超声铸造对AZ31镁合金铸锭及热轧板材组织与性能的影响

余琨1,薛新颖1,毛大恒2,李建平2,胡亚男1,李少君1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 机电工程学院,湖南 长沙,410083)

摘要:采用超声铸造方法制备AZ31镁合金铸锭,并对其组织性能进行研究。研究结果表明:超声铸造后AZ31合金铸锭晶粒尺寸平均值为140 μm,比常规铸造的铸锭晶粒尺寸350 μm更细小,同时合金中第二相分布更加均匀弥散,这使合金铸锭的综合力学性能提高并有利于后续铸锭的热轧开坯。经过超声铸造的AZ31镁合金热轧后板材的晶粒尺寸(5~30 μm)也比常规铸造锭坯热轧板材晶粒尺寸(40~60 μm)要细小,这使超声铸造AZ31镁合金热轧后板材的典型力学性能比常规铸造后热轧的合金板材的好,抗拉强度提高约18%,伸长率相当;超声铸造有利于细化AZ31镁合金晶粒,改善第二相在枝晶间的分布,提高合金的力学性能和加工变形能力。

关键词:超声铸造;AZ31镁合金;显微组织;力学性能

中图分类号:TG146 文献标志码:A 文章编号:1672-7207(2011)07-1918-05

Effects of ultrasonic vibration on microstructure and

properties of as-cast and hot rolled AZ31 magnesium alloy

YU Kun1, XUE Xin-ying1, MAO Da-heng2, LI Jian-ping2, HU Ya-nan1, LI Shao-jun1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: The ultrasonic vibration was introduced into the solidification of the AZ31 magnesium alloy. The results show that the average grain size of the experimental alloy ingots is about 140 μm, which is smaller of AZ31 alloy with ordinary casting process. Meanwhile, the intermetallics of experimental alloy distribute more uniform and disperse. Such structure is attribute to enhancing ingot’s mechanical properties and benefit to the sequential hot rolling. The grain size (5-30 μm) of hot rolled plate is produced by casting with ultrasonic vibration and sequential hot rolling is smaller than that (40-60 μm) of plate prepared by ordinary casting process. The mechanical properties of AZ31 magnesium alloy plate produced by ultrasonic vibration casting and sequential hot rolling are greatly improved due to the microstructure modification. The tensile strength increases by 18%, and the elongation is maintained. Ultrasonic vibration casting process enhances the mechanical properties and refines microstructure of AZ31 magnesium alloy and improves its deformability.

Key words: ultrasonic vibration; AZ31 magnesium alloy; microstructure; mechanical properties

镁合金属于典型的高比强度、高比刚度的轻质结构材料,其优良的综合力学性能具有代替钢铁、铝合金等其他金属结构材料的潜力,在汽车、航空航天等领域有广泛的应用,被誉为21世纪的绿色工程材 料[1-4]。目前,要获得高质量的镁合金产品,关键是要提供高品质的镁合金坯料,这是影响镁合金材料后续加工产品的组织和性能的重要因素[5-7]。引入外场是一种有效地提高镁合金铸锭综合性能、细化镁合金铸锭晶粒的方法,而超声铸造是铸造过程中引入外场细化镁合金晶粒简便有效的方法之一[8-9]。在凝固过程中引入超声外场时,可以使镁合金晶粒获得细化、提高第二相分布的均匀性。对铝合金熔炼铸造过程的研究表明,超声震动可明显细化铝合金铸锭的晶粒[10]。但是在镁合金铸造过程中引入超声外场的研究工作不多,目前的一些研究工作主要针对铸造用AZ91镁合金的组织和性能的影响,LIU等[11]的研究表明在铸造的过程中引入超声震动可获得比常规铸造铸锭更加均匀细小的铸造组织;GAO等[8]指出在铸造过程中引入超声震动,当超声功率从0 W增加到700 W时,AZ91镁合金的晶粒尺寸从202 μm减小到146 μm。然而,对于后续需要进行热变形的变形镁合金,超声外场引入到铸造过程对合金铸锭组织性能的影响,尤其对后续变形过程以及变形后合金组织性能的影响研究很少,在此,本文作者主要针对典型的变形镁合金AZ31,研究超声铸造对AZ31镁合金铸锭及热轧板材的组织与性能的影响。

