Effect of VC and NbC additions on microstructure and properties of ultrafine WC-10Co cemented carbides

XIAO Dai-hong(肖代红)1, HE Yue-hui(贺跃辉)1, LUO Wei-hong(罗伟红)2, SONG Min(宋 旼)1

1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Hunan Import and Export Company of Chinese Automobile Industry, Changsha 410001, China

Received 10 August 2009; accepted 15 September 2009

Abstract: The nanocomposite WC-Co powders were prepared through planetary ball milling method. Effects of grain growth inhibitor addition and the vacuum sintering parameters on the microstructure and properties of ultrafine WC-10Co cemented carbides were investigated using X-ray diffractometer, scanning electron microscope and mechanical property tester. The results show that VC and NbC additions can refine the WC grains, decrease the volume fraction of Co3W3C phase in ultrafine WC-10Co cemented carbides, and increase the hardness and fracture toughness of the base alloys. After sintering for 60 min at 1 400 ℃, the average grain size and hardness of ultrafine-grained WC-10Co-1VC cemented carbide are 470 nm and HRA 91.5, respectively. The fracture toughness of cemented carbide WC-10Co-1NbC alloy is over 7 MN·m-3/2.

Key words: ultrafine WC-10Co cemented carbide; VC; NbC; microstructure; mechanical properties

1 Introduction

WC-Co cemented carbides are widely used for machining, cutting, drilling, mining, forming tools and wear resistant parts, for their exceptionally high hardness, excellent wear resistance and better toughness than other hard materials[1-2]. The hardness and strength, as well as wear resistance of WC-Co materials can be improved by decreasing the WC grain size to the submicron meter or nanometer scale[3]. Therefore, research on ultrafine-grained and nanocrystalline WC-Co cemented carbides has become one of the hot issues in the field of high-performance hard materials over the last decade. The main application of the ultrafine-grained WC-Co cemented carbides is the production of micro-drills and routers for printed circuit board (PCB), which can promote the development of many industrial and technological fields, such as electronics, computer and automobile[4].

However, extensive WC grain coarsening occurs when nanometer sized WC-Co starting powder mixtures are sintered by the conventional pressureless sintering, especially in liquid state[3, 5]. Ongoing research is focused on the development of sintering techniques that allow full densification of WC-Co materials at lower sintering temperature and/or within a shorter thermal cycle time, such as hot pressing[6], microwave sintering[7] and spark plasma sintering (SPS)[8-10]. However, it seems that the environmental contamination and high cost are hardly avoidable with such process in industrialization.

So far, the most successful way of controlling the WC grain growth is the addition of small amounts of grain growth inhibitor, typically <1.0% (mass fraction) of a metallic carbide such as VC, Cr3C2, NbC or Mo2C, into the starting powder mixtures[11-15]. Small amounts of VC and/or Cr3C2 are commonly used in conventional WC-Co hardmetals, occasionally as major carbide phase additions. Since minor VC is effective to increase the hardness of WC-Co hardmetals through WC grain growth inhibition, it is of high interests to investigate the influence of VC and NbC addition on WC grain growth in nano-grained WC-10Co cemented carbides and to measure the resulting hardness and toughness of WC-Co hardmetals. NbC is selected due to its high hardness (19.6 GPa) and high melting temperature (3 600 ℃). In this work, the relationships between the starting powder compositions, and the microstructure and mechanical properties of ultrafine WC-10Co-NbC-VC cemented carbides are investigated and discussed.

2 Experimental

Four kinds of alloys with the nominal compositions given in Table 1 were used. WC (99.5%), Co (99.9%), VC (99.5%) and NbC (99.5%) with average particle size of 0.8, 1.5, 2.0 and 2.3 μm, respectively, were used as starting materials. Their morphologies are shown in Fig.1. VC and NbC as grain growth inhibitors were added to WC-10%Co powders before milling. Mechanical milling was carried out in 4-planetary ball mill in methanol under argon atmosphere using WC-5Co milling media for 72 h. The milling ball to powder mass ratio was 10?1 and the speed was 350 r/min. After milling, the powders were dried in a vacuum oven at 100 ℃ for 24 h. The mean particle size (by laser particle size analysis) and crystallite size (from X-ray diffraction peak width) of the WC-Co powder were measured for the powder as- received and after milling. The nanocomposite powders were mixed with 1% polyethylene glycol, granulated and pressed to compacts of 10 mm in diameter. Pressing was carried out at 200-300 MPa and the relative green density varied in the range of 50%-60%. Dewaxing of green compacts was carried out in a separated cycle in flowing hydrogen. The adopted sintering cycle included the following steps: heating to 1 200 ℃ at 10 ℃/min and keeping for 60 min, followed by heating to the final sintering temperature (1 350-1 450 ℃) at the rate of 20 ℃/min. The holding time at the different sintering temperature was 30 min or 60 min. After sintering, the alloys were cooled to room temperature in the furnace.

