DOI: 10.11817/j.ysxb.1004.0609.2021-36675

90W-Ni-Fe合金在应变率6000 s-1不同应变条件下的微观组织

张 磊,黄宇峰,陈 逊,刘文胜,马运柱

(中南大学 轻质高强结构材料国家级重点实验室,长沙 410083)

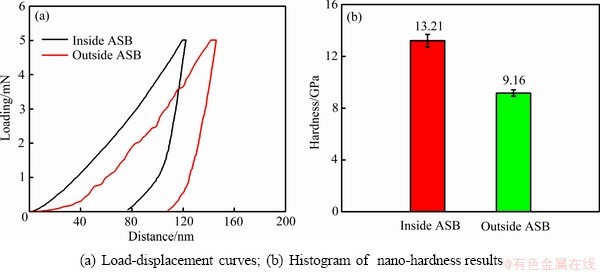

摘 要:通过分离式霍普金森杆(SHPB)和应变限位环方法实现90W-Ni-Fe合金在应变率6000 s-1不同应变条件下(0.15、0.25、0.45、0.6)的动态变形,并利用扫描电子显微镜(SEM)、透射电子显微镜(TEM),电子背散射衍射(EBSD)技术及纳米压痕技术对变形后钨颗粒的微观组织及力学性能进行表征。结果表明:应变低于0.25,钨颗粒主要发生均匀塑性变形,位错滑移是其变形的主要机制;当应变达到0.45时,冲击过程中的温升加速钨颗粒内位错的重排和湮灭,导致钨颗粒内部发生动态回复,形成大量板条状的亚晶粒;当应变达到0.6时,试样内部形成绝热剪切带,其内部组织主要由大量细小的等轴晶组成。晶粒细化导致剪切带内的硬度(13.21 GPa)高于剪切带外的硬度(9.16 GPa)。随着应变的继续增加,微裂纹在剪切带内形核和扩展,导致90W-Ni-Fe合金断裂失效。

关键词:钨合金;动态载荷;应变;绝热剪切

文章编号:1004-0609(2021)-07-1747-10 中图分类号:TF124 文献标志码:A

引文格式:张 磊,黄宇峰,陈 逊, 等. 90W-Ni-Fe合金在应变率6000 s-1不同应变条件下的微观组织[J]. 中国有色金属学报, 2021, 31(7): 1747-1756. DOI: 10.11817/j.ysxb.1004.0609.2021-36675

ZHANG Lei, HUANG Yu-feng, CHEN Xun, et al. Microstructural characteristic of 90W-Ni-Fe alloy at strain rate of 6000 s-1 and different strains[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(7): 1747-1756. DOI: 10.11817/j.ysxb.1004.0609.2021-36675

钨合金是一类以钨为基体(钨含量高达85%~ 99%),并添加有Ni、Fe、Cu、Co、Mo等低熔点元素组成的两相合金, 由于其具有密度高、强度好、延性好等优异的性能,被广泛应用于动能穿甲弹、反重器、辐射屏蔽等领域[1-3]。特别是,钨合金是替代贫铀合金(DUA)作为动能穿甲弹的主要候选材料,与贫铀相比,钨合金具有无毒、无辐射污染的优点[4]。钨合金在服役过程中需要承受较大的动态冲击载荷,因此,全面了解钨合金在动态冲击载荷下的塑性变形和断裂行为极其重要。

目前,分离式霍普金森杆是研究钨合金在动态冲击载荷下力学行为的重要实验装置。WOODWARD等[5]研究了钨合金在高应变率下(1×103 s-1)的动态力学性能, 其流动应力随着应变率的增加而增加。LEE等[6]讨论了钨合金在动态冲击响应下的应变率和温度敏感性。李树奎等[7]研究了97.5W-1.25Ni-1.25Fe在高应变率冲击下的破坏机理,试样与加载方向呈45°方向发生了局部剪切断裂,主要以钨-钨断裂以及钨颗粒解理断裂为主。LUO等[8]研究了钨合金杆式穿甲弹的穿透性能和自锐行为,在服役过程中出现的各种开裂现象与绝热剪切带的形成密切相关。虽然国内外有关钨合金动态载荷下的变形行为的研究已有报道,但研究内容侧重于力学性能、破坏机理和穿甲自锐性等方面,特别是在动态加载过程的微观组织演化鲜有报道。这是因为在传统的霍普金森杆加载实验中,由于加载时间极短,无法像准静态试验一样通过控制在加载过程中试样的变形量研究材料的微观组织演化规律。综上所述,研究钨合金在动态加载过程中组织的演变过程,探讨其变形和断裂机制,对于新型钨合金材料的设计与应用扩展具有非常重要的指导意义。

