锻造和热处理对Al-Si和Al-Pb轴承合金 在油润滑条件下耐磨性的影响

来源期刊:中国有色金属学报(英文版)2013年第12期

论文作者:Erol FEYZULLAHO?LU Alpay Tamer ERTüRK Ersin Asim GüVEN

文章页码:3575 - 3583

关键词:热处理;锻造;Al-Si合金;Al-Pb合金;磨损

Key words:heat treatment; forging; Al-Si alloy; Al-Pb alloy; wear

摘 要:研究了锻造态和热处理态不同成分铝基轴承合金在油润滑条件下的摩擦行为,以及材料的硬度、热处理制度和锻造对材料耐磨性的影响。所用材料是Al-8.5Si-3.5Cu和Al-15Pb-3.7Cu-1.5Si-1.1Fe。在锻造过程中,应变范围为10%~20%。并对材料进行T6热处理。在销-盘式磨损试验机上对材料的摩擦性能进行测试。结果表明,锻造过程使材料的硬度得到增加;铸造应变在10%~20%的范围内对材料的摩擦磨损影响不明显。

Abstract: The tribological behaviours of aluminium-based bearing alloys with different compositions, forged and heat treated materials, were investigated in oil lubricated conditions. Tested materials were Al-8.5Si-3.5Cu and Al-15Pb-3.7Cu-1.5Si-1.1Fe. The effects of hardness, heat treatment and forging on wear behaviours of the tested materials were investigated. In forging process, 10%-20% strains were applied. Heat treatment (T6) was performed to the materials. The wear tests of all specimens were performed with a pin- on-disc wear test machine. Forging process increased hardness value of the tested materials. A forging strain of 10%-20% has no significant effect on mass loss.

Trans. Nonferrous Met. Soc. China 23(2013) 3575-3583

, Alpay Tamer

, Alpay Tamer  , Ersin Asim

, Ersin Asim

Mechanical Engineering Department, Engineering Faculty, Kocaeli University, Izmit-Kocaeli, Turkey

Received 26 March 2013; accepted 5 August 2013

Abstract: The tribological behaviours of aluminium-based bearing alloys with different compositions, forged and heat treated materials, were investigated in oil lubricated conditions. Tested materials were Al-8.5Si-3.5Cu and Al-15Pb-3.7Cu-1.5Si-1.1Fe. The effects of hardness, heat treatment and forging on wear behaviours of the tested materials were investigated. In forging process, 10%-20% strains were applied. Heat treatment (T6) was performed to the materials. The wear tests of all specimens were performed with a pin- on-disc wear test machine. Forging process increased hardness value of the tested materials. A forging strain of 10%-20% has no significant effect on mass loss.

Key words: heat treatment; forging; Al-Si alloy; Al-Pb alloy; wear

1 Introduction

Aluminium alloys have been used for bearing applications for many years. Aluminum bearing alloys have wear resistance, fatigue strength, low modulus of elasticity, high load carrying capacity, excellent corrosion resistance, castability and thermal conductivity. They are used in main bearings of internal combustion and diesel engines, hydraulic gear pumps, reciprocating compressors and aircraft equipments. Aluminium and its alloys have low density. That’s why better serviceable bearing parts can be produced [1,2]. Wear is a major problem in industry. The wear complicates power transmission and reduces working efficiency. Therefore, many efforts have been made to produce more wear- resistance materials and methods to reduce wear of machine elements. These efforts include variety of properties of materials, surface treatment, coatings and different production techniques.

Commercial pure aluminium and its alloys have some disadvantages such as low strength and unstable mechanical properties in the engineering practice. Aluminium has been the most selected material when using as bearing components by alloying such elements as Sn, Si, Pb, Cu and Mg. The mechanical properties of aluminium can be increased by alloying. Heat treatment, cold working and precipitation hardening increase their strength [1,3,4]. An important way to improve wear properties of Al-based bearing alloys is to add alloying elements. ZHU et al [5] showed that the addition of silicon (Si), cupper (Cu) and magnesium (Mg) increases the hardness, strength and wear resistance. The strength and microstructure of alloy matrix are important factors influencing wear behaviours. For a long time, Al-Sn based alloys are used as Al-based bearing alloys in most situations. As Pb is easy to create lubrication film and cheaper than Sn, many attempts have been made to use Pb to substitute Sn in bearing alloys [6]. Al-Pb bearing alloys could be very appealing alternative to Al-Sn bearing alloys. Al-Pb alloys show lower friction coefficient than Al-Sn alloys [7]. Al-Pb bearing alloys are used in automotive industry. Al-Pb alloys are more common particularly due to cost-effectiveness and easy to form a lubrication film than other alloys. Owing to the sedimentary tendency of lead in aluminium matrix and wide miscibility gap along with the big difference of the densities, Al-Pb alloys have difficulties during the casting stage. Despite the difficulties in casting, many techniques have been developed like recasting, spray casting, ultrasonic mixing and powder metallurgy [1,6-8]. One approach is having a reduced amount of Sn in alloys for decreasing the cost and a think bearing Al-Pb-Sn and Al-Pb-Cu alloys to utilize a combination of beneficial bearing properties [5,9]. Al-Si based alloys have also good wear performance due to their good mechanical characteristics. Aluminum alloys which contain higher Si content (17%) are used in numerous applications where high wear resistance is required. Al-Si alloys have been classified depending upon the silicon content as hypoeutectic (less than 11% Si), eutectic (11%-13% Si) and hypereutectic (more than 13% Si) types [10,11]. Al-Si alloys have potential for excellent castability, good weldability, thermal conductivity, high strength, low thermal expansion and excellent corrosion resistance [12]. The previous investigations presented that wear behaviours of Al-Si alloys were considerably affected by Si content and size [13].

