DOI: 10.11817/j.issn.1672-7207.2017.02.035

焦炉荒煤气显热回收传热行为的数值模拟

冯明杰,王恩刚,刘兵,李艳东,王海

(东北大学 材料电磁过程研究教育部重点实验室,辽宁 沈阳,110819)

摘要:以Fluent6.3为计算平台,利用其自定义函数功能,采用数值模拟的方法对焦炉荒煤气显热回收管束间的传热特性进行研究,探讨荒煤气的入口流速和初始温度对管束内流场和温度场的影响。研究结果表明:荒煤气在管束内是以绕流的方式流动,在管道的后面会形成流速很小的尾流漩涡。在换热管束第1排管道的后壁以及其余管道的前壁和后壁焦油易发生冷凝附着。提高荒煤气的入口流速和初始温度有利于减轻焦油附着,但随着荒煤气入口流速的增大和初始温度的升高,显热回收管束的热回收效率降低,荒煤气离开管束中时的平均温度升高。

关键词:焦炉荒煤气;显热回收;流场;温度场;管束

中图分类号:TQ522.15 文献标志码:A 文章编号:1672-7207(2017)02-0540-07

Numerical simulation of heat transfer behavior in a coke oven crude gas sensible heat tube bundle

FENG Mingjie, WANG Engang, LIU Bing, LI Yandong, WANG Hai

(Key Laboratory of National Education Ministry for Electromagnetic Processing of Materials,

Northeastern University, Shenyang 110819, China)

Abstract: The effects of inlet velocity and original temperature on flow field and temperature field in a sensible heat recovery tube bundle of coke oven crude gas and the heat transfer behavior between coke oven crude gas and water cooling tubes were numerically simulated by use of user-defined functions based on Fluent 6.3 software. The results indicate that the coke oven crude gas flows around the tubes in the tube bundle and the wake flow eddy whose velocity is very low lies the in the back of tubes. The easier condensation zone for coal tar lies in the bake of the first row tubes and the bake or front of the others. It has the advantage to avoid coal tar condensation by increasing inlet velocity and original temperature of crude gas, at the same time the sensible heat recovery efficiency decreases and the average temperature increases at the tube bundle outlet under the same condition.

Key words: coke oven crude gas; sensible heat recovery; flow filed; temperature field; tube bundle

炼焦是钢铁冶金工业重要的组成部分,焦炉荒煤气带出的显热约占炼焦总耗热量的30%,温度高达650~750 ℃,回收这部分显热对于节能降耗具有重要意义[1-2]。直接将高温荒煤气引入火焰炉中燃烧,显然这部分显热可以得到充分利用,但荒煤气中的焦油、苯、奈等宝贵的化工原料也会被白白地烧掉而带来更大的损失[3-9],此外,经处理后的净煤气也是一种重要的洁净能源,并可以远距离输运。因此,采取措施仅回收荒煤气中的显热而不影响化工原料的回收和净煤气的应用一直是研究的热点[10-14]。目前采取的技术主要有[15]:上升管汽化冷却技术、导热油夹套技术和热管式换热技术。尽管这些技术经过多年的发展和改进,但依旧存在很多弊端。在这些技术中都是将换热设备安装在焦炉的上升管处,换热介质为液态的水或油,一旦泄露将会严重危害焦炉的安全。近几年来,焦炉荒煤气管束换热技术开始崭露头角,但该技术还有待于发展,其主要原因是随着荒煤气温度的降低,气态的焦油、苯、奈等杂质馏分会逐渐析出,沉积在温度较低的换热壁面上并炭化,使换热壁面的热阻增大,换热效率降低,并最终导致设备失效[16-17]。因此,有必要开展这方面的研究工作。本文作者以Fluent 6.3为计算平台,在充分考虑荒煤气物性参数随温度变化的基础上,以某焦化厂正在进行中试的换热管束为研究对象,系统研究荒煤气入口流速和初始温度对换热管束内流场、温度场、换热系数、换热效率,沿程平均温降的影响,以期为该项技术的发展和应用提供参考。

