纳米/微米金刚石薄膜对钛合金摩擦性能和耐腐蚀性能的影响

来源期刊:中国有色金属学报2015年第6期

论文作者:王菁清 龙航宇 谢友能 邓泽军 周静 魏秋平 余志明 唐瞻贵

文章页码:1597 - 1607

关键词:金刚石薄膜;钛合金;结合强度;摩擦学性能;耐腐蚀性能

Key words:diamond film; titanium alloy; adhesive strength; tribological behavior; corrosion resistance

摘 要:金刚石薄膜可以加强牙科用钛合金(TC4)基台止动螺钉稳定性,延长其使用寿命。通过热丝辅助化学气相沉积(HFCVD)在TC4上沉积微米晶金刚石(MCD)和纳米金刚石(NCD)薄膜,分别采用SEM、AFM和Raman光谱对金刚石薄膜的形貌和质量进行表征,采用划痕实验检测了薄膜的结合强度。结果表明:沉积得到的NCD和MCD薄膜连续致密,表面粗糙度小,结合良好;金刚石薄膜有效地降低了TC4表面的摩擦因数和磨损率,NCD的摩擦因数约为0.09~0.15,MCD的约为0.18~0.22,其中在人工唾液环境下表现出更低的摩擦因数;金刚石薄膜人工唾液环境中能有效地提升材料的耐腐蚀性能,TC4表面沉积所得NCD薄膜的各项性能指标均优于MCD薄膜的。

Abstract: The diamond coatings may strengthen the stability of the titanium abutment screw in dentistry for improving its lifespan. The nanocrystalline diamond (NCD) and microcrystalline diamond (MCD) films were deposited on titanium alloy (TC4) by hot-?lament-assisted chemical vapor deposition (HFCVD). The morphology and quality of the diamond films were evaluated by SEM, AFM and Raman spectroscopy, respectively. The adhesive strength between the film and substrate was characterized by scratch test. The results show that as-deposited NCD and MCD films have continuous, dense, small surface roughness and good adhesion. The friction experiments indicate that diamond coating lowers the friction coefficient and friction rate. The friction coefficient of NCD and MCD are about 0.09-0.15 and 0.18-0.22, wherein, the artificial saliva exhibit even lower. MCD coating also promotes the corrosion resistance in artificial saliva. All the results present that TC4 surface deposited with NCD film provides superior performances than MCD film.

文章编号:1004-0609(2015)06-1597-10

王菁清1,龙航宇1,谢友能1,邓泽军1,周 静2,魏秋平1, 3,余志明1, 3,唐瞻贵2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 湘雅口腔医院,长沙 410078;

3. 中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:金刚石薄膜可以加强牙科用钛合金(TC4)基台止动螺钉稳定性,延长其使用寿命。通过热丝辅助化学气相沉积(HFCVD)在TC4上沉积微米晶金刚石(MCD)和纳米金刚石(NCD)薄膜,分别采用SEM、AFM和Raman光谱对金刚石薄膜的形貌和质量进行表征,采用划痕实验检测了薄膜的结合强度。结果表明:沉积得到的NCD和MCD薄膜连续致密,表面粗糙度小,结合良好;金刚石薄膜有效地降低了TC4表面的摩擦因数和磨损率,NCD的摩擦因数约为0.09~0.15,MCD的约为0.18~0.22,其中在人工唾液环境下表现出更低的摩擦因数;金刚石薄膜人工唾液环境中能有效地提升材料的耐腐蚀性能,TC4表面沉积所得NCD薄膜的各项性能指标均优于MCD薄膜的。

关键词:金刚石薄膜;钛合金;结合强度;摩擦学性能;耐腐蚀性能

中图分类号:TG135.5 文献标志码:A

WANG Jing-qing1, LONG Hang-yu1, XIE You-neng1, DENG Ze-jun1, ZHOU Jing2,

WEI Qiu-ping1, 3, YU Zhi-ming1, 3, TANG Zhan-gui2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Xiangya Stomatological Hospital, Central South University, Changsha 410078, China;

3. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The diamond coatings may strengthen the stability of the titanium abutment screw in dentistry for improving its lifespan. The nanocrystalline diamond (NCD) and microcrystalline diamond (MCD) films were deposited on titanium alloy (TC4) by hot-filament-assisted chemical vapor deposition (HFCVD). The morphology and quality of the diamond films were evaluated by SEM, AFM and Raman spectroscopy, respectively. The adhesive strength between the film and substrate was characterized by scratch test. The results show that as-deposited NCD and MCD films have continuous, dense, small surface roughness and good adhesion. The friction experiments indicate that diamond coating lowers the friction coefficient and friction rate. The friction coefficient of NCD and MCD are about 0.09-0.15 and 0.18-0.22, wherein, the artificial saliva exhibit even lower. MCD coating also promotes the corrosion resistance in artificial saliva. All the results present that TC4 surface deposited with NCD film provides superior performances than MCD film.