本文通过应变限位环的方法精确实现了动态冲击载荷加载过程中90W-Ni-Fe合金不同应变条件下的变形,随后对变形后合金的显微组织进行了深入的表征,揭示了90W-Ni-Fe合金在动态冲击载荷下的微观组织特征及演化规律。

1 实验

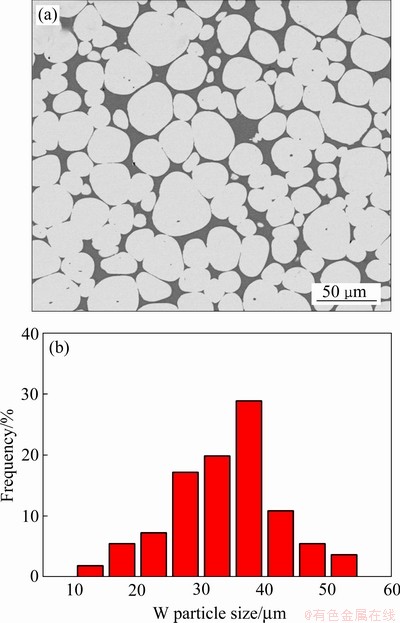

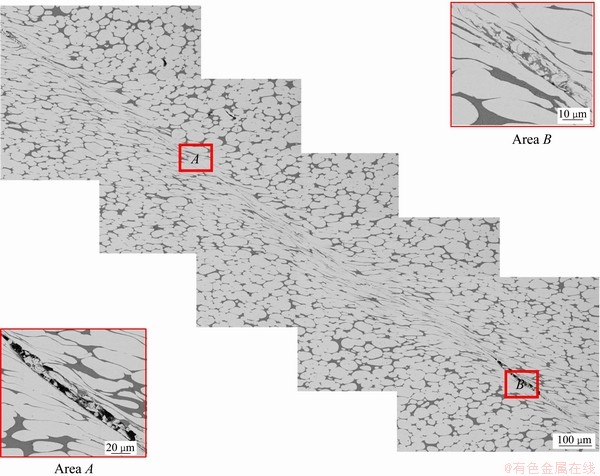

本实验所用的材料为厦门钨业有限公司提供的90W-Ni-Fe合金,原始形貌如图1 所示,平均颗粒尺寸为35 μm的近球形钨颗粒均匀嵌入连续分布的γ-(Ni, Fe)固溶体相中。

图1 90W-Ni-Fe合金原始形貌及钨晶粒尺寸分布

Fig. 1 Original microstructure of 90W-Ni-Fe alloy(a) and tungsten grain size distribution(b)

将试样加工成直径4 mm、高度4 mm 的圆柱,采用直径15 mm的分离式霍普金森杆(SHPB)系统进行冲击测试,设备示意图如图2所示,将试样固定在入射杆与透射杆之间,通过高压气体驱动子弹撞击入射杆,在入射杆中产生沿杆传递的入射脉冲,当脉冲传递到试样时,试样产生高速变形,一部分脉冲能量被试样变形吸收,另一部分传播至透射杆中形成透射脉冲,剩余部分脉冲能量被反射回至入射杆,利用贴在杆上的应变片可以记录整个应力波的传递过程。通过一维应力假设和均匀性假设可以得到应变,应变和应变速率的关系[9],计算公示如下:

(1)

(1)

(2)

(2)

(3)

(3)

式中: ,

, 和

和 分别为计算的应力,应变和应变速率;

分别为计算的应力,应变和应变速率; ,

, 分别为试验记录的透射脉冲和反射脉冲;E,Ah分别为杆的弹性模量和横截面积;AS,LS分别为试样的初始长度和初始横截面积;c0为杆的弹性纵波波速。

分别为试验记录的透射脉冲和反射脉冲;E,Ah分别为杆的弹性模量和横截面积;AS,LS分别为试样的初始长度和初始横截面积;c0为杆的弹性纵波波速。

图2 分离式霍普金森杆装置示意图[10]

