铂族金属铑的合金化活化溶解规律及其机理

董海刚1, 2,陈家林1,赵家春1, 2,范兴祥1, 2,吴跃东1,李博捷1,刘杨1

(1. 昆明贵金属研究所,云南 昆明,650106;

2. 贵研铂业股份有限公司 稀贵金属综合利用新技术国家重点实验室,云南 昆明,650106)

摘要:对铂族金属铑添加金属铝粉进行合金化活化溶解规律及机理进行研究。采用XRD和SEM等技术对铝铑合金经稀酸溶出铝后所得的粉末状铑物料的微观结构物及相组成进行表征。研究结果表明:在铝粉与铑质量比为10、合金化活化温度为1 200 ℃、活化时间为120 min的条件下所得铝铑合金经稀酸溶出铝,所得铑物料采用王水溶解,铑的溶解率达到99%以上;该过程的机理主要在于铝铑合金经稀酸溶出铝后,所得铑物料粒度变细,处于高度分散状态,晶体结晶程度较差,晶格存在缺陷,具备较高的反应活性;该铑物料通过王水溶解,实现了铑的高效溶解。

关键词:铑;合金化活化;溶解

中图分类号:TF837 文献标志码:A 文章编号:1672-7207(2014)11-3746-06

Rules and mechanism of alloying activation dissolution of platinum group metals rhodium

DONG Haigang1, 2, CHEN Jialin1, ZHAO Jiachun1, 2, FAN Xingxiang1, 2,

WU Yuedong1, LI Bojie1, LIU Yang1

(1. Kunming Institute of Precious Metals, Kunming 650106, China

2. Sino-platinum Metals Co. Ltd., State Key Laboratory of Advanced Technologies for

Comprehensive Utilization of Platinum Metals, Kunming 650106, China)

Abstract: Alloying activation dissolution of rhodium by adding metal aluminum powder was studied out. The microstructure and mineral phase composition of powder rhodium material obtained from the material leached by dilute acid were characterized by XRD and SEM. The results show that, under the conditions of mass ratio of Al to Rh of 10, alloying activation temperature of 1 200 ℃ and activation time of 90 min, an Al-Rh alloy is obtained, which is leached to remove Al by dilute acid, and the leached product is dissolved by aqua regia, and the Rh dissolution is above 99%. The mechanism of the process is that after Al being dissolved out in the Al-Rh alloy, the obtained rhodium material has fine particle size, high dispersion state, incomplete crystalline, lattice defects and high reactivity. The obtained rhodium material is dissolved by aqua regia, realizing high efficient solution of rhodium.

Key words: rhodium; alloying activation; dissolution

铂族金属铑具有稳定的电阻和良好的导电、导热性以及高催化活性。铑化学性质十分稳定,具有良好的耐酸碱腐蚀性和高温抗氧化性,广泛应用于日常生活、农业、传统工业、高新技术、军工航天、医药卫生及环境保护等各个领域[1-2]。铑最具化学惰性,用王水溶解数月也难溶解完全,铑的高效快速溶解是铂族金属冶金科技发展中的重要前沿技术和公认的难题[3]。铂族金属的溶解在铂族金属冶金领域是一个重要且必不可少的环节。铑的分离、提纯精炼、化合物制备过程都首先需要将铑物料进行有效溶解使其转入溶液,并以配合物状态存在,然后进行分离、提纯以及铑化合物、有机化合物的合成制备[4]。铑通常以化合物形式,如RhCl3·nH2O,Rh2(SO4)3,Rh(NO3)3,RhI3,Rh(OAc)x和RhH(CO)(PPh3)3等应用于汽车尾气净化催化剂、首饰镀铑、医药及石化催化剂,在此过程中必须先将金属铑转化为铑的基础化合物,再加工成催化剂活性涂层材料、镀铑液、有机铑化合物等。目前,根据物料中铑的含量、存在状态和活性的差异,其溶解方法各有不同,大致可以分为:

1) 水溶液化学溶解法[4-7](包括常压和加压溶解法),常压溶解法适合于处理铑含量低、活性高的物料,加压溶解法对设备要求高,需要密闭高温高压耐腐蚀反应器,仅适宜于处理分散度大、粒度细的物料。

2) 中温熔融法[3-4, 8-10](包括中温氯化法、KHSO4熔融法、过氧化钡熔融法等)。中温氯化法只能在密闭石英管式炉中进行,需反复多次,溶解效率低,并且大量尾气氯气需要碱吸收,试剂消耗量大,还存在氯化铑的挥发损失;KHSO4熔融法需用高温设备,溶解周期长,试剂消耗量大,需要反复溶解才能溶解完全;过氧化钡熔融法在硫酸钡沉淀除钡的过程中,沉淀夹带、吸附部分铑,降低了铑的回收率。