Key words: diamond film; titanium alloy; adhesive strength; tribological behavior; corrosion resistance

植入义齿已经成为目前最有效的修复牙列缺损及缺失的方法[1]。然而,由于种植义齿部件多、结构复杂,临床上易产生意外及并发症[2-3],其中,最常见的并发症是部件松动,尤其是螺钉松动,据报道,其发病率高达2%至45%[4-5]。如果不及时处理,可能因应力的产生、传递和分布异常导致螺钉断裂、植入体断裂、甚至失去骨结合,导致种植失败。因此,加强基台螺钉的稳定性可以提高义齿种植成功的几率。

目前,种植体的止动螺钉采用钛合金(TC4)材料。众所周知,钛合金作为生物医学常用材料,拥有高耐腐蚀性、高力学强度、低密度以及良好的生物相容性等优异性能。然而,在负载下,它的摩擦疲劳脆化和磨损性能不利于口腔种植材料使用的长期性,尤其影响止动螺钉的使用寿命。在反复咀嚼的循环咬合力作用下,基台螺丝与种植体及基台间的微小位移以及反复拧紧和松懈的过程都会造成部件损耗。此外,在口腔生物环境中,唾液、食品中的弱酸弱碱和盐类物质、食物分解和食物残渣发酵产生的物质以及细菌、龈沟液等,可从种植体与基台之间的缝隙渗入,产生微生物腐蚀和电化学腐蚀。这种长期的摩耗和腐蚀,会影响界面间的匹配度,并使基台螺钉和义齿之间失去预负荷,最终导致螺钉松动或断裂。因此,改善钛合金止动螺钉的表面性能具有重要的临床意义。

根据上述情况,为了避免止动螺钉的松动,螺纹的理想表面应满足下列要求:高结合强度和耐磨性、低摩擦因数、强的耐蚀性和良好的生物相容性。

迄今为止,大量的研究表明,化学气相沉积(CVD)金刚石薄膜,拥有与常用于可植入材料钛和不锈钢类似的生物相容性[6-12]。在牙科的临床应用中,也已有关于沉积有微米金刚石(MCD)涂层的牙锉[13]、化学气相沉积微米/纳米金刚石(MCD/NCD)双层牙科医用工具[14]等研究报道。金刚石拥有极高的硬度、强度、耐腐蚀性和低摩擦磨损的性质,因此,有金刚石涂覆的钛合金部件可以克服钛合金的缺点[15],金刚石的这些特性也完全满足理想止动螺钉表面的要求。然而,采用CVD生长的MCD薄膜呈现出粗糙的表面形貌,具有较高的摩擦因数,不利于涂层的耐磨性能,而具有多晶形态的NCD薄膜,使得该材料在应用磨损中能够减少晶体解理的可能性[16],从而能够解决上述问题。因此,NCD薄膜除了具有MCD的一系列优良性能外,其在生物摩擦学上的优势,使得在提高螺钉的性能和使用寿命上,具有比MCD薄膜更大的潜力。目前已经有很多研究关注到NCD薄膜的生物医学应用,其对于牙科种植体的应用更是一种创新[17-20]。

众所周知,大多数研究仅集中在生物、力学性能或耐腐蚀性能方面,应用也主要集中在牙科器具上,很少有报道对NCD和MCD薄膜改善钛合金基台螺丝方面进行比较研究。为了满足组件的良好契合要求,使用热丝CVD的方法,在TC4基体上沉积一层薄的NCD与MCD薄膜。通过场发射扫描电子显微镜、原子力显微镜和拉曼光谱仪表征金刚石薄膜的表面形貌和质量;采用划痕法检验薄膜与基体的结合强度。为了模拟临床使用环境,在人工唾液环境中,对无涂层的钛合金样品、沉积有NCD薄膜和MCD薄膜的钛合金样品进行摩擦实验和耐腐蚀性试验。模拟了止动螺钉和基台、螺钉与牙齿的接触摩擦,分别选择铬钢球和ZrO2球进行对磨实验,与空气中的铬钢球对磨实验对比。

1 实验

试验基体为经过机械镜面抛光的钛合金(TC4)圆片,直径为9 mm厚度为1 mm。基体预处理如下:1) 先用2%HF + 2%HNO3(体积分数)腐蚀15 s;2) 在去离子水中超声清洗10 min,然后在含有纳米金刚石粉末的丙酮悬浊液中超声震荡30 min;3) 最后在乙醇中超声清洗2 min,得到表面粗糙度为28 nm的TC4基体。

预处理完成后,用热丝辅助化学气相沉积法(HFCVD)在基体表面沉积金刚石薄膜。NCD薄膜的反应气体为CH4+H2+Ar混合气体,MCD薄膜的反应气体为CH4+H2混合气体,气体总流量均为100 mL/min。详细的沉积参数见表1。

表1 金刚石薄膜沉积参数

Table 1 Deposition conditions for diamond films on TC4 substrates

采用场发射扫描电子显微镜(FEI Sirion200 FE-SEM)和原子力显微镜(Solver P47 AFM)对薄膜表面形貌和表面粗糙度进行表征测试。使用拉曼光谱(LabRAM ARAMIS Raman spectroscopy)对薄膜质量进行表征,其中激光波长为532 nm,氩气激发功率为21 mW,光斑大小为直径为1 μm。

采用划痕测试法检测薄膜与基体的结合强度,划痕仪为美国UMT-2多试样测试系统,所用压头为标准洛氏硬度C型金刚石压头,圆锥形压头顶角为120°,锥头半径为0.2 mm,最大载荷为25 N。薄膜的结合强度通过发射特征声波检测,试样在不断增大压头正应力的划动过程中,薄膜开始从基体剥落时的临界载荷来确定。

摩擦磨损实验使用的是美国UMT-2摩擦磨损试验机,有金刚石薄膜和没有金刚石薄膜的TC4圆片作为摩擦件,分别在人工唾液和空气中,使用9.5 mm直径的铬钢球和氧化锆球作为摩擦副进行对磨,滑行速度为180 r/min,施加载荷为5 N,摩擦时间为1500 s。