The heat treatment provides comparable improvement in wear resistance. The heat-treated specimens had a lower friction coefficient than non-treated specimens [11]. Several investigators have studied the effect of heat treatment on wear behaviours of Al alloys. It was stated that the heat treatment improved mechanical properties and increased wear resistance [14]. HARUN et al [15] reported that modification and heat treatment of cast Al-Si alloys improved wear resistance. HAQUE and SHARIF [12] presented that the heat treated Al-Si alloy had higher strength, hardness and wear resistance properties. Generally, the bearing components have been shaped by standard metal processing technologies such as casting and forging methods, which affect the wear performance of the materials [16-19]. Al alloys pieces can be produced economically by conventional casting techniques. When the plastic forming methods are applied to Al alloys, some improvements in strength and ductility of Al alloys are observed [20]. In recent years, the used process such as extrusion, rolling and forging have profound impact on the improvement of wear resistance in severe abrasion such as dry friction [21].

In the present investigation, an attempt is made to study the combined effect of forging and heat treatment on the wear behaviour of Al-Si (Al-8.5Si-3.5Cu) and Al-Pb (Al-15Pb-3.7Cu-1.5Si-1.1Fe). Effects of heat treatment, hardness and forging on wear behaviours of tested materials are investigated under identical test and in oil lubricated conditions. Microstructure and worn surface of tested materials are examined. The wear resistance behaviours of tested materials are discussed according to tribology theory.

2 Experimental

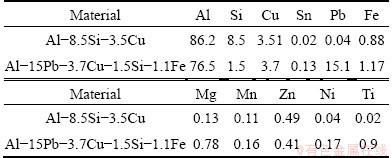

The tested materials had specific proportions of Si, Pb, Cu, Fe and Mg and the other elements. Two compositions of aluminium-based alloys (Al-Si and Al-Pb) were cast into steel mould. Elemental analyses of the Al-8.5Si-3.5Cu (referred as Al-Si) and Al-15Pb- 3.7Cu-1.5Si-1.1Fe (referred as Al-Pb) are listed in Table 1.

Table 1 Chemical compositions of tested alloys (mass fraction, %)

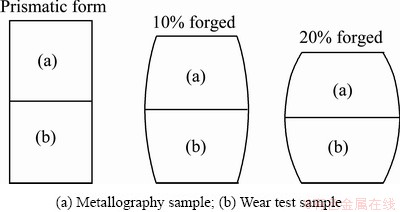

At first, the cast specimens were machined to 10 mm×10 mm×20 mm prismatic form. Two-piece pressing tool of carbon steel was used in open-die forging procedure. Two faces were pressed each other. A Dartec universal tensile test machine was used for open-die forging. The specimen of 20 mm in height was forged at 200 °C, between two plain plates, into 18 and 15 mm height to obtain 10% and 20% strains respectively. The specimens began to flow at 300-600 MPa. The force was increased at about 0.6 mm/s. Before forging, in order to reduce level of barrelling, surfaces of specimens, which were in contact with dies, have been ground with P800 SiC paper to reduce roughness and also coefficient of friction between die and specimen. As illustrated in Fig. 1, after open-die forging, all specimens were cut at the centre line by diamond disc. One part was used for metallographic examination and the other was used as wear specimen.

Fig. 1 Illustration of open-die forging and specimen preparation

The full heat treatment (T6), including solution, ageing and precipitation treatment, was carried out for Al-Si and Al-Pb specimens. For solutionizing, specimens were heated in electronically operated Severn heat treating furnace at (50±3) °C for about 6 h. After then specimens were quenched in water and immediately heated to (160±3) °C and kept for 16 h in order to prevent natural aging. Finally, they were cooled in ambient air.

The test specimens for microstructural examination were prepared by standard polishing methods. All specimens were ground with the Metcon Forcipol 2V rotating polishing machine with various grades of SiC papers up to 2400 grid. Specimens were subjected to fine polishing by using 1 μm diamond paste and then final polishing with 0.06 μm colloidal silica suspension. Specimens were cleaned with water and dried with acetone before etching. Polished specimens were immersed into Keller’s etchant (190 mL distilled water, 5 mL HCl, 3 mL HNO3, 2 mL HF) for 20 s and washed with warm water in order to neutralise residual of etchant. Different etchant solution (2 g NaOH, 100 mL distilled water at 50 °C) was used to appear grain boundaries and also to obtain better contrast. Nikon MA100 optical microscope was used for microstructural examination.

Hardness values of as-cast, forged and heat treated specimens were measured by using Zwick Vickers micro hardness test machine. 200 g test load and 20 s dwell time were applied and the average of least 5 readings was reported.

