New development of powder metallurgy in automotive industry

来源期刊:中南大学学报(英文版)2020年第6期

论文作者:周承商 刘咏 谭兆强 张青 郭学益 赵伟江

文章页码:1611 - 1623

Key words:automotive; powder metallurgy; lean alloy; Al alloy; Ti alloy; metal injection molding, additive manufacturing

Abstract: The driving force for using powder metallurgy (PM) mostly relies on its near net-shape ability and cost-performance ratio. The automotive application is a main market of PM industry, requiring parts with competitive mechanical or functional performance in a mass production scale. As the automobile technology transforms from traditional internal combustion engine vehicles to new energy vehicles, PM technology is undergoing significant changes in manufacturing and materials development. This review outlines the challenges and opportunities generated by the changes in the automotive technology for PM. Low-cost, high-performance and light-weight are critical aspects for future PM materials development. Therefore, the studies on PM lean-alloyed steel, aluminum alloys, and titanium alloy materials were reviewed. In addition, PM soft magnetic composite applied to new energy vehicles was discussed. Then new opportunities for advanced processing, such as metal injection molding (MIM) and additive manufacturing (AM), in automotive industry were stated. In general, the change in automotive industry raises sufficient development space for PM. While, emerging technologies require more preeminent PM materials. Iron-based parts are still the main PM products due to their mechanical performance and low cost. MIM will occupy the growing market of highly flexible and complex parts. AM opens a door for fast prototyping, great flexibility and customizing at low cost, driving weight and assembling reduction.

Cite this article as: TAN Zhao-qiang, ZHANG Qing, GUO Xue-yi, ZHAO Wei-jiang, ZHOU Cheng-shang, LIU Yong. New development of powder metallurgy in automotive industry [J]. Journal of Central South University, 2020, 27(6): 1611-1623. DOI: https://doi.org/10.1007/s11771-020-4394-y.

J. Cent. South Univ. (2020) 27: 1611-1623

DOI: https://doi.org/10.1007/s11771-020-4394-y

TAN Zhao-qiang(谭兆强)1, 2, ZHANG Qing(张青)2, GUO Xue-yi(郭学益)3,

ZHAO Wei-jiang(赵伟江)1, ZHOU Cheng-shang(周承商)1, LIU Yong(刘咏)1

1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Hoganas (China) Co., Ltd., Shanghai 201799, China;

3. School of Metallurgy and Environment, Central South University, Changsha 410083, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Abstract: The driving force for using powder metallurgy (PM) mostly relies on its near net-shape ability and cost-performance ratio. The automotive application is a main market of PM industry, requiring parts with competitive mechanical or functional performance in a mass production scale. As the automobile technology transforms from traditional internal combustion engine vehicles to new energy vehicles, PM technology is undergoing significant changes in manufacturing and materials development. This review outlines the challenges and opportunities generated by the changes in the automotive technology for PM. Low-cost, high-performance and light-weight are critical aspects for future PM materials development. Therefore, the studies on PM lean-alloyed steel, aluminum alloys, and titanium alloy materials were reviewed. In addition, PM soft magnetic composite applied to new energy vehicles was discussed. Then new opportunities for advanced processing, such as metal injection molding (MIM) and additive manufacturing (AM), in automotive industry were stated. In general, the change in automotive industry raises sufficient development space for PM. While, emerging technologies require more preeminent PM materials. Iron-based parts are still the main PM products due to their mechanical performance and low cost. MIM will occupy the growing market of highly flexible and complex parts. AM opens a door for fast prototyping, great flexibility and customizing at low cost, driving weight and assembling reduction.

Key words: automotive; powder metallurgy; lean alloy; Al alloy; Ti alloy; metal injection molding, additive manufacturing

Cite this article as: TAN Zhao-qiang, ZHANG Qing, GUO Xue-yi, ZHAO Wei-jiang, ZHOU Cheng-shang, LIU Yong. New development of powder metallurgy in automotive industry [J]. Journal of Central South University, 2020, 27(6): 1611-1623. DOI: https://doi.org/10.1007/s11771-020-4394-y.

1 Introduction

1.1 Advantages of PM technology

Powder metallurgy (PM) is a technology that fabricates metal powders into useful engineering components [1]. The essential benefit of PM is that it provides a cost-effective shaping process, with virtual no loss of material, to mass produce components with close dimensional precision and required mechanical properties. The earliest finding of using PM technology was about 3000 BC when Egyptians used iron ores to make tools. The initial interests of mass-production products in the automotive industry made the use of iron and copper powders possible in large tonnages and spawned many of the technological advances in modern PM industry. The first commercial auto application of a PM product, the self-lubricating bearing, made from a combination of copper and tin powders, was used in 1927 [2]. In recent years, PM materials as structural components have gone through rapid development, since the properties of sintered steels today are comparable to those of wrought materials, as shown in Figure 1 [3].

