文章编号:1004-0609(2015)04-0975-07

铝/铜异种材料填丝钨极氩弧焊对接接头的组织和性能

彭 迟,程东海,陈益平,胡德安

(南昌航空大学 航空制造与工程学院,南昌 330063)

摘 要:采用lincolnTIG-355交直流钨极氩弧焊机和8515药芯锌-铝焊丝对T2紫铜与LY16铝合金异种材料进行了对接焊。利用扫描电镜(SEM)和能谱分析仪(EDS)对接头各区域的显微组织和成分进行分析,并通过拉伸试验机测试接头的力学性能。结果表明:所焊接的对接接头无气孔、裂纹等缺陷,焊缝成形良好。当焊接电流为100 A、焊接速度为62 mm/min、保护气流量为15 L/min时,接头抗拉强度达到了240 MPa,断裂于铜侧热影响区。焊缝组织为白色条块状的CuZn4化合物,均匀分布于由Zn基和Al基固溶体组成的(α+η)共晶组织中;铜侧界面平直清晰,界面附近存在较多的金属间化合物组织,在铝侧界面有一沿界面呈链状分布的灰黑色球块状的α相铝基固溶体组织。

关键词:铝铜异种材料;钨极氩弧焊;力学性能;显微组织

中图分类号:TG444+.74 文献标志码:A

Microstructure and properties of Al/Cu dissimilar materials TIG butt joints with filler wire

PENG Chi, CHENG Dong-hai, CHEN Yi-ping, HU De-an

(Aviation Manufacturing and Engineering College, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: Lincoln TIG-355 AC/DC arc welding machine and 8515 Zn-Al flux cored wire were used to butt weld T2 copper with LY16 aluminum in AC mode. The microstructure and the elements composition of the joint were studied by scanning electron microscope and energy spectrum analysis, respectively, the mechanical properties of the joints were tested by a tensile testing machine. The results show that sound butt joints without pores, cracks and other defects are obtained by this method. When the welding current is 100 A, welding speed is 62 mm/min, shielding gas flow is 15 L/min, the joint tensile strength can reach 240 MPa, fails at the heat affected zone of the copper side. The weld microstructure is white striped blocky CuZn4 compounds uniformly, distributes at the (α+η) eutectic, which consists of Zn-based and Al-based solid solution. The interface of the copper side is clear, and there are many intermetallic compounds near the interface. At interface of the aluminum side, there is gray black ball blocky α-phase aluminum solid solution organization distributing with chain shape linear distribution along the interface.

Key words: aluminum-copper dissimilar material; tungsten inert gas arc welding; mechanical property; microstructure

铜和铝均有良好的导电性与导热性,且都具有良好的塑性和一定的耐腐蚀性能,因而在电器工业和散热器械等方面这两种金属有广泛的应用。我国是有色金属大国,但铜、铝等有色金属资源短缺[1],由于铜的成本和密度都较铝合金要高,因而,在很多应用场合都可用铝代替铜以降低生产成本及构件质量,从而使得铜/铝异种材料的连接对我国工业的发展很有必要。目前,铝/铜异种金属接头广泛应用于电力、化工、制冷和航空航天工业中,因而,铝/铜异种材料焊接问题的解决具有广泛的实际应用价值。