In wear tests, all experiments were done in pin-on- disc type apparatus. Wear tests were conducted against hardened steel disc. Disc had 60 mm in diameter, 95 HRB hardness and 0.5 mm in surface roughness. Disc was rotated by AC motor, having speed range of 0-2000 r/min. In wear tests, the rotation speed of the disc was 750 r/min and the normal load was 150 N. Test time for all specimens was 4 h. Speed, load, pressure and lubrication circumstances were all maintained in every test. Humidity and temperature were detected respectively as 50% relative humidity (RH) and 22 °C. Wear tests were performed in oil lubricated conditions. The thick and continuous oil film occurred. SAE 20/50 mineral oil was used in experiments. The viscosity of oil was 1.57×10-4 m2/s at 40 °C. In all experiments, 10 mm×10 mm×10 mm cubic specimens were used. Before testing, both test specimen and disc were cleaned with acetone. The mass loss of specimen before and after each wear test was measured using Precisa 125A precision scale. The scale has 0.1 mg precision and can measure a maximum mass of 220 g. After the test, the wear tracks were examined by Nikon MA100 optical microscope to recognize the type of wear.

3 Results and discussion

3.1 Microstructure

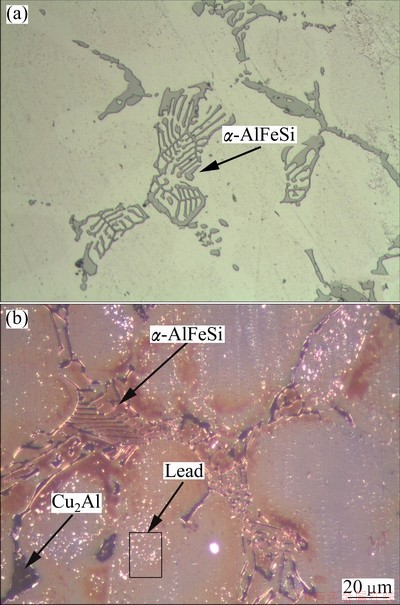

The optical microscopy clearly shows the presence of α-AlFeSi phase particles in Fig. 2. The type of phase in Al-Si alloys mainly depends on the cooling rate and composition of Fe and Si [22,23]. The α-AlFeSi precipitates called as “Chinese script” tend to nucleation at the grain boundaries at high solidification rate (nearly 32 °C/min) and also Fe or Si content [24]. When more solidification rate (nearly 54 °C/min) takes place in a process like direct chill casting, the α-AlFeSi intermetallic precipitation is impeded and the needle-like β-AlFeSi precipitate occurs [25,26]. The presence of Cu-rich regions in scarlet colour was clearly detected by using of cross polarise light. Segregation of copper regions was settled at grain boundaries and around α-AlFeSi phases. Remaining copper precipitated as Cu2Al and settled around α-AlFeSi phases in dark particles as seen in Fig. 2(b).

Fig. 2 Optical microstructural graphs of Al-Pb alloy under day (a) and polarise light (b)

Al and Pb have different atomic radii and electro- negativities, also no common valences. Therefore, solubility of Pb in Al is zero at room temperature up to 580 °C. In Fig. 2(b), the Pb segregations are seen as white dots under cross polarise light. Additionally these segregations are not only settled as liquid pools in the α(Al) grains but also seen rarely at the grain boundaries and between the α-AlFeSi arms.

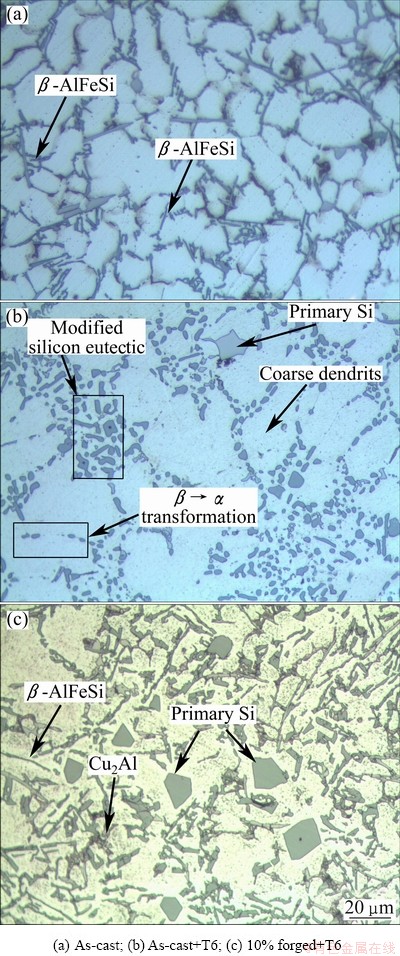

In optical microstructural graph of Al-Si alloy (Fig. 3(a)), coarse dendritic primary α(Al) and modified eutectic Si at the dendrite boundary can be clearly seen. The eutectic Al-Si phase with nearly spherical primary silicon particles is distributed in the matrix [19,27,28]. The spherical shape eutectic silicon improves mechanical properties of Al-Si alloys. Increasing of Si and decreasing of both Fe and Mn amounts at the same time in total composition cause solidification of β-AlFeSi rather than α-AlFeSi [29,30]. The solidification rate and total amount of alloying elements in the studied Al-Si alloy cause solidification of the needle-shape β-AlFeSi phases at dendrite boundary, as seen in Figs. 3(a) and (b). There is no Cu segregation on primary α(Al) in the Al-Si unlikely the Al-Pb alloys. Copper is precipitated on the eutectic silicon as Cu2Al (dark regions in Fig. 3(c)).