1 数学物理模型的建立

所采用的工艺流程如下:荒煤气首先经上升管由三通导出管及高温蝶阀导入集气管,送至除尘器,除掉煤气中夹带的煤粉和焦粉,然后进入显热回收管束进行换热,温度降至200~300 ℃;随后进入冷却器,经低压氨水喷洒冷却后,送到集气管的端部,最后经集气管送往煤气净化工段。根据工艺流程,本模拟所采用的显热回收管束为交错排布方式,管道水平间距248 mm,竖直间距140 mm,荒煤气在管外流动,且沿垂直于管束长度的方向进入,换热介质-水在管内流动,荒煤气所携带的显热穿过管壁将水加热以产生蒸汽。根据周期性,仅取具有代表性的部分管束为研究对象,由于管束在长度方向上的尺寸远大于横向尺寸,沿长度方向上的传热可忽略不计,故简化为2维问题来研究。将坐标原点设在2根管子的中间,并以荒煤气的流动方向为x轴的正方向,建立笛卡尔坐标系。

为了使求解成为可能,特作如下假定:1) 荒煤气为不可压缩理想流体,且散射系数为零;2) 管外壁为灰体,且黑度为定值;3) 管内流体(水)与管内壁的换热系数恒定;4) 荒煤气的各组分之间无化学反应;5) 馏分析出对换热的影响忽略不计。

1.1 流动模型

质量守恒方程:

(1)

(1)

动量守恒方程:

(2)

(2)

湍动能方程:

(3)

(3)

湍动能耗散方程:

(4)

(4)

式中:ui和uj分别为xi和xj方向上的速度分量;P为压力;μeff为有效黏度系数,μeff=μ+μi; ;

;

;模型常数的取值分别为:c1=1.44,c2=1.92,cμ=0.09,ue=0.09,σk=1.0,σε=1.3。

;模型常数的取值分别为:c1=1.44,c2=1.92,cμ=0.09,ue=0.09,σk=1.0,σε=1.3。

1.2 换热模型

(5)

(5)

式中:ρ为密度;h为气体的焓;λ为导热系数;Sh为能量源项。

1.3 辐射模型

焦炉荒煤气中含有大量的三原子气体,辐射传热将占有较大的比例。比较常用的辐射模型有DTRM模型、P-1模型、Rosseland模型和DO模型[18-19]。由于P-1模型在求解高温气体换热等问题时具有很大的优势,而且扩散方程也相对容易求解[20-22],故在本研究中选取P-1模型来求解气体的辐射问题。辐射热流由下式求得:

(6)

(6)

式中:a为吸收系数;δs为扩散系数;G为附带辐射;C为线性各向异性阶段函数系数。G的运输方程为

(7)

(7)

式中:σ为玻尔兹曼常量。

1.4 边界条件

1) 入口边界。能量方程的求解采用第一类边界条件,温度值根据计算所选用的荒煤气初始温度值赋给;流动采用速度边界条件,各入口处的流速根据所模拟的流量条件换算后得到,其中入口处的湍动能k和湍动能耗散率ε按下式取值:

(8)

(8)

(9)

(9)

式中:I=0.16Re-1/8,为湍流强度;Re为雷诺数;u为入口的平均速度;d为入口的水力直径。

2) 出口边界。采用压力出口边界,并将出口处的压力设为0。

3) 固体壁面。本研究涉及到的固体壁面是指管束中各管道的内外表面,管道内外壁分别与饱和水和荒煤气相接触,饱和水的温度取473 K,饱和水与管内壁之间的对流换热取2 kW/(m2·K),荒煤气与管外壁之间的对流换热系数取65 W/(m2·K),管外壁黑度取0.75,壁厚为δ=4 mm,壁面的材质为碳钢,局部导热系数根据壁面温度分布求得。外壁面与荒煤气相接触,设为无滑移壁面条件,并采用标准壁面函数法进行处理。

