文章编号:1004-0609(2010)07-1247-07

异步轧制AZ31镁合金的微观组织与室温成形性能

夏伟军,蔡建国,陈振华,陈 刚,蒋俊峰

(湖南大学 材料科学与工程学院,长沙 410082)

摘 要:探讨采用小异速比多道次异步轧制技术提高AZ31镁合金板材室温成形性能的可行性,研究异步轧制板材微观组织的特点、形成机理及其与成形性能间的内在联系。结果表明:多道次异步轧制所累积的剪切应变能有效促进压缩孪晶的交互作用,细化合金晶粒组织,削弱(0002)基面的织构强度;异步轧制AZ31镁合金板材后续退火处理后的室温伸长率和Erichsen值分别可达32%和6.14 mm;(0002)基面织构减弱和塑性应变比的降低是板材室温成形性能提高的根本原因。

关键词:AZ31镁合金;异步轧制;织构;孪晶;成形性能

中图分类号:TG146.2 文献标志码:A

Microstructure and room temperature formability of AZ31 magnesium alloy produced by differential speed rolling

XIA Wei-jun, CAI Jian-guo, CHEN Zhen-hua, CHEN Gang, JIANG Jun-feng

(School of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: To explore the possibility for enhancing the room temperature formability of AZ31 magnesium alloy sheets by multiple pass differential speed rolling(DSR) technic with small-speed ratio, the characteristic of microstructures and formation mechanisms for DSRed sheets were studied, and the intrinsic relationship between the microstructure and formability was discussed. The results show that the accumulated shear strain induced by multiple pass differential speed rolling promotes the interaction of compression twins. Furthermore, fine-grained microstructure and weakened (0002) basal texture can be achieved. A higher ductility with elongation of 32% and an evidently enhanced press formability with Erichsen value of 6.14 mm at room temperature are presented for as-DSRed/annealed specimen. The weakened (0002) basal texture intensity and lower plastic strain ratio are thought to be mainly responsible for the enhancement of room temperature formability.

Key word: AZ31 magnesium alloy; differential speed rolling; texture; twins; formability

作为最轻的金属结构材料,镁合金被誉为是“21世纪最具有发展前途的绿色金属材料”,特别是变形镁合金板材以其优异的综合性能表现出极其广阔的应用前景。然而,由于在密排六方结构的镁合金中滑移系少,采用常规挤压和轧制技术制备的镁合金板材内存在强烈的(0002)基面织构,严重制约了其室温塑性和成形性能的提高,镁合金板材的成形通常需在高温下进行[1-5]。因此,提高镁合金的塑性和改善镁合金的室温成形性能已成为拓展变形镁合金应用的关键。

采用热机械处理等工艺来细化晶粒是改善镁合金塑性的有效途径。近年来,一些特殊的成形技术如等径角挤压(ECAE)、叠轧和连续剪切变形等被广泛应用于变形镁合金的成形,并获得较满意的晶粒细化效 果[6-13]。此外,由于室温下镁合金非基面滑移的临界剪切应力远大于基面滑移的,因此织构特别是(0002)基面的取向分布特征对镁合金的二次成形性能具有显著的影响[14-15]。MUKAI等[16]的研究表明,通过控制合金的晶粒取向分布,粗晶镁合金也能获得良好的塑性。IWANAGA等[17]的研究也发现,通过削弱(0002)基面织构的强度可使镁合金板材的室温杯突值(Er值)由1.2增大至1.4。大量研究[6-8]表明,采用ECAE工艺制备的镁合金不仅晶粒细小,而且由于剪切应力的作用可以获得非基面织构,因而ECAE镁合金具有良好的室温塑性。尽管如此,由于受模具结构的限制,采用ECAE技术难以制备镁合金板材。近来,国外有少量研究[18-20]报道,采用大异速比异步轧制技术(异速比在1.5以上)制备的镁合金板材的基面织构被削弱,具有良好的室温塑性。但这些研究很少涉及镁合金板材的室温成形性能,而有关小异速比异步轧制技术的研究更是鲜见报导。因此,本文作者旨在探索采用多道次小异速比轧制(异速比为1.05)技术来提高AZ31镁合金板材室温成形性能,并重点研究异步轧制镁合金板材的微观组织及其与室温成形性能间的内在联系。