焊接是实现铝铜连接并满足铝/铜接头导电、导热性能的可靠方法,但铝和铜焊接性较差,具体表现为两种金属都很容易被氧化,会形成氧化膜,两者的导热率和比热性都较高,熔点相差较大,在高温下,两种金属液体能够吸收大量气体,使得焊缝中出现气孔,而且焊接时铜和铝极易形成脆性的金属间化合物(Cu2Al、CuAl、CuAl2和Cu2Al3等)[2]。目前,铝/铜的连接常采用压力焊[2-8]、钎焊[9-13]、高能束焊[14-16]等方法[17-18],JI等[10]采用不同成分的Zn-Al钎料对铜铝异种金属进行搭接火焰钎焊,发现当钎料中Al含量为15%时,Cu/Al 接头的抗剪强度达到最大值88 MPa。吴小伟等[7]研究了铝-铜异种金属搅拌摩擦焊,搭接接头最大剪切力达到2579 N,发现铝-铜界面易生成Al-CuAl2共晶组织,恶化接头性能。董红刚等[18]采用Zn-15%Al实芯焊丝对铝合金/黄铜进行了TIG熔钎焊搭接试验,接头抗拉强度为164 MPa。可以看出,多数研究都集中在搭接接头,而对接接头的研究极少。普遍认为一般的熔焊方法(电弧焊)不适合铝/铜的焊接,主要由于其能量密度较低,而铝和铜的导热系数和熔点相差均很大,焊接时易导致热输入过大,使得焊缝中出现大量的脆性相化合物,降低接头的力学性能。为此,采用钎焊和扩散焊技术可获得强度较高的接头,但钎焊和扩散焊需要将构件整体放入真空炉中,加热时间长,生产效率低,而且影响整个构件的性能。由于普通的熔焊方法操作简单,相对于高能束焊、钎焊和压力焊,对设备和构件要求较低,因而采用普通的熔焊方法焊接铝/铜异种金属获得性能良好的接头有重要的实际应用价值和意义。本文作者采用铝/铜钎焊常用的Zn-Al药芯焊丝对铝/铜异种材料进行对接TIG焊,从工艺理论上探讨铜/铝异种材料的电弧焊,为铝/铜连接的实际应用提供基础数据。

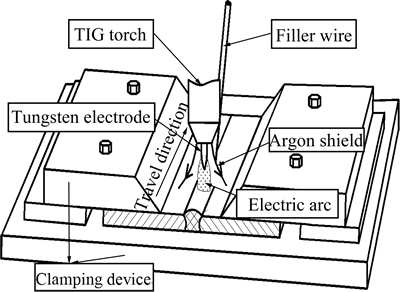

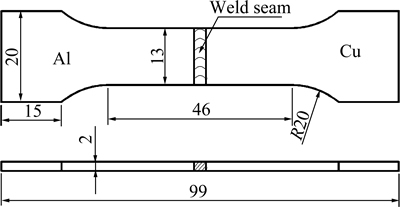

1 实验

利用LincolnTIG-355交直流氩弧焊机,对几何尺寸均为100 mm×25 mm×1 mm的2A16铝合金板和T2紫铜板进行填丝对接焊,焊接电流方式采用交流方式,以利用阴极清理作用去除氧化膜。T2紫铜和2A16铝合金的化学组成及部分物理性能分别如表1~3所示,填充材料采用直径为2 mm的8515药芯锌-铝焊丝(其中Zn含量为95%,Al含量为5%)。采用纯度为99.99%的氩气(Ar)作为保护气体,焊前用钢丝刷去除铝合金待焊面的氧化膜并用丙酮对待焊试板进行清洗,将铝板和铜板靠紧对接。焊接开始后,电弧作用于两板材接缝处,并将焊丝放置在焊接前进方向的前端,采用手动送丝方式,以一定的速度送丝,以保证送丝充足。图1所示为焊接过程的示意图。试验选定的焊接速度分别为35、62、85 mm/min;其对应的焊接电流分别是60~95、70~105、70~105 A,每5 A为一个递增单位;焊接保护气流量固定为15L/min。焊后对在不同参数下得到的焊接接头进行打磨处理,并在WDW-100型电子拉伸实验机上进行力学性能试验,其拉伸速度为1 mm/min。图2所示为焊接拉伸试样的示意图。并采用能谱分析仪(EDS)和扫描电镜(SEM)对接头的显微组织和元素组成进行观察和分析。

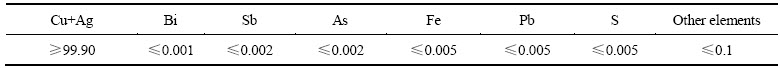

表1 T2紫铜的化学成分

Table 1 Chemical composition of T2 copper (mass fraction, %)

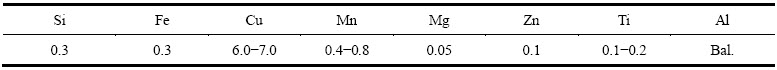

表2 2A16铝化学成分

Table 2 Chemical composition of LY16 aluminum (mass fraction, %)

