铜阳极泥预处理富集金银的研究

郑雅杰1,汪蓓1, 2,史建远2,孙召明1,刘昭成1

(1. 中南大学 冶金科学与工程学院,湖南 长沙,410083;

2. 大冶有色金属有限公司,湖北 黄石,435002)

摘 要:对铜阳极泥预处理富集金银进行研究。先经硫酸预浸脱铜,当反应温度为353 K,H2SO4与Cu的物质的量比n(H2SO4):n(Cu)为1.5,液固比为3?1,反应时间为1.5 h时,铜浸出率达到90%;脱铜阳极泥再与碳酸钠进行球磨转化后硝酸浸出脱铅;当球磨时间为3 h,Na2CO3与Pb的物质的量比即n(Na2CO3)?n(Pb)为2.5,液固比为2?1,球料比为8?1,HNO3与Pb的物质的量比即n(HNO3)?n(Pb)为6.0,浸出时间为0.5 h,浸出温度为296 K时,铅浸出率为69.5%。研究结果表明:经上述预处理后阳极泥金、银含量分别从0.152%和7.81%增加到0.31%和13.7%,阳极泥量减少一半,大大提高了回转窑生产能力,并减少了SO2的排放量。

关键词:铜阳极泥;预处理;铜;铅;浸出

中图分类号:TF04 文献标志码:A 文章编号:1672-7207(2010)03-0865-06

Pretreatment of copper anode slime for

concentrating gold and silver

ZHENG Ya-jie1, WANG Bei1, 2, SHI Jian-yuan2, SUN Zhao-ming1, LIU Zhao-cheng1

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. Daye Nonferrous Metals Company, Huangshi 435002, China)

Abstract: The pretreatment of copper anode slime for concentrating gold and silver was studied. The leaching rate of copper is 90% after the sulfuric acid leaching when leaching temperature is 353 K, n(H2SO4)?n(Cu) is 1.5, liquid-solid ratio is 3?1 and reaction time is 1.5 h. Then the decopper anode slime is milled with sodium carbonate and leached by nitric acid solution. The leaching rate of lead is 69.5% when the milling conditions are as follows: milling time is 3 h, n(Na2CO3)?n(Pb) is 2.5, liquid-solid ratio is 2?1, ball-to-powder mass ratio is 8?1 and the leaching conditions are as follows: n(HNO3)?n(Pb) is 6.0, leaching time is 0.5 h and leaching temperature is 296 K. After the pretreatment process, the results show that the contents of gold and silver increase from 0.152% and 7.81% to 0.31% and 13.7%, respectively. The amount of anode slime is reduced by half, the production capacity of rotary kiln is enhanced greatly and the emission of SO2 is decreased.

Key words: copper anode slime; pretreatment; copper; lead; leaching

铜电解精炼过程中产出的阳极泥,含有大量的贵金属和稀有元素,是提取稀贵金属的重要原料[1-2]。国内外铜阳极泥处理工艺主要有3类:一是以火法为主,湿法和火法相结合的火法流程;二是以湿法为主,火法和湿法相结合的半湿法工艺流程;三是全湿法工艺流程[3]。目前,国内大多数厂家所采用的是半湿法流程。随着冶炼厂电解铜阳极泥产量增加及成分变化,造成采用半湿法流程厂家回转窑蒸硒、分金和分银等关键工序出现异常,主要表现为物料结窑周期缩短、回转窑处理能力不足、蒸硒渣硒含量、分金渣金含量及分银渣银含量升高[4-7]。因此,采用阳极泥预处理工序大大有利于阳极泥的处理,并使金银得到富集[8-11]。铜阳极泥因其铅含量高,对金银的回收产生较大影 响[12-14]。按阳极泥中铅存在形态不同,阳极泥除铅的主要方法有氯盐法、碱法和胺法。氯盐法铅回收率 低,污染环境,腐蚀设备;碱法铅浸出率高,但成本高,操作困难;胺法铅浸出率高,但成本高,设备易腐蚀[15-16]。本文作者采用硫酸预浸脱铜、碳酸钠转化和硝酸浸出脱铅对阳极泥进行预处理,铜浸出率达到90%,铅浸出率达到69.5%,阳极泥中金和银富集提高1倍。该研究成果[17]有助于阳极泥处理,提高金银回收率;同时,阳极泥量的减少将大大提高硫酸化焙烧蒸硒的产能,降低蒸硒硫酸用量从而减少SO2的排放。

