DOI: 10.11817/j.ysxb.1004.0609.2021-37930

淬火、预拉伸对铝锂合金板材残余应力的影响

杨胜利1,刘乐乐1,李亚楠2,沈 健2

(1. 中国船舶重工集团公司第七二五研究所,洛阳 471039;

2. 有研科技集团有限公司,北京 100088)

摘 要:结合钻孔法应力测试和有限元模型构建,研究了淬火介质参数、预拉伸对铝锂合金板材淬火残余应力分布与演变的影响。结果表明:淬火介质冷却速率越慢,板材残余应力越小,不同淬火介质的冷却能力为:10%NaCl>水>5%PAG。随预拉伸量的增加,板材表层压应力减小,并逐渐转变为拉应力,预变形量为2.5%时,淬火残余应力绝对值稳定在25 MPa内。有限元点追踪表明,40 ℃水温淬火过程,板材体中心点(A)和上表面中心(B)三个方向残余应力变化规律相反,最终均呈平面应力状态;而板材宽向线中心(C)和长向线中心(D)演变规律相似,但分应力的方向不同;板材顶点(E)三个方向残余应力均较小。

关键词:铝锂合金;淬火;预拉伸;残余应力;有限元

文章编号:1004-0609(2021)-xx-- 中图分类号:TG146.2 文献标志码:A

引文格式:杨胜利, 刘乐乐, 李亚楠, 等. 淬火、预拉伸对铝锂合金板材残余应力的影响[J]. 中国有色金属学报, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37470

YANG Sheng-li, LIU Le-le, LI Ya-nan, et al. Effect of quenching and pre-strenching on residual stress of Al-Li alloy plate[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37470

残余应力在铝合金工件中普遍存在,时效强化型铝合金板材的残余应力主要是由于淬火过程板材的温度梯度引起,它严重影响了板材的加工和使用性能。一方面导致板材淬火后或后续机加工易产生弯曲或翘起等变形;另一方面,严重影响合金板材的服役性能,如断裂韧性、抗应力腐蚀性能和疲劳性能等[1-6]。铝锂合金因其较高的比强度、比刚度和弹性模量等特点而在航空航天领域得到越来越广泛的应用[7-9]。但目前鲜有关于不同淬火介质对铝锂合金板材残余应力影响的研究。淬火工艺是时效强化铝合金不可或缺的重要工序,但淬火过程中是涉及多维物理量的变化过程,如热场、相变、力场及其耦合作用等[10-13]。淬火残余应力可通过改变淬火工艺、淬火后预拉伸、去应力退火、以及其他机械或热处理方法适当消减残余应力[14-17]。目前还未能找到一种合适的方法测量淬火过程应力的动态演变过程,传统的钻孔法[18]、X-ray法[19]和裂纹柔度[20]等方法只能测量淬火后残余应力的状态分布,且测量过程复杂,耗时长且价格昂贵。有限元数值模拟能克服上述问题,建立有限元仿真模型,可快速有效的获得淬火过程应力的演变和分布规律,受到国内学者日益重视[21-23]。

本研究采用钻孔法测量铝锂合金板材表层参与应力,分析淬火参数和预变形量对板材残余应力影响。并结合有限元模型构建,分析淬火过程残余应力的分布与演变过程,最终为铝锂合金板材淬火过程残余应力的控制和消减提供实验依据和理论支持。

1 实验方法

本实验采用国内某铝业公司生产的45 mm厚铝锂合金热轧板,经线切割加工为350 mm(轧向)×100 mm(宽向)×22 mm(厚向)规格尺寸,然后进行530 ℃、2 h固溶处理,采用浸入式淬火,淬火介质参数分别为不同温度的水(20 ℃、40 ℃和60 ℃)、10%NaCl溶液以及不同浓度的PAG淬火液(5%、10%和15%),淬火前试样两端侧边埋入热电偶,利用温度测量仪进行冷却曲线测定,淬火转移时间小于3 s。