Table 1 Nominal compositions of alloys (mass fraction, %)

Fig.1 Morphologies of starting powders: (a) WC; (b) Co; (c) VC; (d) NbC

The density of the sintered alloys was measured by Archimedes method, while Micro-Plus laser diffraction particle size analyzer was employed to measure the powder particle size. The D/max2500pc X-ray diffractometer with Cu Kα radiation (λ=0.154 nm) was used to identify the phases in materials and determine the crystallite size of the composite powder through Williamson-Hall method[16]. The sintered alloys were ground and polished by diamond pastes. The microstructure observation of the alloys as well as the compositional analysis of some certain phases was conducted on a JEOL-6510 scanning electron microscope (SEM) equipped with the Oxford X-ray energy dispersive spectroscope (EDS). The phases in the sintered alloys were analyzed by X-ray diffraction analysis.

The hardness was measured by Rockwell hardness tester with 600 N load. The fracture toughness KIC of the alloys was computed by[17]

KIC=0.002 8(HP/∑L)1/2 (1)

where H is the Vicker hardness (N/mm2) with 300 N load, P is the load (N) and ∑L is the sum of crack lengths (mm) from the center of the indent to tip of the crack. Crack length measurement was carried out on an optical microscope (LEICA MEF4A/M).

3 Results and discussion

3.1 Microstructure of nanocomposite powder

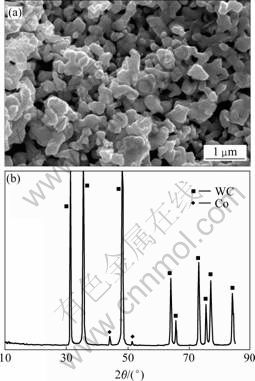

SEM observation shows that the prepared WC-10Co composite powders are small and uniform. The average particle size is about 400 nm. The WC particles show a spherical morphology with a narrow particle size distribution. The X-ray diffraction analysis shows that the main phases of the composite powders are WC and Co. The mean grain size of WC is 35 nm. The typical SEM morphology and XRD spectrum of the nanocrystalline composite powders are shown in Fig.2.

Fig.2 SEM image (a) and XRD pattern (b) of composite powder of WC-10Co alloy

3.2 Microstructure and phases of sintered alloys

Fig.3 shows the variation of the WC grain size of the sintered alloys. Different behaviors are observed in the effect of inhibitor addition on the WC grain growth when being compared with the base alloy (Alloy 1). Obviously, adding VC and/or NbC significantly decreases the average grain size of WC phase. For example, after sintering for 60 min at 1 400 ℃, the mean grain size of WC phase in the Alloy 1 is 723 nm. It is reduced to 470 nm when 1%VC is added (Alloy 2). The WC grain size for the Alloy 3 with 0.5% VC and 0.5% NbC is 491 nm. But, that for the Alloy 4 is increased to 560 nm when 1% NbC is added. Meanwhile, the WC grain size is affected by both the sintering temperature and holding time.

Fig.3 Average grain size of WC in sintered alloys

Fig.4 shows SEM images of the fractured surface of ultrafine WC-10Co cemented carbide after sintering for 60 min at 1 400 ℃. It can be seen that most of the WC grains are 470-700 nm, which are about several times those of the starting nanocrystalline composite powders. It is obvious that the average grain size of the alloys with VC and/or NbC is less than that of the Alloy 1, in which no grain growth inhibitor is added.

Fig.4 SEM images of fractured surface of alloys after sintering at 1 400 ℃ for 60 min: (a) Alloy 1; (b) Alloy 2; (c) Alloy 3; (d) Alloy 4

The WC grain growth of the nanocrystalline WC-10Co powders during vacuum sintering occurs by Ostward ripening with dissolution of smaller WC grain and reprecipitation on larger grains in liquid Co. The growth is predominantly interface controlled[18], and addition of grain growth inhibitor such as VC or NbC probably alters the interface energy and interferes with the dissolution and reprecipitation steps. VC and/or NbC are proved to be effective WC grain growth inhibitors in WC-10Co cemented carbide from Figs.3 and 4. The decrease in growth rate is attributed to a decrease of difference in interfacial free energies of the WC grains[19]. Since both VC and NbC have a low solubility in WC, the grain will not grow to incorporate those impurity atoms. The precipitation is accompanied by one or more of the following phenomena[15]: face-specific adsorption, face-orientated deposition or blocking of active growth center of the crystals, including a change in edge energy. As a result of these processes, the WC grain growth is inhibited.