1 实验材料及方法

采用工业纯镁、纯铝、纯锌作为AZ31合金的原料,合金成分为Mg-2.9%Al-1.0%Zn(质量分数)。合金在720 ℃电阻炉内熔炼,熔化后加入合金元素,待合金元素完全熔化后,加超声波搅拌,逐渐冷却,所加超声波的功率为2 kW,频率在20 kHz左右变化。超声铸造示意图见图1。为了对比,采用常规铸造造工艺制得相同合金成分的铸锭。将直径为150 mm的铸锭沿径向切开,用宏观腐蚀液腐蚀,用数码相机获得铸锭的宏观组织照片。将坯料在LG500型2辊轧机上热轧,轧制速度为0.36 m/s,轧制前将坯料预热至 400 ℃保温30 min,经多道次轧制,获得厚度为3 mm的板材,作为轧制后检测力学性能的样品,热轧总变形量为85%,热轧后的板材在400 ℃退火1 h来检测板材热加工后退火的性能。

图1 超声铸造示意图

Fig.1 Schematic of ultrasonic vibration casting equipment

将表面预磨、机械抛光并浸蚀后,使用金相显微镜观察试样微观组织,采用线性相交方法测量晶粒尺寸;力学拉伸试样按标准进行加工,在CSS-41000型电子试验机上进行拉伸实验,取3个试样的平均值;在JSM-5600LV型扫描电镜上观察试样表面,进行能谱分析,确定析出物的化学成分。

2 实验结果与讨论

2.1 超声铸造对AZ31镁合金铸锭组织的影响

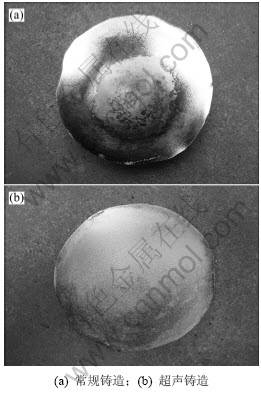

图2所示为AZ31镁合金铸锭宏观组织。从图2可见:常规铸造锭坯中间为粗大的柱状晶;超声铸造锭坯的组织为细小均匀的等轴晶。铸锭的组织依赖于形核过程及其后的长大过程[11]。在常规铸造过程 中,与坩埚壁接触的金属液冷却速度快,因此,凝固首先在坩埚壁处优先进行,此处形核率较其他部分的高,晶核可以向不同方向长大,故形成表面等轴晶。当形成稳定的凝固壳后,金属液的热量必须经过这一细晶层再经过坩埚壁向外散热,冷却速度明显下降,散热的方向性增强,促使晶核择向生长,最终形成柱状晶组织[5]。而超声的引入使熔液发生旋转,使温度场得到重新分布,并变得更加稳定和均匀,同时,熔池整体的温度波动也较小,这有效地抑制了晶粒的择向生长[12]。因此,在超声铸造过程中可得到细小均匀的晶粒。

图2 AZ31镁合金铸锭宏观组织

Fig.2 Macrostructure of AZ31 magnesium alloy

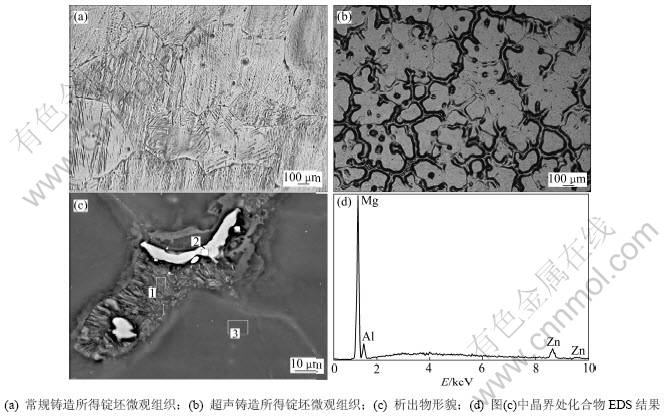

图3所示为AZ31镁合金铸锭微观组织及能谱成分分析(EDS)结果。从图3可见:常规铸造锭坯的平均晶粒粒径为350 μm左右,晶界平直或为弓形。超声铸造锭坯的平均晶粒粒径为140 μm左右,这是因为在超声铸造的过程中熔体的流动使枝晶臂受到冲击进而断裂,使粗大的树枝晶破碎,减小了一次枝晶臂的生长速度,从而抑制了粗大柱状晶的形成,同时这些碎片还可成为结晶的晶核,形成新的晶粒[13]。超声铸造所得锭坯的第二相在晶界上连续分布。这是因为常规铸锭是由熔液直接空冷而形成的,接近于平衡凝固的过程,所以第二相较少而且细小。在超声铸造的过程中,因为有超声搅拌,熔液散热速度快,是一种非平衡凝固过程,这一过程中会产生伪共晶组织,有利于第二相的析出。从超声铸造铸锭在扫描电镜下的析出相形貌及能谱分析结果可知:析出相为以β-Mg17Al12为主与少量的β-Mg17(Al, Zn)12的混合化合物。