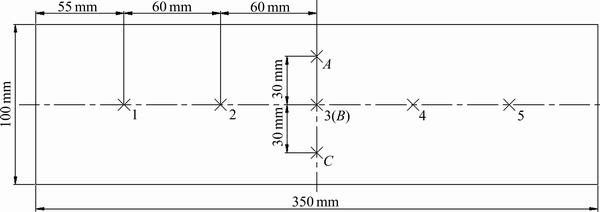

采用钻孔法测量淬火板材残余应力,所用设备为RSD1型钻孔装置和ASMB2-32型变阻箱,测量过程分为三个步骤:贴片、钻孔、测量计算。根据测量结果,计算释放应变、轧向应力和横向应力。本研究铝锂合金,弹性模量E=75.1,泊松比 0.38,可求得理论释放系数后分别求得轧向应力(σRD)和横向应力(σTD)。如图1所示,轧向相邻测量点(1~5)之间间隔60 mm,共5个点,宽向测量点(A~C)之间间隔30 mm,共3个点。

0.38,可求得理论释放系数后分别求得轧向应力(σRD)和横向应力(σTD)。如图1所示,轧向相邻测量点(1~5)之间间隔60 mm,共5个点,宽向测量点(A~C)之间间隔30 mm,共3个点。

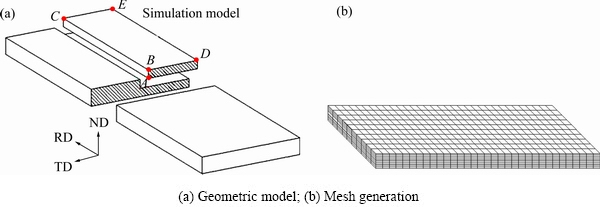

模拟在ANSYS软件上进行,模拟几何模型与实验试样尺寸相同(350 mm(RD)×100 mm(TD) ×22 mm(ND))。鉴于板材几何结构和边界条件的对称性,取其八分之一进行构建几何模型(175 mm(RD)×50 mm(TD)×11 mm(ND)),如图2(a)所示,其中A为板材的体中心;B点为板材上表面中心,C为板材宽向线中心,D为长向线中心,E为板材顶点。模型均采用六面体二十节点3D实体单元进行网格划分(见图2(b))。其中温度场采用SOLID90单元,应力场采用SOLID186单元。合金不同温度对应的材料参数如表1所示。