1 实验

试验用材料为截面尺寸为120 mm×10 mm的挤压AZ31镁合金板坯,合金的名义化学成分为:Mg-3%A1-0.8%Zn-0.4%Mn(质量分数)。采用多道次异步轧制工艺制得2 mm厚的板材,异步轧制(DSR)试验在异径异步轧机上进行,异速比为1.05(下轧辊为大辊,其辊径为260 mm),道次压下量恒定为5%,每道次轧制前板坯加热温度为573 K,保温时间为5 min。将最终所得板材在厢式电阻炉中进行退火处理,退火温度为573 K,保温时间为30 min。同时采用相同的热轧工艺制备常规轧制(CR)板材,以便与异步轧制板材进行对比研究。

从轧板和退火板材中截取试样进行微观组织观察和室温成形性能分析。沿轧制面观察板材的金相组织,所用腐蚀剂为5 g苦味酸+5 g冰醋酸+10 mL水+80 mL乙醇的混合液;采用JSM-5600型透射电镜观察板材的微观组织、XRD仪测定板材的{0002}和 极图;用Deforme 2D 对不同异步轧制道次板材的切

极图;用Deforme 2D 对不同异步轧制道次板材的切

变特征进行模拟。在WDW-E200电子万能试验机上进行室温拉伸试验,试样标距尺寸为25 mm×5 mm,拉伸速度恒定为0.5 mm/min。在计算机控制杯突试验机上进行室温成形性能测试,测定室温胀形时的杯突值。

2 结果与讨论

2.1 微观组织观察

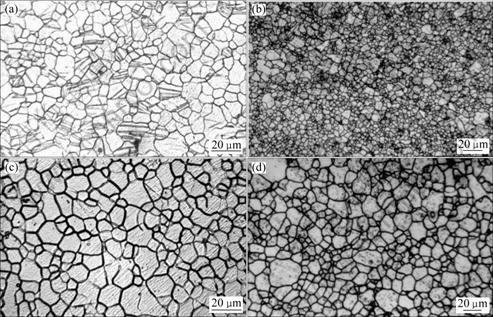

图1所示为常规轧制和异步轧制AZ31镁合金板材在退火前、后的金相组织。由图1可看出,常规轧制板材的金相组织主要由大小极不均匀的等轴晶粒组成,大晶粒内部存在大量的孪晶,细小的再结晶晶粒则主要环绕大晶粒的晶界分布,表明在轧制过程中发生了动态再结晶。异步轧制后板材晶粒明显细化,且晶粒大小趋于均匀,同时孪晶数量则大幅度减少。而采用大异速比单道次轧制的AZ31板材内则以局部流变为主,很少发生动态再结晶[19, 21]。退火处理后,常规轧制板材的晶粒尺寸变化不大,但其中的孪晶组织基本消失,且在原始孪晶处出现新的等轴状晶粒;异步轧制板材中部分晶粒发生了明显的长大,大、小晶粒各占50%左右。由此可见,异步轧制与常规轧制板材不仅组织形貌不同,而且在热变形和后续退火过程中的组织演变规律也存在差异。大量研究表明,动态再结晶是镁合金热变形过程中主要的晶粒细化机制。常规轧制时虽然发生了动态再结晶,但由于道次变形量较小,动态再结晶进行得不完全,因此细小的再结晶新晶粒较少。同时,镁合金的滑移系少而使变形组织中存在大量的孪晶,且由于板材轧制前的初始取向为基面取向,这些孪晶属于界面稳定性较低的

图1所示为常规轧制和异步轧制AZ31镁合金板材在退火前、后的金相组织。由图1可看出,常规轧制板材的金相组织主要由大小极不均匀的等轴晶粒组成,大晶粒内部存在大量的孪晶,细小的再结晶晶粒则主要环绕大晶粒的晶界分布,表明在轧制过程中发生了动态再结晶。异步轧制后板材晶粒明显细化,且晶粒大小趋于均匀,同时孪晶数量则大幅度减少。而采用大异速比单道次轧制的AZ31板材内则以局部流变为主,很少发生动态再结晶[19, 21]。退火处理后,常规轧制板材的晶粒尺寸变化不大,但其中的孪晶组织基本消失,且在原始孪晶处出现新的等轴状晶粒;异步轧制板材中部分晶粒发生了明显的长大,大、小晶粒各占50%左右。由此可见,异步轧制与常规轧制板材不仅组织形貌不同,而且在热变形和后续退火过程中的组织演变规律也存在差异。大量研究表明,动态再结晶是镁合金热变形过程中主要的晶粒细化机制。常规轧制时虽然发生了动态再结晶,但由于道次变形量较小,动态再结晶进行得不完全,因此细小的再结晶新晶粒较少。同时,镁合金的滑移系少而使变形组织中存在大量的孪晶,且由于板材轧制前的初始取向为基面取向,这些孪晶属于界面稳定性较低的 压缩孪晶。