阳极极化曲线用来测试材料的耐腐蚀性能,采用的是CHI660E电化学工作站(CH Instruments, Austin, TX)。将试件制成电极,试件表面和电极表面使用双蒸超纯水(>18 MΩ)清洗,在测试之前,将样品浸于人工唾液中24 h以达到试件的表面稳定。试验采用的是三电极测试方法,钛片作为对电极,饱和Ag/AgCl电极为参比电极,人工唾液为电解质溶液;实验的扫描速率为1 mV/s,扫描范围从自腐蚀电位向正向电位扫描2 V;测试装置置于水浴中,温度保持恒定37 ℃。

2 结果与讨论

2.1 金刚石表面形貌分析

图1所示为金刚石薄膜表面和截面SEM像。从图1中可以看出,NCD和MCD薄膜都是致密、连续的,没有明显的裂纹,已满足作为保护性涂层的基本应用要求。从图1(a)中无法直接分辨出NCD薄膜的单颗晶粒形貌,估计晶粒尺寸为纳米级(100 nm以下),表面由大量菜花状团聚结构组成,该结构是由具有细密结构的纳米微晶团聚或者二次形核形成[21-22];图1(b)中MCD薄膜晶粒刻面显露,能清晰地分辨出单颗晶粒,晶粒尺寸在微米量级(200 nm~1 μm)。从图1(c)和(d)截面的SEM像可知,NCD和MCD的薄膜厚度分别约为0.6 μm和1.7 μm。

图1 沉积于TC4基体NCD和MCD薄膜的表面形貌及NCD和MCD横截面的FE-SEM像

Fig. 1 Surface morphologies of NCD(a) and MCD(b) films deposited on TC4 substrates and cross-section FE-SEM images of NCD(c) and MCD(d)

图2所示为NCD和MCD的原子力显微镜图像,NCD表面明显比MCD表面更平滑,它们的表面均方根粗糙度分别为34 nm和50 nm,这种表面粗糙度的减小主要来自晶粒尺寸的减小。一般来说,在MCD薄膜中,随着薄膜厚度的增加,晶粒尺寸和薄膜的表面粗糙度也会相应增加,而NCD薄膜则不同,当膜厚大约在1 μm 到17 μm的范围时,晶粒尺寸和表面粗糙度都不会随着膜厚的增加而增加[16]。因此,在沉积过程中以及不同的实际应用过程中,NCD薄膜的表面粗糙度都会表现得更加稳定。TC4经过预处理之后表面粗糙度约为28 nm,相比之下,NCD薄膜沉积到螺丝表面时,更能够复制出基体的表面形貌,也不会影响到螺纹的表面特征以及表面粗糙度,有利于组件的良好契合。

图3所示为NCD和MCD薄膜的拉曼光谱图。从图3中可以看出,MCD的金刚石特征峰位于1348 cm-1,相较于1332 cm-1的典型金刚石峰向高波数偏移并有显著宽化,这是由于金刚石薄膜和钛合金基体的热膨胀系数相差较大,在CVD沉积结束时,从高温降到室温的过程中膜基收缩不同导致界面处产生较大的热应力,计算值约为-7.84 GPa,表现为压应力[23]。NCD的金刚石特征峰位于1338 cm-1,相较于MCD的金刚石特征峰,NCD的特征峰向高波数偏移量较小,强度较弱,宽高比更大,说明此时薄膜的表面残余应力减小了,通过计算为-2.94 GPa,这种压应力的减小有利于增加膜基结合力,使沉积的薄膜更稳定,而峰的宽化则是晶粒尺寸减小的结果[24]。在NCD的拉曼光谱中,还能看到波长位于1140 cm-1、1350 cm-1、1480 cm-1和1550 cm-1的4个峰。其中1140 cm-1和1480 cm-1的拉曼特征峰一般认为源自于反式聚乙炔,它是一种形成在晶界处的聚合物,是证明纳米金刚石存在的可靠间接证据[25]。而1350 cm-1和1550 cm-1分别代表无序碳的D峰和G峰[22, 26],它们来自晶界处的sp2相。1140 cm-1和1550 cm-1特征峰同样出现在MCD的拉曼光谱中,表明薄膜中有一定量的非金刚石相。在薄膜的沉积过程中,甲烷和氢气(CH4+H2)的流量比会影响金刚石薄膜晶粒尺寸和拉曼光谱的特征表现[27]。随着CH4+H2的气体流量比增大,晶粒尺寸减小,晶界明显增加,随之无定型碳(sp2相)比例增加,也会引起金刚石特征峰(sp3 相)的弱化,D峰增强,甚至可能与金刚石峰重叠。由于拉曼共振效应,该光谱对sp2相的敏感度约比 sp3相的高出50倍[28],NCD薄膜相较于MCD薄膜,虽然sp2相强度增加,但是拉曼光谱中高强度的sp3相说明NCD薄膜中主要成分依然是金刚石相。

2.2 结合强度

金刚石膜应用于基台螺丝上的关键是薄膜与基体的之间的结合强度,它一般可通过划痕实验中薄膜开始从基体剥落时的临界载荷来确定。结果表明:NCD薄膜和MCD薄膜与TC4合金的附着力分别约为5.5 N和4.3 N。图4所示为划痕实验后样品的表面形貌。从图4中可以看出,金刚石薄膜并未出现大面积的崩裂和脱落,表明两种薄膜与基体均有良好的结合强度。