3) 高温熔炼法[11-13](金属合金化活化法、锍捕集-铝热活化法等),金属合金化活化法虽然可能带入杂质,但是可以控制,同时其优点是对原料的适应性强,可以处理各种难处理铑物料,如致密状的铑、铑铱合金、铂铑合金等;锍捕集-铝热活化法溶解周期长、能耗高、适宜用于复杂铑物料的富集溶解。

4) 电化学溶解法[14-16]。电化学溶解法的优点是溶解过程不引入新的杂质,缺点是溶解速度慢。

铑的合金化活化溶解法是将含铑物料添加贱金属(Al,Fe,Cu,Mn,Bi,Sn等)或其合金活化剂进行高温活化焙烧,生成铑与贱金属的合金,通过酸溶合金中的贱金属后获得高化学反应活性的铑物料,再进行铑的溶解。合金化活化溶解适宜于处理各种状态的铑物料,操作较为简单,过程易控制,但对于铑合金化活化溶解的过程机制认识还不十分清楚。因此,本文以难溶铂族金属铑为研究对象,通过添加金属铝在高温下进行合金化活化,获得铝铑合金,采稀酸溶出铝,获得活性铑物料,再采用王水溶解铑,实现铑的高效溶解,同时对其过程机理通过XRD和SEM分析检测技术进行讨论。

1 原料及研究方法

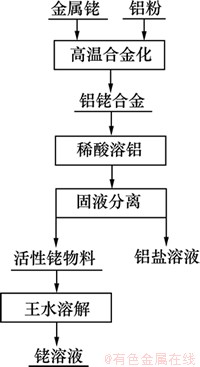

研究所用的原料为购置于某公司的金属铑(品位99.95%),铝粉为化学纯试剂。其工艺流程如图1所示。

图1 金属铑合金化活化溶解工艺流程

Fig. 1 Flowsheet of alloying activation dissolution of metal Rh

具体实验方法为:取一定质量的金属铑(1~2 g),按一定的质量比添加铝粉,充分混合后,装入坩埚,置于设定温度的马弗炉内,恒定高温进行铝铑合金化反应至指定时间,获得铝铑合金。自然冷却后,采用稀硫酸溶出铝铑合金中的铝,固液分离后获得活性铑物料,取样进行XRD和SEM分析。余样采用王水溶解,采用ICP分析溶解液中铑含量,计算铑溶解率。在本研究过程中,固定铝铑合金稀酸溶出铝的条件:稀硫酸在80 ℃温度下以液固比为6溶解8 h。活性铑溶解条件为:王水在90 ℃以液固质量比为4溶解3 h。

2 结果与讨论

2.1 实验原理

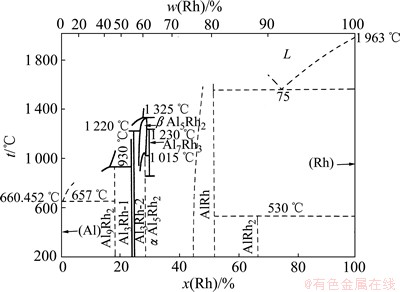

本研究提出铑添加金属铝在高温条件下进行合金化活化,获得铝铑合金,采用稀酸溶出铝,获得活性铑物料,再采用王水溶解铑,实现铑的高效溶解。从Al-Rh系相图[17]可以看出:在一定条件下,铝与铑可以形成一系列合金AlxRhy,如Al9Rh2,Al3Rh-1,Al3Rh-1,Al3Rh-2,αAl3Rh2,Al3Rh2,βAl3Rh2,AlRh和AlRh2。

图2 Al-Rh系相图

Fig. 2 Phase diagram of Al-Rh system

铂族金属铑合金化活化溶解过程发生的全部反应如下。

活化焙烧过程:

xAl+yRh=AlxRhy

稀酸溶出铝过程:

AlxRhy+1.5xH2SO4=0.5xAl2(SO4)3+yRh+1.5H2

王水溶解铑的过程:

Rh+HNO3+6HCl=H3RhCl6+NO+2H2O

由此可知,只要控制适宜的铝和铑质量比,在一定的温度下进行焙烧,能形成铝铑合金。该合金采用稀硫酸溶出铝,获得活性铑物料,再采用王水溶解铑,获得铑溶液,实现了铑的溶解。