Fig. 2 Schematic diagram of split Hopkinson pressure bar[10]

本次试验采用的子弹长度为300 mm,冲击气压为0.4 MPa,基于反射脉冲和透射脉冲计算得到的应变速率约为6000 s-1,通过应力应变曲线设计了4个不同高度的应变限位环来控制冲击过程的变形量,为保证数据的可靠性与真实性,每次试验均进行3次。应变限位环所用材料与试样保持一致,为90W-Ni-Fe合金。冲击过程中当入射杆撞击到限位环时即结束加载,从而“冻结”了合金在不同阶段的动态变形。

将动态变形后的试样沿加载方向进行线切割,然后用砂纸和1.0 μm的金刚石悬浮液分别进行研磨和抛光,在FEI Quanta 250 FEG扫描电镜(SEM)中观察了冲击前后样品的显微组织变化,扫描电镜的加速电压设置为15 kV。在FEI Tecnai G2 F20透射电镜(TEM)观察了冲击后钨颗粒的内部组织结构,加速电压为200 kV。透射样品的制备采用聚焦离子束系统(FIB, FEI Helios Nano Lab600i)进行定点取样切割、减薄。在FEI Helios NanoLab600i双束电子显微镜上进行电子背散射衍射(EBSD)的分析,标定时加速电压设置为25 kV。采用瑞士CSM公司UNHT+MCT纳米力学性能综合测试仪进行了纳米硬度的测量,纳米压痕仪采用超纳米压入,本实验所施加载荷为5 mN,加载时间为10 s。

2 结果与讨论

2.1 应力-应变曲线

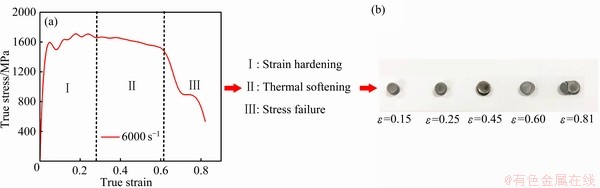

图3所示为90W-Ni-Fe合金在应变速率6000 s-1下的应力-应变曲线,从曲线上可知,在变形初期,由于位错密度急剧增加,流动应力迅速上升并产生突变,可以判断钨合金在此处发生了屈服,屈服后流动应力随着应变的增加而缓慢增加,表现出轻微的应变硬化。当应变达到一定程度后,此时的塑性变形足以产生大量塑性功,且绝大部分转化为热能,由于变形时间较快热能来不及散失,使材料内部温度升高,导致热软化效应发生,从应力应变曲线上表现为流动应力随着应变的增加而下降。在应力应变曲线的末端,流动应力出现坍塌,表明试样的承载能力已经完全丧失。根据应力应变曲线可以将90W-Ni-Fe合金在动态载荷下的力学行为分为3个阶段,分别为应变硬化阶段,热软化阶段及应力塌陷阶段,根据应力应变曲线设计了4个应变水平为0.15、0.25、0.45、0.6,应变为0.15时,试样处于应变硬化阶段;应变为0.25时,试样刚好达到最大流动应力;应变为0.45时,试样已经处于软化阶段;应变为0.6时,试样已经处于承载能力丧失的阶段。所以4个应变水平可以清楚地描述90W-Ni-Fe合金在应变率6000 s-1下的动态变形过程。变形后的试样宏观形貌如图3(b)所示,应变小于0.45时,试样仍保持完整。应变为0.6时试样表面可观察到剪切现象,但此时试样仍保持完整;应变为0.81时,试样沿45°方向完全断裂。

图3 90W-Ni-Fe合金在应变速率6000 s-1获得的应力-应变曲线和不同应变条件变形后试样宏观形貌

Fig. 3 Stress-strain curves (a) and specimen macroscopic morphologies (b) of 90W-Ni-Fe alloy deformed at strain rate of 6000 s-1 and different strains