Foundation item: Project(51625404) supported by the National Science Fund for Distinguished Young Scholars, China

Received date: 2020-05-07; Accepted date: 2020-06-16

Corresponding author: ZHOU Cheng-shang, PhD, Professor; Tel: +86-15387502509; E-mail: chengshang.zhou@csu.edu.cn; LIU Yong, PhD, Professor; Tel: +86-13307318308; E-mail: yonliu@csu.edu.cn

Figure 1 Comparison of tensile strength between PM and other steel materials

As most manufacturing methods consume energy and natural resources, there are growing concerns in selection of greener raw materials and production processes. PM is believed as an environmentally friendly process due to high material utilization and low energy consumption. A comparative Life Cycle Assessment (LCA) studied by ENGSTROM et al [4] was carried out on an injection molded yoke used in a heavy truck application. One objective was to compare the environmental impact of a typical automobile component produced either by machining and forging or by PM technology. Another objective was to study the environmental impact of two different PM materials. The LCA comparison result in Figure 2 shows that PM shows environmental advantage over the conventional wrought steel component due to less energy consumption by PM, and the Cr-containing PM material is advantageous compared to the Ni-containing one.

During the past decades, the PM technology has made obvious progress in areas where earlier were believed to be challenge. This positive growth is driven by improved mechanical performance, better dimensional tolerances, and cost-efficient processes. In 2017, the total sales volume of steel powder market in China reached 553 kt, achieving an annual growth rate of 10% over the past ten years. 53.2% of total volume was used in manufacturing the parts for various sections of automobile and motorcycle applications [5]. These achievements have been possible thanks to the rapid development of China’s automotive industry, as well as advanced metal powder development in combination with the new manufacturing equipment development in compaction tooling, presses and sintering furnaces.

Figure 2 LCA results for steel, SS2225 (a) and two PM materials, Astaloy CrM (b) and Distaloy AE (c) (Notes: environmental impact is calculated and expressed in global warming potential (GWP), photochemical ozone creation potential (POCP), acidification potential (AP), and eutrophication potential (EP))

1.2 Innovation in automotive industry

China has become the largest automobile production and sales market in worldwide since 2013 by a rapid annual increasing rate, as shown in Figure 3 [6]. As production of automotive parts and accessories in the supply chain gradually realizes localization, China has become a huge market for PM industry. A majority of PM parts are mainly used in the body and chasis, pump and hydraulic system, transmission and engine system.

Figure 3 China automobile sales volume and increasing rate

Published forecast for future propulsion technology penetrations is shown in Figure 4 [7]. Full electrical and hybrid vehicles have been considered main technologies to meet future emission standards, in which hydraulic, transmission and engine system in traditional vehicles containing many PM parts will get smaller and smaller and even disappear. However, the rapidity and completeness of this transition are far from certain. Significant growth electrification is expected in the next 15 years. In view of the strong dependence of the PM industry on the automotive market, the potential impact on PM industry from any technological change in automotive sector needs to be assessed to require careful consideration. The gradual move from the conventional internal combustion engine to hybrid or full electric powered vehicles will pose significant challenges to the PM industry in a long term. Clearly, change will not happen shortly. PM industry is well positioned to continue offering solutions that can increase efficiency in traditional powertrains, as well as taking advantage of opportunities in new electric and hybrid systems.

Figure 4 Forecast of transmission type

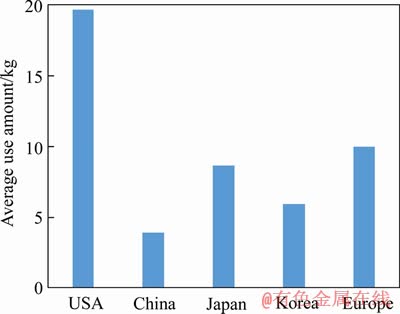

However, according to the data shown in Figure 5, the average use of powder metallurgy parts per car in China is only 3.97 kg, far less than that in Europe or America [8]. It indicates that there is still a technology gap in Chinese powder metallurgy industry, and also a huge room and opportunity for development in the domestic market of China.

Figure 5 Average use amount of powder metallurgy parts per car in different countries and regions

2 PM alloys

2.1 New PM ferrous alloys

Several ferrous alloy systems have been standardized in PM structure parts manufacturing, including iron-carbon (Fe-C), iron-copper-carbon (Fe-Cu-C), pre-alloyed steel, mixed low alloy steel, sintered hardened steel, and diffusion alloyed steel, covering a comprehensive materials system from low to high strength [9]. However, traditional molybdenum and nickel are commonly used as alloying elements in low-alloyed PM steel to enhance the hardenability and strength of structural PM components. Dramatic volatility of prices of these elements in recent years gave a lot of pressure on cost and reduced profitability within the entire value chain to lower levels, making PM technology less competitive when competing with other manufacture process, such as forging and casting. Figure 6 shows metal elements price development of these elements compared to Cr during 2005-2018 [10]. As a result, there is a continuous growing interest in utilizing more cost effective and less volatile alloy systems to enhance mechanical properties.