1 实验

1.1 实验原料

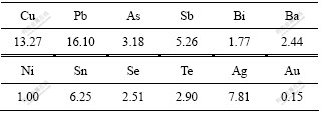

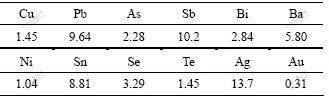

实验所用铜阳极泥来自国内某冶炼厂,其成分(质量分数)如表1所示。

表1 铜阳极泥成分

Table 1 Chemical compositions of copper anode slime %

由表1可知:该阳极泥中主要元素为Cu和Pb,其质量分数分别为13.27%和16.10%; 贵金属Au和Ag质量分数分别为0.152%和7.810%。

1.2 实验步骤

1.2.1 硫酸预浸脱铜

取一定量的铜阳极泥,置于三颈瓶中,按一定液固比加入稀硫酸,控制一定的反应温度及反应时间搅拌浸出。反应后过滤得到脱铜阳极泥。

1.2.2 碳酸钠转化

向滚动球磨罐加入脱铜阳极泥和一定量碳酸钠,按一定的液固比加入水,控制一定的球磨时间及球料比进行密闭球磨。反应后过滤得到转化阳极泥。

1.2.3 酸浸脱铅

将转化阳极泥置于三颈瓶中,加入一定量醋酸或硝酸,在室温下搅拌浸出,反应一定时间后过滤,得到脱铅阳极泥。

1.3 工艺流程

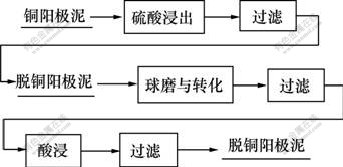

根据上述实验步骤,其工艺流程如图1所示。

图1 铜阳极泥预处理工艺流程图

Fig.1 Pretreatment flowsheet of copper anode slime

1.4 分析及检测

X荧光分析仪(菲利浦24,荷兰菲利浦公司)分析阳极泥成分,X线衍射仪(D/max-rA,日本理学Rigaku株式会社)分析阳极泥物相(X射线的发射源为Cu Kα,发射功率为50 kV×100 mA,步宽为0.01?,扫描速率为8 (?)/min,2θ为5?~80?)。采用化学分析法检测铜阳极泥铜物相,采用等离子发射光谱(IRIS IntrepidⅡXSP,Thermo electron corporation, USA)检测溶液中铅含量。

2 实验结果与讨论

2.1 硫酸预浸脱铜

实验对铜阳极泥中铜物相分析结果如表2所示。

表2 阳极泥铜物相及其铜质量分数

Table 2 Copper phase and content of copper anode slim %

由表2可知:铜阳极泥中总铜含量为13.27%,85.1%的Cu(即11.29%/13.27%)以硫酸铜形式存在。采用硫酸预浸有助于铜阳极泥中铜的浸出。研究表明[17]硫酸预浸脱铜适宜条件是:H2SO4与Cu的物质的量比n(H2SO4)?n(Cu)为1.5,反应温度为353 K,液固比为3?1,反应时间为1.5 h。

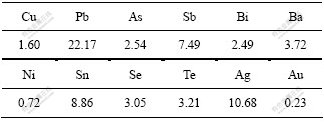

在上述适宜条件下,充分浸出后过滤洗涤,得到脱铜阳极泥,其成分(质量分数)如表3所示。

表3 脱铜阳极泥成分

Table 3 Chemical compositions of decoppered anode slime %

由表3可知,硫酸浸出后,阳极泥中铜质量分数降低到1.6%,铜浸出率达到90%。同时,金、银和铅质量分数分别从0.15%,7.81%和16.10%增加到0.23%,10.68%和22.17%。