4) 周期边界。在周期边界上,垂直于周期边界的流体速度取为零,而其他场变量的值在边界内外相等。

2 求解方法和模型验证

2.1 求解方法

求解区域由前处理软件Gambit 2.0创建,采用四边形网格对该区域进行网格剖分,并定义边界类型后以Mesh文件格式导入到Fluent6.3中,然后采用自适应网格细化技术对流动和温度变化剧烈的区域进行网格加密。计算时,荒煤气在管束前的入口流速u0分别取2,4,6,8和10 m/s,入口初始温度T0分别取773,873,973和1 073 K,交叉配对后分别进行计算。其中焦炉荒煤气的组成如表1所示,物性参数如表2所示[23-24]。

计算时,先将辐射能量模型关闭,进行流场计算,当流场收敛后再打开辐射和能量模型继续计算,直至收敛。其中连续性方程、各方向上的速度方程、k和ε方程的残差限均设为10-3,辐射模型和能量方程设为10-6,当各方程的残差计算结果小于此规定值时,认为计算结果收敛,结束运算,随后进行结果分析和后处理。

表1 焦炉荒煤气的组成(体积分数)

Table 1 Chemical compositions of coke oven gas %

表2 焦炉荒煤气的物性参数

Table 2 Properties of coke oven gas

2.2 模型验证

为了验证该模型和计算方法的可靠性,现场测定了当入口流速为3.26 m/s时的主流区,荒煤气流出管束时的温度Tout随入口初始温度Tin的变化,并与计算结果进行比较,结果如图1所示。从图1可以看出:温度计算结果与测定结果在变化趋势上一致,数值上也极为接近,因此,本文所建立的数学模型具有较高的可信度。

图1 计算结果与测定结果的比较

Fig. 1 Comparison of simulation and measured results

3 模拟结果与分析

3.1 温度场和流场

当荒煤气在换热管束前的入口温度为1 073 K时,不同入口流速下管束内的温度分布如图2所示 (计算结果表明,其他条件下的温度分布与此相似。从图2可以看出:高温区位于管束的前部,低温区位于管束的末端。高温荒煤气沿着横向进入换热管束后,在向前流动的同时,自身的温度逐渐降低,最后以较低的温度离开管束,从而将大部分显热以辐射和对流换热的方式传给了管子中的换热介质;随着入口流速的增大,高温区所占面积逐渐增大而低温区面积逐渐缩小。这是由于在高温区,荒煤气与管内介质之间传热以辐射换热为主,由辐射换热方程可知,传热热流与温度的4次方差成正比,在低温区,荒煤气与管内介质之间传热以对流换热为主,由Newton冷却公式可知,传热热流与温差的1次方成正比;此外,随着流速的增大,荒煤气与管道外壁之间的对流换热系数也将增大,而管壁的温度变化不大,因此,随着入口流速的增大,荒煤气与管内介质之间传热强度将大大增强。

图2 荒煤气初始温度为1 073 K时不同入口流速下管束内的温度分布

Fig. 2 Temperature distribution in tube bundle under different inlet velocities when Tin=1 073 K

图3 当Tin=1 073 K,uin=10 m/s时,管束内的速度分布

Fig. 3 Velocity distribution in tube bundle when Tin=1 073 K, uin=10 m/s

当荒煤气的入口温度和入口流速分别为1 073 K和10 m/s时管束内的速度分布如图3所示。从图3可以看出:荒煤气在管束内是以绕流的方式流动的,具有流体横掠圆管流动的一般特点。刚进入管束时的荒煤气差不多以相同的速度流动,流动到管道前端的荒煤气由于受到管道的阻碍作用,流速逐渐降低,由伯努利方程可知,此时的压强将逐渐升高,其余部分的气体由于流通面积缩小而流速逐渐增大,在管道前分为2股作横绕管道流动,在管道的后面形成流速很小的尾流漩涡,同时由于2排管道之间的水平间距较小,横绕管道的2股气体来不及交汇,就流入了下一排管道,因而,除第1排管道外,在其余管道的前面也会形成漩涡。此外,在本研究中,可能是由于管道附近的网格划分不是足够细小,尽管流体的Re很大,但没观察到边界层中的回流及脱流现象。