2.2 超声铸造对热轧板材微观结构的影响

图4所示为镁合金热轧板材轧制方向微观组织。从图4(a)和(c)可见:常规铸造锭坯和超声铸造锭坯热轧后都具有轧制薄板的典型组织,都可以观察到加工流线的方向,并存在细小的动态再结晶新晶粒、粗大原始变形晶粒和孪晶,采用常规铸造锭坯热轧后的板材未完全再结晶组织晶粒的尺寸约为100 μm;超声铸造锭坯热轧后的板材晶粒尺寸约为5 μm。超声铸造锭坯热轧后的组织更加细小均匀。这是因为在热轧开坯过程中,动态再结晶的晶粒是在铸锭的晶界上开始形核的,超声铸造后铸锭的晶粒更加细小,即可以提供更多的动态再结晶形核位置,所以,超声铸锭的锭坯经热轧后所得组织更加细小均匀[14]。

从图4可见:2种板材退火后变形组织形貌都消失,常规铸造锭坯热轧板材退火的组织并不均匀,大晶粒的尺寸约为60 μm,小晶粒的尺寸约为40 μm,小晶粒的晶界向大尺寸晶粒内部弓出。超声铸造锭坯热轧板板材退火后的晶粒均匀细小,晶粒尺寸约为12 μm。这是因为超声铸造后的铸锭热轧过程中出现的孪晶更加细小和分散,孪晶不仅在镁合金的塑性变形中具有重要的协调变形的作用,在轧制过程中形成的孪晶在随后的退火过程中也具有重要的作用[15]。在退火过程中,新晶粒形成于孪晶片层或孪晶的相交处。超声铸造锭坯在热轧后形成的大量的孪晶为镁合金退火过程中的晶粒形核提供了更多的形核源,得到了晶粒更加均匀细小的退火板材组织。可见,超声铸造有利于镁合金板材的后续热加工和退火。

图3 AZ31镁合金铸态微观组织及能谱成分分析结果

Fig.3 Microstructure and EDS analysis of AZ31magnesium ingots

图4 AZ31镁合金板材轧制方向微观组织

Fig.4 Microstructure of AZ31 magnesium alloy sheet in rolling direction

2.3 超声铸造对镁合金热轧板材力学性能的影响

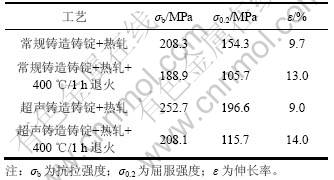

超声铸造对热轧AZ31镁合金力学性能的影响见表1。可见:超声铸造锭坯经热轧后得到的板材抗拉强度比常规铸造锭坯热轧后得到的板材高50 MPa左右,屈服极限高40 MPa左右;但是,伸长率没有明显的区别;2种板材在经过退火之后强度都有所下降,而伸长率都有所提高,超声铸造锭坯经热轧退火后得到的板材抗拉强度比常规铸造锭坯热轧退火后得到的板材高20 MPa左右,屈服极限高40 MPa左右,2种板材伸长率的差别不大。镁合金的强度符合Hall-Petch公式[16-17]。超声铸造锭坯热轧后的板材和退火后的板材具有更细小的晶粒,有更多的晶界可以阻止位错的移动,从而强度更高。

表1 AZ31镁合金板材力学性能

Table 1 Mechanical properties of AZ31 magnesium alloy

3 结论

(1) 超声铸造锭坯的组织为细小均匀的等轴晶而常规铸造锭坯中间为粗大的柱状晶,超声铸造后AZ31合金铸锭晶粒尺寸平均值为140 μm,比常规铸造的铸锭的晶粒尺寸350 μm更细小。同时第二相分布更加均匀弥散。这样的显微组织提高了合金铸锭的综合力学性能并有利于后续铸锭的热轧开坯。

(2) 经过超声铸造的AZ31镁合金热轧后板材的晶粒尺寸(5~30 μm)也比常规铸造锭坯热轧板材晶粒(40~60 μm)要细小,这使超声铸造AZ31镁合金热轧后板材的典型力学性能比常规铸造后热轧的合金板材要好,抗拉强度提高约18%,伸长率相当。

(3) 超声铸造有利于细化AZ31镁合金晶粒,改善第二相在枝晶间的分布,提高合金的力学性能和加工变形能力。

参考文献:

[1] Maksoud I A, Ahmed H, Rodel J. Investigation of the effect of strain rate and temperature on the deformability and microstructure evolution of AZ31 magnesium alloy[J]. Materials Science and Engineering A, 2009, 504(1/2): 40-48.

[2] 詹美燕, 李元元, 陈宛德, 等. 大应变轧制技术制备细晶AZ31镁合金板材[J]. 华南理工大学学报: 自然科学版, 2007, 35(8): 16-23.

