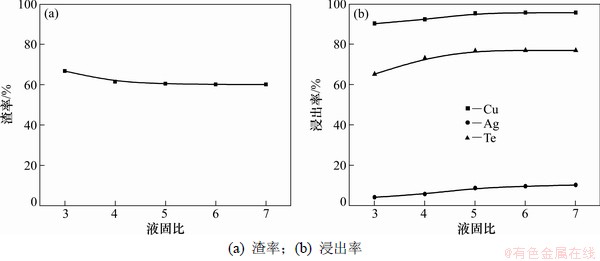

初始条件:碱性浸出渣质量为20 g,硫酸浓度为2.7 mol/L,时间为2 h,温度为85 ℃和搅拌速度为400 r/min。在此条件下,考察液固比对碱性浸出渣硫酸浸出过程的影响,结果如图6所示。

从图6(a)可以看出:随着液固比的增加,硫酸浸出过程的渣率逐渐降低,当液固比≥5.0时,渣率一直保持在60.0%左右。各种金属的溶解行为见图6(b)。Cu和Te的浸出率都随液固比的增加而增大,当液固比≥5.0时,Cu和Te的浸出率基本不发生变化,分别保持在95.0%和77.0%左右。Ag的浸出率随液固比的增加不断增大,当液固比为5时,Ag的浸出率为8.86%,主要原因是溶液体积增大。为了彻底脱除碱性浸出渣中的Cu和Te,同时保持溶液中高的金属离子浓度,减少废水排放,选择液固比为5比较合适。

2.3 温度的影响

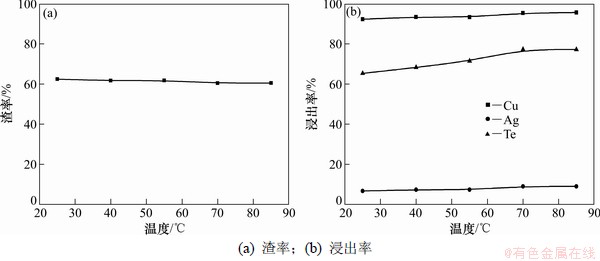

初始条件:碱性浸出渣质量为20 g,硫酸浓度为2.7 mol/L,液固比为5,时间为2 h,搅拌速度为400 r/min。在此条件下,考察温度对碱性浸出渣硫酸浸出过程的影响,结果如图7所示。

图6 液固比对碱性浸出渣硫酸浸出过程的影响

Fig. 6 Effect of L/S on sulfuric acid leaching

图7 温度对碱性浸出渣硫酸浸出过程的影响

Fig. 7 Effect of temperature on sulfuric aicd leaching

从图7(a)可以看出:随着温度增大,硫酸浸出过程的渣率逐渐降低,但是降低幅度很小;当温度不低于70℃时,碱性浸出渣率保持至60.57%。各金属浸出率的变化见图7(b)。从图7(b)可见:各金属浸出率随反应温度升高而缓慢增加,其中:Cu和Ag浸出率增加幅度非常小,说明温度对碱性浸出渣硫酸浸出过程影响较小。为了保证反应过程顺利进行,同时尽可能减少溶液蒸发量,所以,选择温度为85 ℃比较合适。

2.4 反应时间的影响

初始条件:碱性浸出渣质量为20 g,硫酸浓度为2.7 mol/L,液固比为5,温度为85 ℃和搅拌速度为400 r/min。在此条件下,考察反应时间对碱性浸出渣硫酸浸出过程的影响,结果如图8所示。

从图8可以看出:反应时间对碱性浸出渣硫酸过程的影响较小,随反应时间的延长,硫酸浸出过程的渣率始终保持在60.0%左右,Cu,Te和Ag的浸出率分别保持在95.0%,77.0%和8.80%左右,基本不发生变化,从热力学平衡的角度,延长反应时间有利于化学反应趋于平衡,但是过多的延长反应时间,不仅设备利用率低,而且降低了生产效率,所以,选择反应时间为2 h比较合适。