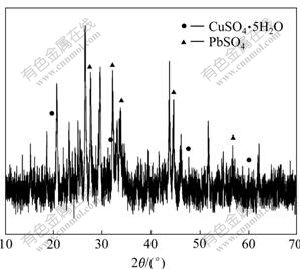

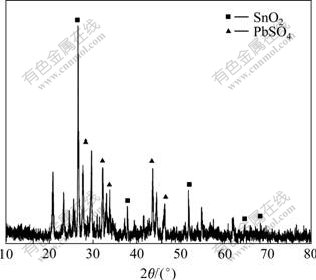

对铜阳极泥及硫酸浸出脱铜阳极泥进行X线衍射(XRD)分析其物相,其结果分别如图2和图3所示。

图2 铜阳极泥XRD图

Fig.2 XRD diagram of copper anode slime

图3 脱铜阳极泥XRD图

Fig.3 XRD diagram of decoppered anode slime

由图2和图3比较可以知道:阳极泥中铅主要以PbSO4存在,经过硫酸浸出,硫酸铜物相消失,证明硫酸铜已被浸出,硫酸浸出后出现SnO2物相。

2.2 碳酸钠转化条件对铅浸出率的影响

经过硫酸预浸脱铜后,进行碳酸钠转化,然后,醋酸脱铅,固定醋酸脱铅条件:在HAC与Pb的物质的量比n(HAc)?n(Pb)为4.0,液固比为3?1,浸出温度为296 K,浸出时间为1.5 h的条件下对阳极泥进行脱铅,考查转化时球磨时间、Na2CO3与Pb的物质的量比n(Na2CO3)?n(Pb)、液固比和球料质量比对铅浸出率的影响。

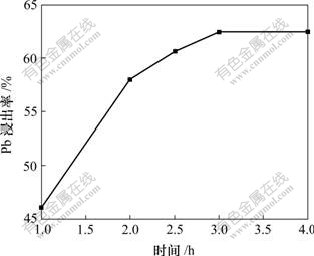

2.2.1 球磨时间对铅浸出率的影响

取一定量经干燥后的脱铜阳极泥,当n(Na2CO3)? n(Pb)为2.0,液固比为2?1,球料比为11?1时,球磨时间对铅浸出率的影响如图4所示。

图4 球磨时间对铅浸出率的影响

Fig.4 Effect of milling time on leaching rate of Pb

由图4可知:铅浸出率随着球磨时间的增加而增加;当球磨时间从1.0 h增加到3.0 h时,铅浸出率由46.2%增加到62.4 %;当球磨时间大于3.0 h时,随着球磨时间增加,铅浸出率基本不变。采用球磨方式可使新生成的PbCO3尽可能脱离PbSO4表面,从而大大提高铅的转化率,当球磨时间大于3.0 h时,反应已基本完成,继续增加球磨时间对铅浸出率影响不大。适宜的球磨时间为3.0 h。

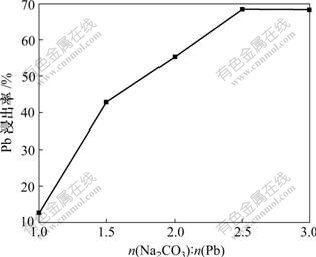

2.2.2 Na2CO3与Pb的物质的量比n(Na2CO3)?n(Pb)对铅浸出率的影响

上述其他条件不变,当球磨时间为3.0 h时,n(Na2CO3)?n(Pb)对铅浸出率的影响如图5所示。

由图5可知:随着n(Na2CO3)?n(Pb)的增加铅浸出率明显增大;当n(Na2CO3)?n(Pb)从1.0倍增加到2.5倍时,铅浸出率从12.7%增加到68.3%。在25 ℃时PbSO4溶度积为1.6×10-8,而PbCO3的溶度积为7.4×10-14,由于PbCO3溶度积小于PbSO4溶度积,加入Na2CO3可使PbSO4转化为PbCO3,其反应方程式为[18]:

PbSO4 + Na2CO3=PbCO3↓+ Na2SO4 (1)

