文章编号:1004-0609(2010)02-0318-05

1100-H14铝合金板冷冲锻成形过程的有限元模拟

王可胜1,2,刘全坤2,张德元2

(1. 宁波工程学院 机械学院,宁波 315016;

2. 合肥工业大学 材料科学与工程学院,合肥 230009)

摘要:金属板材冷冲锻成形是近年来发展起来的复合成形新技术,其特点是板材冲锻时不但完成零件形状的成形,还兼有局部结构的体积成形,如凸柱成形。针对带有凸柱的散热板基座,通过对1100-H14铝合金板材冷冲锻成形有限元模拟,探讨坯料厚度、坯料形状、摩擦因数及模具结构对凸柱成形的影响规律。结果表明:坯料越厚,越有利于凸柱成形;摩擦因数越大,越有利于凸柱成形;圆形坯料形状及带有背压的模具结构有利于凸柱成形。模拟结果与实验结果吻合。

关键词:凸柱;冲锻成形;有限元;模具设计

中图分类号:TG376;TG386 文献标识码:A

FEM simulation for forming process of cold press forging of

1100-H14 aluminum alloy sheets

WANG Ke-sheng1, 2, LIU Quan-kun2, ZHANG De-yuan2

(1. School of Mechanics, Ningbo University of Technology, Ningbo 315016, China;

2. School of Materials Science and Engineering, Hefei University of Technology, Heifei 230009, China)

Abstract: Cold press forging forming of sheet metals is a new technology for complex forming, developed in recent years. During press forging the sheet, it has the features that not only the geometries of the part can be shaped, but also local structures like embossment can be formed simultaneously. In order to shape a heat sink base with embossment, the forming process of cold press forging of 1100-H14 aluminum alloy sheet was simulated based on the finite element method, and the blank thickness, blank shape, friction coefficient and die structure on the embossment forming were studied. The results show that the thicker the blank is, the better the embossment can be formed, and also the greater the friction coefficient is, the better the embossment can be done. Meanwhile, the cylindrical blank and tooling structure with counter pressure can be helpful to the form of embossment as well. The simulation results are in good agreement with the experimental data.

Key words: embossment; press forging forming; finite element; die design

冷冲锻成形技术是一种新的铝合金成形工艺,该工艺的主要特点是将冷锻工序与冲压连续模结合,以便在连续模内进行冲压及锻造成形, 使产品的外形和厚度产生很大的变化,进而取代原本需要铸造、烧结、焊接或机加工的工艺[1?7]。由于该工艺既能成形形状较复杂零件,又具有产品力学性能和表面质量良好、成品率高、生产速度快等优点,因此可满足3C类产品带有凸柱的散热板基座及3C产品外壳内部突起的螺柱、凸筋等成形要求。1999年由Sony公司、日立金属公司、东京精锻工所共同开发了一项新的镁合金锻造技术—Press Forging,在业界受到了极大的关注[8?9]。CHEN等[10?11]研究了镁合金冲锻成形的金属流动规律、凸凹模形状对凸柱成形的影响及吸孔产生的原因。KWAN等[12?13]利用有限元软件对镁合金冲锻成形工艺进行模拟,研究了镁合金的成形性能及影响成形的因素。张士宏等[14?15]在国内较早开展了镁合金热冲锻成形的研究,通过实验和有限元模拟研究镁合金热冲锻成形工艺,并且成功地制造出无吸孔等工艺缺陷的镁合金方盒件。以上研究主要集中在镁合金热冲锻成形方面,对于带有凸柱的铝合金板的冷冲锻成形研究较少。而近年来3C电子产品的外观设计追求轻量、坚固和美观的理念,铝合金因为具有高强度、高刚性、表面处理方式多样化及良好的热传导性,故比塑胶及镁合金更适合用于3C产品的壳体,同时,铝合金也大量应用于散热板中。与镁合金只能热冲锻成形相比,铝合金能够冷冲锻成形,具有更大的竞争性。本文作者以1100-H14铝板为原材料,通过有限元模拟探讨坯料厚度、坯料形状、摩擦状况及带背压的模具结构等对凸柱成形的影响规律,在此基础上,结合实验方法研究带有凸柱的散热板基座的冷冲锻工艺。