Fig. 3 Optical microstructural graphs of Al-Si alloy

It is well known that the phase transformation of β-AlFeSi to α-Al(FeMn)Si is an important process during the homogenisation (500-600 °C) of cast Al-Mg-Si alloys. This process also occurs in artificial aging. As seen in Fig. 3(b), monoclinic intermetallic β-AlFeSi particles transform to multiple rounded α-Al(FeMn)Si particles. This transformation improves the process ability of the aluminium considerably. The more rounded α-particles in the homogenised material improve the ductility of material and improve surface quality [14,31]. The needle-like β-particles can lead to local crack initiation and induce surface defects.

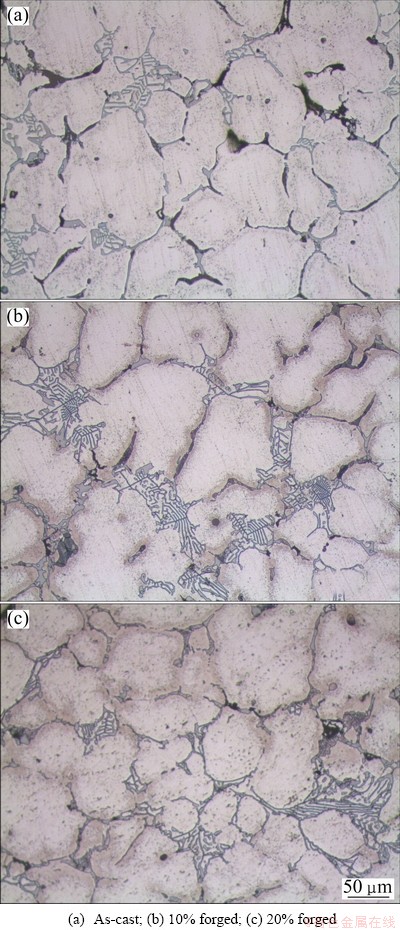

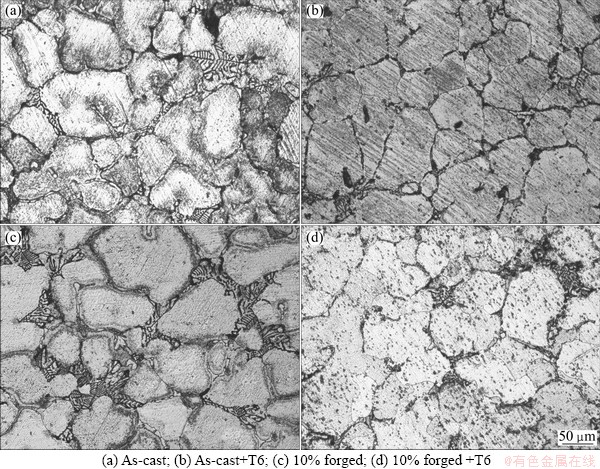

Microstructural examinations were performed on the traverse cross section to the forging direction. Instead of grain elongation which is perpendicular to forging direction, the grains tend to spread and the grain size increases (Fig. 4). Although the forging strain on the examined surface has less effect on the grain shape, hardness increases with the increasing of the forging strain.

Fig. 4 Optical microstructural graphs of Al-Pb alloy

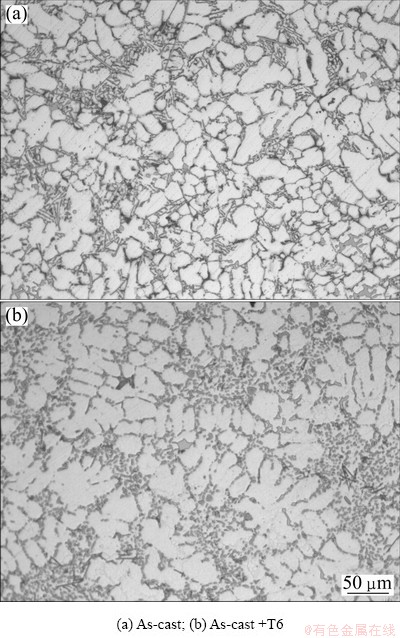

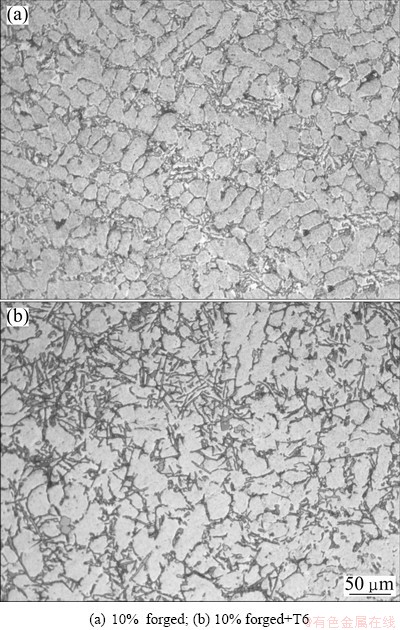

During heat treatment stage (T6) of the homogenization, holding the specimens at elevated temperature for up to 6 h affects the grains to grow especially in the Al-Si alloy (see Fig. 5). But, significant grain growing was not detected on the forged specimens (see Fig. 6). Even though, forged and un-forged specimens were exposed to the same heat treating conditions, increasing of dislocation based strain resisted to grain growing at elevated temperatures.

The holding at elevated temperatures caused solving eutectic grain boundary in as-cast specimen (Figs. 7(a, b)) and also forged specimens in Al-Pb alloy (Figs. 7(c, d)).