The XRD patterns of the Alloys 1, 2 and 4 after sintering for 60 min at 1 400 ℃ are presented in Fig.5. The results show that WC-10Co cemented carbide contains WC, FCC-Co and Co3W3C phases. The Co3W3C phase can affect the mechanical properties of cemented carbides. Meanwhile, the volume fraction of Co3W3C phase in the Alloys 2 and 4 is lower than that in the Alloy 1. The starting powders are hexagonal WC, cubic VC and NbC, and HCP-Co. A stabilized FCC-Co binder is found in the sintered alloys, indicating the dissolution of W, C, V and/or Nb in the solid Co binder phase.

Fig.5 XRD patterns of Alloys 1, 2 and 4 after sintering at 1 400 ℃ for 60 min

The specific surface area of nanocrystalline WC-10Co composite powder is much larger than that of normal ultrafine powder. Because a lot of oxygen absorbs on the surface of nanocrystalline powder, oxygen concentration is higher in nanocrystalline composite powder. During vacuum sintering process, Co3W3C phases are generated because of carbon shortage. Adding VC and/or NbC may decrease the oxygen concentration, and then decrease the volume fraction of Co3W3C phases.

3.3 Properties of sintered alloys

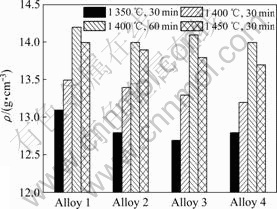

The densities of the alloys with different content inhibitor, formed in various vacuum sintering processes (different temperatures and time) are given in Fig.6. The density is affected by both temperature and holding time. Addition of grain growth inhibitors, VC and NbC, leads to slight decrease in the sintered density of the alloys. In 1%VC added alloy, the decrease in density achieves the extent of 0.1-0.3 g/cm3.

Fig.6 Variation of density of sintered alloys at different sintering temperature for different time

Fig.7 gives the effects of VC and NbC addition on Rockwell hardness of the alloys under different conditions. The hardness values of the alloys with VC and NbC addition in all cases are higher than those of the base alloy. This is evidently a result from microstructural parameters, mainly the finer WC grain size. It can be concluded that the mechanical properties are improved by VC and NbC additions. On one hand, it is due to refinement of WC particle size as shown in Figs.3 and 4. With the addition of both VC and NbC, the continuous and discontinuous growth of WC grains are inhibited, hence the WC grains are refined. According to the Hall-Petch relation, the hardness of the alloys is enhanced due to the decrease of grain size. Another mechanism for the increase of the hardness may be that the improvement of wettability between WC and Co due to the additions of VC and NbC.

Fig.7 Hardness of sintered alloys at different sintering temperature for different time

Fracture toughness is also seen to be improved with VC and NbC additions in vacuum sintering for 60 min at 1 400 ℃ (Fig.8). With VC and NbC additions in vacuum sintering, fracture toughness increases with decreasing density. With fracture occurring through interfacial decohesion rather than cleavage, pores in cobalt layer are likely to provide crack arrestors, which can contribute to the improved toughness. Density changes with VC and NbC addition in liquid phase sintered alloys are considerably less marked. However, there is significant improvement in toughness for the alloys with VC and NbC additions than that for the based WC-10Co alloy. In the hardness range reported, SCHUBERT et al[17] suggested that nano-grained precursors VC addition may contribute to higher toughness at higher hardness values. Meanwhile, adding VC and NbC decreases the volume fraction of Co3W3C phases of the alloys (Fig.3), thus increases the fracture toughness of the alloys. Analysis of the microstructures and mechanical properties in Figs.3-8 reveals that both the sintering technique and grain growth inhibitor have a crucial impact on the final WC grain size and microstructure as well as the concomitant hardness and toughness of WC-10Co alloys.

Fig.8 Fracture toughness of sintered alloys after sintering at 1 400 ℃ for 60 min

4 Conclusions

1) Nanocrystalline composite powder of WC-10Co with the WC average grain size of 35 nm is generated by planetary ball milling of conventional powder.

2) VC and/or NbC addition decreases the grain size of ultrafine WC-10Co alloys in vacuum sintering. With inhibiting grain growth, the addition also slightly decreases the sintered density.

3) Addition of both VC and NbC improves the hardness and fracture toughness of the alloys in all cases.

4) Both VC and NbC additions can decrease the volume fraction of Co3W3C phase in the alloys after sintering at 1 400 ℃ for 60 min.

References

[1] KOC R, KODAMBAKE S K. Tungsten carbide (WC) synthesis from novel precursors [J]. J Eur Ceram Soc, 2000, 20(11): 1859-1869.