2 结果与讨论

2.1 淬火介质对残余应力的影响

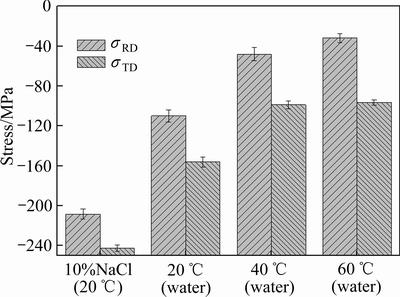

图3所示为NaCl和不同温度的水介质淬火过程试样温度随时间的变化曲线,可以看出,水温由20 ℃升高至60 ℃,试样的冷却速率不断降低,由61.4 ℃/s降低至26.9 ℃/s;当介质为10%的NaCl溶液,其冷却速率高达107.5 s-1。图4所示为板材不同介质淬火后的残余应力,可以看出,淬火后合金表层残余应力均为负值,即为压应力;随冷却速率的增加,板材的残余应力σRD和σTD逐渐升高。图3和图4表明,随着淬火水温的不断升高,合金的冷却速率逐渐降低;10%NaCl(20 ℃)溶液冷却能力比同温度的水冷却能力大,随着冷却速率的逐渐升高,合金板材内外层的冷却速率差异性扩大。试样表层因与淬火液接触面积大,其温度下降速度比较快。而试样芯部热量扩散速度较低,一定时间内仍接近固溶温度。试样内外层巨大的温差致使表层和芯部的热膨胀系数、导热率和弹性模量等参数不同,导致两者内外层变形不同,从而形成热应力。所以,淬火溶液温度越低,或其冷却能力越强,试样内外层的温度场梯度将越大,导致对应板材热应力不均匀程度增加,板材σRD和σTD应力绝对值升高;反之,淬火溶液温度越高,残余应力绝对值降低。高温试样浸入淬火液中,试样与淬火液之间的导热过程由三个阶段构成:1) 蒸汽膜阶段:高温试样导致淬火液瞬间气化,在其表面形成一层连续的蒸汽膜,阻止了溶液和试样的直接接触,蒸汽膜不利于热传导,从而降低了试样的冷却速率。2) 淬火液沸腾阶段:淬火时间延长,试样温度不断降低,蒸汽膜变薄直至破裂,淬火液与试样直接接触,热量快速试样中传至淬火液,导致其沸腾并产生大量气泡,试样温降速率加快。3) 对流导热阶段:当试样温度低于淬火介质沸点以下,此时试样的热传导由介质流动的速度以及淬火介质和试样间的温差决定。对冷却速率和σRD、σTD方向残余应力进行拟合,如图5所示,可以看出,轧制方向残余应力,σRD、σTD均与冷却速率成一定的线性关系,相关系数分别为99.8,92.1。

图1 板材轧向和宽向残余应力测量点分布

Fig. 1 Plate rolling and width direction to residual stress measurement point distribution

图2 几何模型的构建和网格划分

Fig. 2 Construction of geometric model and mesh generation

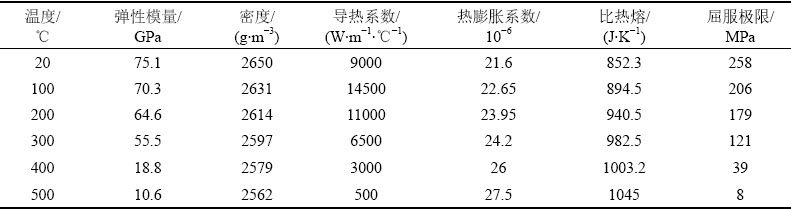

表1 不同温度对应铝锂合金材料参数

Table 1 Material parameters of Al-Li alloy corresponding to different temperature

图3 不同水温和NaCl溶液淬火冷却曲线

Fig. 3 Cooling curves of quenching treatment of different water temperature and NaCl solution

图6所示为板材经40 ℃水淬火处理后沿轧制方向和宽度方向等距离位置处的表面残余应力。可以看出,板材表面残余应力均为压应力。σRD和σTD成对称分布,靠近板材棱边位置(图1中1、5和A、C点)的压应力大,中心位置(图1中3(B)点)压应力大。反之,中心位置冷却速率低,温度梯度小。最较小。这是因为淬火过程,板材边缘和角端效应所引起[24],板材棱边处表面积大,距试样中心位置距离远,不能及时热量补充,冷却速率大,温度梯度终导致在试样近棱边位置处具有较大的残余应力,而表面中心位置具有较低的残余应力。

图4 淬火介质参数对残余应力的影响

Fig. 4 Effect of quenching medium parameters on residual stress

图5 冷却速率与σRD、σTD方向残余应力的拟合关系

Fig. 5 Fitting relationship between cooling rate and residual stress in σRD and σTD

图6 铝锂合金板材板材40 ℃水温淬火轧向和宽向残余应力

Fig. 6 Residual stress of rolling and width direction of 2297 Al-Li alloy palte after 40 ℃ water temperature quenching