Thus, the restriction of grain coarsening by grain boundary has disappeared.

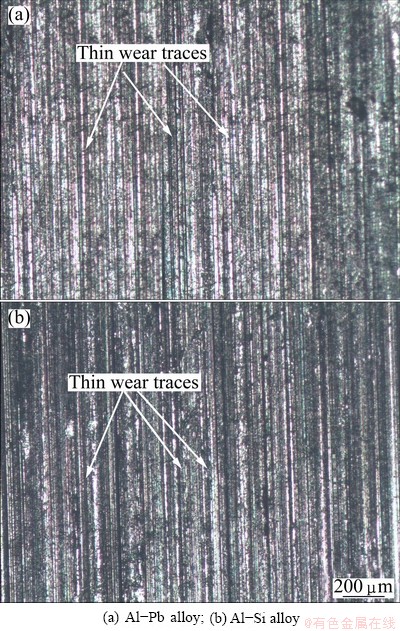

View of wear surfaces can be seen in Fig. 8. It can be seen easily that deeper wear traces occurred on the surface of Al-Si than Al-Pb samples. In this figure, wear scars and craters were observed.

Fig. 5 Optical microstructural graphs of Al-Si alloy

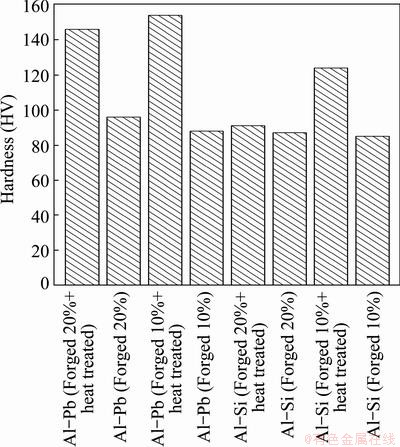

3.2 Hardness

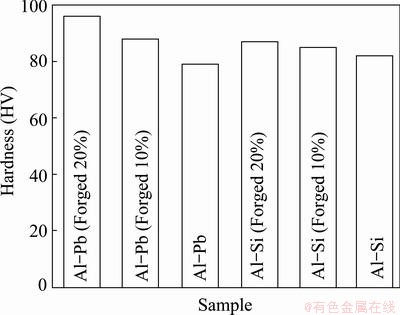

Figure 9 shows the hardness of unforged and forged (10%-20% strains) materials. The forged specimens have higher hardness values than the unforged specimens. Strained specimen at 10% has lower hardness value than the 20% strained one. Also,  et al [20] presented that specimens had better strength values than cast specimens. As the addition of Si into alloy increases hardness, Al-Si alloy is one of the hardest materials in the tested materials (Fig. 9).

et al [20] presented that specimens had better strength values than cast specimens. As the addition of Si into alloy increases hardness, Al-Si alloy is one of the hardest materials in the tested materials (Fig. 9).

Fig. 6 Optical microstructural graphs of Al-Si alloy

Fig. 7 Optical microstructural graphs of Al-Pb alloy

Fig. 8 Optical photographs of worn surface

Fig. 9 Hardness values of unforged and forged materials

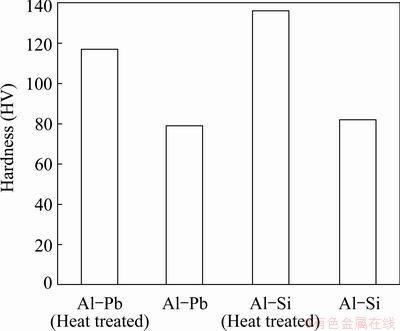

Figure 10 shows the relationship between heat treatment and hardness of the tested materials. As the heat treatment process increases the hardness of materials, the heat treated specimens have higher hardness values than the non-treated one. Heat treated Al-Si alloy has higher hardness value than the heat treated Al-Pb alloy. HAQUE and SHARIF [12] presented similar results.

In the previous investigations, there are no adequate studies about relationship between forging and heat treatment. Therefore, the aim of performed multi-process is detection of the heat treatment effects on forged specimens. Firstly, specimens were forged and the hardness values of them were measured using an Vickers indenter. Subsequently, the forged specimens were heat treated (T6) and the hardness measurements were repeated. Figure 11 shows the hardness values of specimens subjected to multi-process stages, namely, the forging + heat treatment. It was clearly seen that heat treatment process increased the hardness values of the forged specimens.

Fig. 10 Hardness of heat treated (T6) and non-treated Al-Si and Al-Pb alloys

Fig. 11 Relationship between hardness and forging+heat treatment (T6) for Al-Si and Al-Pb alloys

3.3 Wear behaviour

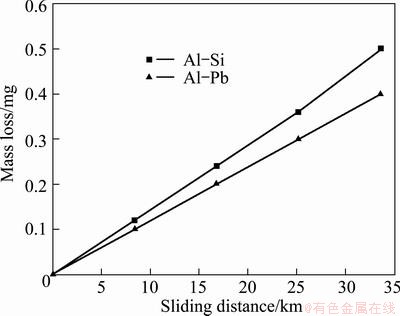

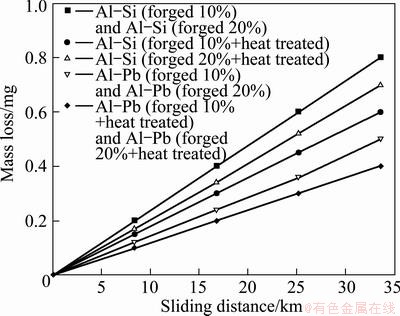

The wear depends on sliding distance (as well sliding time). Figure 12 shows the relationship between sliding distance and mass loss of tested materials in oil lubricated conditions. Al-Pb alloy is the least worn, contrary Al-Si is the most worn material in the study. Si is mostly used alloying element to improve wear characteristic and hardness, while Pb has the most enhancing effect on the wear resistance of Al alloys. The wear properties of Al-Pb alloys depend on extremely microstructure, in particular, size and distribution of Pb grains [6]. The homogeneous distribution of Pb is helpful to wear properties.