图2 TC4基体沉积金刚石薄膜的AFM像

Fig. 2 AFM images of different diamond films deposited on TC4 substrates

图3 NCD和MCD薄膜拉曼光谱

Fig. 3 Raman spectra of deposited NCD and MCD films

图4 划痕实验后样品的表面形貌

Fig. 4 Surface morphologies of samples after scratch test

影响薄膜附着力的主要因素之一为金刚石薄膜的残余应力,其主要由热应力和本征应力组成,热应力是由于材料之间的热膨胀系数差异而产生,钛合金的热膨胀系数为7.1×10-6~4.9×10-6,金刚石的热膨胀系数约为1.0×10-6,较大的热膨胀系数差异一直是影响薄膜附着力的主要原因。而本征应力主要是由晶界上的石墨、薄膜中的氢以及薄膜自身缺陷造成的。由于sp2相的键长比sp3相的短,更高比例的sp2键可以提高膜与基体之间的粘着强度[29-30],因此,NCD薄膜可以提供比MCD薄膜更好的与基体的结合性能,这与NCD薄膜相较于MCD薄膜残余应力的下降相对应。有研究报道[31],临界载荷会随着膜厚的增加而降低,残余应力也会随着膜厚的增加而增加[32-34],这是因为薄膜厚度增加时,增强的残余应力削弱了膜和衬底之间的界面结合强度,在临界载荷时,膜基界面的材料更容易迁移。由此可以推断,较厚的薄膜比较薄的薄膜更容易剥离。

2.3 摩擦学性能

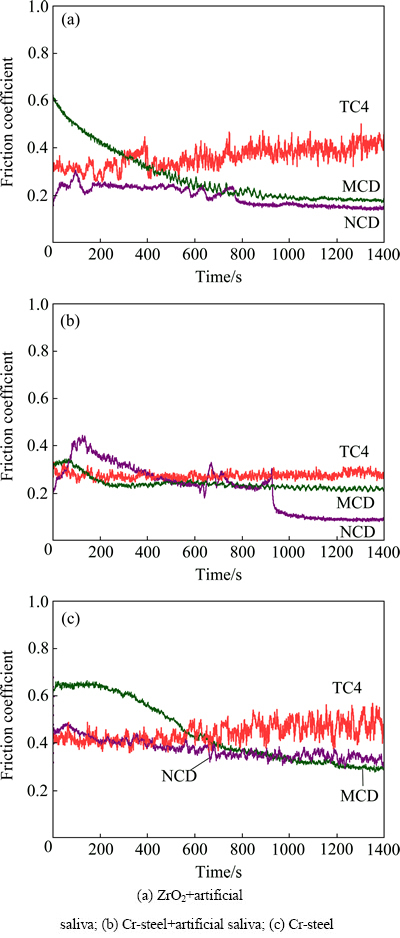

图5 NCD、MCD和TC4在不同环境中的摩擦因数变化

Fig. 5 Variations of friction coefficients during sliding of NCD film, MCD film and uncoated TC4 substrate (3 Hz frequency and 5 N normal load for 1400 s)

图5所示为NCD、MCD和TC4摩擦磨损实验所得摩擦因数随时间的变化曲线,其中(a)、(b)、(c)图展示了不同摩擦副材料和测试环境下的摩擦因数变化曲线,依次为ZrO2球-唾液、铬钢球-唾液和铬钢球-空气。从图5中可以看出,有金刚石涂层的试件,其摩擦因数都是随时间增加而呈总体下降趋势,而TC4试件的摩擦因数在微小波动中保持基本稳定,甚至还略有上升趋势。首先,NCD和MCD薄膜的摩擦因数在开始都有一个先上升再下降的过程,而TC4从一开始就一直保持在一定的波动范围内,这是因为TC4的表面是镜面抛光的,而沉积有NCD和MCD薄膜的TC4试件,经过表面预处理和金刚石沉积后,表面具有一定的粗糙度,由于磨料切削效应,摩擦初期需要一个磨合期以达到较低的稳态值,此磨合期与表面粗糙度和金刚石的平均晶粒尺寸有关。在磨合期之后的一段时间内,NCD和MCD的摩擦因数都减小,并最终保持在一定的范围之内,达到相对平稳的摩擦因数,并随时间的推移略微降低。不同环境中的试件表面最终稳定的平均摩擦因数如表2所列。由表2可以看出,当摩擦因数进入稳定阶段之后,金刚石薄膜的摩擦因数均低于TC4的摩擦因数,并且波动范围较小,性能稳定,因此,都起到了降低摩擦因数的作用。

表2 不同摩擦副时NCD、MCD和TC4最终稳定的摩擦系数

Table 2 Final friction coefficients of NCD, MCD and TC4

对比NCD和MCD的摩擦磨损性能,NCD比MCD拥有更低的摩擦因数。薄膜的表面粗糙度和微观结构,对金刚石的摩擦磨损也有着显著的影响[35]。首先,摩擦性能主要受薄膜初始表面粗糙度的影响。在一般情况下,较高的表面粗糙度会带来更长的磨合期和更大的磨擦磨损[36];足够光滑的NCD薄膜,在干燥或潮湿的环境中,与任何金属材料的滑动摩擦都表现出极低的摩擦因数。事实上,在磨合之后,NCD的表面几乎是原子级的平滑度(Ra≈6  ),其摩擦因数为表现出纯粘着摩擦组件[37]。其次,低粘着组件的形成是由于表面的悬空碳键与氢原子相结合[38],如果氢原子从金刚石表面脱离,摩擦因数将大幅增加。传统的CVD金刚石中含有少量的的氢(仅0.5%),而NCD中的氢含量约为5%,这就会使NCD产生一个自供给氢原子的表面,从而改善摩擦性能[37]。再次,低摩擦与滑动接触点附近金刚石的无定型化或石墨化有直接的联系[39-40]。这可以合理地解释,无论NCD还是MCD的摩擦因数都随着时间增加而呈下降趋势。当金刚石被抛光的时候,受表面取向和滑动方向的影响,金刚石表面经历了sp3相向sp2相的转化,产生了一个非晶依附层,这种结构相的无定型化会一定程度上造成摩擦性能的变化。增加的无定型碳会减小剪切阻力,降低表面摩擦因数。最终形成稳定的低摩擦因数,可以归因于一个连续、有润滑作用的无定型碳层的形成。相比于MCD,NCD由于二次形核使其本身具有更多的晶界,晶界处聚集了大量的sp2聚芳烃和无定型碳,因此,NCD中无定型碳对于摩擦的润滑作用也就表现得更为明显,摩擦因数更低,磨损更小。