2.2 PAG淬火液浓度对残余应力的影响

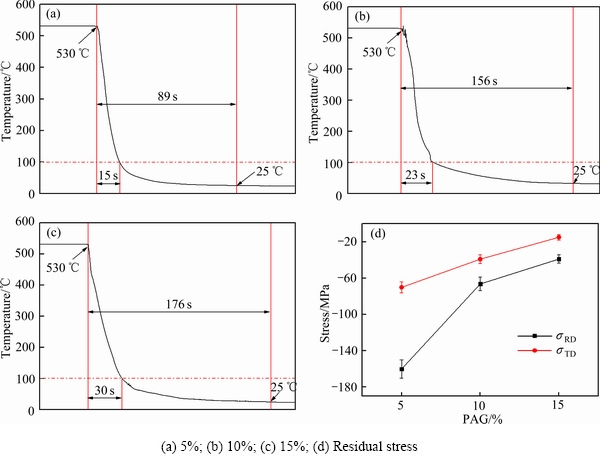

图7所示为不同浓度的PAG溶液(20 ℃)淬火冷却曲线和相应的淬火残余应力。可以看出,随PAG溶液浓度的升高,试样冷却速率不断降低,板材表层残余应力逐渐降低。对比图4和图7(d)可知,PAG溶液淬火板材比同温度的水淬火板具有更低的表面残余应力。这与PAG溶液淬火过程形成的聚合物薄膜密切相关。随PAG溶液浓度的提高,淬火初期在试样表面可形成的聚合物膜厚度增加,降低试样冷却速率,致使试样内部热量具有更长的时间均匀扩散,减小不同部位间的温度差,从而降低了板材淬火开始瞬间的热应力。当板材温度降低到聚合物溶解温度时,聚合物薄膜逐渐溶解,试样与淬火液接触,冷却速率提高,但因前一段阶段的大幅度降温,试样内部的温差已较小,引起的热应力很难引起塑性变形,从而不会产生较大的残余应力。

2.3 预拉伸对残余应力影响

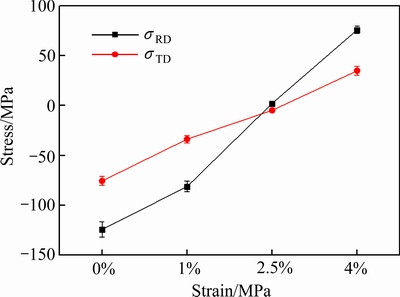

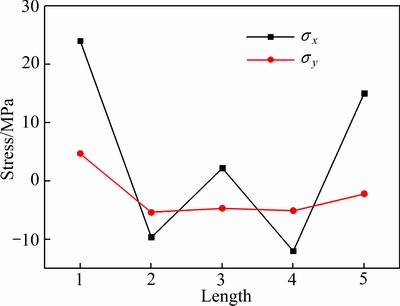

图8所示为不同预拉伸量对20 ℃水淬火板材表层残余应力的影响,可以看出,当变形1%时,σRD和σTD应力分别为-81.2 MPa和-33.6 MPa,相对淬火态两个方向的残余应力分别消减了34.7%和56%;当变形为2.5%时,对应σRD和σTD应力分别仅为2.2 MPa和-4.7 MPa;预变形量达4%后,表层应力转变为拉应力,σRD和σTD应力分别为76.1 MPa和35.3 MPa,即产生了新的残余拉应力,表明预变形量过大。图9所示为预变形量为2.5%板材沿轧向的应力分布,可以看出,经2.5%预拉伸后,板材残余应力基本在20 MPa以内,板材整体残余应力水平降低,淬火残余应力消减效果良好。