Fig. 12 Relationship between sliding distance and mass loss of as-cast specimens

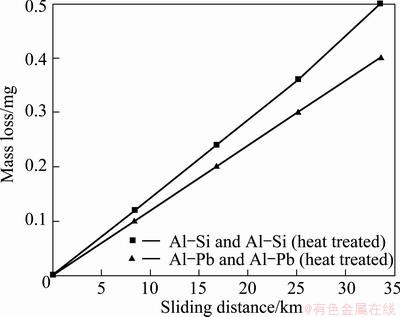

Figure 13 shows the relationship between sliding distance, heat treatment and mass loss in oil lubricated conditions. Heat treatment increases hardness and wear resistance of materials [11,27]. When an alloy is heat treated, it creates a homogeneous phase. Gained hardness by a heat treatment increases wear resistance of materials [14]. As mentioned above holding the material at elevated temperature acts as grain growing. Also, the grain growing has negative effect on wear resistance. Therefore, the results show that the obtained wear resistance with hardness in heat treatment has disappeared by grain growing mechanism. Thus, as-cast and as-cast + heat treated alloys have same mass loss values, as seen in Fig. 13.

Fig. 13 Relationship between sliding distance, heat treatment and mass loss for specimens

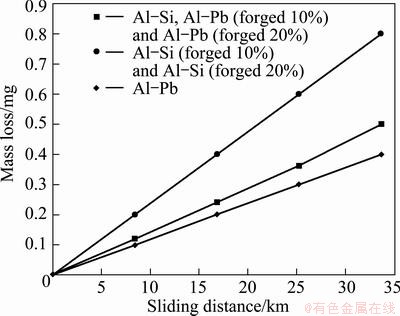

The wear resistance of Al alloy decreases due to forging in milder abrasion conditions such as under lubrication. But in more severe abrasion such as dry friction, there is a tendency against to opposite behaviour [32]. Figure 14 shows relationship between forging and mass loss depending on sliding distance in oil lubricated conditions. It is seen that the forged specimens have weaker wear resistance than the unforged specimens.  and

and  [32] presented similar results in their study. Also, Fig. 14 shows that there is no significant effect between 10% and 20% forging on mass loss. Al-Pb alloy is the least worn, contrary Al-Si is the most worn material among the forged specimens, because of their hardness values.

[32] presented similar results in their study. Also, Fig. 14 shows that there is no significant effect between 10% and 20% forging on mass loss. Al-Pb alloy is the least worn, contrary Al-Si is the most worn material among the forged specimens, because of their hardness values.

Fig. 14 Relationship between forging, mass loss and sliding distance for alloys

Figure 15 shows relationship between mass loss and sliding distance of forged and forged + heat treated materials in oil lubricated conditions. When the heat treatment is applied to the forged specimens, mass loss decreases. The wear resistance increases with an application of heat treatment.

Fig. 15 Relationship between mass loss, forging, heat treatment and sliding distance for alloys

Due to the effects of heat treatment (T6) on hardness and strength, wear properties of the Al-Si alloys were increased. Similar results were presented in further studies [3,11,15,27,33]. The wear resistance of Al-Si alloys was increased by refinement of Si particles [1]. The high wear resistance is usually based on the presence of hard silicon particles distributed throughout matrix [18]. Mass loss decreased with rising Si contents up 10% [1]. Si, Cu, and Pb improve wear properties of Al alloys [6,18]. Small amount of Cu or Mg increases strength, hardness and scuff resistance [1]. The additional Cu content of Al-Si alloy makes it more resistant to wear [19].

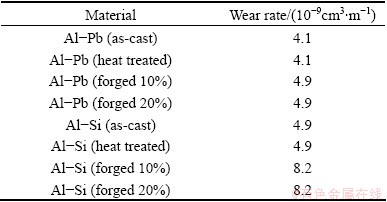

The wear rates of specimens are shown in Table 2. The wear rates are used for comparative studies. The wear rate is greatly affected by sliding conditions (e.g. contact pressure, sliding speed). The material with low friction coefficient has less wear rate value than the others.

Wear rate is estimated by following equation [34]:

(1)

(1)

where ms is the wear rate; Dm is the mass loss; r is the density; L is the sliding distance.

Table 2 Wear rates of studied alloys

Table 2 shows relationship between studied alloys and wear rates in oil lubricated conditions. Al-Si alloy has the highest wear rate among as-cast specimens. RAMESH and SAFIULLA [21] reported that the improved hardness causes decreasing of wear rate.

The relationship between heat treatment and wear rate in oil lubricated conditions is given in Table 2. The Heat treated Al-Si alloy has a higher wear rate value than the heat treated Al-Pb alloy. As-cast and as-cast + heat treated specimens have same mass loss values in Fig. 13. Also, this situation is seen in Table 2.