压缩孪晶。

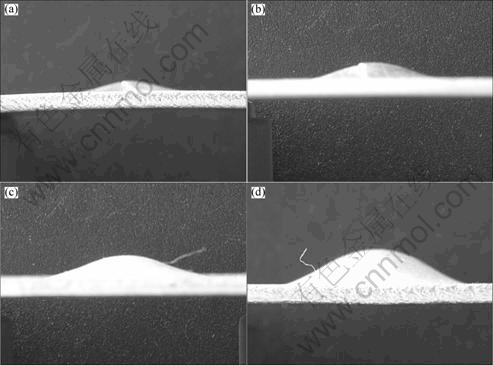

图1 AZ31镁合金板材在退火前后的金相组织

Fig.1 Optical microstructures of AZ31 alloy sheets before and after annealing: (a) As-CRed; (b) As-DSRed; (c) As-CRed/annealed; (d) As-DSRed/anneale

TEM分析表明,在后续退火过程中, 压缩孪晶内部发生静态再结晶而使孪晶消失,同时在原始孪晶处形成细小的新晶粒(见图2(a))。但由于在AZ31合金中缺少有效的晶界钉扎相,小晶粒在加热时容易长大。两者综合作用的结果使常规轧制板材在退火前、后的晶粒尺寸变化不大。异步轧制时,在压下量相同的条件下“搓轧”变形区内所引入的附加剪切变形使总应变增大,孪晶内部及孪晶界附近区域的

压缩孪晶内部发生静态再结晶而使孪晶消失,同时在原始孪晶处形成细小的新晶粒(见图2(a))。但由于在AZ31合金中缺少有效的晶界钉扎相,小晶粒在加热时容易长大。两者综合作用的结果使常规轧制板材在退火前、后的晶粒尺寸变化不大。异步轧制时,在压下量相同的条件下“搓轧”变形区内所引入的附加剪切变形使总应变增大,孪晶内部及孪晶界附近区域的

畸变增加, 压缩孪晶的稳定性进一步降低。不

压缩孪晶的稳定性进一步降低。不

仅孪晶内,孪晶与孪晶、孪晶与基体之间均可发生强烈的交互作用,结果发生基于孪晶的动态再结晶而细化晶粒,并使压缩孪晶的体积分数减小(见图2(b))。因此,在后续退火过程中,异步轧制板材内,孪晶较少的区域难以通过基于压缩孪晶的静态再结晶来细化晶粒,退火前,细小的晶粒在界面能的驱动下发生明显的晶粒长大。而在轧板内孪晶较密集的区域,退火过程中其组织变化规律与常规轧制板材的相同,退火后仍保持细晶组织。