3.2 管子周围的温度分布和沿程平均温降

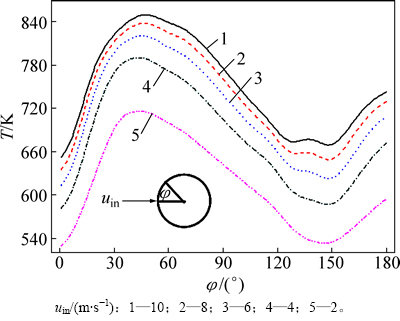

为了研究上的方便,特取有代表性的第二排管道中的一个单管为对象,图4所示为荒煤气入口温度Tin=973 K时,不同入口流速下离该管道外壁0.5 mm圆环上的温度分布。从图4可知:在管道附近,在圆环不同位置处的温度是不同的,在管道的前端和后端温度都较低,而两侧的温度较高,这与前文的流场分析结果是相互对应的,造成管道前后端温度低的主要原因是该处受涡流的影响使气体得不到快速的更新。荒煤气中含有大量的杂质,其中焦油蒸汽占有较大比例,在温度较低的情况下会冷凝成焦油而附着在管壁上,对显热回收造成重大影响。文献[8,13]表明:在常压下荒煤气中重质焦油成分的冷凝开始温度(冷凝点)为400~500 ℃。对荒煤气而言,在气液界面上焦油由气态变为液态和由液态变为气态是同时进行的2个过程,荒煤气的温度越底,液态焦油失去黏结变为气态所需要的时间越长,当同一时间内气态变为液态的量大于液态变为气态的量时,液态物就会不断地在界面上聚集,析出的液态焦油遇到高温会发生热解和缩聚而固化,随后逐渐炭化和石墨化[25]。由此可见:在换热管束第1排管道的前端以及其余管道的前端和后端都易附着焦油,且在管束尾部由于荒煤气的温度较低而更易出现焦油附着现象。从模拟结果来看,采取必要措施,消除或减弱管道前后端的漩涡是防止管道壁面附着焦油的有效手段。随着入口流速的增大,沿圆环周向的温度曲线逐渐上移,最低和最高温度都逐渐升高,当入口流速由2 m/s增加到10 m/s时,其最低和最高温度分别由532和713 K升高到689和845 K,由此可见,提高荒煤气的入口流速有利于减轻焦油附着。

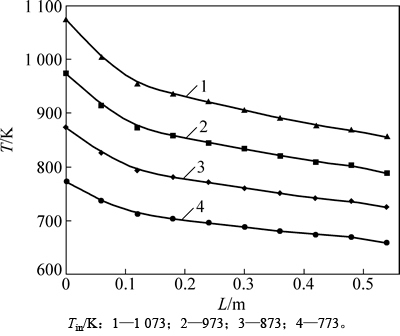

图5所示为当uin=10 m/s时不同入口温度下管束内的沿程平均温降。从图5可以看出:荒煤气在管束中向前流动的同时,其整体温度逐渐降低,且荒煤气在管束前部的温降速率大于后部的温降,当入口流速一定时,随着入口温度的升高,温降曲线逐渐上移。较大的温降速率意味着荒煤气中有更多的显热被释放,意味着在换热面积一定的情况下可以获得更多的能量,由此可见,管束前部的传热强度比后部的大。

图4 当Tin=973 K时不同入口流速下管子周围的温度分布

Fig. 4 Temperature distribution around tube under different inlet velocities when Tin=973 K

图5 当uin=10 m/s时不同入口温度下管束内的沿程平均温降

Fig. 5 Average temperature reducing curves along flow direction under different inlet temperatures when uin=10 m/s