Figure 6 Price changes of metallic elements and raw materials in history

In order to achieve mechanical properties comparable to wrought steel, both high hardenability and high density must be utilized. Besides alloying content, the strength is determined by the sintering process in combination with the cooling rate. By using separate heat treatments, such as hardening or case carburizing, the strength can be further improved. The density is of the greatest importance and this is preferably achieved directly through high pressure or warm compaction to avoid large shrinkage during sintering. With subsequent processing operations, the density can be further increased by using local densification, such as surface rolling, shot peening or re-striking [11, 12].

Pure and highly compressible iron powder and Mo pre-alloyed powders, diffusion-alloyed powders with combinations of Cu, Ni and Mo are to date the most used materials for high performance applications. Recently, studies have been carried out to take advantage of Cr and Mn as alloying elements [13-15]. Cr and Mn alloying elements provide hardenability and strengthening effect while maintaining cost effectiveness. However, Cr and Mn elements are prone to oxidization. By utilizing pre-alloyed Cr-containing powders in combination with high temperature sintering, namely >1200 °C, a significant improved strength can be achieved [16]. Some high-performance commercial PM steels are described in Table 1. The mechanical properties at a conventional sintering temperature of 1120 °C and a high temperature 1250 °C are shown in Table 2.

Table 1 High performance PM steels and their compositions in mass fraction

Table 2 Mechanical properties after compaction at 600 MPa and sintering at 1120 °C and 1250 °C for 30 min in protection atmosphere 90 N2+10 H2, and with cooling rate 0.5-1.0 °C/s

It is indicating clearly that high temperature sintering is beneficial for high strength. After sintering at 1120 °C, the tensile strength is between 520 and 800 MPa, while after 1250 °C, it is between 800 and 1100 MPa. The yield strength for the pre-alloyed Cr-alloyed steels is higher than that of the diffusion-alloyed steels due to the higher hardenability. The shrinkage, however, increases from a level of around 0.2% at 1120 °C to 0.8% at 1250 °C, which in turn influences the dimensional tolerances control of PM parts. As a result, sizing of high-hardness materials after high temperature sintering is difficult. However, the improved dimensional precision sintered at 1250 °C was obtained by roller hearth furnace presented by TAN et al [17]. This makes it important to achieve a good tolerance level after sintering and thus to avoid or minimize machining operation.

In compacted and sintered parts, the presence of porosity in the sintered component often has negative effects on properties. Nevertheless, some studies show the porosity has the benefit in the noise suppression and increased damping effect [18]. Therefore, PM could offer big potential advantage in the development of electric and hybrid drivetrains that require as small noise as possible. Another case is synchronizing hubs that used in manual transmission (MT) and dual clutch transmission (DCT) that have complex shape while require high performance. Consequently, it needs high strength to withstand the transmitting torque and high hardness to withstand the sliding with the sleeves. The edge face of the boss also needs high hardness to withstand the sliding with opposite materials. One lean alloyed iron material, Astaloy CrM, used in synchronizing hubs that fabricated by sinter-hardening process [19], proves a cost-effective solution and well balance with high strength, high hardness, as well as less dimensional distortion. Therefore, iron-based parts are dominant in automotive applications due to their mechanical performance and the cost.

2.2 PM Al alloys

Light-weight materials can make a considerable improvement of fuel economy for vehicle, since a 10% reduction in vehicle weight translates to a 5.5% enhancement in fuel economy [20]. Aluminum and its alloys have been considered primary option for light-weight application in automotive industry, due to their low density (2.7 g/cm3), excellent formability, machinability as well as corrosion resistance. Four of the most frequently used PM aluminum alloy families are 2014, 6061, 7075 and Al-14Si, while aluminum matrix composites are more and more used in the industry. The typical mechanical properties of these materials are presented in Table 3 [21]. Al alloys are used in various applications of automotive parts. For instance, cam caps have been produced and employed successfully since 1993 by metal powder products Co (MPP) and GKN sinter metals [22].

Al alloy powder can be conveniently produced by conventional gas atomization. However, fully pre-alloyed Al powders are rarely used because of the insufficient compressibility and sintering activity. Powder blending methods are developed, and carefully designed to achieve an optimum press-and-sinter response for sufficient mechanical, tribological and physical properties. Very fine elemental powders (typically <45 μm), or binary pre-alloyed powders at near eutectic composition (e.g., AlSi12, AlMg50) containing up to 50% aluminum, were used for introducing alloying elements.

Sintering is considered the most critical process in PM Al manufacturing. It should be pointed out the oxide layer on Al powder surface prevents the sintering of Al powder particles. One practical solution is Cu-containing liquid phase sintering. Cu can form liquid phase with Al and thus disrupt the stable oxide layer during sintering. Some transient liquid phase sintering systems were developed, such as hypereutectic Al-14Si-2.5Cu- 0.5Mg alloy and the Al-6Zn-2.5Mg-1.7Cu alloy by ECKA, Germany.