2.2 宏观织构分析

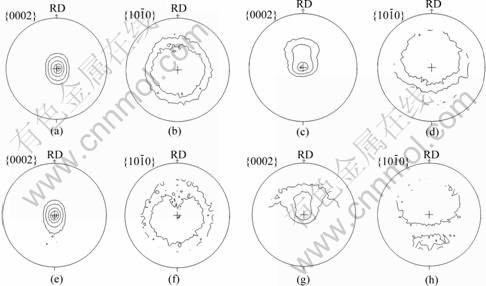

常规轧制和异步轧制AZ31镁合金板材在退火

前、后的{0002}和 极图如图3所示。由图3可

极图如图3所示。由图3可

见,常规轧制板材具有典型的强(0002)基面织构,即大部分晶粒均以其(0002)基面平行于板材的表面,对板材的后续成形极为不利。异步轧制后,板材的织构

图2 常规轧制+退火态与异步轧制态AZ31镁合金板材的TEM像

Fig.2 TEM images of as-CRed/annealed (a) and as-DSRed AZ31 (b) alloy sheets

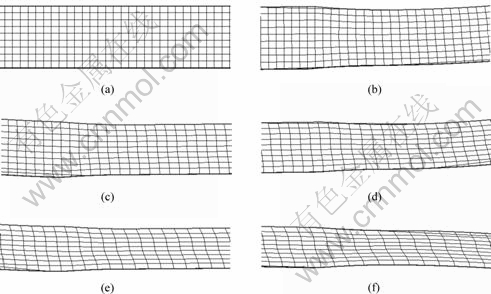

类型不变,但织构强度明显减弱,{0002}极图的最大极密度由10降至6,且基面绕TD轴沿RD方向发生明显的偏转。退火后,两种板材的织构类型不变而强度均有所减弱,特别是异步轧制板材{0002}极图的最大极密度仅为2,这对提高镁合金的塑性和成形性能极为有利。退火后镁合金板材基面织构减弱的现象在其它文献中也有报导[22]。根据镁合金织构的形成机理,(0002)基面织构是塑性变形过程中基面滑移和锥面孪生共同作用的结果,并与轧制变形区的应力条件密切相关。异步轧制时变形区内存在“搓轧”区,该区内的剪切应力平行于板材表面,是促使基面织构弱化的根本原因。异步轧制后镁合金基面织构减弱的现象在文献中[19]也有报导,但这些文献都是基于大异速比单道次异步轧制。为了进一步分析小异速比多道次异步轧制条件下AZ31镁合金基面织构减弱的机理,采用Deforme 2D 对不同异步轧制道次板材的切变特征进行模拟,结果如图4所示。由图4见,尽管小异速比单道次轧制时的切变量较小,但随着轧制道次的增加,剪切应变不断积累,多道次轧制后可获得较大的剪切应变,从而弱化基面织构。

图3 轧制板材在退火前后的{0002}和 极图

极图

Fig.3 {0002} and pole figures for as-rolled and as-annealed sheets: (a) As-CRed, ρmax=10; (b) As-CRed, ρmax=2; (c) As-DSRed, ρmax=6; (d) As-DSRed, ρmax=2; (e) As-CRed, ρmax=8; (f) As-CRed/annealed, ρmax=2; (g) As-DSRed/annealed,ρmax=2; (h) As-DSRed/annealed, ρmax=2

pole figures for as-rolled and as-annealed sheets: (a) As-CRed, ρmax=10; (b) As-CRed, ρmax=2; (c) As-DSRed, ρmax=6; (d) As-DSRed, ρmax=2; (e) As-CRed, ρmax=8; (f) As-CRed/annealed, ρmax=2; (g) As-DSRed/annealed,ρmax=2; (h) As-DSRed/annealed, ρmax=2

图4 不同道次异步轧制后板材的切变模拟

Fig.4 Simulation of shear deformation induced by multiple pass differential speed rolling: (a) 0 pass; (b) 1 pass; (c) 2 passes; (d) 3 passes; (e) 4 passes; (f) 5 passes

2.3 成形性能分析

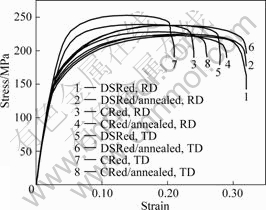

常规轧制和异步轧制AZ31镁合金板材在退火前、后的室温拉伸曲线如图5所示。两种板材均具有较明显的塑性各向异性,这是由板材的织构特征所引起的,即{0002}极图沿RD和TD方向呈不对称分布而沿TD方向压扁。但与常规轧制板材相比,异步轧制后板材的室温抗拉强度降低约8%,而伸长率提高33%,沿RD和TD方向的室温伸长率分别达24%和32%。由前述宏观织构分析可知,异步轧制可以弱化板材的基面织构,这也是异步轧制板材室温塑性得以大幅提高的根本原因。两种板材的强度均有所降低而伸长率有所提高。值得注意的是,异步轧制板材退火后,沿轧向(RD)和横向(TD)方向的室温伸长率均高达32%,表现出良好的室温塑性和面内各向同性。这一结果也与前面的织构分析相符,退火后织构漫散度增大,对称性增强。

图5 轧制板材退火前后室温拉伸的名义应力—应变曲线

Fig.5 Nominal stress—strain curves for as-rolled and as- annealed specimens tested at room temperature

