从粉煤灰中提取氧化铝熟料溶出过程工艺研究

孙培梅,童军武,徐红艳,赵喆,薛冰,张佼阳

(中国矿业大学(北京) 化学与环境工程学院,北京,100083)

摘 要:对粉煤灰和石灰石烧成的熟料在碳酸钠溶液中的溶出过程进行研究,探讨碳酸钠用量、溶出温度、溶出时间及液固比等工艺条件对熟料溶出中Al2O3和SiO2溶出效果的影响。研究结果表明:在碳酸钠用量约为理论量的1.0倍,溶出温度为50~60 ℃,保温时间为40~60 min,液固比为3~4的条件下,熟料中Al2O3的溶出率大于82%,溶出液中Al2O3质量浓度约为36 g/L,溶液的硅量指数铝、硅质量比大于46;溶出产生的钙硅渣成分及其质量分数为:Al2O3 2.60%,SiO2 24.31%,CaO 58.40%,Fe2O3 1.79%,TiO2。0.49%,Na2O 0.53%;熟料的主要物相为g-2CaO·SiO2和CaCO3。

关键词:粉煤灰;熟料溶出;氧化铝;溶出率

中图分类号:TQ110.3 文献标志码:A 文章编号:1672-7207(2010)05-1698-05

Study on leaching process of sintered powder in

extracting alumina from fly ash

SUN Pei-mei, TONG Jun-wu, XU Hong-yan, ZHAO Zhe, XUE Bing, ZHANG Jiao-yang

(School of Chemical and Environmental Engineering, China University of Mining and Technology(Beijing),

Beijing 100083, China)

Abstract: The Na2CO3 solution leaching process of sintered powder obtained from sintering process of fly ash and limestone was studied. The influence of technical conditions on leaching of Al2O3 and SiO2 in leaching process was examined. The results indicate that the leaching ratio of alumina in sintered powder can be more than 82%, the concentration of Al2O3 in leaching solution is about 36 g/L and the siliceous modulus is more than 46, when the dosage of sodium carbonate is about 1.0 times of theoretical value, the ratio of solution and solid reacting material is 3-4, the temperature is 50-60 ℃ and the time is 40~60 min. The residue obtained from leaching process contains 2.60% Al2O3, 24.31% SiO2, 58.40% CaO, 1.79% Fe2O3, 0.49% TiO2 and 0.53% Na2O, and the main phase composition is g-2CaO·SiO2 and CaCO3.

Key words: fly ash; leaching process of sintered powder; aluminum oxide; leaching rate

目前,粉煤灰主要用于建材和筑路工程等方 面[1-4],基本上属于低附加值的粗放式利用,效率低。因此,提高粉煤灰的综合利用价值,一直是煤炭部门和冶金部门亟待解决的问题。粉煤灰中含有大量有价元素,如Al2O3含量一般为 15%~40%,SiO2含量一般高达50%。目前,我国燃煤电厂每年排放的粉煤灰约1.6亿t,其中,30%为含Al2O3 30%以上的高铝粉煤灰,这部分粉煤灰含Al2O3约1 440万t以上。我国氧化铝工业由于受铝土矿资源的制约,其缺少量逐年增大。因此,开展从粉煤灰中提取氧化铝的研究,不但能提高粉煤灰的综合利用效益,而且对氧化铝工业的可持续发展具有重要意义。关于如何从粉煤灰中提取氧化铝,国内外进行了大量的研究工作,采用的方法有酸溶法、苏打烧结法、石灰石烧结法、酸碱联合法等[5-12]。本文作者采用石灰石烧结熟料自粉化方法从粉煤灰中提取氧化铝。熟料烧成和熟料溶出是该法提取氧化铝的2个主要阶段。孙培梅等[13]对粉煤灰和石灰石的烧结及自粉化过程进行了研究,现对烧成熟料在碳酸钠溶液中的溶出过程进行研究。

1 熟料溶出过程基本原理

在熟料的烧成过程中,粉煤灰中以莫来石(3Al2O3·2SiO2) 形态存在的氧化铝和以石英(SiO2)形态存在的硅和石灰石反应,转变为12CaO·7Al2O3和2CaO·SiO2。当在碳酸钠溶液中溶出时,熟料中的氧化铝和碳酸钠反应生成铝酸钠进入溶液,主要反应为:

12CaO·7Al2O3+12Na2CO3+33H2O=14NaAl(OH)4+12CaCO3+10NaOH

得到的铝酸钠溶液经脱硅、碳分和煅烧后得到产品氧化铝[14-15]。

在溶出过程中也会发生负反应,主要是熟料中的含硅化合物与碱反应使部分二氧化硅进入溶液以及水化石榴石系固溶体(3CaO·Al2O3·xSiO2·yH2O)的生成,导致部分已溶出的氧化铝又进入渣中,从而造成氧化铝含量降低[14-18]。