Table 3 Mechanical properites of commerical PM aluminium alloys

At present, PM Al parts are used primarily in low performance applications which require net shape forming capability. Mechanical properties of PM Al alloys are usually higher than those of cast alloys, yet lower than as-wrought ones. Exiting PM Al materials cannot meet the needs for expanded applications that require high modulus, wear resistance or elevated temperature properties retention [23]. Therefore, new development is needed from a research perspective for the development of wide range of high-performance PM Al alloys that would be suitable for medium to high strength grade applications. Heat treatment is a key factor to develop a significantly high level of mechanical property for PM Al alloys [24].

2.3 PM Ti alloys

Since 1990’s, Ti parts have been widely used for engine, braking, chassis, and exhausting systems, with a weight reduction up to 55%, and typical applications are shown in Table 4 [25]. However, the volume of Ti parts in automobile is still limited in passage vehicles. The biggest challenge to expand use of titanium is that its cost is substantially greater than that of competing materials, such as steel and aluminum. The comparison is shown in Table 5 [26]. Manufacturing Ti parts by PM routes is promising in near net-shape capability. However, the high cost of powder manufacture is a main hurdle to the development of Ti product in automobile. There are two approaches for making PM Ti products,namely, the blended elemental (BE) method and pre-alloyed (PA) method. BE approach is regarded as cost effective method, although its mechanical properties are often unsatisfactory compared to wrought Ti parts.

Table 4 Standard components manufactured from titanium by PM

Table 5 Cost of titanium compared to competing automobile materials

Ti and Ti alloys powder production has been established since the Kroll process was first commercialized in the early 1950s [27]. A strong affinity of oxygen with Ti requires a strictly controlled environment during process (especially at high temperature) to minimize oxidation and oxygen pickup that decreases ductility. Oxygen content in Ti powder is a critical factor that determines the quality of the powder but also the mechanical properties of sintered parts. The cost of Ti powder varies in terms of different production techniques and raw materials sources. There are relatively less expensive powders made from the by-product of Kroll process, or from Ti sponge, ingot, or scrap by hydride-dehydride process. High- quality Ti and alloy powders are generally produced by atomizing techniques, such as gas atomizing and plasma rotating electrode process [28]. To date, numerous efforts have been devoted to developing new powder production process, and most of them focused on reduction (deoxygenation) of TiOx or TiO2 as inexpensive raw materials. FFC-Cambridge process is one of the well-known electrochemical processes that allow conversion of TiO2 into the corresponding metals through cathodic polarization of the oxide in a molten salt electrolyte based on CaCl2. Most recently, ZHANG et al [29] introduced a direct thermal reduction of Ti-O solid solution by Mg under hydrogen atmosphere, known as hydrogen-assisted magnesium reduction (HAMR) process. The HAMR process featured low oxygen content in powder product and its potential of cost reduction.

Sintering of Ti powder compact can be realized by a variety of techniques, such as vacuum sintering, hot pressing (spark plasma sintering), and CHIP (Dynamet/Arconic). The essential of the Ti sintering is to achieve high density, near net shaping, and low oxygen content. For the purpose of reducing cost, single press-sinter method is preferred; however, mechanical properties will be compromised. One approach for increasing sintered density is to use titanium hydride (TiH2) powder or sintering in hydrogen atmosphere. FANG et al [30] reported a process named hydrogen sintering and phase transformation (HSPT). HSPT is a multi-step sintering process, in which TiH2 powder is blended with master alloy or elemental powder and sintered under a dynamically controlled H2. Additionally, following vacuum annealing step is applied to remove residual hydrogen in Ti parts.

Efforts have been also aimed to reduce or mitigate the detrimental effect of oxygen in PM Ti parts. Recent studies have demonstrated that rare earth elements are effective in scavenging oxygen from PM Ti during sintering. LIU et al [31, 32] showed that rare earth elements can effectively scavenge oxygen when sintering cp-Ti and Ti-6Al-4V. On the other hand, alloys elements of low cost are very important. By introducing Fe and Mo, both the sinterability and mechanical properties of PM Ti can be significantly improved [33-35].

Titanium should be the material of choice for a wide variety of applications. However, because of its relatively high cost, it is used only when it is the only choice, like luxury cars. Numerous conferences and reports have been devoted to low cost titanium to foster its more automotive use. Due to the emission legislation becoming stricter, the mass saving will be first consideration in selection of materials. Therefore, more attention would be drawn on the Ti due to both of performance of mechanical property and mass saving.

2.4 Soft magnetic composite

Soft magnetic composite (SMC) materials have attracted wide interests due to their electrification for automotive. During the last decades, a variety of soft magnetic materials, including pure iron, phosphorous iron, silicon iron, nickel iron, cobalt iron, and stainless steel, are developed. This family of materials is mainly used for direct current applications and called as the first generation of magnetic materials. In this paper, only the second generation of soft magnetic composites that are basically pure iron powder particles coated with a very thin electrically insulated layer, was discussed. SMC has such advantages in unique combination of magnetic saturation and low eddy current losses, 3D flux carrying capability, and cost-efficient production of 3D-net shaped component by PM process, as schematically shown in Figure 7 [36, 37].