),其摩擦因数为表现出纯粘着摩擦组件[37]。其次,低粘着组件的形成是由于表面的悬空碳键与氢原子相结合[38],如果氢原子从金刚石表面脱离,摩擦因数将大幅增加。传统的CVD金刚石中含有少量的的氢(仅0.5%),而NCD中的氢含量约为5%,这就会使NCD产生一个自供给氢原子的表面,从而改善摩擦性能[37]。再次,低摩擦与滑动接触点附近金刚石的无定型化或石墨化有直接的联系[39-40]。这可以合理地解释,无论NCD还是MCD的摩擦因数都随着时间增加而呈下降趋势。当金刚石被抛光的时候,受表面取向和滑动方向的影响,金刚石表面经历了sp3相向sp2相的转化,产生了一个非晶依附层,这种结构相的无定型化会一定程度上造成摩擦性能的变化。增加的无定型碳会减小剪切阻力,降低表面摩擦因数。最终形成稳定的低摩擦因数,可以归因于一个连续、有润滑作用的无定型碳层的形成。相比于MCD,NCD由于二次形核使其本身具有更多的晶界,晶界处聚集了大量的sp2聚芳烃和无定型碳,因此,NCD中无定型碳对于摩擦的润滑作用也就表现得更为明显,摩擦因数更低,磨损更小。

从图5(a)和(b)中可以看出,在模拟人体口腔环境的人工唾液中,NCD薄膜的摩擦因数呈现出两个稳定阶段;从图5(b)和(c)中可以看到,人工唾液环境和空气环境相比较,唾液环境中的试件表面摩擦因数都比在空气中得到的实验值更低,这些可以归因于金刚石滑动面的高度钝化性质[36]。研究报告指出,活性的气态物质如水蒸汽等,可吸附和钝化大部分碳材料表面的悬空键,阻止试样和摩擦副之间的键的生成。图5(a)和(b)两个实验组都是模拟人体口腔环境,摩擦之后会产生一些物理和化学反应,随着表面温度的升高,生成的水蒸汽富集在滑动摩擦面,因此摩擦减小。

图6所示为空气环境下试样与铬钢球对磨后的表面FE-SEM像。从图6中可以清晰分辨样品的磨损轨迹和表面变形的情况,沉积有金刚石薄膜的样品中,薄膜均无剥落和脆裂,进一步证明金刚石薄膜与基体之间有良好的结合强度;在相同的摩擦条件下,沉积有金刚石薄膜样品表面的磨损轨迹比无薄膜样品要浅,说明金刚石薄膜能够有效减少磨损率,提升基体的耐磨性,其磨损形式主要是微动磨损[41]。在本实验中,金刚石薄膜的磨损基本为0,但由于制动效应,轻微磨损是可能出现的,而当薄膜具有比摩擦副更高的硬度和弹性模量时(如表3所列),摩擦球的表面可能产生比金刚石表面更多的磨损[41],摩擦球的磨损率会随着硬度的降低而增加[42]。

NCD薄膜相较于MCD薄膜,NCD薄膜的晶粒尺寸和粗糙度在一定范围内都不会随着膜厚的增加而增加[16],这也进一步证明,NCD薄膜的摩擦性能会比MCD薄膜的摩擦性能更稳定。在不同膜厚和不同摩擦程度时,MCD薄膜很可能在膜厚较厚、摩擦程度较浅的时候表现出比较大的摩擦因数和磨损,而NCD薄膜则会一直保持更好的摩擦性能。再者,MCD膜具有较高的硬度和弹性模量,还含有较高的残余压应力。通过摩擦试验中的外部压力,薄膜容易变形甚至从基体表面剥落。而有研究表明[43],相比于其他的金刚石材料,尽管面临严峻的边界润滑条件下,NCD膜依然具有较低摩擦因数和较高的耐磨性,润滑剂的作用可以被忽略。因此,TC4的表面沉积NCD涂层可以降低磨耗提高耐磨性。

图6 与铬钢球在空气中的摩擦试验后试样表面的FE-SEM像

Fig. 6 FE-SEM images of NCD(a), MCD(b) and TC4(c) after friction tests against chrome steel ball in ambient air

表3 不同材料的硬度和弹性模量

Table 3 Hardness and elastic modulus of different materials

综上所述,钛合金表面沉积金刚石涂层能够很好地改善材料的摩擦学性能,其中NCD薄膜相较于MCD薄膜可提供更小的更稳定的摩擦因数,其特征性质均有利于生物医学的临床应用,亦符合牙科止动螺钉表面的理想要求。