Table 2 also shows relationship between wear rate and forging in oil lubricated conditions. When the forging was applied to specimens, the wear rates were increased. The forged Al-Si has a higher wear rate than another forged material. The forged Al-Pb alloy has a lower wear rate than another forged material.

It is known from basic wear law that mass loss of the material, during the wear process, is clearly proportional to sliding distance and applied load, while hardness value of the material is inversely proportional to mass loss. Wear rate of a material depends on the hardness of it, so that hard alloys have greater wear resistances [13]. The several researchers [2,21] reported that the improved hardness causes decreasing of wear rate.

4 Conclusions

1) Forging process increased hardness value of the tested materials. 10%-strained alloy has a lower hardness than 20%-strained one. However, forged alloys have worse wear properties compared with cast ones under milder abrasion conditions. When the forging was applied to specimens, the mass loss (as well wear rate) of the materials increased. But a forging strain of 10%-20% has no significant effect on mass loss.

2) The heat treatment process increased hardness of tested materials. The obtained wear resistance with hardness in heat treatment has disappeared by grain growing mechanism. Thus, as-cast and as-cast+heat treated alloys in this study have same mass loss values. When the heat treatment is applied to forged specimens, mass loss decreases.

3) The results showed that the wear resistance performance of Al-Pb alloy is superior to Al-Si alloy under oil lubricated conditions.

References

[1] RANA R S, PUROHIT R, DAS S. Reviews on the influences of alloying elements on the microstructure and mechanical properties of aluminum alloys and aluminum alloy composites [J]. International Journal of Scientific and Research Publication, 2012, 2(6): 1-7.

[2] FEYZULLAHOGLU E, SAKIROGLU N. The tribological behaviours of aluminium-based materials under dry sliding [J]. Industrial Lubrication and Tribology, 2011, 63(5): 350-358.

[3] KIM S W, KIM D Y, KIM W G, WOO K D.The study on characteristics of heat treatment of the direct squeeze cast 7075 wrought Al alloy [J]. Materials Science and Engineering A, 2001, 304: 721-726.

[4] MA X, SAMUEL A M, SAMUEL F H, DOTY H W, VALTIERRA S. A study of tensile properties in Al-Si-Cu and Al-Si-Mg alloys: Effect of β-iron intermetallics and porosity [J]. Materials Science and Engineering A, 2008, 490: 36-51.

[5] ZHU M, ZENG M Q, GAO Y, OUYANG L Z, LI B L. Microstructure and wear properties of Al-Pb-Cu alloys prepared by mechanical alloying [J]. Wear, 2002, 253: 832-838.

[6] ZHU M, GAO Y, CHUNG C Y, CHE Z X, LUO K C, LI B L. Improvement of the wear behaviour of Al-Pb alloys by mechanical alloying [J]. Wear, 2000, 242: 47-53.

[7] PATHAK J P, MOHAN S. Tribological behaviour of conventional Al-Sn and equivalent Al-Pb alloys under lubrication [J]. Bulletin of Materials Science, 2003, 26(3): 315-320.

[8] AN J, LIU Y B, LU Y. The influence of Pb on the friction and wear behaviour of Al-Si-Pb alloys [J]. Materials Science and Engineering A, 2004, 373: 294-302.

[9] AGARWALA V, SATYANARAYANA K G, AGARWALA R C, GARG R. A study on the development and wear characteristics of rheocast Al-5Cu-2Pb alloy and Al-5Cu/Pb-18Sn wire composites [J]. Materials Science and Engineering A, 2002, 327: 186-202.

[10] DWIVEDI D K. Adhesive wear behaviour of cast aluminium–silicon alloys: Overview [J]. Materials and Design, 2010, 31: 2517-2531.

[11] OTT R D, BLUE C A, SANTELLA M L, BLAU P J. The influence of a heat treatment on the tribological performance of a high wear resistant high Si Al-Si alloy weld overlay [J]. Wear, 2001, 251(1): 868-874.

[12] HAQUE M M, SHARIF A. Study on wear properties of aluminium–silicon piston alloy [J]. Journal of Materials Processing Technology, 2001, 118(1-3): 69-73.

[13] ALIDOKHT S A, ABDOLLAH-ZADEH A, SOLEYMANI S, SAEID T, ASSADI H. Evaluation of microstructure and wear behaviour of friction stir processed cast aluminum alloy [J]. Materials Characterization, 2012, 63: 90-97.

[14] SAWLA S, DAS S. Combined effect of reinforcement and heat treatment on the two body abrasive wear of aluminum alloy and aluminum particle composites [J]. Wear, 2004, 257(5-6): 555-561.

[15] HARUN M, TALIB I A, DAUD A R. Effect of element additions on wear property of eutectic aluminium-silicon alloys [J]. Wear, 1996, 194(1-2): 54-59.

[16] YASMIN T, KHALID A A, HAQUE M M. Tribological (wear) properties of aluminum–silicon eutectic base alloy under dry sliding condition [J]. Journal of Materials Processing Technology, 2004, 153: 833-838.

[17] TIMMERMANS G, FROYEN L. Fretting wear behaviour of hypereutectic P/M Al-Si in oil environment [J]. Wear, 1999, 230: 105-117.