2.2 微观组织分析

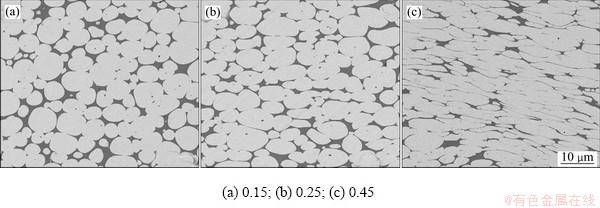

为了全面研究90W-Ni-Fe合金在动态变形过程的微观组织演化,对不同应变下试样的加载面进行了扫描电镜观察,结果如图4~6所示。图4所示为不同应变下的显微组织,应变为0.15时,钨颗粒发生了轻微的塑性变形,这是由于黏结相具有较好的塑形流动能力,可以承受绝大部分的变形。随着应变增大到0.25时,钨颗粒沿着加载方向被压扁;应变继续增大到0.45时,钨颗粒发生了较大的塑性变形且颗粒横纵比增加。应变低于0.45时,钨颗粒的变形行为主要以均匀塑形变形为主,即每一个钨颗粒都发生了塑性变形。图5所示为不同应变水平下钨颗粒内部结构的透射电子显微镜观察结果。应变为0.25时,钨颗粒内部有一些位错线以及缠结的位错,相应的选区电子衍射结果表示钨颗粒仍保持为一个单晶钨颗粒。随着应变增加到0.6时,钨颗粒内可以观察到大量宽度约为100~200 μm的板条状亚晶粒,相应的选区电子衍射结果表明其晶界处的夹角小于15°,属于小角度晶界,亚晶的形成被认为是动态回复的主要结果,说明在此应变水平下,试样内温度已经足够高可以激活钨颗粒内部的位错发生湮灭、再生和重排。

图4 90W-Ni-Fe合金在应变速率6000 s-1不同应变下的显微组织

Fig. 4 Microstructures of 90W-Ni-Fe at strain rate of 6000 s-1 and under different strains

图5 90W-Ni-Fe合金在应变速率6000 s-1不同应变下钨相的TEM像

Fig. 5 TEM images of 90W-Ni-Fe alloy at strain rate 6000 s-1 and different strains

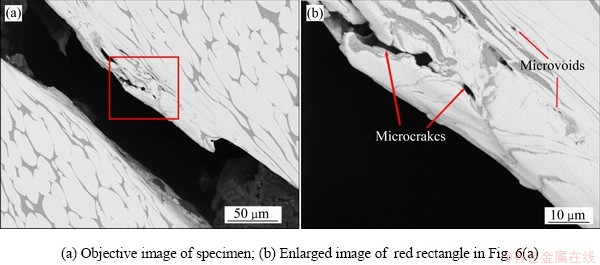

应变增加到0.6时,在试样沿对角线方向可以明显的观察到一条宽度约为30 μm的绝热剪切带,如图6所示。在剪切带内部,塑性流动高度局域化,钨颗粒沿着剪切方向被严重拉长,同时也能观察到钨颗粒的旋转,而剪切带外侧的钨颗粒沿着与剪切带平行的方向被拉长。一般而言,由于剪切变形集中在较窄的局部区域,剪切带内部的应变远远高于带外。区域A的放大图像可以看到在剪切带内部有少量微裂纹的存在,且裂纹尖端方向与剪切带扩展方向一致,区域B的放大图像可以观察到钨颗粒的破碎。图7所示为试样失效后断口处的显微组织,90W-Ni-Fe合金沿着绝热剪切带断裂,区域放大后观察到微孔洞和微裂纹是沿着剪切带萌生及扩展,导致试样最终沿着剪切带断裂失效。

图6 90W-Ni-Fe合金在应变0.6时形成的绝热剪切带显微组织

Fig. 6 Microstructures of adiabatic shear bands formed by 90W-Ni-Fe alloy at strain of 0.6

图7 90W-Ni-Fe合金失效后的断裂路径观察

Fig. 7 Observation of fracture path of 90W-Ni-Fe alloy after failure

2.3 绝热剪切带内部结构

绝热剪切带的形成是材料在动态冲击载荷作用下的一种重要变形模式,对绝热剪切带的形成机制最常见的解释是应变硬化和热软化之间的竞争。冲击过程中材料内部的绝热温度上升抑制了应变硬化,从而导致塑性流动不稳定,进而使变形在狭窄区域内发生局部化[11-12]。一般而言,结构材料在动态冲击载荷过程中形成绝热剪切带,则认为材料已经失效。这是由于剪切带形成后的任何变形都会导致裂纹沿剪切带快速形核和扩展最终使得材料发生破坏[13]。