2.4 淬火过程的有限元模拟

2.4.1 淬火态残余应力的分布规律

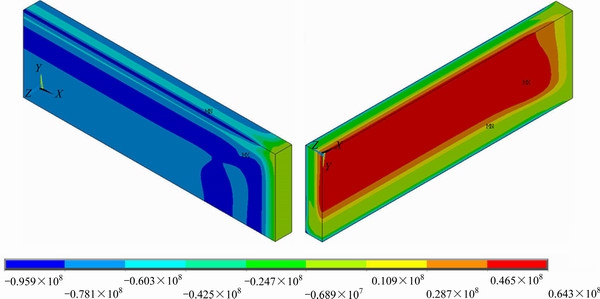

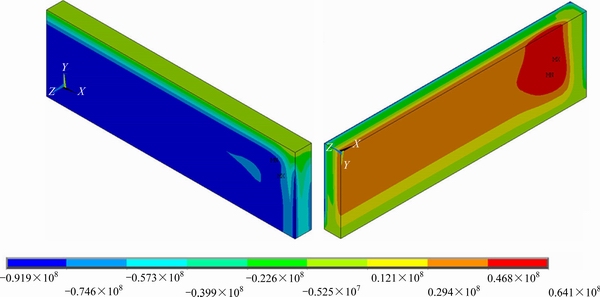

图10~12分别为合金板经40 ℃水淬火后σRD、σTD和σND三个方向分应力分布的有限元分析。可以看出,σRD、σTD和σND三个方向应力分布规律相同,即表层为压应力,芯部为拉应力,峰值出现在板材棱边位置和板材芯部的端部位置。但σND应力的绝对值较小,大范围内的压应力值仅为-9.5 MPa左右;芯部拉应力峰值仅20.5 MPa。

图7 不同浓度PAG溶液淬火冷却曲线和对应板材的残余应力

Fig. 7 Cooling curves of PAG solution quenching treatment with different concentration and corresponding residual stress of plate

图8 预拉伸量对铝锂合金板材残余应力的影响

Fig. 8 Effect of predeformation on residual stress of Al-Li alloy palte

图9 预拉伸量为2.5%的板材轧向应力分布

Fig. 9 Distribution of residual stress in plate with 2.5% predeformation

图10 40 ℃水淬火后板材σRD向分应力分布云图

Fig. 10 Distribution of stress in σRD direction of plate after quenching in 40 ℃ water

图11 40 ℃水淬火后σTD向分应力分布云图

Fig. 11 Distribution of stress in σTD direction of plate after quenching in 40 ℃ water

图12 40℃水淬火后σND向分应力分布云图

Fig. 12 Distribution of stress in σND direction of plate after quenching in 40 ℃ water

图13所示为沿板材厚向路径(图2(a)中A-B)的三向应力分布规律,可以看出,σRD和σTD应力分布规律相似,即从表层到芯部,逐渐由压应力向拉应力转变,且σRD≥σTD;而σND向应力值接近零,说明铝锂合金板材40 ℃水淬后的残余应力分布主要沿σRD和σTD方向分布。且板材表面的压应力绝对值大于芯部拉应力的绝对值,图10~12应力分布云图也呈现同样的规律,这是因为淬火过程中的边角效应影响了板材表面的应力分布[24]。

图13 沿板材厚向路径(A-B)的应力分布

Fig. 13 Stress distribution along thickness path (A-B) of plate

2.4.2 淬火过程中应力的演变规律

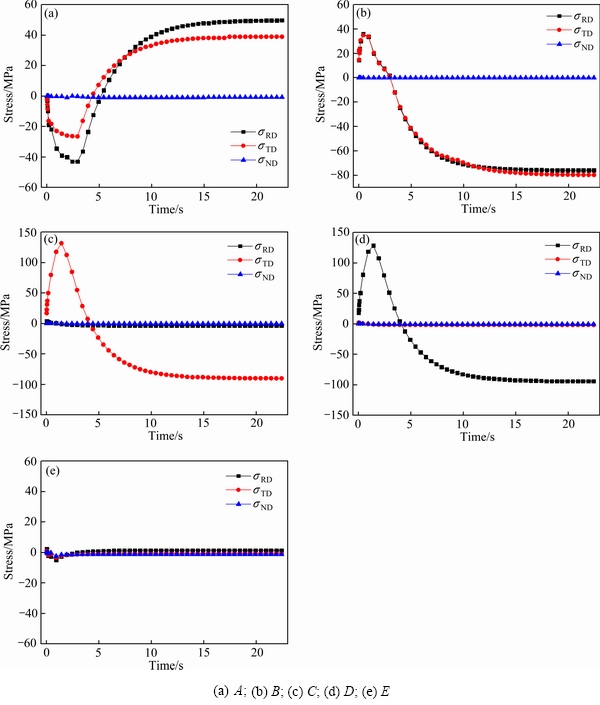

图14所示为利用时间历程后处理器中的点追踪技术获得的40 ℃水温淬火过程中合金板材上特征点的应力随时间延长的演变规律,A~E点分布如图2(a)所示。可以看出:

A点σRD和σTD方向分应力变化规律相似,淬火初期,σRD和σTD均为压应力,绝对值随冷却时间的延长而逐渐增大,2.4 s达到峰值。之后,压应力开始减小,4.9 s时转变为拉应力,然后随冷却时间延长拉应力逐渐增加,在15 s后趋于稳定,约49 MPa。在整个淬火过程中,σND向应力始终很小,说明A点的应力状态为典型的平面应力。B点应力变化规律与A点规律相反,B点亦为平面应力状态。

C点σTD向应力在淬火初期为拉应力,随时间延长而逐渐增加,在1.4 s时达到峰值131.8 MPa,之后不断降低,在4.1 s时转变为压应力,随后压应力不断增加,在16.5 s时到达稳定值-89 MPa,而σRD和σND对时间变化较小,因为C点为板材宽向线中心,冷却过程中宽向(即TD方向)受到较大的收缩变形,而长向(RD方向)和高向(ND向)收缩不明显,导致其σTD向应力出现上述演变,而σRD和σND应力值小且变化不明显。D点产生与C点类似的演变规律相似的,只是分应力的方向不同。

E点应力仅在±4 MPa内波动,因为在淬火过程,板材顶点处冷却速度快,但其自由度也大,冷收缩可以自由进行,导致其应力值较小;而因三个方向的尺寸效应不明显,其三向应力差别也较小。

图14 淬火板材特征点应力随时间变化的演变过程

Fig. 14 Evolution of characteristic point stress of quenching plate with time

3 结论

1) 三种淬火介质(20 ℃)对合金冷却能力顺序为:10%NaCl>水>5%PAG;且随水温升高或PAG溶液浓度的升高,板材残余应力减小。

2) 随预变形量的增加,板材残余应力逐渐减小,当预变形量达4%,板材表层压应力转变为拉应力。预变形量为2.5%时,板材淬火残余应力绝对值稳定在25 MPa以内,消减效果较好。

3) 构建了铝锂合金有限元淬火模型,采用点追踪技术分析板材特征点应力随时间的演变规律:芯部压应力在4.9 s时转变为拉应力,在15 s后趋于稳定值49 MPa;表层拉应力在3.4 s时转变为压应力,17 s后趋于稳定值-79 MPa。

REFERENCES

[1] 唐志涛, 刘战强, 艾 兴, 等. 基于裂纹柔度法的铝合金预拉伸板内部残余应力测试[J]. 中国有色金属学报, 2007, 17(9): 1404-1409.

TANG Zhi-tao, LIU Zhan-qiang, AI Xing, et al. Measuring residual stresses depth profile in pre-stretched aluminum alloy plate using crack compliance method[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(9): 1404-1409.

[2] QIN W J, DONG C. FEM simulation of quenching process and investigation of residual stresses of crankshafts[J]. Key Engineering Materials, 2015, 626: 149-154.

[3] SINGH A, AGRAWAL A. Investigation of surface residual stress distribution in deformation machining process for aluminum alloy[J]. Journal of Materials Processing Tech, 2015, 225: 195-202.

[4] WU B, ZHANG L J, ZHANG J X, et al. An investigation of ultrasonic nanocrystal surface modification machining process by numerical simulation[J]. Advances in Engineering Software, 2015, 83: 59-69.

[5] 龚 海, 吴运新, 廖 凯. 不同淬火工艺对7075铝合金厚板残余应力的影响[J]. 中南大学学报(自然科学版), 2010, 41(4): 1354-1359.

GONG Hai, WU Yun-xin, LIAO Kai. Influence of different quenching techniques on residual stress of 7075 aluminum alloy thick-plate[J]. South-Central University for Nationalities (Natural Science Edition), 2010, 41(4): 1354-1359.