熟料溶出试验的目的是选择适宜的溶出工艺条件如碳酸钠用量、溶出温度和时间、液固比等,促进溶出反应的进行,抑制负反应的进行,以获得较高的氧化铝溶出率和氧化铝质量浓度较高的溶出液。

2 试验方法

2.1 试验原料

溶出试验所用原料为粉煤灰和石灰石经高温烧结后的熟料,孙培梅等[13]报道了粉煤灰和石灰石的化学成分及烧结过程工艺条件。烧成熟料的化学成分(质量分数)如表1所示。

使用X线衍射法测定熟料的物相组成,其主要为12CaO·7Al2O3和γ-2CaO·SiO2,用筛分法对熟料粒度进行测定,其中45 μm为98.3%。溶出所用碳酸钠为分析纯。

表1 熟料的化学成分

Table 1 Chemical composition of sintered powder %

2.2 试验设备及操作

溶出试验在用水浴加热的可控磁力搅拌器内进行。在玻璃烧杯内加入已计量的水、碳酸钠,然后,将其放入水浴内进行加热。当烧杯内溶液升至预定反应温度后,将熟料加入烧杯内处于搅拌状态下的溶液中,到预定时间后,将其取出进行液固分离,根据渣中Al2O3含量计算熟料中Al2O3溶出率。

3 试验结果和讨论

3.1 碳酸钠用量对熟料溶出过程的影响

试验固定条件如下:溶出温度为60 ℃,溶出时间为60 min,液固比为3。碳酸钠用量是按照化学反应理论量的倍数来表示,试验结果如表2所示。其中:ρk表示苛性碱质量浓度,ρT表示全碱质量浓度。

由表2可知:在碳酸钠用量为理论量的0.6~1.0倍范围内时,熟料中Al2O3溶出率随着碱用量升高而增大;在1.0~1.8倍范围内,溶出率的变化不大,但溶液中SiO2质量浓度随着碱用量的增加而有所增大。因此,可认为:在上述试验条件下,碳酸钠用量为理论量的1.0倍左右是比较合适的。因为在保证熟料中Al2O3溶出的前提下,应尽量减少碳酸钠用量,不但可以降低原料费用,而且可以减少熟料中硅的溶出,对后续工序从溶液中脱硅也是有利的。

3.2 溶出温度对熟料溶出过程的影响

试验固定条件如下:碳酸钠用量为理论量的1.0倍,液固比为3,溶出时间为60 min。试验结果如表3所示。

从表3可知:溶出温度为30~60 ℃时,Al2O3溶出率随温度的升高而增大;在50~70 ℃时,Al2O3溶出率都较高,且基本不变;但温度高于70 ℃后,Al2O3溶出率下降。硅的溶出在70 ℃以下时随温度的升高有所增加,在70 ℃以上时变化不大。这是因为当温度低于70 ℃时,温度升高有利于提高溶出反应的速度,在一定时间内,Al2O3的溶出反应进行得比较顺利,而负反应尚未明显发生,Al2O3溶出率随着溶出温度的升高而增大;当溶出温度高于70 ℃时,氧化铝的溶出反应速度加快,但熟料中的含硅化合物与碱溶液的反

表2 碳酸钠用量对熟料溶出过程的影响

Table 2 Influence of soda dosage on leaching process

表3 溶出温度对熟料溶出过程的影响

Table 3 Influence of leaching temperature on leaching process

应也加剧,进入溶液中的硅又进一步与溶出液中铝化合物发生反应,生成更稳定的化合物3CaO·Al2O3·xSiO2·yH2O(水化石榴石),使已溶出的Al2O3又进入渣中而损失,导致渣中Al2O3含量增大,Al2O3溶出率降低。试验结果表明:溶出温度为50~ 60 ℃较合适。