图5 Na2CO3与Pb的物质的量比n(Na2CO3)?n(Pb)对

铅浸出率的影响

Fig.5 Effect of n(Na2CO3)?n(Pb)on leaching rate of Pb

显然,n(Na2CO3)?n(Pb)增加,CO32-浓度增大,有利于PbSO4向PbCO3转化。因此,适宜的n(Na2CO3)?n(Pb)为2.5。

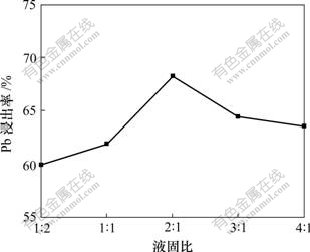

2.2.3 液固比对铅浸出率的影响

上述其他条件不变,当n(Na2CO3)?n(Pb)为2.5时,液固比对铅浸出率影响如图6所示。

图6 液固比对铅浸出率的影响

Fig.6 Effect of liquid-solid ratio on leaching rate of Pb

从图6可知,当液固比从1?2增加到2?1时,铅浸出率从60.1%增加到68.3%。这是因为当液固比增加时,碳酸钠浓度降低,生成的碳酸铅迅速向溶液主体扩散,增加了液相传质;继续增加液固比,铅浸出率下降。由于碳酸钠浓度降低,碳酸铅转化速度减小,同时,CO32-转化平衡浓度小,从而铅浸出率降低。因此,适宜液固比为2?1。

2.2.4 球料质量比对浸出率的影响

上述其他条件不变,当液固比为2?1时,球料质量比对铅浸出率的影响如图7所示。

图7 球料质量比对铅浸出率的影响

Fig.7 Effect of ball-to-powder mass ratio on

leaching rate of Pb

从图7可知:铅浸出率随球料比的增加而增加,当球料比从4?1增加到11?1时,铅浸出率从47.2%增加到68.3%。这主要是由于球料比较小时,球与物料间的机械摩擦作用小,不利于新生成的碳酸铅与硫酸铅分离,从而不利于反应的充分进行。综合考虑能耗、生产效率及铅浸出率,适宜的球料质量比为 8?1。

实验结果表明,适宜的球磨转化条件为:球磨时间为3 h,n(Na2CO3)?n(Pb)为2.5,球磨液固比为2?1,球料比为8?1。

2.3 酸浸条件对铅浸出率的影响

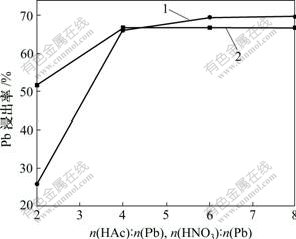

当液固比为3?1,浸出温度为296 K,浸出时间为1.5 h时,n(HAc)?n(Pb)和n(HNO3)?n(Pb)对铅浸出率影响如图8所示。由图8可知,铅浸出率随n(HAc)?n(Pb)和n(HNO3)?n(Pb)增加而增加;当n(HAc)?n(Pb)从2.0倍增加到4.0倍,铅浸出率从51.6%增加到66.8%;当n(HNO3)?n(Pb)从2.0倍增加到6.0倍,铅浸出率从25.8%增加到69.5%。这主要是由于HAc或HNO3与PbCO3反应生成易溶于水的Pb(Ac)2和Pb(NO3)2,其反应式如下:

PbCO3 + 2HAc=Pb(Ac)2 + CO2↑+ H2O (2)

PbCO3 +2HNO3=Pb(NO3)2 + CO2↑+ H2O (3)

1—硝酸浸出;2—醋酸浸出

图8 HAc与Pb的物质的量比n(HAc)?n(Pb)以及HNO3与Pb的物质的量比n(HNO3)?n(Pb)对铅浸出率影响

Fig.8 Effects of n(HAc)?n(Pb) and n(HNO3)?n(Pb) on leaching rate of Pb

随着n(HAc)?n(Pb)和n(HNO3)?n(Pb)增加,PbCO3 反应量增加,铅浸出率增加。当n(HAc)?n(Pb)和n(HNO3)? n(Pb)增加时,硝酸浸铅优于醋酸浸铅。其原因是铅在阳极泥中除以硫酸铅的形式存在外,可能还有少部分以硫物形态形式存在[19],硝酸易将其氧化 浸出。