[6] DING H, ZHU C, SONG C. Effect of the quenching residual stress on ductile fracture behavior of pre-stretched aluminum alloy plates[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2017, 39(6): 1-9.

[7] LI J F, HUANG J L, LI D Y, et al. Distribution and evolution of aging precipitates in Al-Cu-Li alloy with high Li concentration[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(1): 15-24.

[8] 杨胜利, 沈 健, 陈利阳, 等. Al-Cu-Li合金热变形过程中微观组织的动态演变规律[J]. 中国有色金属学报, 2019, 29(4): 674-683.

YANG Sheng-li, SHEN Jian, CHEN Li-yang, et al. Dynamic evolution of microstructure of Al-Cu-Li alloy during hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(4): 674-683

[9] 杨胜利, 沈 健, 蒋 鹏, 等. 热处理制度对新型Al-Cu-Li合金组织与性能的影响[J]. 中国有色金属学报, 2018, 28(6): 1111-1119.

YANG Sheng-li, SHEN Jian, JIANG Peng, et al. Effect of heat treatment on Microstructure and properties of new Al Cu Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(6): 1111-1119.

[10] 张 维. 2A14铝合金热成形及淬火过程中的残余应力研究[D]. 武汉: 武汉理工大学, 2016.

ZHANG Wei. Study on residual stress in the process of hot forming and quenching of 2A14 aluminum alloy[D]. Wuhan: Wuhan University of Technology, 2016.

[11] 张李强, 王 婧, 骆晓萌, 等. 热处理过程流场-温度场-组织场-应力场耦合模拟研究[J]. 金属热处理, 2017(8): 22-26.

ZHANG Li-qiang, WANG Jing, LUO Xiao-meng, et al. Coupled simulation of flow temperature microstructure stress field in heat treatment process[D]. Heat Treatment of Metals, 2017(8): 22-26.

[12] TANNER D A, ROBINSON J S. Effect of precipitation during quenching on the mechanical properties of the aluminium alloy 7010 in the W-temper[J]. Journal of Materials Processing Technology, 2004, 153/154(22): 998-1004.

[13] 戴晓元, 熊超宇. 数值模拟在铝合金淬火过程中的应用[J]. 金属热处理, 2019, 44(507): 203-211.

DAI Xiao-yuan, XIONG Chao-yu. Application of numerical simulation in quenching process of aluminum alloy[J], Heat Treatment of Metals, 2019, 44(507): 203-211.

[14] 范 宁, 熊柏青, 李志辉, 等. 预拉伸变形量对7055铝合金厚板表面残余应力的影响[J]. 中国有色金属学报, 2020, 30(2): 301-307.

FAN Ning, XIONG Bai-qing, LI Zhi-hui, et al. Effect of pre stretching deformation on surface residual stress of 7055 aluminum alloy thick plate[J]. The Chinese Journal of Nonferrous Metals, 2020, 30(2): 301-307.

[15] 罗国云. 7085铝合金大锻件多向锻造均匀性调控及淬火残余应力消减工艺研究[D]. 长沙: 中南大学, 2014.

LUO Guo-yun. Research on multi direction forging uniformity control and quenching residual stress reduction process of 7085 aluminum alloy heavy forgings[D]. Changsha: Central South University, 2014.

[16] LI X, LIAO H, MA M, et al. Effect of pre-stretching process on quenching residual stress of EW75 magnesium alloy[C]// International Conference on Advanced Design & Manufacturing Engineering. 2015.

[17] 张福全, 杨 重, 袁武华, 等. 7050铝合金淬火残余应力及消减工艺研究[J]. 热加工工艺, 2018, 47(24): 185-188.

ZHANG Fu-quan, YANG Chong, YUAN Wu-hua, et al. Study on quenching residual stress and reduction process of 7050 aluminum alloy[J]. Hot Working Process, 2018, 47(24): 185-188.

[18] 黄超群, 李 桓, 罗传光, 等. 盲孔法与压痕法测量2219铝合金熔焊焊缝残余应力的对比分析[J]. 焊接学报, 2017(7): 24-27.