2.5 搅拌速度的影响

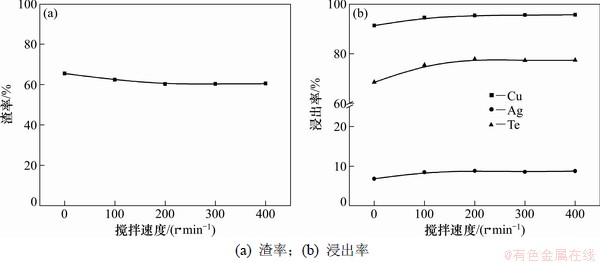

初始条件:碱性浸出渣质量为20 g,硫酸浓度为2.7 mol/L,液固比为5,温度为85 ℃,时间为2 h。在此条件下,考察了搅拌速度对碱性浸出渣硫酸浸出过程的影响,结果如图9所示。

从图9(a)可以看出:随搅拌速度的提高,碱性浸出渣硫酸浸出过程渣率先明显降低然后保持不变,当搅拌速度高于300 r/min时,酸性浸出渣率始终维持在60.0%左右。从图9(b)可以看出:随着搅拌速度的增大,Cu,Te和Ag的浸出率先增加然后保持不变,当搅拌速度高于300 r/min时,这3种金属的浸出率分别维持在95.0%,77.0%和8.5%左右,说明增加搅拌速度,可以强化碱性浸出渣的硫酸浸出过程,原因是提高搅拌速度,削弱了反应生成物的包裹作用,促进化学反应进行得更加完全。故选择搅拌速度为300 r/min。

图8 时间对碱性浸出渣硫酸浸出过程的影响

Fig. 8 Effect of time on sulfuric acid leaching

图9 搅拌速度对碱性浸出渣硫酸浸出过程的影响

Fig. 9 Effect of stirring speed on sulfuric acid leaching

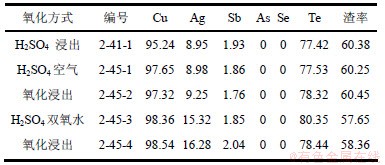

2.6 氧化方式的影响

碱性浸出渣硫酸浸出时,虽然铜的浸出率可以达到95.0%左右,但是硫酸浸出渣中铜的质量分数仍然有1.10%,对硫酸浸出渣进行化学物相分析,结果见表3。

由表3可以看出:硫酸浸出渣中残余的铜主要以金属铜形式存在,为了提高铜的浸出率,在硫酸浸出过程中加入氧化剂以强化浸出过程,研究了压缩空气和双氧水作为氧化剂对碱性浸出渣硫酸浸出过程的影响。

初始条件:碱性浸出渣质量为20 g,硫酸浓度为2.7 mol/L,温度为85 ℃,液固比为5,时间为2 h和搅拌速度为300 r/min,空气氧化过程空气泵压力为0.1~0.2 MPa,双氧水用量与碱性浸出渣的质量比为0.2。在此条件下,考察空气和双氧水对碱性浸出渣硫酸浸出过程各金属浸出率的影响,结果见表4。

表3 硫酸浸出渣中铜的物相分析结果

Table 3 Phase of Cu in acid leaching residue %

表4 氧化方式对碱性浸出渣硫酸浸出率的影响 (质量分数)

Table 4 Effects of oxidation types on sulfuric acid leaching rate %

从表4可以看出:硫酸浸出过程中加入氧化剂后,Cu的浸出率都有提高,达到了预期的实验目的,但是,用双氧水氧化浸出时,Ag的浸出率也会增大,不利于贵金属的集中回收,故选择空气作氧化剂以强化硫酸浸出过程比较合理。