2.4 耐腐蚀性

图7所示为恒温37 ℃时NCD、MCD和基体TC4的阳极极化曲线。从图7中看出,3个测量得到的极化曲线中都没有活化区,表明这3种测试材料的表面经过24 h浸泡预处理后,已经在人工唾液中钝化,一定程度上证明试件都具有良好的耐腐蚀性。在电化学扫描的过程中,电流随着电压的增加而增加,当电位升高到初始稳态电位时,电流达到钝化状态。根据电化学理论,初始稳态电位和维钝电流密度的降低,以及维钝区间的扩大,都表明了材料的耐腐蚀性能的提高。在图7中可以看到,初始稳态电位从负到正依次为NCD、MCD和TC4,其中NCD拥有最小的初始稳态电位和最大的维钝区间,而TC4呈现出最大的初始稳态电位和最小的维钝区间。这表明沉积金刚石薄膜具有较好的耐腐蚀性,其中NCD比MCD的改善效果更为明显。在临床应用中,口腔环境中的电位一般不超过600 mV[44],与此对应,在本次测试中,NCD薄膜试样的电流密度几乎为0,MCD和SUB也都在10 μA·cm2以下。

图7 NCD、MCD和TC4的阳极极化曲线图

Fig. 7 Anodic polarization curves of different diamond films and uncoated substrate in artificial saliva at 37 ℃

另外,基体宏观结构对材料的耐腐蚀性能也有很大的影响,宏观结构的差异会影响材料的表面状态。钛合金具有良好的耐蚀性是由于表面上形成的TiO2钝化膜,该膜稳定、致密、具有较高的氧化电势和机械损伤愈合能力[45]。然而,作为螺丝的螺纹面,其表面钝化膜容易受使用过程中产生的应力影响而破裂,从而可能导致金属离子的释放并危害人体的正常新陈代谢[46]。而沉积金刚石薄膜之后,致密连续结合良好的薄膜将大大提高表面状态的稳定性,可以有效防止金属元素的析出,其中,NCD薄膜结合良好,其内应力低于MCD的。因而,NCD具有更优异的综合性能。

3 结论

1) 通过HFCVD在TC4基体上沉积得到了连续致密、低表面粗糙度和结合良好的NCD和MCD薄膜。

2) NCD涂层的摩擦因数最低(0.09~0.15),MCD的次之(0.18~0.22),且均降低了磨损率,金刚石薄膜较低的表面粗糙度和特有的微观结构以及其优异的力学性能,有效地改善了TC4的摩擦磨损性能。此外,人工唾液的存在能够降低材料的摩擦因数。

3) 金刚石薄膜能有效地提升材料的抗腐蚀性能,特别是NCD薄膜拥有最小的初始稳态电位、维钝电流密度(接近0)和最大的维钝区间。

4) 致密连续结合良好的金刚石薄膜,大大提高了金属表面状态的稳定性,其中NCD薄膜具有更优异的物理化学性能和生物相容性,使其在牙齿修复方面具有很好的临床使用意义。

REFERENCES

[1] CHOI S H, JEON Y C, HWANG H S, JEONG C M. Effect of thin-gold coating on the preload torque and unscrewing torque of implant prosthetic retaining screw[J]. J Korean Res Soc Dent Mater, 2000, 27(2): 117-127.

[2] JUNG R E, ZEMBIC A, PJETURSSON B E, ZWAHLEN M, THOMA D S. Systematic review of the survival rate and the incidence of biological, technical, and aesthetic complications of single crowns on implants reported in longitudinal studies with a mean follow-up of 5years[J]. Clin Oral Implants Res, 2012, 23(S6): s2-s21.

[3] SINGER A, SERFATY V. Cement-retained implant-supported fixed partial dentures: A 6-month to 3-year follow-up[J]. International Journal of Oral & Maxillofacial Implants, 1996, 11: 645-659.

[4] JEMT T, PETTERSSON P. A 3-year follow-up study on single implant treatment[J]. Journal of dentistry, 1993, 21(4): 203-208.

[5] KIM H J, CHOE H C, CHUNG C H. Effect of TiN coating of abutment screw on detorque force[J]. Journal of Korean Academic Prosthodontic, 2007, 45: 329-338.

[6] 易建宏. 开孔隙对粉末触媒合成金刚石的影响[J]. 中国有色金属学报, 1997, 7(3): 90-93.

YI Jian-hong. Effects of open pore on diamond synthesis by powder catalyst[J]. The Chinese Journal of Nonferrous Metals, 1997, 7(3): 90-93.

[7] 易建宏. 类泡沫触媒合成金刚石的工艺特征[J]. 中南大学学报(自然科学版), 1998, 29(4): 351-353.

YI Jian-hong. Synthesis diamond’s process character by the similar catalyst foams[J]. Journal of Central South University (Science and Technology), 1998, 29(4): 351-353.

[8] TANG L, TSAI C, GERBERICH W W, KRUCKEBERG L, KANIA D R. Biocompatibility of chemical-vapour-deposited diamond[J]. Biomaterials, 1995, 16(6): 483-488.

[9] ARIANO P, BALDELLI P, CARBONE E, GILARDINO A, LO GIUDICE A, LOVISOLO D, MANFREDOTTI C, NOVARA M, STERNSCHULTE H, VITTONE E. Cellular adhesion and neuronal excitability on functionalised diamond surfaces[J]. Diamond and Related Materials, 2005, 14(3/7): 669-674.

[10] HEINRICH G, GR GLER T, ROSIWAL S M, SINGER R F. CVD diamond coated titanium alloys for biomedical and aerospace applications[J]. Surface and Coatings Technology, 1997, 94: 514-520.

GLER T, ROSIWAL S M, SINGER R F. CVD diamond coated titanium alloys for biomedical and aerospace applications[J]. Surface and Coatings Technology, 1997, 94: 514-520.