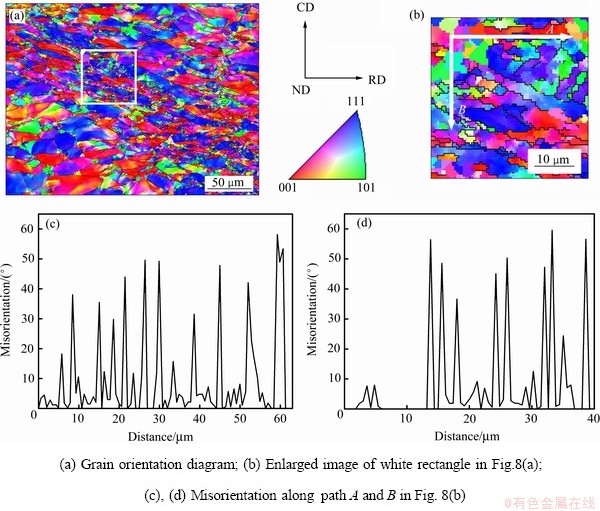

采用EBSD技术对90W-Ni-Fe合金绝热剪切带内部的组织进行分析,图8(a)所示为应变0.6时的晶粒取向分布图,剪切带内部组织与外部组织有明显的差异,剪切带内部放大图像如图8(b)所示,可以清晰地分辨出大小在100~200 nm之间的细小晶粒,与带外的晶粒尺寸相比小了两个数量级。图8(c)和(d)所示分别为图8(b)中路径A和路径B中点与点之间的相邻取向差角度分布,其结果表明晶粒中小角晶界的数量明显降低,且晶粒之间的取向差均大于15°,说明剪切带带内发生了明显的晶粒细化,其主要原因是在动态冲击载荷作用下,变形过程产生的塑形功转换为热能,由于变形时间较快温度来不及扩散,使得局部温度升高,超过了钨的再结晶温度。剪切带形成过程中的温升对理解剪切局部化机制具有重要意义,一种常用计算冲击过程中温升的方法是利用功-热转换方程[14-15],变形过程中样品内温升可由式(4)进行计算。

(4)

(4)

式中: 为真应力;

为真应力; 为真应变;

为真应变; 为密度(17.25 g/cm3);

为密度(17.25 g/cm3); 为比热容(0.134 J/(g·K))。在均匀塑性变形阶段,通过实际真应变计算90W-Ni-Fe合金在变形过程的温升,应变0.15、0.25和0.45时温升分别为96 ℃、165 ℃和350 ℃,而应变为0.6时,变形模式为绝热剪切变形,剪切带内的真实应变远远高于应力应变曲线所获得的应变,通过测量钨颗粒的纵横比可以估算出局部剪切应变,一般约为200%[16],通过式(4)计算剪切带内温升为1185 ℃,显然超过了钨的再结晶温度,在随后的冷却阶段,只需几微秒的时间,便可使动态再结晶后形成的微观结构得以保留。

为比热容(0.134 J/(g·K))。在均匀塑性变形阶段,通过实际真应变计算90W-Ni-Fe合金在变形过程的温升,应变0.15、0.25和0.45时温升分别为96 ℃、165 ℃和350 ℃,而应变为0.6时,变形模式为绝热剪切变形,剪切带内的真实应变远远高于应力应变曲线所获得的应变,通过测量钨颗粒的纵横比可以估算出局部剪切应变,一般约为200%[16],通过式(4)计算剪切带内温升为1185 ℃,显然超过了钨的再结晶温度,在随后的冷却阶段,只需几微秒的时间,便可使动态再结晶后形成的微观结构得以保留。

图8 90W-Ni-Fe合金在应变速率6000 s-1/应变0.6 下绝热剪切带组织EBSD表征

Fig. 8 EBSD characterization of microstructure of adiabatic shear bands in 90W-Ni-Fe alloy at strain rate of 6000 s-1 and strain of 0.6