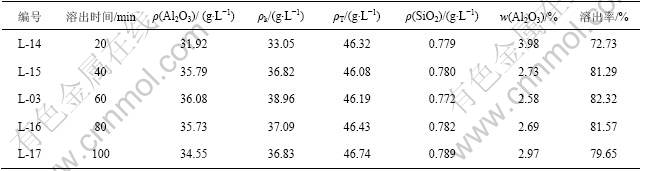

3.3 溶出时间对熟料溶出过程的影响

试验固定条件如下:碳酸钠用量为理论量的1.0倍,溶出温度为60 ℃,液固比为3。试验结果如表4所示。

从表4可知:溶出时间为20~60 min时,Al2O3溶出率随着溶出时间的增加而增大,在60 min时达到最大值,随后,又随着时间的增加而减小。这是因为在一定的溶出温度下,溶出反应随着时间的增加,溶出率逐步升高,但反应进行到一定的时间后,溶出反应已基本结束,如果再继续进行下去,进入溶液中的含硅化合物又会与溶液中的铝化合物进行二次反应,导致渣中Al2O3含量增高,Al2O3的溶出率降低。因此,在60℃溶出时,溶出时间以40~60 min为宜。

3.4 液固比对熟料溶出过程的影响

试验固定条件如下:碳酸钠用量为理论量的1.0倍,溶出温度为60 ℃,溶出时间为60 min。试验结果如表5所示。

从表5可知:液固比为3~4时,熟料溶出效果最好;当液固比高于或低于此值时,溶出率都会降低。液固比反映了溶液中碳酸钠浓度。在碳酸钠用量一定的情况下,液固比越大,溶液中碳酸钠浓度越低,不利于溶出反应的进行。但液固比过小,会导致矿浆浓度大,不利于反应传质过程的进行。在工业生产中,希望在保证氧化铝较高溶出率的前提下,尽量提高溶出液中氧化铝浓度,以减少物料流量。为此,认为溶出液固比以3~4为宜。

表4 溶出时间对熟料溶出过程的影响

Table 4 Influence of leaching time on leaching process

表5 液固比对熟料溶出过程的影响

Table 5 Influence of ration of water to solid on leaching process

4 结论

(1) 粉煤灰和石灰石烧成熟料在碳酸钠溶液中溶出较合适的工艺条件如下:酸钠用量为理论值的1.0倍左右,溶出温度为50~60 ℃,溶出时间为40~60 min,液固比为3~4。

(2) 在上述工艺条件下,熟料中Al2O3溶出率可达82%以上,溶出液中Al2O3质量浓度为36 g/L左右,硅量指数A/S大于46。

(3) 溶出产生的钙硅渣成分及其质量分数为:Al2O3 2.60%,SiO2 24.31%,CaO 58.40%,Fe2O3 1.79%,TiO2 0.49%,Na2O 0.53%。X线衍射分析表明:其物相主要为γ-2CaO·SiO2和CaCO3。

参考文献:

[1] 宣怀平, 董金道. 我国粉煤灰综合利用现状及若干实用技术的介绍[J]. 粉煤灰, 2005, 17(3): 29-32.

Xuan Huai-ping, Dong Jin-dao. An introduction to China’s state-of-the-art of fly ash comprehensive utilization and several practical technologies[J]. Coal Ash China, 2005, 17(3): 29-32.

[2] 刘伯元. 中国非金属矿开发与应用[M]. 北京: 冶金工业出版社, 2003: 307-312.

Liu Bo-yuan. Development and application of Chinese non-metal mine[M]. Beijing: Metallurgical Industry Press, 2003: 307-312.

[3] 韩怀强, 蒋挺大. 粉煤灰利用技术[M]. 北京: 化学工业出版社, 2001: 30-140.

Han Huai-qiang, Jiang Ting-da. Utilization technology of fly ash[M]. Beijing: Chemical Industry Press, 2001: 30-140.

[4] 王福元, 吴正严. 粉煤灰利用手册[M]. 北京: 中国电力出版社, 1997: 82-116.

WANG Fu-yuan, WU Zheng-yan. Utilization handbook of fly ash[M]. Beijing: China Electric Power Press, 1997: 82-116.

[5] 李来时, 翟玉春, 吴艳, 等. 硫酸浸取法提取粉煤灰中氧化铝[J]. 轻金属, 2006(12): 9-12.

LI Lai-shi, ZHAI Yu-chun, WU Yan, et al. Extracting alumina from fly ash by sulfuric acid[J]. Light Medals, 2006(12): 9-12.

[6] 刘成长. 粉煤灰提取氧化铝和二氧化硅新工艺[J]. 粉煤灰综合利用, 2008(4): 32-35.

Liu Cheng-zhang. New technology for extraction alumina and silicon dioxide from fly ash[J]. Fly Ash Comprehensive Utilization, 2008(4): 32-35.

[7] 余超, 方荣利. 精细化利用粉煤灰制备超细氧化铝[J]. 无机盐工艺, 2005, 37(12): 47-49.

Yu Chao, Fang Rong-li. The preparation of ultrafine alumina from fly ash[J]. Inorganic Chemicals Industry, 2005, 37(12): 47-49.