2.2 合金化活化溶解实验

2.2.1 铝与铑质量比对铑溶解率的影响

在合金化温度为1 300 ℃,合金化时间120 min的条件下,研究了铝与铑质量比对铑溶解率的影响,结果如图3所示。

由图3可看出:随着铝与铑质量比的提高,铑的溶解率逐渐提高。当铝与铑质量比为2时,铑溶解率极低,不到10%;当铝与铑质量比为10时,铑溶解率接近99%;继续提高铝与铑质量比,铑溶解率变化不明显。这表明:当铝与铑质量比较低时,合金化过程中熔融态的铝少且很难与金属铑形成合金,同时金属铝表面容易形成一层高熔点的氧化铝薄膜,抑制了合金化活化过程,铑的溶解率很低。随着铝与铑质量比的提高,合金化活化过程中产生大量的熔融态的铝,体系中熔体数量增多,金属间接触充分,反应完全,形成的铝铑合金中铑的分散程度高,有利于后续铑的溶解。

图3 铝与铑质量比对铑溶解率的影响

Fig. 3 Effect of Al to Rh weight ratio on Rh dissolution

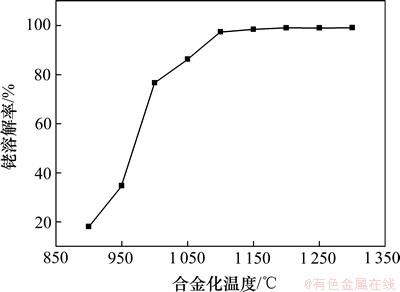

2.2.2 活化温度对铑溶解率的影响

在铝与铑质量比为10,合金化时间为120 min的条件下,合金化活化温度对铑粉溶解率的影响如图4所示。

图4 合金化活化温度对铑溶解率的影响

Fig. 4 Effect of activation temperature on Rh dissolution

由图4可看出:随着合金化活化温度的升高,铑的溶解率逐渐提高;当合金化活化温度低于900 ℃时,铑的溶解率低于20%;当合金化温度达到1 200 ℃时,铑溶解率为99.01%,此后随着合金化温度升高,铑溶解率变化不大。这是由于铝的熔点为660.4 ℃,当合金化温度较低时,形成的金属熔体的黏度较大,流动性差;随着合金化温度的升高,金属熔体黏度降低,金属铑在熔融铝液中的流动性增强,接触充分,有利于铝铑合金的形成,合金中铑的分散度高。

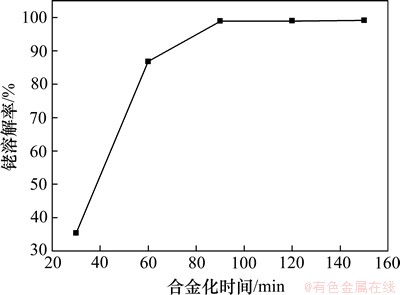

2.2.3 合金化活化时间对铑溶解率的影响

在铝与铑质量比为10,合金化焙烧温度为1 200 ℃的条件下,合金化时间对铑溶解率的影响如图5所示。

图5 合金化时间对铑溶解率的影响

Fig. 5 Effect of alloying time on Rh dissolution

由图5可以看出:随着合金化时间的延长,铑的溶解率逐渐增加;当合金化时间为30 min时,铑的溶解率仅为35.38%,延长合金化时间为120 min,铑的溶解率达到99.01%;继续延长合金化时间,铑的溶解率变化不大。合金化时间延长,铑在熔融铝液中得到充分分散,合金化反应进行比较彻底,合金化活化程度高。但是,合金活化时间过长,合金表面可能会产生部分抗酸碱腐蚀的α-Al2O3,导致酸溶过程中铝的溶出效果变差,从而影响后续铑的溶解。从实验结果看,合金化反应在120 min内基本完成。

3 过程机理研究

3.1 铑物料形貌特征变化

对铝铑合金溶出铝后所得的铑物料与未合金化活化的铑物料的形貌进行SEM分析,结果见图6。

由图6可以看出:未合金化活化的铑物料颗粒粗并且致密,其表面光滑,轮廓、边界明晰可辨。经过铝合金化活化、稀酸溶出铝处理后,所得铑物料颗粒变细且分散度增大,比表面积相应增大,新生表面产生,对应的表面积增大,活性增加。从动力学的角度来说,这些微观形貌的变化有利于铑的溶解反应的进行。