Comparing with traditional laminated electrical steel, SMC could provide significant advantages in three-dimensional shape design by PM, as listed in Table 6. For automobile application, a huge of potential opportunities will be generated for SMC in traction motors, pumps, ignition systems, common rail diesel injection systems, reactors for DC/DC converters, e-turbo systems, and AC compressor. Some typical applications of SMCs are shown in Figure 8.

It is interesting to note that the most striking advantage by using SMC in linear machines is from manufacturing point of view. It is clearly illustrated in Figure 9 that the number of parts can be decreased and assembly simplified by changing from lamination to SMC. Moreover, by actually modifying the design for SMC, the performance could not only be matched but also improved.

Figure 7 (a) Schematic of a SMC-material; (b) 3D-flux capability; (c) Schematic representative of magnetic properties of ferrites, electrical steel and SMC

Table 6 Advantages and disadvantages of SMCs compared to electrical steel [38]

Figure 8 Main applications of SMC on automotive [39]

Figure 9 Parts required laminated steel with 1300 parts (a) and SMC solutions with only 5 parts (b) [40]

3 Opportunities of new manufacturing processes

3.1 Metal injection molding (MIM)

MIM has long been considered a near net-shape and cost effective manufacturing process, which was developed from the combination of powder metallurgy and plastic injection molding [41]. The final product is nearly full density, which is different from traditional PM, and delivers excellent performance. Table 7 lists the comparison of the tensile properties of the stainless-steel alloy 17-4PH, made by MIM, MIM+HIP, wrought and casting method. Since MIM products are usually sintered to about 98% density, the properties are superior to the most cast products and slightly inferior to wrought products. As MIM enables parts manufactured with composition flexibility, shape complexity, high-production quantities, excellent performance, and low cost, MIM has expanded its applications into automobile in the past decades.

Table 7 A comparison of tensile properties of 17-4PH with different processes [42]

The MIM materials for automotive application include plain and low alloy steels, high speed steels, stainless steels, super alloys, magnetic alloys and hard metals. Stainless steel is a dominated material in automotive applications, mainly owing to their excellent properties, including high strength and corrosion resistance. The majority of MIM automotive parts are made of 17-4PH stainless steel. 316L stainless steel, due to its high tensile strength and excellent ductility, is selected for the BMW Hydrogen 7 car [43]. Also, an increased potential has been recently recognized for high Ni content alloys that are featured with high corrosion resistant against hot gas and better microstructure and mechanical properties than parts made by centrifugal casting [44]. GKN Sinter Metal (Germany) produces several hundred tons of MIM parts per year, mainly for automotive industry from Fe-Ni alloys, 42CrMo4, 17-4PH and superalloys for high temperature applications. The MIM markets are different among Europe, Asia and America. In Europe, automotive application is the leading portion, accounting for more than 40% of the market share. MIM application in Asia is dominated by electronics and mobile demands but there are expectations for strong growth in the automotive market, driven by local markets in China. In USA, the importance of medical markets remains strong [45].

With the development of MIM technology, there are some new trends in its automotive application. One is producing larger and heavier MIM component to meet the challenges in automotive. An example of successful case in sensor housing is produced by Schunk Sintermet- alltechnik GmbH in Germany, with mass of 67.3 g [46]. Another trend is the injection molded and co-sintered two material components (2C-MIM) [47]. This technology means that two different feedstocks are co-injected into mold and followed by sintering to a strong join. The pin is weldable stainless steel and the adjusting lever is a wear-resistant cobalt alloy [48], as shown in Figure 10. This process enables the combination of different material properties in one part without additional assembling operations, which makes it a cost-effective production technique. It is promising to be widely used to make functional composites with joining magnetic/non-magnetic stainless steel, weldable/wear resistant, wear resistant/heat resistant, low cost/high cost, metal/ceramic, and porous/dense materials.

3.2 Additive manufacturing (AM)

Metal AM processes can be broadly classified into three major groups, namely, powder bed fusion based technologies, directed energy deposition based technologies, and inkjet printing technologies. Both of the first two technologies can be further classified based on the type of energy source used, either by using laser or electron beam. The comparison of the features and capabilities of the above three processes is listed in Table 8 [49].

Metal powder bed fusion process is typically capable of producing homogeneous metallic and polymer parts. Directed energy deposition processes can process an even wider range of materials and may also have multi-material capability. In principle inkjet printing, AM is capable of handling almost all the powder materials as long as there exist compatible binder systems. However, there are additional design constraints for inkjet printing process due to the requirement of secondary processes to achieve satisfactory mechanical properties.

Figure 10 (a) MIM sensor housing weighting 67.3 g developed for automotive application by Schunk [46];(b) Turbocharger adjusting lever and pin made by 2C-MIM [48]

Table 8 Comparison between powder bed fusion, direct energy deposition and inkjet printing

The growing number of metal materials available for additive manufacturing systems is impressive. The designer can choose from a wide range of materials including tool steels, stainless steels, aluminum alloys, commercially pure titanium and titanium alloys, cobalt-chromium and nickel-based superalloys, copper alloys, precious metals.

