Al-Si合金粉末的高能球磨及其表征

杨伏良,易丹青

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘 要:为制备能满足使用要求的高硅铝合金电子封装材料,采用高能球磨对Al-Si合金粉末进行氧化预处 理,结合包套热挤压制备Al2O3与SiO2增强的弥散强化型铝硅复合材料,并利用粉末粒度分析仪、氧分析仪、金相显微镜及扫描电镜对球磨粉末氧含量、粉末粒度及材料组织进行分析。研究结果表明:Al-Si合金粉末经24 h球磨后,粉末粒度明显减小,部分粒径从3~5 μm减小到0.1~0.2 μm;球磨后粉末形状从原来的长条状转变为细小的球状;粉末氧含量随着球磨时间延长而增加,且与球磨时间接近于呈线性关系;粉末经高能球磨后,所制备材料晶粒更加细小,特别是硅粒子已明显细化,材料组织更均匀、更致密;随着粉末球磨时间延长,材料热导率增加,球磨32 h后,材料热导率高达145.5 W?m-1?K-1。

关键词:高硅铝合金;铝硅复合材料;电子封装;球磨

中图分类号:TF112;TG337 文献标识码:A 文章编号:1672-7207(2008)01-0029-06

High-energy ball milling and characterization of Al-Si alloy powders

YANG Fu-liang, YI Dan-qing

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: In order to fabricate high-silicon aluminum alloys electronic packaging materials, the high-energy ball milling process was applied to the Al-Si alloy powder, combined with vacuum canning hot-extrusion process to fabricate SiO2 and Al2O3 dispersion strengthening composites. Powder particle size analyzer, oxygen content analyzer, optical microscope and scanning electron microscope were used to study the oxygen content and particle size of milled powders and fabricated material microstructure. The results show that when Al-Si alloy powder was milled after 24 h, the particle size decreases obviously and some from 3-5 μm to 0.1-0.2 μm. Particle shape varies from long strip to fine globosity after milling. Oxygen content increases and is linear with milling time. The crystal grain of material fabricated by milling powder is finer, especially Si particles minish obviously, and the microstructure is more uniform and compact. Thermal conductivity increases with the prolonging milling time, and after being milled for 32 h, it is 145.5 W?m-1?K-1.

Key words: high-silicon aluminum alloy; Al-Si composites; electronic packaging; ball milling

高硅铝合金作为电子封装材料,其密度仅为传统金属基W-Cu电子封装材料的1/6,且高硅铝合金具有很好的导热性能,线膨胀系数可控[1],能与电路板广泛使用的半导体材料相匹配,因此,作为基片衬底、机壳及盖板等材料,可保证电子器件在使用过程中不致受热或开裂而过早失效。高硅铝合金电子封装材料代表了新型轻质电子封装材料的发展方向。高硅铝合金制备工艺有熔铸法[2-4]、粉末冶金烧结法、喷射沉积法[5-9]和溶渗法锭坯制备技术,以及热挤压、半固态挤压、热锻造等加工成形技术[10],然而,采用这些方法所制备的材料,其热导率、热膨胀系数及抗拉强度难以同时满足电子封装材料的使用要求,因此,必须寻求新的途径,制备出能完全满足使用要求的材料。

弥散强化金属基复合材料由于微粒子阻碍金属基体的位错运动其基体被强化,典型材料为SAP,由于其强化相多为氧化物,故也叫ODS合金。美国Glidden Metals公司研究了Al2O3粒子分散强化Cu合金的技术,其制备方法是:将Cu-Al合金用气体雾化法雾化成粉末,然后对粉末进行内氧化,使其内部Al氧化成Al2O3粒子,再挤压成制品,便得到了性能优良的Al2O3弥散强化铜合金材料。为此,实验采用高能球磨对Al-Si合金粉末进行氧化预处理,然后,结合包套挤压,制备出Al2O3与SiO2增强的弥散强化型铝硅复合材料。本文作者对Al-Si合金粉末球磨氧化机制进行探讨,并对球磨时间对合金粉末粒度、形貌、氧含量及其所制备材料组织的影响进行研究。