采用醋酸浸出时,由于醋酸易挥发导致刺激性气味较大,对生产环境造成较大影响。因此,经综合考虑,采用硝酸浸出较适宜,确定n(HNO3)?n(Pb)为6.0。

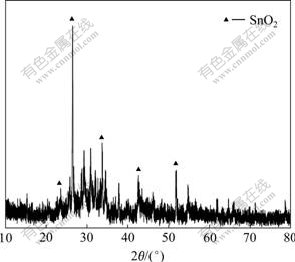

实验将脱铅阳极泥进行X衍射分析其物相,结果如图9所示。由图9可知:经过碳酸钠转化-硝酸脱铅的阳极泥中,PbSO4物相消失,XRD实验结果说明PbSO4被脱除。

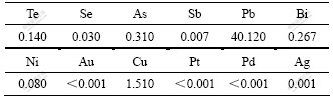

将脱铅阳极泥进行XRF(X线荧光分析),硝酸浸出液采用ICP进行检测,其结果如表4和表5所示。

由表1和表4可知:经过碳酸钠球磨转化和硝酸浸出脱铅后,铅含量从16.10%减少到9.64%。根据渣率和铅含量计算,每1 kg阳极泥脱铅量达到0.11 kg。金和银含量分别从0.15%和7.81%增加到0.31%和13.7%,金和银富集增加约1倍。阳极泥经预处理后,质量减少50%,有利于后继蒸硒工艺的进行,回转窑蒸硒能力增大1倍,蒸硒硫酸用量减少,从而SO2的排放量也减小。

图9 脱铅阳极泥XRD图

Fig.9 XRD diagram of delead anode slime

表4 脱铅阳极泥质量分数

Table 4 Chemical compositions of deleaded anode slim %

表5 硝酸浸出液质量浓度

Table 5 Chemical compositions of nitric acid leaching solution g/L

由表5可知:硝酸浸出液中铅质量浓度为40.12 g/L,铜质量浓度为1.51 g/L,可用来进一步回收铅。同时,硝酸浸出液中Au,Ag,Pt和Pd质量浓度均小于或等于0.001 g/L,贵金属没有损失。

3 结论

(1) 通过硫酸预浸脱铜,当H2SO4与Cu的物质的量比n(H2SO4)?n(Cu)为1.5,反应温度为353 K,液固比为3?1,反应时间为1.5 h时,铜浸出率达到90%。

(2) 在适宜的球磨条件(时间为3 h,Na2CO3与Pb的物质的量比n(Na2CO3)? n(Pb)为2.5,球磨液固比为2?1,球料比为8?1)和酸浸出条件(HNO3与Pb的物质的量比n(HNO3)?n(Pb)为6.0,浸出时间为0.5 h,浸出温度为296 K)下,铅浸出率达到69.50%。

(3) 经预处理后,阳极泥中金含量从0.15%增加到0.31%,银含量从7.81%增加到13.70%。阳极泥量减少约一半,回转窑能力增大约1倍,SO2排放量减少,对环境危害减小。

参考文献:

[1] 邱光文, 徐远志. 高银铜阳极泥湿法处理流程研究[J]. 有色金属设计, 2000, 27(2): 19-24.

QIU Guang-wen, XU Yuan-zhi. Hydrometallurgical process study on treating high silver copper anode slime[J]. Nonferrous Design, 2000, 27(2): 19-24.

[2] 侯惠芬. 从铜阳极泥中综合回收重有色金属和稀、贵金属[J]. 上海有色金属, 2000, 21(2): 88-93.

HOU Hui-fen. Complex recovery of non-ferrous, rare and noble metals from copper anode slime[J]. Shanghai Nonferrous Metals, 2000, 21(2): 88-93.

[3] 王小龙, 张昕红. 铜阳极泥处理工艺的探讨[J]. 矿冶, 2005, 14(2): 46-48.

WANG Xiao-long, ZHANG Xin-hong. Discussion on process for treating copper anode slime[J]. Mining & Metallurgy, 2005, 14(2): 46-48.

[4] 农大桂. 铜阳极泥处理工艺的改进[J]. 中国有色冶金, 2004, 33(6): 44-46.

LONG Da-gui. Process improvement in copper anode slime treatment[J]. China Nonferrous Metallurgy, 2004, 33(6): 44-46.

[5] 尹湘华. 高杂质铜阳极泥的处理[J]. 有色金属: 冶炼部分, 2005(5): 16-17.

YIN Xiang-hua. Treatment of copper anode slime with high impurity[J]. Nonferrous Metals: Extractive Metallurgy, 2005(5): 16-17.

[6] 王日. 铜阳极泥预处理工艺优化[J]. 矿冶, 2004, 13(4): 46-49.

WANG Ri. Optimization of pretreatment technology for copper anode slime[J]. Mining & Metallurgy, 2004, 13(4): 46-49.

[7] 周犇, 赵忱. 阳极泥处理工艺优化实践[J]. 有色金属: 冶炼部分, 2003(1): 26-28.