In the automotive industry, AM has opened a door for fast prototyping, greater flexibility at a lower cost, more complex designs that drive weight and assembling reduction, customized fabrication of tooling. Each new automobile starts off as a prototype before it heads into production. Through using AM, automakers are able to efficiently test and adjust the design. GM sets up a rapid prototyping department, which produces test models of more than 20000 components with the technology of selective laser sintering and stereo lithography [50].

Additive manufacturing can also be an effective way to achieve light-weight structure and high fuel efficiency. In 2014, Swedish car manufacturer Koenigsegg used 3D printing for both the design and manufacturing stages of its sports car. The company utilized rapid prototyping to ensure various details of the car, including the pedals, foot rest and mirror housing. Besides, a number of production features were also 3D printed, including the patented variable turbo housing (the company claims giving improved response and bottom end torque), air ducts, interior mirror pieces, and the titanium exhaust end piece that is 400 g lighter than a similar piece made from aluminum [51]. GM designed a 3D printed stainless steel seat frame by combining original 8 parts into 1, saving 40% weight while increasing 20% strength [52].

AM could also exert its advantages in producing spare or aftermarket parts. For example, Porsche has adopted additive manufacturing to produce spare parts for rare and limited-edition vehicles, instead of reworking a factory to make a specific part. Mercedes-Benz prints thermostat covers with AlSi10Mg by selective laser melting process for old trucks and Unimog models that were phased out around 15 years ago.

4 Perspectives

Powder metallurgy is not only a cost-effective near-net shaping process, but also an environmental friendly process due to major environmental advantages, high material utilization and low energy consumption. With automobile industry development, PM technology has been developed rapidly. However, with the automobile technology changes from combustion to new energy vehicles, a few competitive threats are from alternative manufacturing technologies, but the changes cannot happen overnight. PM technology will undergo significant changes in terms of manufacturing process and materials requirements. The opportunities for the materials with cost advantage, high performance, as well as light weight, will be always open. In consideration of these aspects, PM ferrous steel, Al and Ti alloys materials are facing great challenges and technological innovations. Huge opportunities will be generated for soft magnetic composite materials, while some applications are already established. It is expected that MIM and AM can obtain opportunities in the new design of component with complicate geometry, in prerequisite of the limits of these technologies overcome, such as tolerance, size and cost effective.

References

[1] RANDALL M. Powder metallurgy science [M]. Metal Powder Industries Federation, 1994: 1-18. DOI: 10.1016/ 0261-3069(85)90117-7.

[2] STANLEY A. Powder metal technologies and applications [M]. ASM International, 1998: 10-18. https://www.osti. gov/biblio/289959.

[3] TAN Zhao-qiang. Trends and opportunities for future growth [R]. Shanghai, China: Hoganas PM School, 2019.

[4] ENGSTROM U. From raw material to new challenging applications [C]// Proceedings of EURO PM 2013. 2013(3): 301-306.

[5] HUANG Bai-yun, WEI Wei-feng, LI Song-lin, ZHANG Li, LI Li-ya, LIU Feng, LI Rui-di. Advances in modern powder metallurgy materials and technologies [J]. The Chinese Journal of Nonferrous Metals, 2019, 29(9): 1917-1933. DOI: 10.19476/j.ysxb.1004.0609.2019.09.08. (in Chinese)

[6] LMC Automotive. Global forecasting and market intelligence service [EB/OL]. [2019-11-25]. https://www. lmc-auto.com/.

[7] China Association of Automobile Manufactures. Automotive report China market [EB/OL]. [2019-11-25]. http://www. caam.org.cn/chn/4/ cate_39/list_1.html.

[8] FLODIN A. Automotive teardown: Dismantling of three modern vehicles to discover current and potential uses of PM [J]. Powder Metallurgy Review, 2017, 6(2): 41-47.

[9] MPIF Standard 35. Materials standard for PM structural parts [S].

[10] London Metal Exchange. Featured LME prices [EB/OL]. [2019-11-25]. https://www.lme.com/.

[11] ANGELOPOULOS V, HIRSCH M, WEIHMANN C. A parametric study on PM gear rolling densification simulations coupled with experimental results [C]// Proceeding of the World Conference on Powder Metallurgy. 2018: 16-20.

[12] KLOCKE F, LOPENHAUS C. Densifying PM gears by shot peening [C]// European Congress and Exhibition on Powder Metallurgy. European PM Conference Proceedings. The European Powder Metallurgy Association, 2016: 1-6.

[13] AKHTAR S, SAAD M, MISBAH M R, SATI M C. Recent advancements in powder metallurgy: A review [J]. Materials Today: Proceedings, 2018, 5(9): 18649-18655. DOI: 10.1016/j.matpr.2018.06.210

[14] BERGMAN O, CHASOGLOU D, DAHLSTROM M. Mechanical performance of Cr-alloyed PM steel after different sintering and heat treatment operations [J]. Metal Powder Report, 2017, 73(1): 1-5. DOI: 10.1016/j.mprp. 2017.01.003.

[15] HRYHA E, GIERL C, NYBORG L, DANNINGER H, DUDROVA E. Surface composition of the steel powders pre-alloyed with manganese [J]. Applied Surface Science, 2010, 256(12): 3946-3961. DOI: 10.1016/j.apsusc.2010. 01.055.