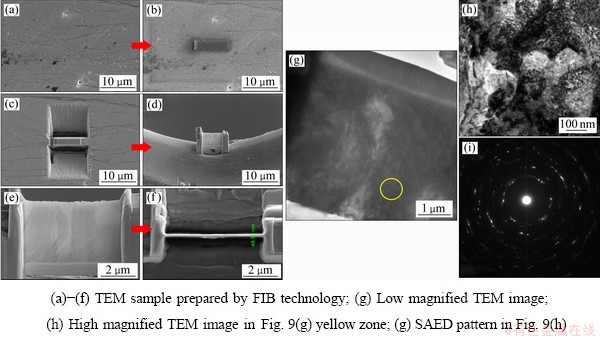

为了更进一步确定剪切带内的组织结构,采用TEM进行分析,由于该条件下90W-Ni-Fe合金变形模式为局部剪切变形,传统的离子减薄及双喷减薄难以对剪切带进行深入的表征,本文采用FIB技术进行定点取样,具体过程见图9(a)~(f)。TEM的表征结果如图9(g)~(i)所示,钨颗粒内部有许多大量等轴的再结晶晶粒,晶粒尺寸介于100~200 nm,从图9(i)的衍射图可以看出,钨颗粒内部没有较强的织构,表明钨颗粒内的微观结构是完全再结晶的。

图10所示为使用纳米压痕对剪切带带内和带外的力学性能表征后的结果,图10(a)所示的载荷位移曲线当加载到最大载荷5 mN时,剪切带内平均最大加载位移为90 nm,带外的最大加载位移为120 nm,该结果也说明了剪切带带内的硬度值高于带外的硬度值。进一步根据图10(b)所示的各区域平均硬度值分布可以发现,剪切带内的平均硬度(13.21 GPa),高于剪切带外的平均硬度(9.16 GPa),这一现象与前人的研究结果一致[17-18],造成这种差异的主要原因是由于剪切带内晶粒细化造成的。

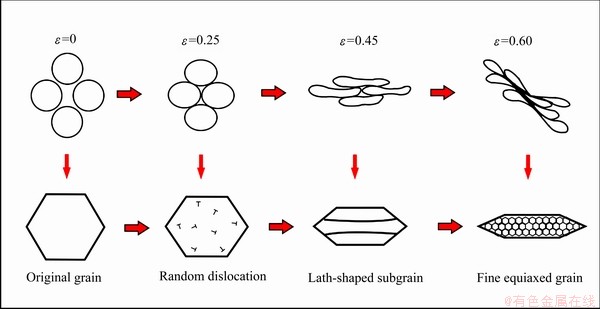

2.4 动态变形过程

90W-Ni-Fe合金在动态冲击载荷作用下钨颗粒的塑性变形过程如图11所示,在初始阶段,应变低于0.25时,钨颗粒主要均匀塑性变形,位错滑移是其变形的主要机制,随着应变的增加, 位错持续增殖导致流动应力增加,直至最大流动应力;由于冲击过程中温升效应会加速钨颗粒内位错的重排和湮灭,导致钨颗粒内部发生了动态回复,形成了大量板条状的亚晶粒。当应变超过0.45时, 90W-Ni-Fe合金以局部剪切变形为主,形成了绝热剪切带,由于剪切带内部积累了较大的应变,内部温度超过了钨的再结晶温度,便会发生动态再结晶形成大量细小的等轴晶粒。应变超过0.6时,由于剪切带内非常硬而脆,并伴有高缺陷密度、晶格应变和残余应力,因此,微裂纹在剪切带内形核和扩展,导致试样失效。

图9 90W-Ni-Fe合金在应变速率6000 s-1、应变0.6 下绝热剪切带FIB取样过程及TEM像

Fig. 9 Characterization of microstructure of adiabatic shear bands in 90W-Ni-Fe alloy at strain rate of 6000 s-1 and strain of 0.6

图10 绝热剪切带的纳米压痕

Fig. 10 Nano indentation tests on cross section of adiabatic shear band

图11 90W-Ni-Fe合金钨颗粒在应变速率6000 s-1下的动态变形过程示意图

Fig. 11 Schematic diagram of dynamic deformation process of 90W-Ni-Fe alloy at strain rate of 6000 s-1