2.7 最佳工艺条件

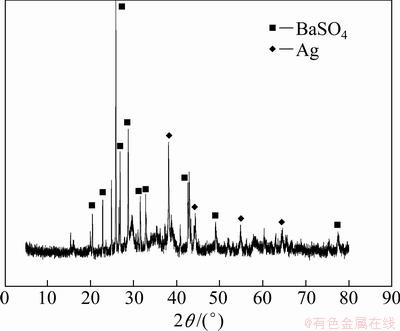

根据以上研究结果,确定了铜阳极泥碱性加压氧化浸出渣硫酸浸出过程的最佳工艺条件:硫酸浓度为2.7 mol/L,温度为85 ℃,液固比为5:1,时间为2 h,空气压力为0.1~0.2 MPa和搅拌速度为300 r/min。在此条件下,硫酸浸出渣率保持在60.0%,Cu和Te的浸出率分别为97.65%和77.53%,Ag和Sb的浸出率分别为8.95%和2.0%,硫酸浸出液的主要成分为(g/L):Cu 35.50,Te 2.45,Ag 1.82,Ni 0.22,Sb 0.11和Sn 0.16,硫酸浸出渣的主要成分(质量分数,%)为:Cu 0.60,Te 0.22,Ag 18.95和Sb 4.85。可见,完全实现了Cu和Te的分离以及Ag的富集。硫酸浸出渣的XRD分析结果如图10所示。

图10 硫酸浸出渣的XRD图谱

Fig. 10 XRD pattern of acid leaching residue

将图10与碱性浸出渣的XRD结果(图2)对比可以看出:硫酸浸出渣中重新出现了硫酸铅物相,说明硫酸浸出过程中发生了铅化合物与硫酸的中和反应,与铜阳极泥的XRD结果(图1)对比发现,经过碱性加压氧化浸出和硫酸浸出2个过程后出现了单质Ag的物相。

3 结论

(1) 以铜阳极泥碱性加压氧化浸出渣为原料,提出采用硫酸浸出方法分离Cu和Te的研究思路,考察了硫酸浓度、温度、时间、液固比、搅拌速度和氧化方式等因素对碱性浸出渣硫酸浸出过程的影响。

(2) 硫酸浓度对金属浸出率的影响较大,尤其对Ag的溶解影响较大;硫酸浸出渣中未溶解的Cu主要以单质存在,采用空气氧化方式可以提高Cu的浸出率;硫酸浸出过程又将Pb转化为PbSO4物相。

(3) 确定铜阳极泥碱性浸出渣硫酸浸出过程最佳的工艺条件如下:硫酸浓度为2.7 mol/L,温度为85 ℃,液固比为5:1,时间为2 h,空气压力为0.1~0.2 MPa和搅拌速度为300 r/min,在此条件下,硫酸浸出渣率为60.0%,Cu和Te的浸出率分别为97.65%和77.53%,Ag和Sb的浸出率分别为8.95%和2.0%,实现了有价金属的有效分离。

参考文献:

[1] Devenport W G, King M, Schlesinger M, et al. Extractive metallurgy of copper[M]. 4ed. Oxford: Elsevier Science Ltd, 2002: 207-308.

[2] 杨天足. 贵金属冶金及产品深加工[M]. 长沙: 中南大学出版社, 2005: 371-372.

YANG Tianzu. Metallurgy and product of precious metals[M]. Changsha: Central South University Press, 2005: 371-372.

[3] Ludvigsson B M, Larsson S R. Anode slime treatmen-the boliden experience[J]. JOM, 2003, 55(4): 41-44.

[4] 周令治, 陈少纯. 稀散金属提取冶金[M]. 北京: 冶金工业出版社, 2008: 304-311.

ZHOU Lingzhi, CHEN Shaochun. Extractive metallurgy of scare metals[M]. Beijing: Metallurgical Industry Press, 2008: 304-311.

[5] Hait J, Jana R K, Sanyal S K. Processing of copper electrorefining anode slime: A review[J]. Mineral Processing and Extractive Metallurgy, 2010, 118(4): 240-252.

[6] 张博亚, 王吉坤. 加压酸浸预处理铜阳极泥的工艺研究[J]. 矿冶工程, 2007, 27(5): 41-43.