1 实 验

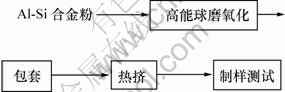

材料制备工艺流程如图1所示。

图1 材料制备工艺流程

Fig.1 Process of material fabrication

1.1 粉末制备

实验所用粉末名义成分为Al-30Si,粉末采用氮气雾化水冷制得,Si,O和Al的质量分数分别为24.46%,0.25%和75.00%,其余为杂质。粉末中位径、面积平均径、体积平均径分别为17.01,10.46和27.20 μm。高能球磨设备采用自制专用球磨机,选择直径为10 mm与5 mm 2种不锈钢球进行搭配,它们的质量配比为1?1,球料质量比为10?1,分别采用8,16,24与32 h 4种球磨时间进行球磨(另有实验采用了高温空气氧化对粉末进行预处理,氧化温度为300 ℃,为便于比较,设定氧化时间与球磨时间相同)。

1.2 粉末成形

采用包套封装方法[11-12],将球磨后的合金粉末装入特制的纯铝包套内,振实后其密度可达理论密度的70%,封闭焊合包套(包套盖板上留有一小孔,以便挤压时包套内气体排出)。挤压前对样品采用520 ℃加热保温,保温时间为1 h,挤压比为21.3(挤压筒直径为60 mm,挤压后样品直径为13 mm)。

1.3 粉末氧化特性分析及材料组织观察

粉末粒度分布测试在Microplus激光衍射粒度分析仪上进行,其测量范围为0.05~550 μm;氧含量分析在TC-436氮/氧分析仪上进行,功率为5 kW,分析时间为30 s,气流量为300 mL/min;粉末形貌分析在JSM-5600LV扫描电镜中进行,在NeophotoⅡ型金相显微镜下观察材料组织。

2 结果分析与讨论

2.1粉末形貌

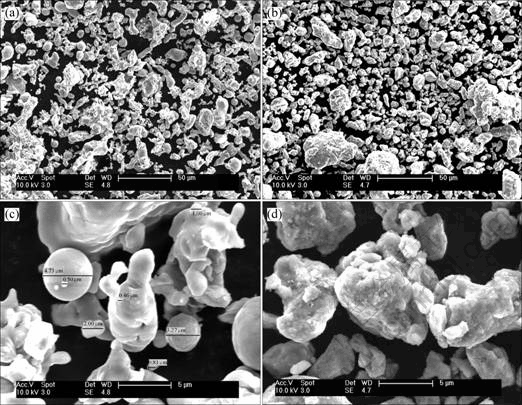

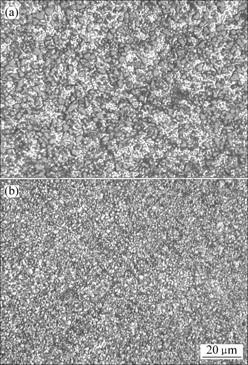

图2所示为球磨前后不同放大倍数粉末形貌的扫描电镜(SEM)照片。图2(a)和2(b)显示,从整体上来看,粉末从原来的长条状已转变为细小的球状。考虑到粉末的后续加工成形性,为减少球磨过程对粉末所产生的污染,在球磨过程中没有加入分散剂。因此,随着球磨的进行,粉末表面能增加,粉末发生了团聚,但球磨效果仍非常明显。

(a) Al-30Si原始粉末;(b) Al-30Si球磨24 h粉末;(c) Al-30Si原始粉末;(d) Al-30Si球磨24 h粉末

图2 球磨前后粉末扫描电镜照片

Fig.2 SEM images of original and milled powders

2.2 粉末粒度

粉末经不同时间球磨后所测粒度如图3所示。可以看出,粉末中位径及体积平均径随着球磨时间延长而下降(细化),但面积平均径随球磨时间延长,在前16 h呈下降趋势,球磨16 h后反而有所增加。这可能是由于粉末在球磨过程中形貌发生了变化,形成了一定的片状颗粒;另外,由于在粉末球磨过程中没有加入分散剂,粉末发生了明显的团聚现象,所以,图3只能反映粉末球磨粒径的变化趋势。结合图2所示粉末形貌可知,粉末经过24 h球磨后,实际的粉末粒 径要小得多,部分粉末粒径从3~5 μm减小到0.1~0.2 μm。

1—体积平均径;2—中位径;3—面积平均径

图3 粉末经不同时间球磨后的粒度

Fig.3 Granularity of powder by different milling time

从图3还可以发现,随着球磨时间延长,粉末细化作用不断减弱。这是因为当粉末细化到一定程度后,其粒径变小,单位体积的表面自由能增加,若进一步细化,则所需的能量也越大。因此,细小颗粒比粗大颗粒更难进一步细化。