[16] BERGMAN O. Influence of oxygen partial pressure in sintering atmosphere on properties of Cr-Mo prealloyed powder metallurgy steel [J]. Powder Metallurgy, 2007, 50(3): 243-249. DOI: 10.1179/174329007X205073.

[17] TAN Zhao-qiang, GUO Yang, SU Peng-fei, ENGSTROM U. Influence of sintering conditions on dimensional precision for different PM steels [C]// World PM 2018. 2018: 336-341.

[18] GERD K. NVH potential of PM gears for electrified drivetrains [J]. Ratio, 2018, 12: 5.

[19] LARSSON C, ENGSTROM U. High performance sinter hardening materials for synchronizing hubs [J]. Powder Metallurgy, 2012, 55(2): 88-91. DOI: 10.1179/0032589912z. 00000000053.

[20] FROES F H. Advanced metal for aerospace and automotive use [J]. Materials Science and Engineering, 1994, 184(2): 119-133. DOI: 10.1016/0921-5093(94)91026-X.

[21] QIAN Ma, SCHAFFER B. Sintering of aluminum and its alloys [M]. Woodhead Publishing, 2010: 316. DOI: 10.1533/9781845699949.3.291.

[22] WAYNE D. Versatile & cost-effective option for lightweighting [J]. Lightweigting World, 2017(JAN+FEB): 42-52. https://www.mppinnovation.com/wp-content/uploa ds/2017/02/Aluminum-Powder-Metallurgy-Article-Lightweighting-World.pdf.

[23] HUNT W H. New directions in aluminium based P/M materials for automotive applications [J]. The International Journal of Powder Metallurgy, 2000, 36(6): 51-60. DOI: 10.4271/2000-01-0333.

[24] HEO J Y, GWON J H, PARK J K, LEE K A. Effects of heat treatment on the microstructures and high temperature mechanical properties of hypereutectic Al–14Si–Cu–Mg alloy manufactured by liquid phase sintering process [J]. Metals and Materials International, 2018, 24(3): 586-596. DOI: 10.1007/s12540-018-0068-9.

[25] FROES F H, FRIEDRICH H, KIESE J, BERGOINT O. Titanium in the family automobile: The cost challenge [J]. Applying Materials Science and Engineering, 2004, 56(2): 40-44. DOI: 10.1007/s11837-004-0144-0.

[26] FALLER K, FROES H K. The use of titanium in automobiles: Current technology [J]. Applying Materials Science and Engineering, 2001, 53(4): 27-28. DOI: 10.1007/s11837-001-0143-3.

[27] KROLL W J. The production of ductile titanium [J]. Trans Electrochem Soc, 1940, 78(1): 35-47. DOI: 10.1149/ 1.3071290.

[28] FANG Zhigang-zak, JAMES D P, SUN Pei, RAVI CHADRAN K S, ZHANG Ying, XIA Yang, CAO Fei, MARK K, MICHAEL F. Powder metallurgy of titanium– past, present, and future [J]. International Materials Reviews, 2017, 63(7): 407-459. DOI: 10.1080/09506608.2017. 1366003.

[29] ZHANG Ying, FANG Zhigang-zak, SUN Pei, ZHANG Tuo-yang, XIA Yang, ZHOU Cheng-shang, HUANG Zhe. Thermodynamic destabilization of Ti-O solid solution by H2 and deoxygenation of Ti using Mg [J]. Am Chem Soc, 2016, 138(22): 6916-6919. DOI: 10.1021/jacs.6b00845.

[30] FANG Zhigang-zak, SUN Pei, WANG Hong-tao. Hydrogen sintering of titanium to produce high density fine grain titanium alloys [J]. Advanced Engineering Materials, 2012, 14(6): 383-387. DOI: 10.1002/adem.201100269.

[31] LIU Yong, LIU Yang-bin, WANG Bin, TANG Hui-ping. Rare earth element: Is it a necessity for PM Ti alloys? [J]. Key Engineering Materials, 2012, 520: 41-48. DOI: 10.4028/www.scientific.net/KEM.520.41.

[32] LIU Yan-bin, LIU Yong, WANG Bin, QIU Jing-wen, LIU Bin, TANG Hui-ping. Microstructures evolution and mechanical properties of a powder metallurgical titanium alloy with yttrium addition [J]. Materials and Manufacturing Processes, 2010, 25(8): 735-739. DOI: 10.1080/ 10426910903365778.

[33] LIU Yong, CHEN Li-fang, TANG Hui-ping, LIU Chain-tsuan, LIU Bin, HUANG Bai-yun. Design of powder metallurgy titanium alloys and composites [J]. Materials Science and Engineering, 2006, 418(1, 2): 25-35. DOI: 10.1016/j.msea.2005.10.057.