[11] M LLER R, ADAMSCHIK M, STEIDL D, KOHN E, THAMASETT S, STILLER S, HANKE H, HOMBACH V. Application of CVD-diamond for catheter ablation in the heart[J]. Diamond and Related Materials, 2004, 13(4/8): 1080-1083.

LLER R, ADAMSCHIK M, STEIDL D, KOHN E, THAMASETT S, STILLER S, HANKE H, HOMBACH V. Application of CVD-diamond for catheter ablation in the heart[J]. Diamond and Related Materials, 2004, 13(4/8): 1080-1083.

[12] SPECHT C G, WILLIAMS O A, JACKMAN R B, SCHOEPFER R. Ordered growth of neurons on diamond[J]. Biomaterials, 2004, 25(18): 4073-4078.

[13] CARVALHO C A R, FAGUNDES T C, TRAVAAIROLDI V J, NAVARRO M F L. The use of CVD diamond burs for ultraconservative cavity preparations: a report of two cases[J]. Journal of Esthetic and Restorative Dentistry, 2007, 19(1): 19-29.

[14] SALGUEIREDO E, ALMEIDA F A, AMARAL M, FERNANDES A J S, COSTA F M, SILVA R F, OLIVEIRA F J. CVD micro/nanocrystalline diamond (MCD/NCD) bilayer coated odontological drill bits[J]. Diamond and Related Materials, 2009, 18(2): 264-270.

[15] WILKS J, WILKS E. Properties and applications of diamond[M]. Masschusetts, America: Butterworth-Heinemann Limited, 1994.

[16] WIORA M, BR HNE K, FL

HNE K, FL TER A, GLUCHE P, WILLEY T M, KUCHEYEV S O, van BUUREN A W, HAMZA A V, BIENER J, FECHT H J. Grain size dependent mechanical properties of nanocrystalline diamond films grown by hot-filament CVD[J]. Diamond and Related Materials, 2009, 18(5): 927-930.

TER A, GLUCHE P, WILLEY T M, KUCHEYEV S O, van BUUREN A W, HAMZA A V, BIENER J, FECHT H J. Grain size dependent mechanical properties of nanocrystalline diamond films grown by hot-filament CVD[J]. Diamond and Related Materials, 2009, 18(5): 927-930.

[17] XIAO Xing-cheng, WANG Jian, LIU Chao, CARLISLE J A, MECH B, GREENBERG R, GUVEN D, FREDA R, HUMAYUN M S, WEILAND J. In vitro and in vivo evaluation of ultrananocrystalline diamond for coating of implantable retinal microchips[J]. Journal of Biomedical Materials Research Part B, 2006, 77(2): 273-281.

[18] STEINM LLER-NETHL D, KLOSS F R, NAJAM-UL-HAQ M, RAINER M, LARSSON K, LINSMEIER C, K

LLER-NETHL D, KLOSS F R, NAJAM-UL-HAQ M, RAINER M, LARSSON K, LINSMEIER C, K HLER G, FEHRER C, LEPPERDINGER G, LIU Xian-jie. Strong binding of bioactive BMP-2 to nanocrystalline diamond by physisorption[J]. Biomaterials, 2006, 27(26): 4547-4556.

HLER G, FEHRER C, LEPPERDINGER G, LIU Xian-jie. Strong binding of bioactive BMP-2 to nanocrystalline diamond by physisorption[J]. Biomaterials, 2006, 27(26): 4547-4556.

[19] WENMACKERS S, CHRISTIAENS P, DAENEN M, HAENEN K,  M, van deVEN M, VERMEEREN V, MICHIELS L, AMELOOT M, WAGNER P. DNA attachment to nanocrystalline diamond films[J]. Physica Status Solidi a, 2005, 202(11): 2212-2216.

M, van deVEN M, VERMEEREN V, MICHIELS L, AMELOOT M, WAGNER P. DNA attachment to nanocrystalline diamond films[J]. Physica Status Solidi a, 2005, 202(11): 2212-2216.

[20] SIEW P S, LOH K P, POH W C, ZHANG Heng. Biosensing properties of nanocrystalline diamond film grown on polycrystalline diamond electrodes[J]. Diamond and Related Materials, 2005, 14(3): 426-431.

[21] 邱万奇, 刘正义, 陈剑惠. 球形金刚石的形成机制[J]. 中国有色金属学报, 2002, 12(3): 566-569.

QIU Wan-qi, LIU Zheng-yi, CHEN Jia-hui. Formation mechanism of ball-like diamond[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 566-569.

[22] BRAGA N A, CAIRO C A A, FERREIRA N G, BALDAN M R, TRAVA-AIROLDI V J. One-step CVD-diamond coating process on 3-D titanium substrates using reticulated vitreous carbon as a solid carbon source[J]. Diamond and Related Materials, 2010, 19(7): 764-767.

[23] AHMED F, BAYERLEIN K, ROSIWAL S M, G KEN M, DURST K. Stress evolution and cracking of crystalline diamond thin films on ductile titanium substrate: Analysis by micro-Raman spectroscopy and analytical modelling[J]. Acta Materialia, 2011, 59(14): 5422-5433.

KEN M, DURST K. Stress evolution and cracking of crystalline diamond thin films on ductile titanium substrate: Analysis by micro-Raman spectroscopy and analytical modelling[J]. Acta Materialia, 2011, 59(14): 5422-5433.

[24] DUMPALA R, CHANDRAN M, KUMAR N, DASH S, RAMAMOORTHY B, RAO M S. Growth and characterization of integrated nano-and microcrystalline dual layer composite diamond coatings on WC-Co substrates[J]. International Journal of Refractory Metals and Hard Materials, 2013, 37: 127-133.