2.3 粉末氧含量

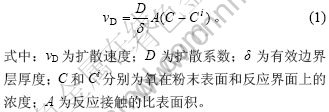

由于Al-Si合金粉末经高能球磨后,从宏观上并没有改变合金成分和环境的氧分压,因而,对氧化过程的热力学影响不显著,而粉末氧化过程要连续进行,首先是氧原子向反应界面前沿扩散,其次反应才进行。氧化推进速度受氧原子在合金内扩散速度控制,动力学分析包括扩散分析和反应分析2部分,α(Al)基体为塑性较好的金属,Si相为脆性颗粒,两者在磨球的冲击碰撞下反复破碎、焊合,使合金粉末晶粒不断细化,与氧原子接触面积增大,扩散距离不断减小,使扩散速度增加。这里仅分析晶粒细化对扩散速度的影响[13]。

由式(1)可知,扩散速度与比表面积成正比,假定晶粒均为球形,则由球面面积公式可知,A∝r2。其中,r为晶粒粒径。

从图2(c)和2(d)可知,球磨前、后粉末的平均粒径比约为26,球磨后比表面积为原来的676倍,如果假定其他参数不变,实际扩散时接触面积仅为计算值的1/20,则根据式(1),实际扩散速度为原来的34倍,实际粉末在球磨氧化过程中储存了大量能量,可使某些微区温度升高或使原子活性增加,有利于氧的扩散,若氧化反应仅受扩散控制,则可大大提高氧化进程,因此,高能球磨对粉末氧化动力学的影响要明显得多。

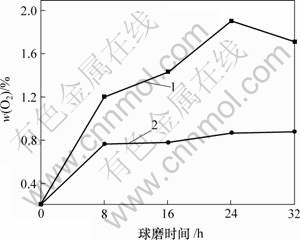

经不同球磨时间球磨后所测粉末氧含量如图4所示(为便于比较,图中列出了相同时间内高温空气氧化粉末的氧含量)。从图4可以看出,在球料比相同时,随着球磨时间延长,粉末氧含量增加,且与球磨时间接近于呈线性关系;与高温空气氧化粉末相比,在相同的氧化时间内,高能球磨工艺对粉末的氧化效果好得多,粉末氧含量大大提高。其原因是:球磨实际上是粉末颗粒在钢球之间受到强烈撞击、挤压、破碎和彼此啮合(冷焊)的过程。当粉末受到球的碰撞、挤压时,一方面,球间中心线上的粉末产生强烈的塑性变形,使粉末表面积扩大,并且表面氧化膜脱落露出洁净的“原子化”金属表面,这些粉末的新鲜表面在压力作用下相互冷焊在一起,形成了层间有一定结合力的复合颗粒。也就是这种反复破碎,使粉末不断露出待氧化的新鲜表面进行氧化反应。另一方面,由于钢球的反复碰撞挤压,使粉末不断经受塑性变形而产生加工硬化,当加工硬化到一定程度后,又将导致粉末破裂。这种反复的冷焊和破碎过程,使复合颗粒内部结构不断精细化,同时发生固相反应扩散和粉末氧化。因此,随着球磨时间延长,粉末粒度越来越小,比表面积增加,表面能增加,与空气中氧接触的界面增多,粉末与氧发生反应的几率增大。

1—球磨粉末;2—空气氧化粉末

图4 经不同球磨时间球磨后粉末氧含量

Fig.4 Oxygen content of powder by different milling time

此外,随着球磨时间延长,由于罐内不断产生的热量使粉末温度升高,促进了粉末与氧反应,加快了粉末氧化过程;随着球磨时间延长,粉末晶体内部缺陷增多,有利于氧在粉末内扩散。

2.4 材料组织

图5所示为粉末经球磨与高温空气氧化后所挤压材料的金相照片。可以看出,与高温空气氧化相比,粉末经高能球磨后,所制备材料的晶粒更加细小,特别是硅粒子已明显细化,材料组织更均匀、更致密,空隙度减少,基体联通更好,这都有利于提高材料气密性、导热性能和加工成形性能。

(a) Al-30Si空气氧化24 h;(b) Al-30Si球磨24 h

图5 粉末经球磨与高温空气氧化后挤压材料的金相照片

Fig.5 Metallographs of material fabricated by ball milling process and high-temperature oxidation method