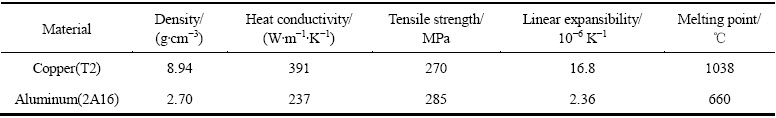

表3 母材的物理性能

Table 3 Physical properties of base materials

图1 焊接过程示意图

Fig. 1 Schematic diagram of welding process

图2 拉伸试样尺寸

Fig. 2 Dimension of tensile specimen (Unit: mm)

2 结果与分析

2.1 接头力学性能分析

不同焊接参数条件下的拉伸试验结果如图3所示。由图3可知,在35 mm/min的焊接速度下,电流为80、85、90 A时,接头的抗拉强度较大;焊接速度为62 mm/min、电流为100 A时和焊接为85 mm/min、电流为95 A时接头的抗拉强度较大,对应图3中颜色较浅的点,其断裂位置均在铜母材热影响区处。而其它参数下即深颜色点对应的参数,则全部断裂于靠近铜侧的焊缝处。其中接头抗拉强度最大为240 MPa,断裂于铜母材热影响区处,其对应的焊接参数为焊接电流为100 A、焊接速度为62 mm/min。由图3可知,当焊接速度为35 mm/min时,有3个参数均断裂于铜侧热影响区,而其它焊接速度下均只有一个断裂于铜侧热影响区处,这说明焊接电流对接头性能的影响要大于焊接速度对接头性能的影响;且在每个焊接速度下,随着焊接电流的增大,接头的抗拉强度先缓慢的增大,然后突然急剧增加到一个较大值,而后又急速下降,这可能是由于在焊接电流较小时,由于热输入较小,铝母材有一定的熔化量,此时填充材料和铝母材反应充分,其结合为冶金结合,而铜侧母材则几乎不熔化,使得Zn-Al填充材料和铜的结合面类似于钎焊,从而使得接头的力学性能较低。而当电流增大到一定值时,由于铜母材熔化量的增大,使得铜和Zn-Al填充材料发生冶金反应,从而使得接头的力学性能急剧增加。同时,由于此时TIG焊的热输入较大,使得两侧母材热影响区的晶粒严重长大,软化严重,从而使得力学性能降低,而铜母材在受热循环后,其软化更为严重(导热性好、温度梯度小、热影响区较大),从而使得接头断裂于铜侧热影响区处。而随着焊接电流的进一步增大,铜母材的熔化量较大,由于Cu和Zn、Al均能生成脆性的金属间化合物,从而在靠近铜母材侧的焊缝中形成了大量的金属间化合物,而使得接头的性能急剧下降,从而使接头断裂于靠近铜侧的焊缝处。

图3 不同焊接速度下接头强度随电流的变化

Fig. 3 Change of tensile strength with welding current at different welding speeds