3 结论

1) 采用应变限位环的方法精确实现了90W-Ni-Fe合金动态冲击载荷下4个不同的应变条件(0.15、0.25、0.45、0.6)下的动态变形。

2) 通过对不同应变水平下微观组织的表征,获得了90W-Ni-Fe合金在应变速率6000 s-1的变形行为,随着应变的增加,90W-Ni-Fe合金由均匀的塑形变形转向局部剪切变形,形成绝热剪切带,最终试样沿着绝热剪切带断裂。

3) 应变低于0.25时,钨颗粒内主要以位错滑移为主,钨颗粒仍保持为单晶;应变增加到0.45时,钨颗粒内发生了动态回复,形成了板条状亚晶;应变增加到0.6时,剪切带内的钨颗粒发生了动态再结晶。

4) 在动态载荷冲击过程中试样内有明显的绝热温升,绝热剪切带内部的温度最高可达1185 ℃。

REFERENCES

[1] 胡 海. 液相烧结90W-7Ni-3Fe高密度钨合金组织性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.

HU Hai. Research on microstructure and properties of 90W-7Ni-3Fe tungsten heavy alloy by liquid phase sintering[D]. Harbin: Harbin Institute of Technology, 2018.

[2] 田开文, 尚福军, 祝理君. 具备绝热剪切敏感性的钨合金穿甲弹材料研究现状[J]. 兵器材料科学与工程, 2005(4): 59-62.

TIAN Kai-wen, SHANG Fu-jun, ZHU Li-jun. Research status of WHA with adiabatic shear susceptibility[J]. Ordnance Material Science and Engineering, 2005(4): 59-62.

[3] 吕 政, 任学平, 卢成壮. 动能穿甲弹用钨合金绝热剪切带的研究进展[J]. 兵器材料科学与工程, 2014, 6: 140-146.

Lü Zheng, REN Xue-ping, LU Cheng-zhuang. Research progress of adiabatic shear bands in tungsten heavy alloy for kinetic energy penetrators[J]. Ordnance Material Science and Engineering, 2014, 6:140-146.

[4] LIU Xing-fa, TIAN Zhi-li, ZHANG Xian-feng, et al. “Self-sharpening” tungsten high-entropy alloy[J]. Acta Materialia, 2020, 186: 257-266.

[5] WOODWARD R L, BALDWIN N J, BURCH I, et al. Effect three of strain rate on the flow stress of liquid phase sintered tungsten alloys[J]. Metallurgical & Materials Transactions A, 1985, 16: 2031-2037.

[6] LEE W S, XIEG L, LIN C F. The strain rate and temperature dependence of the dynamic impact response of tungsten composite[J]. Materials Science & Engineering A, 1998, 257: 256-267.

[7] 王 星, 李树奎, 王迎春, 等. 不同加载应变率下钨合金变形及破坏机理研究[J]. 北京理工大学学报, 2010, 30(11): 1369-1373.

WANG Xing, LI Shu-kui, WANG Ying-chun, et al. The deformation and fracture mechanism of tungsten alloy under different strain rates[J].Transactions of Beijing Institute of Technology, 2010, 30(11): 1369-1373.

[8] LUO Rong-mei, HUANG De-wu, YANG Ming-chuan, et al. Penetrating performance and “self-sharpening” behavior of fine-grained tungsten heavy alloy rod penetrators[J]. Materials Science & Engineering A, 2016, 675: 262-270.

[9] 卢芳云. 霍普金森杆实验技术[M]. 北京: 科学出版社, 2013: 23-43.

LU Fang-yun. Hopkinson bar techniques[M]. Beijing: Science Press, 2013: 23-43.

[10] WU Xiao-dong, LI Luo-xing, LIU Wen-hui, et al. Development of adiabatic shearing bands in 7003-T4 aluminum alloy under high strain rate impacting[J]. Materials Science and Engineering A, 2018, 732: 91-98.

[11] 魏志刚, 李永池, 李剑荣, 等. 冲击载荷作用下钨合金材料绝热剪切带形成机理[J]. 金属学报, 2000, 36(12): 1263-1268.