HUANG Chao-qun, LI Huan, LUO Chuan-guang, et al. Comparative analysis of residual stress measurement of 2219 aluminum alloy fusion welding seam by blind hole method and indentation method[J]. Journal of Welding, 2017(7): 24-27.

[19] 万 鑫. X射线衍射方法分析多晶铝合金和粗晶铁硅合金的残余应力[D]. 上海: 上海交通大学, 2014.

WAN Xin. Analysis of residual stress in polycrystalline aluminum alloy and coarse grained iron silicon alloy by X-ray diffraction[D]. Shanghai: Shanghai Jiao Tong University, 2014.

[20] 李亚楠, 张永安, 李锡武, 等. 不同淬火介质下7055铝合金厚板淬火内应力测试[J]. 中国有色金属学报, 2017, 27(12): 2467-2472.

LI Ya-nan, ZHANG Yong-an, LI Xi-wu, et al. Stress measurement of 7055 aluminum alloy thick plate quenching under different quenching medium[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(12): 2467-2472.

[21] TEIXEIRA J, DENAND B, AEBY-GAUTIER E, et al. Simulation of coupled temperature, microstructure and internal stresses evolutions during quenching of a beta-metastable titanium alloy[J]. Materials Science & Engineering A, 2016, 651(10): 615-625.

[22] CUI J D, YI Y P, LUO G Y. Numerical and experimental research on cold compression deformation method for reducing quenching residual stress of 7A85 aluminum alloy thick block forging[J]. Advances in Materials Science and Engineering, 2017, 3(19): 1-6.

[23] CAO H L, LI X W, LI Y N, et al. Numerical simulation of quenching and pre-stretching residual stress in 7085 aluminum alloy plate[J]. Materials Science Forum, 2016, 852(1): 211-217.

[24] 胡少虬. 大直径高强度高塑性高弹性模量铝合金研制及淬火残余应力演变规律研究[D]. 长沙: 中南大学, 2007.

HU Shao-qiu. Development of large diameter, high strength, high plasticity and high elastic modulus aluminum alloy and Study on evolution law of quenching residual stress[D]. Changsha: Central South University, 2007.

Effect of quenching and pre-strenching on residual stress of Al-Li alloy plate

YANG Sheng-li1, LIU Le-le1, LI Ya-nan2, SHEN Jian2

(1. Luoyang Ship Material Research Institute, Luoyang 471039, China;

2. General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: The influence of quenching medium parameters and pre-strenching on the distribution and evolution of residual stress in Al-Li alloy plate was studied by combining the stress test of drilling method and finite element model. The results show that the slower the cooling rate of quenching medium is, the smaller the residual stress is. The cooling capacity of different quenchants is: 10% NaCl>water>5% PAG. With the increase of pre-strenching amount, the compressive stress on the surface of the plate decreases and gradually changes into tensile stress. When the pre-strenching amount is 2.5%, the absolute value of quenching residual stress is stable within 25 MPa. The finite element point tracing shows that during the quenching process at 40 ℃, the variation of residual stress in the three directions of the center (A) and the center (B) of the upper surface of the plate is opposite, and all of them are in the plane stress state; while the evolution of the center (C) and the center (D) of the wide line of the plate are similar, but the direction of the partial stress is different; the residual stress in the three directions of the top (E) of the plate is smaller.

Key words: Al-Li alloy; quencing; pre-strenching; residual stress; finite element method

Foundation item: Project(202300410005) supported by the Natural Science Foundation of Henan Province, China

Received date: 2021-03-16; Accepted date: 2021-07-14

Corresponding author: YANG Sheng-li; Tel: +86-379-67256994; E-mail: bravictors@126.com

(编辑 )

基金项目:河南省自然科学基金资助项目(202300410005)

收稿日期:2021-03-16;修订日期:2021-07-14

通信作者:杨胜利,高级工程师,博士;电话:0379-67256994;E-mail:bravictors@126.com