ZHOU Ben, ZHAO Chen. Plant practice of process optimizing for treating anode sline[J]. Nonferrous Metals: Extractive Metallurgy, 2003(1): 26-28.

[8] 董爱国, 赵玉福, 王魁珽. 高铅碲铜阳极泥处理工艺的改进[J]. 中国有色冶金, 2008, 37(3): 30-33.

DONG Ai-guo, ZHAO Yu-fu, WANG Kui-ting. Improvement on high lead-tellurium copper anode sludge treatment process[J]. China Nonferrous Metallurgy, 2008, 37(3): 30-33.

[9] Amer A M. Processing of copper anode-slimes for extraction of valuable metals[J]. Waste Management, 2003, 23(8): 763-770.

[10] 张荣良, 丘克强, 胡汉祥, 等. 铅锑复合渣于低温真空蒸发直接制备纳米Sb2O3[J]. 中南大学学报: 自然科学版, 2006, 37(5): 948-953.

ZHANG Rong-liang, QIU Ke-qiang, HU Han-xiang, et al. Preparation of nanometer antimony trioxide from the complex slag containing Pb and Sb at low temperature by the vacuum evaporation method[J]. Journal of Central South University: Science and Technology, 2006, 37(5): 948-953.

[11] Halt J K, Vinay J R, Sanyal S K. Some studies on sulfuric acid leaching of anode slime with additives[J]. Industrial and Engineering Chemistry Research, 2002, 41(25): 6593-6599.

[12] Donmez, Bunyamin, Celik, Cafer; Colak, Sabri; Yartasi, Ahmet. Dissolution optimization of copper from anode slime in H2SO4 solutions[J]. Industrial & Engineering Chemistry Research, 1998, 37(8): 3382-3387.

[13] Omer Y, Recep Z. Recovery of gold and silver from copper anode slime[J]. Separation Science and Technology, 2000, 35(1): 133-141.

[14] 杨宗荣, 朱素芬. 从电解铜阳极泥中提取金和银[J]. 贵金属, 1998, 19(2): 28-33.

YANG Zong-rong, ZHU Su-fen. Extraction of Au, Ag from anode-slime of copper electrolyzation[J]. Precious Metal, 1998, 19(2): 28-33.

[15] 杨喜云, 龚竹青, 李义兵. 铅阳极泥湿法提铅工艺浅述[J]. 矿冶工程, 2002, 22(4): 73-75.

YANG Xi-yun, GONG Zhu-qing, LI Yi-bing. Review on the hydrometallurgical processes of recovery lead from lead anode slime[J]. Ming and Metallurgical Engineering, 2002, 22(4): 73-75.

[16] Abdel B S, Mahmoud A R. Hydrometallurgical recovery of metal values from brass melting slag[J]. Hydrometallurgy, 1999, 53(1): 31-44.

[17] 郑雅杰, 汪蓓. 阳极泥预处理及回收稀散金属的方法: 中国, 200810032022[P]. 2008-08-08.

ZHENG Ya-jie, WANG Bei. A method of recovering metals and pretreating copper anode slime: China, 200810032022[P]. 2008-08-08.

[18] 陈进中, 曹华珍, 郑国渠, 等. 高锑低银类铅阳极泥制备五氯化锑新工艺[J]. 中国有色金属学报, 2008, 18(11): 2094-2099.

CHEN Jin-zhong, CAO Hua-zhen, ZHENG Guo-qu, et al. Novel technology for preparation of SbCl5 from lead anode slime with high antimony and low silver content[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(11): 2094-2099.

[19] Ipinza J, Ibanez J P, Vergara F, et al. Study of anodic slime from chilean copper electrowinning plants[C]//Vancouver B C. Proceedings of the TMS Fall Extraction and Processing Conference. Canada: Minerals, Metals and Materials Society, 2003(2): 1267-1277.

收稿日期:2009-02-21;修回日期:2009-04-21

基金项目:2007年广东省教育部产学研重大项目(2007A090302068)

通信作者:郑雅杰(1959-),男,湖南常德人,博士,教授,博士生导师,从事冶金、资源综合利用、水污染控制等研究;电话:0731-88836285;E-mail: zzyyjj01@yahoo.com.cn

(编辑 任楚威)