[25] AMARAL M, FERNANDES A J S, VILA M, OLIVEIRA F J, SILVA R F. Growth rate improvements in the hot-filament CVD deposition of nanocrystalline diamond[J]. Diamond and Related Materials, 2006, 15(11): 1822-1827.

[26] 王 健, 余志明, 吴晓斌, 刘 倩. 沉积参数对Mo Re合金基体上沉积金刚石薄膜的影响[J]. 中国有色金属学报, 2011, 21(6): 1415-1421.

WANG Jian, YU Zhi-ming, WU Xiao-bin, LIU Qian. Effects of deposition parameters on diamond film on Mo-Re alloy substrate[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(6): 1415-1421.

[27] SUN Z, SHI J R, TAY B K, LAU S P. UV Raman characteristics of nanocrystalline diamond films with different grain size[J]. Diamond and Related Materials, 2000, 9(12): 1979-1983.

[28] DISMUKES J P, PURDES A J, MEYERSON B S, MOUSTAKAS T D, SPEAR K E, RAVI K V, YODER M. First international symposium on diamond and diamond-like films[C]// Proc Electrochem Soc. Manchester, Nh: Electrochemical Society, 1989, 89(12): 692.

[29] N emsp14W Khun, E Liu, H emsp14W Guo. Cyclic voltammetric behavior of nitrogen-doped tetrahedral amorphous carbon films deposited by filtered cathodic vacuum arc[J]. Electroanalysis, 2008, 20(17): 1851-1856.

[30] SULLIVAN J P, FRIEDMANN T A, BACA A G. Stress relaxation and thermal evolution of film properties in amorphous carbon[J]. Journal of Electronic Materials, 1997, 26(9): 1021-1029.

[31] 刘雄飞, 李晨辉. 镀膜对金刚石与结合剂之间结合性能的影响[J]. 中国有色金属学报, 2001, 11(3): 445-448.

LIU Xiong-fei, LI Chen-hui. Effect of coatings on binding capability between diamond and matrix[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 445-448.

[32] ROBERTSON J. Diamond-like amorphous carbon[J]. Materials Science and Engineering R, 2002, 37(4): 129-281.

[33] BURNETT P J, RICKERBY D S. The relationship between hardness and scratch adhession[J]. Thin Solid Films, 1987, 154(1): 403-416.

[34] LEYLAND A, MATTHEWS A. On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour[J]. Wear, 2000, 246(1): 1-11.

[35] KULESZA S, PATYK J, ROZPLOCH F. Spontaneous decrease of high surface electrical conductivity in diamond exposed to atmospheric air[J]. Chemical physics letters, 2004, 391(1): 56-59.

[36] ERDEMIR A, BINDAL C, FENSKE G R, ZUIKER C, KRAUSS A R, GRUEN D M. Friction and wear properties of smooth diamond films grown in fullerene+argon plasmas[J]. Diamond and Related Materials, 1996, 5(9): 923-931.

[37] HOLLMAN P,  O, HOGMARK S. Friction properties of smooth nanocrystalline diamond coatings[J]. Diamond and Related Materials, 1998, 7(10): 1471-1477.

O, HOGMARK S. Friction properties of smooth nanocrystalline diamond coatings[J]. Diamond and Related Materials, 1998, 7(10): 1471-1477.

[38] PEPPER S V. Effect of electronic structure of the diamond surface on the strength of the diamond–metal interface[J]. Journal of Vacuum Science and Technology, 1982, 20(3): 643-646.

[39] PASTEWKA L, MOSER S, GUMBSCH P, MOSELER M. Anisotropic mechanical amorphization drives wear in diamond[J]. Nature Materials, 2011, 10(1): 34-38.

[40] GRIERSON D S, CARPICK R W. Nanotribology of carbon- based materials[J]. Nano Today, 2007, 2(5): 12-21.

[41] PANDA K, KUMAR N, PANIGRAHI B K, POLAKI S R, SUNDARAVEL B, DASH S, TYAGI A K, LIN I N. Tribological properties of N+ion implanted ultrananocrystalline diamond films[J]. Tribology International, 2013, 57: 124-136.

[42] LIU Hui-wen, TANAKA A, KUMAGAI T. Influence of sliding mating materials on the tribological behavior of diamond-like carbon films[J]. Thin Solid Films, 1999, 352(1): 145-150.

[43] SCHNEIDER A, STEINMUELLER-NETHL D, ROY M, FRANEK F. Enhanced tribological performances of nanocrystalline diamond film[J]. International Journal of Refractory Metals and Hard Materials, 2010, 28(1): 40-50.

[44] CORSO P P, GERMAN R M, SIMMONS H D. Corrosion evaluation of gold-based dental alloys[J]. Journal of Dental Research, 1985, 64(5): 854-859.

[45] RECLARU L, MEYER J M. Study of corrosion between a titanium implant and dental alloys[J]. Journal of Dentistry, 1994, 22(3): 159-168.

[46] LARSEN A, STOLTENBERG M, DANSCHER G. In vitro liberation of charged gold atoms: autometallographic tracing of gold ions released by macrophages grown on metallic gold surfaces[J]. Histochemistry and Cell Biology, 2007, 128(1): 1-6.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(21271188,51301211);中国博士后基金资助项目(2012M521541)

收稿日期:2014-04-23;修订日期:2015-04-15

通信作者:余志明,教授;电话:0731-88830335;E-mail: zhiming@mail.csu.edu.cn