2.2 接头显微组织分析

2.2.1 显微组织分析

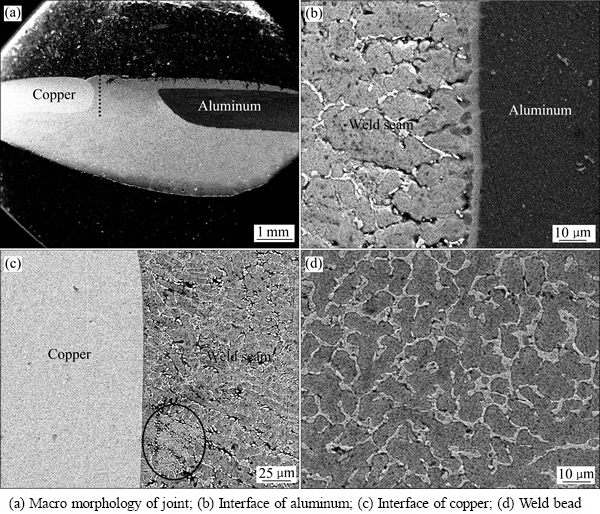

图4所示为当焊接电流为100 A、焊接速度为62 mm/min时所获得焊接接头的SEM像。其中图4(b)、(c)在焊缝组织晶界附近出现的黑色部分是由于腐蚀较深所致。图4(a)为焊接接头的整体形貌图,由图4(a)可知,焊接接头成形良好,无明显的裂纹、气孔等缺陷;图中右侧黑色部分为铝母材,而左侧白色部分为铜母材,中间的灰白色部分为焊缝,图中黑色虚线位置为母材原始的交界面,可知铝的熔化量较铜的熔化量要大很多。图4(b)和(c)分别为接头铝侧界面和铜侧界面的显微组织图。由图4(b)可知,右侧黑色部分为铝母材,在铝侧界面靠近铝母材处有一层灰色的物质,而在灰色物质层与焊缝之间有一沿界面呈链状分布的灰黑色球块状物质,其颜色和铝母材较为接近。这是由于焊接时铝母材的熔化量较大,界面处的液态铝母材温度比焊缝中心的低,因而,其黏度较大,同时,在熔池的搅拌作用下,填充材料冲涮界面,从而使得界面黏度很大的液态铝被黏度较小的液态填充金属包覆,在此过程中,也存在填充材料和被包覆铝之间元素的相互转移和扩散;当熔池凝固后,就形成了类似于图中所示的沿界面呈链状分布的灰黑色球块状物质。而图4(c)中,铜侧界面则较为清晰平直,没有类似于铝侧界面的情况,这可能是由于在焊接过程中Cu的熔化量很少,熔池搅拌剧烈,而且Cu与焊丝中的Zn、Al元素均能反应生成化合物,而Al与Zn则不会形成化合物,只是形成固溶体及共晶组织;在靠近铜母材侧附近的焊缝中分布有较多的白色条块状物质,界面处局部有白色物质聚集,如图中黑色圆圈处所示,且焊缝中白色的条块状组织分布由铜侧向铝侧逐渐减少,初步推测该白色条块状物质形成可能和Cu有关。图4(d)为焊缝中心的组织图,由图4(d)可知,在焊缝中,有白色条块状物质均匀分布于灰色的基体组织中,这也起到了强化焊缝组织的作用。

2.2.2 能谱分析

由于铜侧界面附近组织和焊缝中心类似,无其它特殊组织,从而只对焊缝中心和铝侧界面的组织进行EDS点扫描分析。图5所示为对接头焊缝中心和铝侧界面的形貌及EDS分析结果。其中图5(a)和5(c)中含有的O元素是由于该处的Al含量较高,制样后容易氧化所致,图5(a′)、(b′)分别为对焊缝中心处灰色组织和白色条块状组织的分析结果,图5(c′)、(d′)分别为接头铝侧界面灰黑色球块状物质和铝侧界面附近处白色条块状物质的分析结果。

由图5(a′)可知,灰色基体组织中Zn、Al含量分别为63.1%和22.94%,由Zn-Al二元相图可知,该基体物质可能为Zn基固溶体η相和Al基固溶体α相组成的(α+η)共晶组织,而该处含有微量的Cr元素可能来自于药芯焊丝药芯中的成分。由图5(b′)可知,焊缝中条块状的白色物质由Zn、Cu和Al元素组成,其中Zn含量为88.05%,Cu为9.25%而Al仅为2.7%;而图5(d′)中铝侧界面附近的白色条块状物质由Cu (12.03%)、Zn(87.97%)组成,其组成类似于焊缝中心处的白色条块状物质,这说明焊缝中的白色物质的形成与Cu元素有直接关系。Cu的熔点较高致使焊接热输入比较大,且Cu的导热系数较大,使得热传导很快,在接头处易生成白色的物质,这些物质使得接头具有良好的力学性能。由Cu-Zn二元相图和Cu-Zn-Al三元相图可知,Cu和Zn 能形成固溶体和CuZn、CuZn2、CuZn4(ε相)等金属间化合物,其中ε相成分为78%~88%Zn,能溶解约5%Al[19],从而推测接头中的白色物质极有可能为CuZn4,ε相较硬而且又均匀分布于焊缝中,强化了接头的性能。而在铜侧界面附近,由于Cu 含量较高,故而能形成大量的Cu-Zn金属间化合物,此外Cu和Al也能形成脆性的金属间化合物,这些金属间化合物在铜侧界面处聚集长大,在受外力作用下,易导致组织中较大的脆硬的块状化合物与其周围组织难以实现同步协调变形,易产生应力集中从而萌生裂纹源[11],这也说明了当热输入量过大时,接头为何也断裂于铜侧焊缝处,而且力学性能都较低。