1 有限元模型的建立

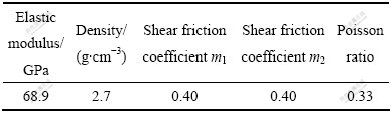

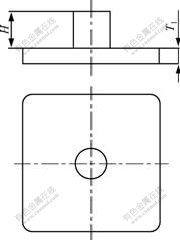

铝合金冷冲锻工艺属于体积变形,弹性变形很小,可忽略,所以可采用刚塑性模型进行有限元计算。摩擦类型采用剪切摩擦类型,凸模(Punch)与板料间的剪切摩擦因数为m1,凹模(Die)与板料间的剪切摩擦因数为m2。经过圆环压缩实验可知:模具与板料间加MoS2润滑,剪切摩擦因数为0.12;不加润滑剂,剪切摩擦因数为0.40;板料表面喷砂且不加润滑剂,剪切摩擦因数为0.70。除坯料外模具均采用刚体。坯料采用厚度为2 mm的1100-H14铝板,加载背压为2 kN,其它模拟工艺参数见表1。考虑到凸柱的成形难度较大,所以铝板冲锻工艺应首先从凸柱成形开始研究,有限元仿真模型如图1所示。

表1 模拟工艺参数

Table 1 Processing parameters for simulation

图1 有限元仿真模型

Fig.1 Model of FE simulation

研究模拟结果时,为了方便讨论,首先要定义一些代表凸柱成形过程中的参数。如图2所示,H为模拟过程中凸柱成形的高度,此H定义为凸柱背面刚刚产生吸孔时的高度;T1为模拟过程中原坯料厚度T减薄后的厚度,坯料的压下量T2=T?T1。

图2 凸柱成形过程中的尺寸示意图

Fig.2 Schematic diagram of geometric dimension of embossment at various forming stages

2 结果与讨论

2.1 相关因素对凸柱成形的影响

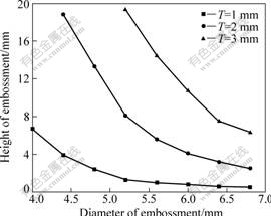

2.1.1 坯料厚度的影响

图1所示的有限元仿真模型的其它参数不变,分别取坯料厚度为1、2、3 mm进行模拟分析。如图3所示,坯料的厚度对凸柱的成形性能影响很大,材料厚度越大,相同直径的凸柱成形越高,主要是因为有足够的材料进入凹模中形成凸柱。对于已知的凸柱高度及直径,应该合理地选择坯料厚度。坯料太厚造成原材料和载荷的浪费,因为产品厚度一定,坯料厚度T越大,坯料的压下量T2就越大,所需做的功就越多,所以成形载荷就越大。另外,如坯料太厚,在凸柱成形后多余的料沿着与凸柱垂直的方向流动,导致“穿流”,造成凸柱根部强度减弱甚至断裂。而坯料太薄会造成凸柱背面产生吸孔,凸柱的顶部不饱满等缺陷,吸孔影响3C产品壳体的外观及散热板基座的贴胶片吸附力;顶部不饱满影响产品装配,所以不能有此两类缺陷。

图3 坯料厚度对凸柱成形的影响

Fig.3 Influence of blank thickness on embossment forming

2.1.2 坯料形状的影响

图1中所示的有限元仿真模型的其它参数不变,坯料的形状分别为直径22.5 mm圆板、边长为22.5 mm的正方板及尺寸为22.5 mm×40 mm的长方板,图4所示为模拟结果。从图4中可以看出,坯料形状为长方形及圆形比坯料的形状为正方形有利于凸柱成形,主要是因为圆形为中心对称,而正方形为轴对称,中心对称比轴对称更有利于材料流动;正方形、长方形都是轴对称,但本模拟中坯料形状为长方形比坯料的形状为正方形的材料要多43.75%。由图4可见,圆形坯料同长方形坯料在凸柱直径约为5.3 mm时,两者高度相等;在凸柱直径小于5.3 mm时,凸柱直径越小,圆形坯料比长方形坯料越有利于凸柱成形;当直径大于5.3 mm时,凸柱直径越大,长方形坯料比圆形坯料越有利于凸柱成形。其主要原因为成形直径较大的凸柱时,凸柱越高耗费的材料相对越多,而长方形坯料的材料比圆形坯料的多了55.8%。因此,成形直径较大的凸柱,不仅需要材料流动均匀性,还需要有足够多的材料及时补充避免吸孔产生。根据以上分析可知:圆形的坯料形状最有利于材料均匀流动,最有利于凸柱成形,而且还能节约较多的原料。