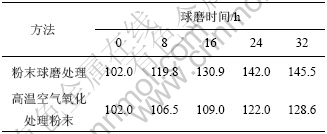

2.5 材料热导率

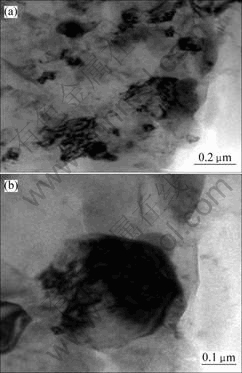

作为电子封装材料用盖板与壳体,热导率是其最主要的性能指标之一。粉末经球磨与高温空气氧化处理后所制备材料热导率如表1所示。可以看出,对于Si含量相同的材料,粉末经球磨预处理后,所制备材料热导率明显高于经相同时间处理的高温空气氧化预处理粉末的材料热导率,在相同处理时间内,球磨后粉末比空气氧化粉末的热导率平均高10%,特别是粉末处理时间为16 h时,球磨与空气氧化处理相比,材料热导率高20%。此外,随着粉末球磨时间延长,材料热导率增加,球磨时间在8~24 h内变化时,材料热导率增加速度较大,球磨24 h后,材料热导率为142 W?m-1?K-1,但继续延长球磨时间,材料热导率增加速度降低,球磨32 h后,材料热导率为145.5 W?m-1?K-1。其原因是:一方面,高能球磨使合金氧化程度增加,氧化物本身的热导率很小,粉末球磨氧化后经热挤压,相当于增强颗粒分布于复合材料中,降低复合材料热导率;但另一方面,高能球磨使Al-Si合金粉末细化,同时使合金粉末内部储藏大量能量,促进Al相流动和Si相重排过程,使Al-Si粉末颗粒更好地粘合,减少材料内部大量存在的气孔、缺陷等造成的孔隙。而这些孔隙的热导率很低,对声子的散射严重,从而对材料导热性能产生不利影响。因此,降低材料孔隙率必然会提高材料导热性能。其次是粉末的细化,不仅使材料致密度提高,而且会使Si相颗粒细小,且分布均匀,界面结合加强。图6所示为Al-30Si粉末球磨24 h后挤压材料的透射电镜照片,可以看出,挤压材料中硅相与氧化物质点分布较均匀。从图6(b)可看出,界面结合良好,因此,界面热阻大大降低。可见,随着球磨时间延长,材料热导率增加。

表1 氧化粉末经热挤压后的热导率

Table 1 Thermal conductivity of materials fabricated by oxidation powders 热导率/( W?m-1?K-1)

(a) 硅相与氧化物质点的分布;(b) 增强相与基体的界面状况

图6 Al-30Si粉末球磨24 h后挤压材料的透射电镜照片

Fig.6 TEM images of material fabricated by milled powders after 24 h milling

总的来说,由于合金粉末的氧化物含量有限,在高能球磨过程中,加速材料内部的固态扩散和反应,改善相界面的结合状态,使材料更加均匀致密,同时明显细化材料中第2相(Si)颗粒,使基体之间更好联通,有利于提高材料热导率。

取球料比为10?1,粉末经球磨24 h后,随着球磨时间延长,粉末颗粒的冷焊与破碎将达到平衡,相应的粉末粒径减小到一定程度后将不再降低,进一步延长球磨时间对热挤压后材料的组织影响大大减小,但研磨过程的机械能仍不断地传递到粉末颗粒中,促进原子扩散,改善界面结合状况,降低界面对传热声子或电子的阻碍作用,从而提高材料热导率,但其提高幅度明显减小。

3 结 论

a. 球料比为10?1时,Al-Si合金粉末经24 h球磨后,粉末粒度明显减小,部分粉末粒径从3~5 μm减小到0.1~0.2 μm;粉末形状从原来的长条状转变为细小的球状。

b. 当球料比相同时,粉末氧含量随着球磨时间延长而增加,且与球磨时间接近于呈线性关系。

c. 粉末经球磨后,所制备材料晶粒更加细小,特别是硅粒子已明显细化,材料组织更加均匀、致密。

d. 粉末经球磨预处理后,所制备材料的热导率明显高于经相同时间处理的高温空气氧化预处理粉末的热导率,且随着粉末球磨时间延长,材料热导率增加,球磨32 h后,材料热导率为145.5 W?M-1?K-1。

参考文献:

[1] Adolfi S, Jacobson D M, Ogilvy A. Aerospace and space materials technology testhouse[C]//Contract Number ERBFMGECT980141. AMTT User No. Ⅱ-03.