[8] 季惠明, 卢会湘, 郝晓光, 等. 用煅烧-沥滤工艺从粉煤灰中提取高纯超细氧化铝[J]. 硅酸盐学报, 2007(12): 1657-1660.

JI Hui-ming, LU Hui-xiang, HAO Xiao-guang, et al. High purity alumina powders extracted from fly ash by the calcining-leaching process[J]. Journal of the Chinese Ceramic Society, 2007(12): 1657-1660.

[9] 丁宏娅, 马鸿文, 高飞, 等. 改良酸碱联合法利用高铝粉煤灰制备氧化铝的试验研究[J]. 矿物岩石地球化学通报, 2006, 25(4): 348-351.

DING Hong-ya, MA Hong-wen, GAO Fei, et al. An experimental study about preparation of alumina from high-aluminum fly ash by improved acid and alkali combination method[J]. Bulletin of Mineralogy, Petrology and Geochemistry, 2006, 25(4): 348-351.

[10] 吴艳, 翟玉春, 李来时, 等. 新酸碱联合法以粉煤灰制备高纯氧化铝和超细二氧化硅[J]. 轻金属, 2007(9): 24-27.

WU Yan, ZHAI Yu-chun, LI Lai-shi, et al. Preparation of high-purity Al2O3 and superfine SiO2 from fly ash by the new acid and alkali combination method[J]. Light Metals, 2007(9): 24-27.

[11] 邬国栋, 叶亚平, 钱维兰, 等. 低温碱溶粉煤灰中铝和硅的溶出规律研究[J]. 环境科学研究, 2006, 19(1): 53-56.

WU Guo-dong, YE Ya-ping, QIAN Wei-lan, et al. Research on the rules of leaching silicon and aluminum from fly ash in alkaline solution at low temperature[J]. Research of Environmental Sciences, 2006, 19(1): 53-56.

[12] 阳勇福, 林海燕, 郭献军. 粉煤灰中氧化铝浸取模型的建立[J]. 煤炭学报, 2008, 33(2): 201-204.

YANG Yong-fu, LIN Hai-yan, GUO Xian-jun. Establishment of model on leaching alumina from fly ash[J]. Journal of China Coal Society, 2008, 33(2): 201-204.

[13] 孙培梅, 李广民, 童军武, 等. 从电厂粉煤灰中提取氧化铝物料烧结过程工艺研究[J]. 煤炭学报, 2007, 32(7): 744-747.

SUN Pei-mei, LI Guang-min, TONG Jun-wu, et al. Study on sintering process of raw materials in extracting alumina from fly ash of coal industry power plate[J]. Journal of China Coal Society, 2007, 32(7): 744-747.

[14] 杨重愚. 轻金属冶金学[M]. 北京: 冶金工业出版社, 2002: 81-95.

YANG Zhong-yu. Light metal metallurgy[M]. Beijing: Metallurgical Industry Press, 2002: 81-95.

[15] 杨重愚. 氧化铝生产工艺学[M]. 北京: 冶金工业出版社, 1993: 249-280.

YANG Zhong-yu. Alumina production technology[M]. Beijing: Metallurgical Industry Press, 1993: 249-280.

[16] 赵清杰, 杨巧芳, 陈启元, 等. 硅矿物在拜耳法溶出中的行为[J]. 中国有色金属学报, 2008, 18(S1): 172-182.

ZHAO Qing-jie, YANG Qiao-fang, CHEN Qi-yuan, et al. Behavior of silicon minerals during bayer digestion[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(S1): 172-182.

[17] 李小斌, 刘祥民, 刘桂华, 等. 强化烧结法生产氧化铝新工艺的研究与实践[J]. 中国有色金属学报, 2004, 14(6): 1031-1036.

LI Xiao-bin, LIU Xiang-min, LIU Gui-hua, et al. Study and application of intensified sintering process for alumina production[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 1031-1036.

[18] 刘桂华, 张亚莉, 彭志宏, 等. 钠硅渣中的氧化铝回收工艺[J]. 中国有色金属学报, 2004, 14(3): 499-504.

LIU Gui-hua, ZHANG Ya-li, PENG Zhi-hong, et al. Alumina recovery from sodium hydrate alumino silicate[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 499-504.

(编辑 刘华森)

收稿日期:2009-10-21;修回日期:2010-01-18

基金项目:国家自然科学基金资助项目(50674094);高等学校博士学科点专项科研基金资助项目(20050290012)

通信作者:孙培梅(1945-),女,山西长子人,教授,博士生导师,从事有色冶金研究;电话:010-62331688;E-mail: spm1688@eyou.com