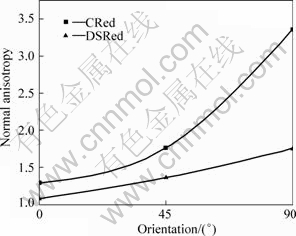

图6所示为两种板材室温冲杯件的宏观照片及相应的杯突值(Erichsen值)。由图6可看出,常规轧制板材的室温成形性能较差,退火前后的杯突值分别为2.04 mm和3.59 mm,而异步轧制板材退火前后的室温杯突值则分别高达4.28 mm和6.14 mm,表现出良好的室温成形性能。为了进一步分析异步轧制板材室温成形性能大幅提高的原因,由室温拉伸试验测定了轧制板材沿0?、45?和90?方向的塑性应变比,其结果如7所示。由图7可看出,常规轧制AZ31镁合金轧制板材沿0?和90?方向的r值分别为1.29和3.36,异步轧制后板材的r值有所降低,分别为1.08和2.96,且板平面方向性明显减小。一般情况, 增大r值能抑制板材厚向应变,有利于提高钢、铝等材料的深冲性能。但r值强烈地依赖于板材的织构特征,并且其对成形性能的影响还与塑性变形机制有关[23]。具有强基面织构的镁合金室温塑性变形的主要机制为锥面孪生,板材厚向变形困难,因此常规轧制板材具有较大的r值。异步轧制后,(0002)基面织构明显减弱,基面滑移成为主要的变形机制,沿板材厚向更容易发生塑性变形,结果使板材的r值降低、胀形时的变形协调性增强。因此,(0002)基面织构减弱所导致的r值和板平面方向性降低有利于镁合金板材室温成形性能特别是胀形性能的提高。异步轧制AZ31镁合金板材仍具有(0002)织构,要进一步提高其室温成形性能,需从根本上改变板材的织构类型。

图6 轧制板材退火前后的室温杯突件形貌

Fig.6 Photographs of cups drawn at room temperature for as-rolled and as-annealed specimens: (a) CRed, Er=2.04 mm; (b) CRed/annealed, Er=3.59 mm; (c) DSRed, Er=4.28 mm; (d) DSRed/annealed, Er=6.14 mm;

图7 轧制板材的塑性应变比与试样方向的关系曲线

Fig.7 Plots of normal anisotropy as function of orientation for as-rolled samples

3 结论

1) 小异速比多道次异步轧制能引入附加的剪切

应变,促进 压缩孪晶的交互作用,抑制孪晶的

压缩孪晶的交互作用,抑制孪晶的

形成,显著细化AZ31镁合金的晶粒组织。

2) 小异速比多道次异步轧制不改变板材的(0002)基面织构类型,但通过多道次轧制时,剪切应变的积累显著削弱基面织构的强度。经573 K,30 min退火处理后,基面织构强度进一步降低且对称性增强。

3) 与常规轧制相比,异步轧制AZ31镁合金板材的室温抗拉强度降低了约8%,而室温伸长率则提高了约33%。异步轧制板材经573 K,30 min退火处理后,室温伸长率高达32%,且表现出良好的面内各向同性。

4) 小异速比多道次异步轧制AZ31镁合金板材的室温杯突值由常规轧制时的2.04 mm增大至4.28 mm;经573 K,30 min退火处理后,杯突值高达6.14 mm。异步轧制板材室温成形性能的提高主要得益于(0002)基面织构强度的减弱以及由此导致的塑性应变比的 降低。

REFERENCES

[1] LEE S, YUNG H C, WANG J. Isothermal sheet formability of magnesium alloy AZ31 and AZ61[J]. Journal of Materials Processing Technology, 2002, 124 (1/2): 19-24.

[2] SEAN R A, OZGUR D. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B[J]. International Journal of Plasticity, 2005, 21(6): 1161-1193.

[3] 汪凌云, 黄光胜, 范永革. 变形AZ31镁合金的晶粒细化[J]. 中国有色金属学报, 2003, 13(3): 594-598.

WANG Ling-yun, HUANG Guang-sheng, FAN Yong-ge. Grain refinement of wrought AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 594-598.

[4] KOIKE J, KOBAYASHI T, MUKAI T. The activity of non-basal slip systems and dynamic recovery at room temperature in fine-grained AZ31B magnesium alloys[J]. Acta Materialia, 2003, 51(7): 2055-2065.

[5] 陈振华, 夏伟军, 程永奇, 傅定发. 镁合金织构与各向异性[J]. 中国有色金属学报, 2005, 15(1): 1-11.

CHEN Zhen-hua, XIA Wei-jun, CHEN Yong-qi, FU Ding-fa. Texture and anisotropy in magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 1-11.

[6] KIM W J, HONG S I, KIM Y S. Texture development and its effect on mechanical properties of an AZ61 Mg alloy fabricated by equal channel angular pressing[J]. Acta Mater, 2003, 51(11): 3293-3307.