[18] BIROL Y, BIROL F.Wear properties of high-pressure die cast and thixoformed aluminium alloys for connecting rod applications in compressors [J]. Wear, 2008, 265:590-597.

[19] LASA L, RODRIGUEZ-IBABE J M. Effect of composition and processing route on the wear behaviour of Al-Si alloys [J].Scripta Materialia,2002, 46:477-481.

[20]  K. The effect of forging on the properties of particulate-SiC-reinforced aluminium-alloy composites [J]. Composites Science and Technology, 2000, 60(3): 411-419.

K. The effect of forging on the properties of particulate-SiC-reinforced aluminium-alloy composites [J]. Composites Science and Technology, 2000, 60(3): 411-419.

[21] RAMESH C S, SAFIULLA M. Wear behaviour of hot extruded Al6061 based composites [J]. Wear, 2007, 263(1-6): 629-635.

[22] KUIJPERS N C W, KOOL W H, KOENIS P T G, NILSEN K E, TODD I, ZWAAG S. Assessment of different techniques for quantification of α-Al(FeMn)Si and β-AlFeSi intermetallics in AA 6xxx alloys [J]. Materials Characterization, 2003, 49: 409-420.

[23] ROGER J, BOSSELET F, VIALA J C. X-rays structural analysis and thermal stability studies of the ternary compound alpha-AlFeSi [J]. Journal of Solid State Chemistry, 2011, 184: 1120-1128.

[24] FERRARINI C F, BOLFARINI C, KIMINAMI C S, BOTTA W J. Microstructure and mechanical properties of spray deposited hypoeutectic Al-Si alloy [J]. Materials Science and Engineering A, 2004, 375: 577-580.

[25] BELMARES-PERALES S, ZALDIVAR-CADENA A A. Addition of iron for the removal of the α-AlFeSi intermetallic by refining of α-AlFeSi phase in an Al-7.5Si-3.6Cu alloy [J]. Materials Science and Engineering B, 2010, 174: 191-195.

[26] BACKERUD L, CHAI G, TAMMINEN J. Solidification characteristics of aluminum alloys [M]. USA: AFS/Akanaluminium Des Plaines, IL, 1990.

[27] DAS S, MONDALD P, SAWLA S, RAMAKRISHNAN N. Synergic effect of reinforcement and heat treatment on the two body abrasive wear of an Al-Si alloy under varying loads and abrasive sizes [J]. Wear, 2008, 264: 47-59.

[28] DWIVEDI D K, ARJUN T S, THAKUR P, VAIDYA H, SINGH K. Sliding wear and friction behaviour of Al-18% Si-0.5% Mg alloy [J]. Journal of Materials Processing Technology, 2004, 152(3): 323-328.

[29] ROSEFORT M, MATTHIES C, BUCK H, KOCH H. Using SEM and EDX for a simple differentiation of α- and β-AlFeSi phases in wrought aluminum billets [J]. Light Metals, 2011: 711-716.

[30] GRIGER A, STEFANIA V, LENDVAI A, TURMEZEY T. Possible modification of cast structure by continuous casting technology in AlFeSi alloys Part III: Intermetallic phases [J]. Aluminium, 1989, 65: 1049-1056.

[31] KUIJPERS N C W, VERMOLEN F J, VUIK K, ZWAAG S. Model of the β-AlFeSi to α-Al(FeMn)Si transformation in Al-Mg-Si alloys [J]. Materials Transactions, 2003, 44(7): 1448-1456.

[32]  N. Abrasion properties of forged fibre-reinforced aluminium [J]. Tribology Letters, 1997, 3(3): 251-255.

N. Abrasion properties of forged fibre-reinforced aluminium [J]. Tribology Letters, 1997, 3(3): 251-255.

[33] GENG Hao-ran, TIAN Xian-fa, CUI Hong-wei, LI Cheng-dong, Z Peng. Antifriction and wear behavior of ZAS35 zinc alloy: Influence of heat treatment and melting technique [J]. Materials Science and Engineering A, 2001, 316(1-2): 109-114.

[34] LIU G, CHEN Y, LI H. A study on sliding wear mechanism of ultrahigh molecular weight polyethylene/polypropylene blends [J]. Wear, 2004, 256: 1088-1094.

, Alpay Tamer

, Alpay Tamer  , Ersin Asim

, Ersin Asim

Mechanical Engineering Department, Engineering Faculty, Kocaeli University, Izmit-Kocaeli, Turkey

摘 要:研究了锻造态和热处理态不同成分铝基轴承合金在油润滑条件下的摩擦行为,以及材料的硬度、热处理制度和锻造对材料耐磨性的影响。所用材料是Al-8.5Si-3.5Cu和Al-15Pb-3.7Cu-1.5Si-1.1Fe。在锻造过程中,应变范围为10%~20%。并对材料进行T6热处理。在销-盘式磨损试验机上对材料的摩擦性能进行测试。结果表明,锻造过程使材料的硬度得到增加;铸造应变在10%~20%的范围内对材料的摩擦磨损影响不明显。

关键词:热处理;锻造;Al-Si合金;Al-Pb合金;磨损

(Edited by Hua YANG)

Corresponding author:  ; Tel: +90-262-3033422; Fax: +90-262-3033003; E-mail: feyzullahoglu@yahoo.com

; Tel: +90-262-3033422; Fax: +90-262-3033003; E-mail: feyzullahoglu@yahoo.com

DOI: 10.1016/S1003-6326(13)62903-9