3.2 铑物料XRD分析

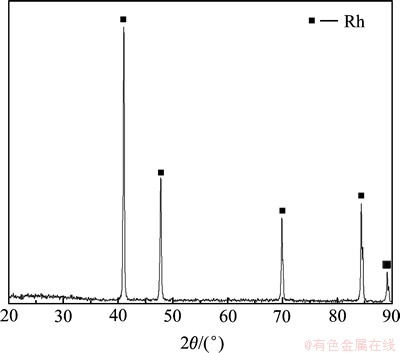

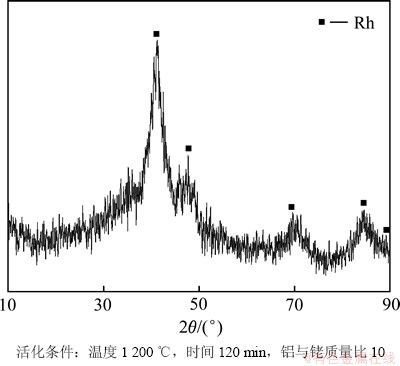

分别对合金化活化前后2种物料进行XRD分析,结果见图7及图8。

由图7及图8可以看出:2种物料的物相主要为金属铑,对未合金化活化的铑物料而言,其特征衍射峰强度在衍射角度为40.96°达到最强,且结晶完整,结构最稳定。铝合金化活化后处理后的铑物料,衍射图谱中铑的特征衍射峰强度下降,并出现部分非晶态物质,结晶程度变差。

图6 SEM分析

Fig. 6 SEM analysis

图7 未合金化活化铑物料XRD分析图谱

Fig. 7 XRD pattern of non-activated Rh material

图8 合金化活化后铑物料的XRD分析图谱

Fig. 8 XRD pattern of activated Rh material

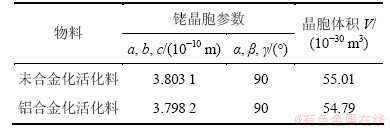

为了进一步查明铝合金化活化处理后铑物料的微观性能的变化,采用美国JADE软件,通过对铝合金化活化前后物料XRD数据的分析计算,得到铑晶体的晶胞参数,结果见表1。

表1 活化前后铑晶胞参数

Table 1 Lattice parameters of Rh before and after activation

由表1可知:铝合金化活化处理后,铑的晶体晶胞边长减小,晶胞体积减小。这是因为铝合金化活化过程中,在高温下原子间相互渗透,金属铝原子取代铑原子的位置,形成的铝铑合金冷却结晶后形成新的晶体,稀酸溶出铝铑合金中的铝后,晶格产生缺陷或畸变,导致晶胞体积减小,从而宏观表现为铑物料的活性提高。

4 结论

1) 铑合金化活化溶解的适宜条件为铝与铑质量比为10,合金化活化温度为1 200 ℃,合金化活化时间120 min,在此条件下所得铝铑合金经稀硫酸溶出铝,获得活性铑物料,再采用王水溶解铑物料,铑的溶解率达到99%以上。

2) 铝铑合金经稀酸溶出铝后,所得铑物料粒度变细,处于高分散状态,晶体结晶程度变差,晶格产生缺陷,晶胞体积减小,物料活性提高,有利于铑溶解。

参考文献:

[1] 黎鼎鑫, 王永录. 贵金属提取与精炼[M]. 2版. 长沙: 中南大学出版社, 2003: 12-36.

LI Dingxin, WANG Yonglu. Extraction and refining of precious metals[M]. 2nd ed. Changsha: Central South University Press, 2003: 12-36.

[2] 刘志斌. 贵金属铑、铱的分离与富集[D]. 昆明: 昆明理工大学国土资源工程学院, 2006: 1-2.

LIU Zhibin. The separation and enrichment of precious metals rhodium, iridium separation and enrichment[D]. Kunming: Kunming University of Science and Technology. School of Land and Resources Engineering, 2006: 1-2.

[3] 彭红建, 谢佑卿. 金属铑的原子状态、物理性质和热力学性质的研究[J]. 稀有金属, 2007, 31(2): 206-230.

PENG Hongjian, XIE Youqing. Atomic states, physical properties and thermodynamic properties of rhodium[J]. Chinese Journal of Rare Metals, 2007, 31(2): 206-230.

[4] 贺小塘. 铑的提取与精炼技术进展[J]. 贵金属, 2011, 32(4): 72-78.

HE Xiaotang. Development of rhodium separation and refining technology[J]. Precious Metals, 2011, 32(4): 72-78.

[5] ZHU Liya, YANG Guangyu, LI Kaizhong, et al. Application of microwave closed digestion technique in the treatment of difficultly dissolved Rh, Ir powders and their samples[J]. Precious Metals, 2008, 29(1): 40-46.