WEI Zhi-gang, LI Yong-chi, LI Jian-rong, et al. Formation mechanism of adiabatic shear band in tungsten heavy alloys[J]. Acta Metallugrgica Sinica, 2000, 36(12): 1263-1268.

[12] MURR L E, TRILLO E A, PAPPU S, et al. Adiabatic shear bands and examples of their role in severe plastic deformation[J], Journal of Materials Science, 2002, 37: 3337-3360.

[13] TANG Lin, CHEN Zhi-yong, ZHAN Cong-hui, et al. Microstructural evolution in adiabatic shear bands of copper at high strain rates: Electron backscatter diffraction characterization[J]. Materials Characterization, 2012, 64: 21-26.

[14] MEYERS M A, NESTERENKO V F, LASALVIA J C, et al. Shear localization in dynamic deformation of materials: Microstructural evolution and self-organization[J]. Materials Science and Engineering A, 2001, 317: 204-225.

[15] MEYERS M A. Dynamic behavior of materials[M]. New York: John Wiley & Sons, 1994.

[16] HU Ke, LI Xiao-qiang, LIU Bo, et al. Dynamic mechanical behavior of 93W-4.9Ni-2.1Fe/95W-2.8Ni-1.2Fe-1Al2O3 heavy alloy composite[J]. Materials Science and Engineering A, 2018, 729: 349-356.

[17] JO M C, KIM S, KIM D W, et al. Understanding of adiabatic shear band evolution during high-strain-rate deformation in high-strength armor steel[J]. Journal of Alloys and Compounds, 2020, 845: 155540.

[18] WANG Ren-ke, ZHANG Hui, TANG Lin, et al. Adiabatic shear deformation behaviors of cold-rolled copper under different impact loading directions[J]. Materials Science and Engineering, 2019, 754: 330-338.

Microstructural characteristic of 90W-Ni-Fe alloy at strain rate of 6000 s-1 and different strains

ZHANG Lei, HUANG Yu-feng, CHEN Xun, LIU Wen-sheng, MA Yun-zhu

(National Key Laboratory of Science and Technology for National Defense on High-strength Structural Materials, Central South University, Changsha 410083)

Abstract: The dynamic deformation of 90W-Ni-Fe alloy at the strain rate of 6000 s-1 and different strains (0.15, 0.25, 0.45, 0.6) was obtained by using the Split Hopkinson pressure bar (SHPB) system and strain stopping rings. Scanning electron microscope (SEM), transmission electron microscope (TEM), electron backscattering diffraction (EBSD) and nano-indentation technique were used to analyze the microstructure characteristics and mechanical properties of the deformed tungsten particles. The results show that homogeneous plastic deformation mainly occurs in the tungsten particles when the strain is lower than 0.25 and the dislocation slip is proposed as the primary deformation mechanism of tungsten alloy. As the strain level increases to 0.45, the temperature rise during the impact process accelerates the dislocation rearrangement and annihilation of tungsten particles, leading to the dynamic recovery occurs in the tungsten particles and the formation of a large number of lath subgrains. As the strain level increases to 0.6, an adiabatic shear band is formed in the specimen, the microstructure in adiabatic shear band is mainly comprised of numerous fine small grains. Grain refinement causes the nano-hardness inside the shear band (13.21 GPa) to be higher than that outside the shear band (9.16 GPa).With the strain increasing, the microcracks nucleate and expand along the shear band, resulting in the failure of 90W-Ni-Fealloy.

Key words: tungsten alloy; dynamic loading; strain; adiabatic shear

Foundation item: Project(51931012) supported by the National Natural Science Foundation of China

Received date: 2021-02-25; Accepted date: 2021-05-10

Corresponding authors: LIU Wen-sheng; Tel: +86-731-88877998; E-mail: liuwensheng@csu.edu.cn

MA Yun-zhu; Tel: +86-731-88877825; E-mail: zhuzipm@csu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51931012)

收稿日期:2021-02-25;修订日期:2021-05-10

通信作者:刘文胜,教授,博士;电话:0731-88877998;E-mail:liuwensheng@csu.edu.cn

马运柱,教授,博士;电话:0731-88877825;E-mail:zhuzipm@csu.edu.cn