图4 坯料形状对凸柱成形的影响

Fig.4 Influence of blank shape on embossment forming

2.1.3 摩擦因数的影响

图1所示的有限元仿真模型的其它参数不变,分别取凸模与板料间的摩擦因数m1和凹模与板料间的摩擦因数m2为:m1=0.12,m2=0.12;m1=0.4,m2=0.4;m1=0.7,m2=0.12,对成形过程进行模拟分析,其模拟结果如图5所示。由图5可见,摩擦因数m1和m2相等时,摩擦因数越大,越有利于凸柱成形;凸模与板料间的摩擦因数m1偏大,凹模与板料间的摩擦因数m2偏小,则更有利于凸柱成形。但摩擦因数越大,摩擦力就越大,从而会造成载荷偏大,模具磨损严重。

1)

图5 摩擦因数对凸柱成形的影响

Fig.5 Influence of friction coefficient on embossment forming

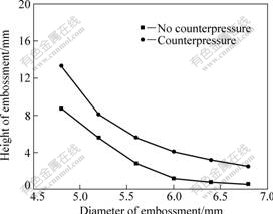

2.1.4 模具结构的影响

图1所示的有限元仿真模型的其它参数不变,凹模形成的凸柱顶部分别加背压(Counterpressure)及不加背压进行有限元模拟,模拟结果如图6所示。从图6中可以看出,增加背压时的凸柱的成形高度H明显高于不加背压,这是因为背压是在与材料流动相反的方向施加适当大小的力以控制零件不同部位材料流动,最终使材料完全充满凹模型腔形成凸柱。但背压选择不当时,否则会导致较大的成形载荷。

图6 模具结构对凸柱成形的影响

Fig.6 Influence of die structure on embossment forming

2.2 散热板基座模拟及实验结果

综合以上的分析结果,对散热板基座进行有限元模拟。凸模与板料间的摩擦因数m1为0.7,凹模与板料间的摩擦因数m2为0.12,其他模拟工艺参数见表1。根据体积不变原理,经过计算坯料的厚度在4.6 mm以上,为了选择合适的厚度来成形,分别对坯料厚度为4.8、5.0和5.2 mm进行有限元模拟,结果显示厚度为5.0 mm的1100-H14铝板能够成形该散热板基座,模拟结果如图7(a)所示。根据散热板有限元模拟的参数,设计了一副实验模具,实验在凹模与坯料间单面加MoS2润滑,与凸模接触的坯料单面喷砂(m1=0.7,m2=0.12),实验结果如图7(b)所示。实验时为了了解摩擦因数及背压结构对凸柱的影响,分别采用无喷砂的原坯料且不润滑(m1=0.4,m2=0.4)及无背压的模具结构进行了对比实验,实验结果见图7(c)和7(d)。

图7 模拟与实验结果

Fig.7 Results of simulation and experiments: (a) Results of simulation for heat sink base; (b) Results of experiment for blank with shot blast in one side; (c) Results of experiment for original blank; (d) Results of experiment for die without counter pressure

从图7(a)和(b)中可以看出,4个凸柱饱满,散热板基座背面无吸孔等工艺缺陷,实验结果与模拟结果非常吻合。图7(c)中在凸柱的背面已发现较小的吸孔(图中圆圈内);图7(d)中不但在凸柱的背面发现较小吸孔(图中圆圈内),而且还出现了较为严重的凸柱顶部不饱满缺陷(图7中圆圈内)。对比实验验证了图5和6的变化趋势的正确性。

综合模拟及实验结果,吸孔及凸柱不饱满的工艺缺陷产生的主要原因为坯料不足、材料流动速度过快。因此,预防凸柱成形过程中的吸孔及凸柱不饱满等工艺缺陷的措施为:增加坯料厚度,坯料形状尽可能选用圆形形状,背压的模具结构以及凸模同凸柱的背面不润滑,而凹模同凸柱形成的面润滑。

3 结论

1) 坯料厚度对凸柱成形的影响非常明显。坯料厚度越厚,越有利于凸柱成形,但太厚的坯料浪费原材料及成形载荷。

2) 摩擦力对凸柱成形有较大影响。当凸模与凸柱背面的板料间的摩擦因数较大、凹模与凸柱形成面的板料间的摩擦因数较小时,最有利于凸柱成形;当两者摩擦因数相等时,摩擦因数越大,越有利于凸柱成形。

3) 坯料的形状对凸柱成形有一定的影响。正方形、长方形及圆形坯料相比较,圆形坯料最有利于凸柱成形。

4) 模具结构对凸柱成形有较大的影响。带有背压的模具结构不仅减少吸孔产生,而且还能抑制凸柱不饱满缺陷,但背压太大,成形载荷会增加较大。

REFERENCES

[1] WANG Xin-yun, XIA Ju-chen, WU You-sheng, HU Guo-an. FE simulation and process analysis on forming of aluminum alloy multi-layer cylinder parts with flow control forming[J]. Trans Nonferrous Met Soc China, 2005, 15(2): 452?456。

[2] 张士宏, 徐永超, 王忠堂, 张青来. 镁合金板材制备及零件塑性成形技术[J].中国有色金属学报, 2004, 14(S3): 1?4.