ZHAN Mei-yan, LI Yuan-yuan, CHEN Wan-de, et al. Fine grained AZ31 magnesium sheet produced by large-strain rolling[J]. Journal of South China University of Technology: Natural Science Edition, 2007, 35(8): 16-23.

[3] Valle J A, Pe?rez-Prado M T, Ruano O A. Texture evolution during large-strain hot rolling of the Mg AZ61alloy[J]. Materials Science and Engineering A, 2003, 355(1/2): 68-78.

[4] 汪凌云, 黄光杰, 陈林, 等. 镁合金板材轧制工艺及组织性能分析[J]. 稀有金属材料与工程, 2007, 36(5): 910-914.

WANG Ling-yun, HUANG Guang-jie, CHEN Lin, et al. Rolling process, microstructure and properties of magnesium alloys sheet[J]. Rare Metal Materials and Engineering, 2007, 36(5): 910-914.

[5] 郑子樵. 材料科学基础[M]. 长沙: 中南大学出版社, 2005: 5-30.

ZHENG Zi-qiao. Materials science and engineering[M]. Changsha: Central South University Press, 2005: 5-30.

[6] Mackenzie L W F, Pekguleryuz M. The influences of alloying additions and processing parameters on the rolling microstructures and textures of magnesium alloys[J]. Materials Science and Engineering A, 2008, 480(1/2): 189-197.

[7] 吕宜振, 尉胤红, 曾小勤, 等. 镁合金铸造成形技术的发展[J]. 铸造, 2000, 49(7): 383-387.

L? Yi-zhen, WEI Ying-hong, ZENG Xiao-qin, et al. Development of casting technology for magnesium alloys[J]. Casting, 2000, 49(7): 383-387.

[8] GAO De-ming, LI Zhi-jun, HAN Qing-you, et al. Effect of ultrasonic power on microstructure and mechanical properties of AZ91alloy[J]. Materials Science and Engineering A, 2009, 502(1/2): 2-5.

[9] Ramirez A, Qian M, Davis B, et al. Potency of high-intensity ultrasonic treatment for grain refinement of magnesium alloys[J]. Scripta Material, 2008, 59(1): 19-22.

[10] Eskin G I. Ultrasonic treatment of light alloy melts[M]. Amsterdam: CRC Press, 1998: 1-6.

[11] LIU Xin-bao, Osawa Y, Takamori S, et al. Microstructure and mechanical properties of AZ91 alloy produced with ultrasonic vibration[J]. Materials Science and Engineering A, 2008, 487(1/2): 120-123.

[12] 苏允海, 刘政军. 电磁搅拌对压铸镁合金组织性能的影响[J]. 铸造, 2007, 56(12): 1273-1276.

SU Yun-hai, LIU Zheng-jun. Effect of electromagetic stirring on microstructure and mechanical properties of die casting magnesium alloy[J]. Casting, 2007, 56(12): 1273-1276.

[13] LIU Xin-bao, Osawa Y, Takamori S, et al. Grain refinement of AZ91 alloy by introducing ultrasonic vibration during solidification[J]. Materials Letters, 2008, 62(17/18): 2872-2875.

[14] 李鹏喜, 张波萍, 陈晶益, 等. 变形工艺对AZ31B 镁合金薄板组织及力学性能的影响[J]. 材料热处理学报, 2006, 27(3): 60-65.

LI Peng-xi, ZHANG Bo-ping, CHEN Jing-yi, et al. Effects of deforming on microstrcture and mechanical properties of AZ31 magnesium alloy[J]. Transaction of Materials and Heat Treatment, 2006, 27(3): 60-65.

[15] 詹美艳, 李元元, 陈维平, 等. AZ31镁合金轧制板材在退火处理中的组织性能演变[J]. 金属热处理, 2007, 32(7): 8-12.

ZHAN Mei-yan, LI Yuan-yuan, CHEN Wei-ping, et al. Evolution of microstructure and mechanical properties of AZ31 magnesium alloy rolled sheets during annealing[J]. Heat Treatment of Metals, 2007, 32(7): 8-12.

[16] LIANG Shu-jin, SUN Hong-fei, LIU Zu-yan, et al. Mechanical properties and texture evolution during rolling process of an AZ31 Mg alloy[J]. Journal of Alloys and Compounds, 2009, 472(1/2): 127-132.

[17] CHANG T C, WANG J Y, Lee S, et al. Grain refining of magnesium alloy AZ31 by rolling[J]. Journal of Materials Processing Technology, 2003, 140(1/3): 588-591.

(编辑 赵俊)

收稿日期:2010-07-10;修回日期:2010-10-27

基金项目:国家重点基础研究发展计划(“973”计划)(2007CB613706)

通信作者:余琨(1974-),男,四川成都人,副教授,从事有色金属材料研究;电话:0731-88879341;E-mail: kunyugroup@163.com