图4 焊接接头的SEM像

Fig. 4 SEM images of welding joint:of copper

图5 焊接接头的形貌及其相应点的EDS分析结果

Fig. 5 Morphologies of welding joint and EDS analysis results of corresponding point

由图5(c)可知,沿铝侧界面呈链状分布的灰黑色球块状物质,其元素组成种类类似于铝合金母材,主要由Zn、Al组成,其中Zn的含量较母材要高出很多,而Al的含量较母材又有所减少。这进一步说明这些沿铝界面呈链状分布的灰黑色球块状物质是在焊接过程中由填充材料所包覆的熔融的铝合金母材所致,该处各元素含量分别为Al 29.67%、Cu 8.51%、Si 3.49%、Zn 40.79%、O 17.55%,从而可知该物质为α相铝基固溶体组织。

3 结论

1) 铝/铜异种材料填丝TIG焊对接接头无气孔、裂纹等缺陷,成形良好;铝母材熔化量较大,而铜母材熔化很少;最佳工艺参数为焊接电流100 A、焊接速度62 mm/min、保护气流量15 L/min,此时的抗拉强度为240.32 MPa,断裂于铜侧热影响区。

2) 由于熔化量和导热系数的不同,在铝侧界面处,有一沿界面呈链状分布的灰黑色球块状的α相铝基固溶体组织,而铜侧界面平直清晰,界面附近有较多的Cu-Zn和Cu-Al金属间化合物。

3) 焊缝组织为白色条块状的金属间化合物ε相(CuZn4),均匀分布于灰黑色的由Zn基和Al基固溶体组成的(α+η)共晶组织中。

REFERENCES

[1] 黄伯云. 我国有色金属材料现状及发展战略[J]. 中国有色金属学报, 2004, 14(5): 122-127.

HUANG Bai-yun. Status and developing strategy for China’s nonferrous metal materials industry[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 122-127.

[2] OUYANG J H, YARRAPAREDDY E, KOVACEVIC R. Microstructural evolution in the friction stir welded 6061 aluminum alloy (T6-temper condition) to copper[J]. Journal of Materials Processing Technology, 2006, 172(1): 110-122.

[3] BEYGI R, KAZEMINEZHAD M, KOKABI A H. Butt joining of Al-Cu bilayer sheet through friction stir welding[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(12): 2925-2929.

[4] LEE K S, KWON Y N. Solid-state bonding between A1 and Cu by vacuum hot pressing[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(2): 341-346.

[5] 李 东, 赵杨洋, 张延松. 焊接能量对铝/铜超声波焊接接头显微组织的影响[J]. 焊接学报, 2014, 35(2): 47-50.

LI Dong, ZHAO Yang-yang, ZHANG Yan-song. Effect of welding energy on microstructures of the Al/Cu joints obtained by ultrasonic welding[J]. Transactions of the China Welding Institution, 2014, 35(2): 47-50.

[6] ABBASI M, TAHERI A K, SALEHI M T. Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process[J]. Journal of Alloys and Compounds, 2001, 319(1): 233-241.

[7] 吴小伟, 沈以赴, 李 博, 周冠男, 姚 磊, 胡伟叶. 铝-铜搅拌摩擦焊搭接焊缝共晶组织形成与抑制[J]. 焊接学报, 2014, 35(1): 87-90.

WU Xiao-wei, SHEN Yi-fu, LI Bo, ZHOU Guan-nan, YAO Lei, HU Wei-ye. Formation and inhibition of eutectics in Al/Cu dissimilar metal lap joint[J]. Transactions of the China Welding Institution, 2014, 35(1): 87-90.