ZHANG Shi-hong, XU Yong-chao, WANG Zhong-tang, ZHANG Qing-lai. Fabrication of Mg alloy sheets and Plastic forming of Mg sheet workpieces[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(S3): 1?4.

[3] 蔡盛祺, 吴春甫. 高精度零件板材冲锻工艺技术的开发[J]. 塑性工程学报, 2002, 9(4): 43?46.

CAI Sheng-qi, WU Chun-fu. Research on press forging of sheets for high precision parts[J]. Journal of Plasticity Engineering, 2002, 9(4): 43?46.

[4] 谢 谈, 贾德伟, 蒋 鹏, 尉 哲. 精密塑性成形技术在中国的应用与进展[J]. 机械工程学报, 2001, 37(7): 100?104.

XIE Tan, JIA De-wei, JIANG Peng, WEI Zhe. The application and development of fine plastic deforming in China[J]. Chinese Journal of Mechanical Engineering, 2001, 37(7): 100?104.

[5] LIU Hua-min, HUANG Liang-ju, YANG Shen-hua, ZHANG Shi-hong. Filling rules of bevel gears in the closed-die cold forging[J]. Journal of Materials Science & Technology, 2005, 21(6): 925?928.

[6] THIPPRAKMAS S, JIN M, MURAKAWA M. Study on flanged shapes in fine blanked-hole flanging process (FB-hole flanging process) using finite element method (FEM) [J]. Materials Processing Technology, 2007(192/193): 128?133.

[7] KIM H S. A study on cold forging process sequence design of terminal pins for high-voltage capacitors[J]. Materials Processing Technology, 2007(187/188): 604?608.

[8] 刘向阳. 镁合金压铸技术及应用[J]. 轻金属, 2007(2): 35?39.

LIU Xiang-yang. Magnesium alloy die-casting technology and its application[J]. Light Metals, 2007(2): 35?39.

[9] 杨 程, 杜红星, 刘晓平. 镁合金在3C产品中应用现状及前景展望[J]. 铸造设备研究, 2005(6): 46?49.

YANG Cheng, DU Hong-xing, LIU Xiao-ping. Application and developing tendency of magnesium alloys in 3C products[J]. Research and Studies on Foundry Equipment, 2005(6): 46?49.

[10] CHEN F K, HUANG T B, CHEN S G. Embossment formation in press forging of AZ31 magnesium-alloy sheets[J]. International Journal of Advanced Manufacturing Technology, 2007(32): 272?279.

[11] CHEN F K, HUANG T B, WANG S J. A study of flow-through phenomenon in the press forging of magnesium-alloy sheets[J]. International Journal of Advanced Manufacturing Technology, 2007(187/188): 770?774.

[12] HWANG J K, SOHN K Y, KIM K H, KANG D M. CAE application to press forging of magnesium alloys[J]. Materials Science Forum, 2003(419/422): 371?376.

[13] HWANG J K, SOHN K Y, KANG D M, SHIN Y S. Finite element analysis of press forging process of AZ31 sheet[J]. Materials Science Forum, 2005, 488/489: 457?460.

[14] 张士宏, 周丽新, 王忠堂. 板材零件局部体积成形技术研究[J]. 塑性工程学报, 2008, 15(2): 31?36.

ZHANG Shi-hong, ZHOU Li-xin, WANG Zhong-tang. Research on local bulk forming of sheet metal parts[J]. Journal of Plasticity Engineering, 2008, 15(2): 31?36.

[15] ZHANG Shi-hong, ZHANG Gang, XU Yong-chao, REN Li-mei, WANG Zhong-tang, ZHOU Li-xin. Press forging of magnesium alloy AZ31 sheets[J]. Materials Science Forum, 2007, 539/543: 1753?1758.

基金项目:国家自然科学基金资助项目(50575097);安徽省教育厅自然科学研究基金资助项目(KJ2007A062)

收稿日期:2009-02-03;修订日期:2009-04-18

通信作者:王可胜,博士;电话:15958281379; E-mail:xclwks@126.com

(编辑 何学锋)