ZHANG Boya, WANG Jikun. The technological research on pre-treating copper anode slime with pressure acid leaching method[J]. Mining and Metallurgical Engineering, 2007, 27(5): 41-43.

[7] 郭学益, 肖彩梅, 钟菊芽, 等. 铜阳极泥处理过程中贵金属的行为[J]. 中国有色金属学报, 2010, 20(5): 990-998.

GUO Xueyi, XIAO Caimei, ZHONG Juya, et al. Behaviors of precious metals in process of copper anode slime treatment[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 990-998.

[8] Hait J, Jana R K, Kumar V, et al. Some studies on sulfuric acid leaching of anode slime with additives[J]. Chem Res, 2002, 41(25): 6593-6599.

[9] 郑雅杰, 洪波. 漂浮阳极泥富集金银及回收锑铋工艺[J]. 中南大学学报: 自然科学版, 2011, 42(8): 221-226.

ZHENG Yajie, HONG Bo. Enrichment of Au and Ag and recovery of Sb and Bi from floating anode slime[J]. Journal of Central South University: Science and Technology, 2011, 42(8): 221-226.

[10] Antipov N I, Arasov A V. Hydrometallurgical methods of recycling interelectrode slime[J]. Metallurgist, 2002, 46(2): 229-233.

[11] Gu Z H, Chen J, Fahidy T Z. A study of anode slime behavior in the electrorefining of copper[J]. Hydrometallurgy, 1995, 37(2): 149-167.

[12] 奚明, 李登斯. 论元素丰度与环境友好型生产工艺[J]. 环境科学与管理, 2010, 35(6): 175-178.

XI Ming, LI Dengsi. On element abundance and environment-friendly process[J]. Environmental Science and Management, 2010, 35(6): 175-178.

[13] Corneli G, Poppe S, Gerven T V, et al. Geochemical modelling of arsenic ans selenium leaching in alkaline water treatment sludge from the production of non-ferrous metals[J]. Journal of Hazardous Materials, 2008, 159: 271-279.

[14] 黄怀国, 江城, 孙鹏, 等. 碱性热压氧化预处理难浸金矿工艺的机理研究[J]. 稀有金属, 2003, 27(2): 249-254.

HUANG Huaiguo, JIANG Cheng, SUN Peng, et al. A mechanism study on technology of pretreatment of refractory gold ores by alkaline hot-pressure oxidation[J]. Chinese Journal of Rare Metals, 2003, 27(2): 249-254.

[15] Saptharishi S, Mohanty D, Kamath B P. Process for selenium recovery from copper anode slime by alkali pressure leaching[J]. In F kongoli, R G Reddy, eds. Proceeding of Sohn International Symposium, 2006 TMS Meeting, Extraction and Processing Division, New Orleans, 2006: 175-184.

[16] 刘伟锋, 杨天足, 王安. 一种铜阳极泥的预处理方法:中国, ZL201019060009.0[P]. 2011-07-13.

LIU Weifeng, YANG Tianzu, WANG An. A pretreatment method of copper anode slimes: China, ZL201019060009.0[P]. 2011-07-13.

[17] 刘伟锋. 碱性氧化法处理铜/铅阳极泥的研究[D]. 长沙: 中南大学冶金科学与工程学院, 2011: 120-128.

LIU Weifeng. Study on copper/anode slimes treated by alkaline oxidative leaching[D]. Changsha: Central South University: School of Metallurgical Science and Engineering, 2011: 120-128.

(编辑 何运斌)

收稿日期:2012-03-06;修回日期:2012-05-04

基金项目:中国博士后科学基金资助项目(2013M531808);中南大学博士后基金资助项目(110768);2009年湖南省科技重大专项(2009FJ1007)

通信作者:刘伟锋(1980-),男,陕西岐山人,讲师,博士后,从事贵重金属的冶金工艺与材料制备研究;电话:0731-88830923;E-mail:liuweifeng1214@163.com