[2] 廖恒成, 孙国雄. 铸造Al-Si合金中Sr与B的交互作用[J]. 中国有色金属学报, 2003, 13(2): 353-359.

LIAO Hong-cheng, SUN Guo-xiong. Interaction between Sr and B in Al-Si casting alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 353-359.

[3] 张金山, 许春香, 韩富银. 复合变质对过共晶高硅铝合金组织和性能的影响[J]. 中国有色金属学报, 2002, 12(S1): 107-110.

ZHANG Jin-shan, XU Chun-xiang, HAN Fu-yin. Effect of composite modifier on structures and properties of hypereutectic Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(S1): 107-110.

[4] 魏朋义, 傅恒志. 熔体搅拌Al-12%Si合金的组织细化[J]. 中国有色金属学报, 1996, 6(1): 98-102.

WEI Peng-yi, FU Heng-zhi. Microstructure refinement of Al-12%Si by melts stirring[J], The Chinese Journal of Nonferrous Metals, 1996, 6(1): 98-102.

[5] 傅定发, 任胜钢, 陈振华. 多层喷射沉积过共晶Al-Si-Cu-Mg合金的微观组织及力学性能[J]. 中南工业大学学报: 自然科学版, 2000, 31(5): 445-447.

FU Din-fa, REN Sheng-gang, CHEN Zhen-hua. Microstructures and mechanical properties of a hypereutectic Al-Si-Cu-Mg alloy by multi-layer spray deposition[J]. Journal of Central South University of Technology: Natural Science, 2000, 31(5): 445-447.

[6] Srivastava V C, Mandal R K, Ojha S N. Microstructure and mechanical properties of Al-Si alloys produced by spray forming process[J]. Materials Science and Engineering, 2001, A304-306: 555-558.

[7] Kim W J, Yeon J H, Lee J C. Superplastic deformation behavior of spray-deposited hyper-eutectic Al-25Si alloy[J]. Journal of Alloys and Compounds, 2000, 308: 237-243.

[8] 甄子胜, 赵爱民, 毛卫民, 等. 喷射沉积高硅铝合金显微组织及形成机理[J]. 中国有色金属学报, 2000, 10(6): 815-817.

ZHEN Zi-sheng, ZHAO Ai-min, MAO Wei-min, et al. Microstructure and formation mechanism of spray deposited hypereutectic Al-Si alloys[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 815-817.

[9] 孙章明, 丁道云, 陈振华. 多层喷射沉积制备高硅铝合金工艺研究[J]. 中南工业大学学报: 自然科学版, 1997, 28(3): 257-259.

SUN Zhang-ming, DING Dao-yun, CHEN Zhen-hua. Studies on preparing technology of high-silicon aluminum alloy by multi-layer spray deposition[J]. Journal of Central South University of Technology: Natural Science, 1997, 28(3): 257-259.

[10] 赵爱民, 甄子胜, 毛卫民, 等. 喷射沉积高硅铝合金的半固态触变成形[J]. 中国有色金属学报, 2000, 10(S1): 126-131.

ZHAO Ai-min, ZHEN Zi-sheng, MAO Wei-min, et al. Semi-solid thixoforming of spray formed high silicon hypereutectic Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(S1): 126-131.

[11] SHEN Jun, ZHUANG De-xie, YU Lai-gao. Microstructure characteristics of a hypereutectic Al-Si alloy manufactured by rapid solidification/powder metallurgy process[J]. Journal of Materials Science Letters, 2001, 20: 1513-1515.

[12] LI Yuan-yuan, ZHANG Da-tong, ZHANG Wei-wen. Rapidly solidified hypereutectic Al-Si alloy prepared by powder hot extrusion[J]. Trans Nonferrous Met Soc China, 2002, 12(5): 878-881.

[13] Liang Y J. Physical chemistry[M]. Beijing: Metallurgical Industry Press, 1983: 236-258.

收稿日期:2007-04-21;修回日期:2007-06-08

基金项目:国防科学技术工业委员会资助项目(2003-151)

作者简介:杨伏良(1962-),女,湖南韶山人,副教授,从事铝合金及信息功能材料研究

通信作者:杨伏良,女,副教授;电话:0731-8877713(O);E-mail:yangflcsu@163.com