[2] XIAO Yi-feng, HE Yue-hui, FENG Ping, XIE Hong, MA Zi-xing, ZHANG Li-juan, HUANG Zi-qian, HUANG Bai-yun. Effects of carburizing process on gradient structure and hardness of WC-Co gradient cemented carbides [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 465-470. (in Chinese)

[3] BERGER S, PORAT R, ROSEN R. Nanocrystalline materials: a study of WC-based hard metals [J]. Prog Mater Sci, 1997, 42(3): 311-320.

[4] MEDEIRORS F F P, de OLIVEIRA S A, de SOUZA C P, da SILVA A G P, de SOUZA J F. Synthesis of tungsten carbide through gas-solid reaction at low temperatures [J]. Mater Sci Eng A, 2001, 315(1/2): 58-62.

[5] ZHANG Li, CHEN Shu, LIU Gang, YANG Gui-bin, HUANG Ze-lan, HUANG Bai-yun, ZHANG Chuan-fu. Ultrafine and nano-structured cemented carbide with high properties and the key issues in its preparation [J]. Materials Review, 2005, 19(11): 4-9. (in Chinese)

[6] AZCONA I, ORD??EZ A, S?NCHEZ J M, CASTRO F. Hot isostatic pressing of ultrafine tungsten carbide-cobalt hardmetals [J]. J Mater Sci, 2002, 37(19): 4189-4195.

[7] ZHOU Jian, CHEN Ji-ping. Property and technology of WC-Co fine grain cemented carbide in microwave sintering [J]. The Chinese Journal of Nonferrous Metals, 1999, 9(3): 464-468. (in Chinese)

[8] TAN Xing-long, QIU Shao-yu, HE Wen-yan, LEI Dai-fu, RENG Da-peng. WC/Co nano hardmetal materials made by spark plasma sintering technology [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(s1): 276-279. (in Chinese)

[9] SIVAPRAHASAM D, CHANDRASEKAR S B, SUNDARESAN R R. Microstructure and mechanical properties of nanocrystalline WC-12Co consolidated by spark plasma sintering [J]. Int J Refract Metal Hard Mater, 2007, 25(2): 144-152.

[10] ZHAO S X, SONG X Y, ZHANG J X, LIU X M. Effects of scale combination and contact condition of raw powders on SPS sintered near-nanocrystalline WC-Co alloy [J]. Mater Sci Eng A, 2008, 473(1/2): 323-329.

[11] FANG Z Z, WANG X, RYU T, HWANGA K S, SOHN H Y. Synthesis, sintering, and mechanical properties of nanocrystalline cemented tungsten carbide—A review [J]. Int J Refract Met Hard Mater, 2009, 27(2): 288-299.

[12] KIM B K, HA G H, LEE G G, LEE D W. Structure and properties of nanophase WC/Co/VC/TaC hardmetal [J]. Nanostruct Mater, 1997, 9(1/8): 233-236.

[13] HUANG S G, LIU R L, LI L, van der BIEST O, VLEUGELS J. NbC as grain growth inhibitor and carbide in WC-Co hard metals [J]. Int J Refract Met Hard Mater, 2008, 26(5): 389-395.

[14] LEE H R, KIM D J, HWANG N M, KIM D Y. Role of vanadium carbide additive during sintering of WC-Co: mechanism of grain growth inhibition [J]. J Am Ceram Soc, 2003, 86(1): 152-154.

[15] GUO Z X, XIONG J, YANG M, SONG X Y, JIANG C J. Effect of Mo2C on the microstructure and properties of WC-TiC-Ni cemented carbide [J]. Int J Refract Met Hard Mater, 2008, 26(6): 601-605.

[16] WILLIAMSON G K, HALL W H. X-ray broadening from filed aluminum and wolfram [J]. Acta Metall, 1953, 1: 22-31.

[17] SCHUBERT W D, NEUMEISTER H, KINGER G, LUX B. Hardness to toughness relationship of fine-grained WC-Co hardmetals [J]. Int J Refract Met Hard Mater, 1998, 16(2): 133-142.

[18] WITTMANN B, SCHUBERT W D, LUX B. WC grain growth and grain growth inhibition in nickel and iron binder hardmetals [J]. Int J Refract Mate Hard Mater, 2002, 20(1): 51-60.

[19] MORTON C W, WILLS D J, STJERNBERG K. The temperature ranges for maximum effectiveness of grain growth inhibitors in WC-Co alloys [J]. Int J Refract Met Hard Mater, 2005, 23(4/6): 287-293.

Foundation item: Project(50823006) supported by the National Natural Science Foundation of China; Project(200801348) supported by China Postdoctoral Science Foundation; Project(50721003) supported by Innovative Research Groups of the National Natural Science Foundation of China

Corresponding author: XIAO Dai-hong; Tel: +86-731-88877880; E-mail: daihongx@mail.csu.edu.cn

DOI: 10.1016/S1003-6326(09)60063-7

(Edited by YANG Bing)