[7] AGNEW S R, HORTON J A, LILLO T M. Enhanced ductility in strongly textured magnesium produced by equal channel angular processing[J]. Scripta Materialia, 2004, 50(3): 377-381.

[8] MUBACHI M, IWASAKI H, YANASE K. Low temperature superplasticity in an AZ91 magnesium alloy processed by ECAE[J]. Scripta Materialia, 1997, 36(6): 681-686.

[9] P?REZ-PRADO M T, VALLE D, RUANO O A. Grain refinement of Mg-Al-Zn alloy via accumulative roll bonding[J]. Scripta Materialia, 2004, 51(11): 1093-1097.

[10] SAITO Y, UTSUNOMIYA H, SUZUKI H. Improvement in the r-value of aluminum strip by a continuous shear deformation process[J]. Scripta Materialia, 2000, 42(12): 1139-1144.

[11] UTSUNOMIYA H., HATSUDA K, SAKAI T. Continuous grain refinement of aluminum strip by conshearing[J]. Mater Sci Eng A, 2004, 372(1/2): 199-206.

[12] 王丽娜, 杨 平, 夏伟军, 陈振华, 陈 鼎, 李 萧, 孟 利. 特殊成形工艺下AZ31镁合金的织构及变形机制[J].金属学报, 2009, 45(1): 58-62.

WANG Li-na, YANG Ping, XIA Wei-jun, CHEN Zhen-hua, CHEN Ding, LI Xiao, MENG Li. Textures and deformation mechanisms of AZ31 magnesium alloys under special processing technologies[J]. Acta Metallurgica Sinica, 2009, 45(1): 58-62.

[13] CHEN Z H, CHENG Y Q, XIA W J. Effect of equal-channel angular rolling pass on microstructure and properties of magnesium alloy sheets[J]. Materials and Manufacturing Processes, 2007, 22: 51-56.

[14] GEHRMANN R, FROMMERTB M M, GOTTSTEIN G. Texture effects on deformation of magnesium[J]. Mater Sci Eng A, 2005, 395(1/2): 338-349.

[15] BARNETTA M R, NAVEA M D, BETTLESB C J. Deformation microstructures and textures of some cold rolled Mg alloys[J]. Mater Sci Eng A, 2004, 386(1/2): 205-211.

[16] MUKAI T, YAMANOI M, WATANABE H. Ductility enhancement in AZ31 magnesium alloy by controlling its grain structure[J]. Scripta Materialia, 2001, 45(1): 89-94.

[17] IWANAGA K, TASHIRO H, OKAMOTO H. Improvement of formability from room temperature to warm temperature in AZ31 magnesium alloy[J]. Journal of Materials Processing Technology, 2004, 155/156: 1313-1316.

[18] WATANBE H, MUKAI T, ISHIKAWA K. Differential speed rolling of an AZ31 magnesium alloy and the resulting mechanical properties[J]. Journal of Materials Science, 2004, 39: 1477-1480.

[19] KIM S H, YOU B S, YIM C D. Texture and microstructure changes in asymmetrically hot rolled AZ31 magnesium alloy sheets[J]. Materials Letters, 2005, 59(29/30): 3876-3880.

[20] KIM W J, PARK J D, KIM W Y. Effect of differential speed rolling on microstructure and mechanical properties of an AZ91 magnesium alloy[J]. Journal of Alloys and Compounds, 2008, 460(1/2): 289-293.

[21] VALLE J A, P?REZ-PRADO M T, RUANO O A. Texture evolution during large-strain hot rolling of the Mg AZ61 alloy[J]. Mater Sci Eng A, 2003, 355(1/2): 68-78

[22] P?REZ-PRADO M T, RUANO O A. Texture evolution during annealing of magnesium AZ31 alloy[J]. Scripta Materialia, 2002, 46(2): 149-155.

[23] CHEN Y Q, CHEN Z H, XIA W J. Drawability of AZ31 magnesium alloy sheet produced by equal channel angular rolling at room temperature[J]. Materials Characterization, 2007, 58(7): 617-622.

(编辑 杨 华)

基金项目:湖南省科技计划资助项目(2008FJ3113)

收稿日期:2009-05-06;修订日期:2010-04-30

通信作者:蔡建国, 副教授, 博士; 电话: 13036789647;E-mail: caijianguo@hnu.cn