[8] AKINLABI E T, ANDREWS A, AKINLABI S A. Effects of processing parameters on corrosion properties of dissimilar friction stir welds of aluminium and copper[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(5): 1323-1330.

[9] 康 宁. 铝铜钎焊用Sn-Zn基无铅钎料的研究[D]. 大连: 大连理工大学, 2012.

KANG Ning. Study on Sn-Zn based lead-free solders for soldering Al and Cu[D]. Dalian: Dalian University of Technology, 2012.

[10] JI Feng, XUE Song-bai, LOU Ji-yuan, LOU Yin-bin, WANG Shui-qing. Microstructure and properties of Cu/Al joints brazed with Zn-Al filler metals[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(2): 281-287.

[11] 张 满, 王鹏飞, 张临财, 林岳宾. Zn-Al-Ag 钎料铜-铝钎焊接头显微组织与力学性能[J]. 焊接学报, 2013, 34(9): 55-58.

ZHANG Man, WANG Peng-fei, ZHANG Lin-cai, LIN Yue-bin. Microstructure and mechanical properties of Cu/Al joint brazed with Zn-Al-Ag filler metal[J]. Transactions of the China Welding Institution, 2013, 34(9): 55-58.

[12] 张洪涛, 刘 多, 冯吉才, 胡乐亮. 铝/铜高频感应接触反应钎焊[J]. 焊接学报, 2012, 33(3): 89-92.

ZHANG Hong-tao, LIU Duo, FENG Jic-ai, HU Le-liang . Reactive contact brazing between aluminium alloy and copper by high frequency induction method[J]. Transactions of the China Welding Institution, 2012, 33(3): 89-92.

[13] JI Feng, XUE Song-bai, DAI Wei. Reliability studies of Cu/Al joints brazed with Zn-Al-Ce filler metals[J]. Materials and Design, 2012, 42: 156-163.

[14] WEIGLA M, ALBERT F, TSCHMID M. Enhancing the ductility of laser-welded copper-aluminum connections by using adapted filler materials[J]. Physics Procedia, 2011, 12: 332-338.

[15] SPRINGER A, KALLAGE P, HUSTEDT M, BARCIKOWSKI S, WESLING V, HAFERKAMP H. Development of new processes for welding of thermal Al-Cu solar absorbers using diode lasers[J]. Journal of Laser Applications, 2012, 24(5): 052002.

[16] KRAETZSCH M, STANDFUSS J, KLOTZBACH A, KASPAR J, BRENNER B, BEYER E. Laser beam welding with high-frequency beam oscillation: Welding of dissimilar materials with brilliant fiber lasers[J]. Physics Procedia, 2011, 12: 142-149.

[17] 刘会杰, 沈俊军. 铝/铜异种材料的焊接研究[J]. 焊接, 2009, 88(3): 14-18.

LIU Hui-jie, SHEN Jun-jun. Progress in welding process of Al/Cu dissimilar metals[J]. Welding & Joining, 2009, 88(3): 14-18.

[18] 董红刚, 张旭超, 杨继承, 胡文金. 铝合金/黄铜异种金属电弧熔钎焊[J]. 中国机械工程, 2014, 25(8): 1122-1125.

DONG Hong-gang, ZHANG Xu-chao, YANG Ji-cheng, HU Wen-jin. Arc-brazing of aluminum alloy to brass[J]. China Mechanical Engineering, 2014, 25(8): 1122-1125.

[19] 陈 辉, 信 昕, 任玉平, 郝士明. A1-Zn-Cu系室温相图低Cu区的研究[J]. 金属学报, 2004, 40(8): 841-845.

CHEN Hui, XIN Xin, REN Yu-ping, HAO Shi-ming. Phase diagram of Al-Zn-Cu system in low copper side at room temperature[J]. Acta Metallurgica Sinica, 2004, 40(8): 841-845.

(编辑 李艳红)

收稿日期:2014-12-11;修订日期:2014-07-28

通信作者:程东海,讲师,博士;电话:18170069935;E-mail: pc755andrew@163.com