[34] XU Sheng-hang, ZHOU Cheng-shang, LIU Yong, LIU Bin, LI Kai-yang. Microstructure and mechanical properties of Ti-15Mo-xTiC composites fabricated by in-situ reactive sintering and hot swaging [J]. Journal of Alloys and Compounds, 2018, 738: 188-196. DOI: 10.1016/ j.jallcom.2017.12.124.

[35] LIU Bin, LIU Yong, HE Xiao-yu, TANG Hui-ping, CHEN Li-fang. Low cycle fatigue improvement of powder metallurgy titanium alloy through thermomechanical treatment [J]. Transactions of Nonferrous Metals Society of China, 2018, 18(2): 227-232. DOI: 10.1016/S1003- 6326(08)60041-2.

[36] ANDERSSON O, HOFECKER P. Advances in soft magnetic composites—Materials and applications [R]. Las Vegas: Hoganas AB, 2009.

[37] HULTMAN L O, JACK A G. Soft magnetic composites- materials and applications [C]// IEEE International Electric Machines and Drives Conference. 2003, 1: 516-522.

[38] GUMBLETON-WOOD D, ATKINSON G, WASHINGTON J, SJOBERG L. The influence of production methods on the magnetic performance of electrical steels and soft magnetic composites [C]// 2017 IEEE International Electric Machines and Drives Conference (IEMDC). IEEE, 2017: 1-7. DOI: 10.1109/IEMDC.2017.8002238.

[39] CHRISTIAN W, CARMEN M. Study on the economic and manufacturing advantages of powder metallurgically produced electric drive concepts [R]. Germany: Fraunhofer IFAM, 2016.

[40] LARS S. Automotive electrification-opportunity for the PM industry [C]// APMA 2017. Hoganas AB, 2017.

[41] DONALD F. Handbook of metal injection molding [M]. Woodhead Publishing, 2018.

[42] DAVID W. PM titanium 2015: Developments in the metal injection moulding of titanium [J]. PIM International, 2015, 9(4): 75-82.

[43] ANONYM. MIM 316L stainless seeks applications in BMW Hydrogen 7 car [J]. PIM International, 2007, 4(1): 5-5. DOI: 10.1007/s11837-999-0109-4.

[44] HAUSNEROVA B. Powder injection moulding-An alternative processing method for automotive items [J]. New Trends and Developments in Automotive System Engineering, 2011: 129-145. DOI: 10.5772/13358.

[45] SCHLIEPER, G. Global PM leader GKN sinter metals optimistic as MIM gains acceptance with end-users [J]. PIM International, 2010, 1(4): 44-46.

[46] WILLIAMS B. World PM 2018 congress: Global MIM markets show healthy growth [J]. PIM International, 2018, 4(12): 67-75.

[47] MULSER M. Joining during shaping: two-component MIM provides new possibilities [J]. Metal Powder Report, 2016, 71(6): 445-449. DOI: 10.1016/j.mprp.2016.08.004.

[48] SCHLIEPER G. The future of powder injection moulding: Innovations and opportunities at Arburg’s second PIM conference [J]. PIM International, 2018, 12(33): 71-81.

[49] DUDA T, RAGHAVAN L V. 3D metal printing technology [J]. IFAC-Papers OnLine, 2016, 49(29): 103-110. DOI: 10.1016/j.ifacol.2016.11.111.

[50] 3Dsystems. 3D rapid prototyping fast tracks GM fuel efficiency gains [EB/OL]. [2019-11-25]. http://www. 3dsystems.com.

[51] JOHN N. Koenigsegg harnesses additive manufacturing for the one [EB/OL]. [2014-04-21]. https://www. digitalengineering247.com.

[52] JAMES G. GM explains its plans for 3D printing better car parts [EB/OL]. [2018-05-11]. https://www.thedrive.com.

(Edited by YANG Hua)

中文导读

粉末冶金技术在汽车工业的新进展

摘要:粉末冶金技术应用的驱动力主要来自于其近净形能力和高性价比。汽车工业是粉末冶金技术的主要市场,而汽车行业要求粉末冶金零部件在机械性能或功能上具有竞争力,同时可满足大规模生产需求。随着汽车技术从传统内燃机向新能源的转变,粉末冶金技术在制造工艺和材料开发方面正经历着重大变化。本文概述了汽车技术的变革给粉末冶金技术带来的挑战和机遇。低成本、高性能和轻量化是未来粉末冶金材料发展的关键因素。因此,本文就粉末冶金合金钢、铝合金和钛合金材料的研究进行了综述。此外,还讨论了粉末冶金软磁复合材料在新能源汽车上的应用,阐述了对先进加工技术如金属注射成形和增材制造产生的新机遇。一般来说,汽车技术的变革为粉末冶金提供了足够的发展空间,新兴技术出现需要更加优异的粉末冶金材料。铁基零件由于其机械性能好、成本低,将仍是粉末冶金的主要产品。金属注射成形也将在灵活和复杂零件的市场得到巨大的发展机会。增材制造提供了一种低成本、灵活性、个性化设计原型零件的快速制造途径,并能减少零件的重量和组装步骤。

关键词:汽车;粉末冶金;低合金钢;铝合金;钛合金;金属注射成形;增材制造