[6] 董海刚, 汪云华, 李柏榆, 等. 稀贵金属铑物料溶解技术研究进展[J]. 稀有金属, 2011, 35(6): 939-945.

DONG Haigang, WANG Yunhua, LI Baiyu, et al. Progress in dissolution technique of precious metal rhodium materials[J]. Chinese Journal of Rare Metals, 2011, 35(6): 939-945.

[7] 赵家春, 汪云华, 范兴祥, 等. 一种高纯铑物料快速溶解方法: 中国, 200810058706.8[P]. 2008-07-21.

ZHAO Jiachu, WANG Yunhua, FAN Xingxiang, et al. A method of quick dissolution of high purity rhodium materials: CN200810058706.8[P]. 2008-07-21.

[8] 廖秋玲, 曲志平, 姚文学. 水合三氯化铑的开发研究[J]. 中国资源综合利用, 2000, 11: 9-10.

LIAO Qiuling, QU Zhiping, YAO Wenxue. The research and development of rhodium trichloride hydrate[J]. China Resources Comprehensive Utilization, 2000, 11: 9-10.

[9] 杨春吉. 从废铑催化剂中提取铑粉[J]. 贵金属, 2002, 23(4): 6-8.

YANG Chunjie. Extraction of rhodium from spent catalyst rhodium powder[J]. Precious Metals, 2002, 23(4): 6-8.

[10] 时一春, 杨冬, 赵麦变, 等. 一种从二元王水不溶渣中回收铂铑的方法: 中国, 200910073730.3[P]. 2009-01-21.

SHI Yichun, YANG Dong, ZHAO Maibian, et al. A method to recover Pt and Rh from an insoluble residue using aqua regia: CN200910073730.3[P]. 2009-01-21.

[11] 刘时杰. 铂族金属矿冶学[M]. 北京: 冶金工业出版社, 2001: 289-300.

LIU Shijie. Mining and metallurgy of platinum group metals[M]. Beijing: Metallurgy Industry Press, 2001: 289-300.

[12] 钱东强, 余建民, 刘时杰. 贵金属的存在状态与溶解技术[J]. 贵金属, 1997, 18(1): 40-42.

QIAN Dongqiang, YU Jianmin, LIU Shijie. The status of precious metals in solutions and the dissotution technologies[J]. Precious Metals, 1997, 18(1): 40-42.

[13] 钱东强, 刘时杰. 低品位及难处理贵金属物料的富集活化溶解方法: 中国, 95106124.0[P]. 1995-05-24.

QIAN Dongqiang, LIU Shijie. The active enrichment and dissolution method of refractory and low-grade precious metal materials: CN95106124.0[P]. 1995-05-24.

[14] Juodkazis K, Stalnionis G,  B, et al. EQCM study of rhodium anodic dissolution in sulfuric acid[J]. Russian Journal of Electrochemistry, 2002, 38(11): 1157-1162.

B, et al. EQCM study of rhodium anodic dissolution in sulfuric acid[J]. Russian Journal of Electrochemistry, 2002, 38(11): 1157-1162.

[15] Styrkas A D, Styrkas D. Electrochemical dissolution of metals of the platinum group by alternating current[J]. Journal of Applied Electrochemistry, 1995, 25(6): 490-494.

[16] 吕顺丰, 张秀英, 吴秀香. 一种三氯化铑的制备方法: 中国, 200610091177.2[P]. 2008-01-09.

L Shunfeng, ZHANG Xiuying, WU Xiuxiang. A method of preparation of rhodium trichloride: CN200610091177.2[P]. 2008-01-09.

Shunfeng, ZHANG Xiuying, WU Xiuxiang. A method of preparation of rhodium trichloride: CN200610091177.2[P]. 2008-01-09.

[17] 何纯孝, 李关芳. 贵金属相图及化合物结构参数[M]. 北京: 冶金工业出版社, 2007: 41.

HE Chunxiao, LI Guangfang. Phase diagrams of precious metal alloys and structure parameters of precious metals compounds[J]. Beijing: Metallurgy Industry Press, 2007: 41.

(编辑 何运斌)

收稿日期:2013-12-28;修回日期:2014-05-29

基金项目(Foundation item):国家高技术研究发展计划(“863”计划)项目(2012AA063203) (Project(2012AA063203) supported by the National High Technology Research and Development Program ( “863” Program))

通信作者:董海刚(1981-),男,甘肃陇南人,博士,副研究员,从事稀贵金属冶金基础理论及回收新技术等研究;电话:0871-68329261;E-mail: donghaigang0404@126.com