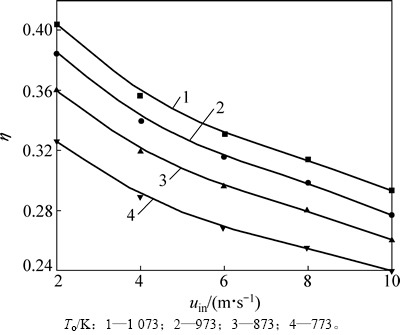

3.3 热回收效率和平均出口温度

图6所示为不同入口温度和入口流速下荒煤气在管束中的传热效率(也就是管束的热回收效率)。从图6可知:当荒煤气在管束前的入口温度一定时,随着入口流速增加,管束的热回收效率逐渐变小。因此,从热回收角度来看,降低入口流速有利于显热回收。但较低的入口流速将带来严重的焦油附着问题,因而在实际生产中,要对入口流速进行合理控制。当入口流速一定时,随着入口温度的升高,管束的热回收效率逐渐增大。在实际生产中,单座焦炉荒煤气的产出量和温度都是周期性波动的,炭化室在装煤初期和成焦后期,荒煤气生成的量少,温度低,而在成焦阶段荒煤气生成的量不仅多,而且温度也高,因此,为了保证显热回收管束运行参数的稳定,应将多座焦炉并行生产,同时供气,相互补偿。

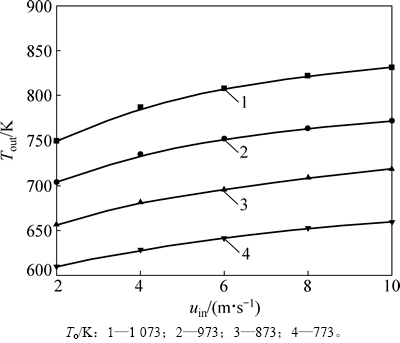

根据现场经验,为了预防或减弱焦炉荒煤气中杂质成分尤其是焦油成分在换热表面的冷凝附着,荒煤气离开管束中时的平均温度应控制到650 K以上。图7所示为不同入口温度和入口流速下荒煤气离开管束中时的平均温度。从图7可以看出:随着入口流速的增大和入口温度的升高,荒煤气离开管束中时的平均温度也逐渐升高,温度变化曲线逐渐上移。当入口流速和入口温度分别由2 m/s和773 K增大和升高到10 m/s和1 073 K时,荒煤气离开管束时的平均温度由604 K升高到827 K。

图6 不同条件下管束的热回收效率

Fig. 6 Heat recovery efficiency under different conditions

图7 不同条件下荒煤气离开管束时的平均温度

Fig. 7 Average temperature of coke oven gas at tube bundle outlet under different conditions

4 结论

1) 通过研究荒煤气显热回收管束内的温度场可知:高温区位于管束的前部,低温区位于管束的末端,管束前部的传热强度大于后部;随着入口流速的增大,高温区所占面积逐渐增大而低温区面积逐渐缩小。

2) 通过研究荒煤气显热回收管束内的流场可知:荒煤气在管束内是以绕流的方式流动的,具有流体横掠圆管流动的一般特点,并在管道的后面形成流速很小的尾流漩涡。

3) 在换热管束第1排管道的后壁以及其余管道的前壁和后壁都易附着焦油,且在管束尾部更甚,适当提高荒煤气的入口流速和入口温度有利于减轻焦油附着。

4) 随着荒煤气入口流速的增大和入口温度的升高,显热回收管束的热回收效率逐渐降低,荒煤气离开管束中时的平均温度逐渐升高。

参考文献:

[1] 周庆中, 王文改, 朱占升. 荒煤气显热的回收[J]. 煤气与热力, 1998, 18(1): 18-20.

ZHOU Qingzhong, WANG Wengai, ZHU Zhansheng. Sensible heat recovery of coke-oven raw gas[J]. Gas & Heat, 1998, 18(1): 18-20.

[2] 欧阳福承, 王振凡. 焦炉荒煤气显热回收利用的研究[J]. 吉林化工学院学报, 1993, 10(3): 1-8.

O’YANG Fucheng, WANG Zhenfan. Study on sensible heat recovery of coke-oven raw gas[J]. Journal of Jilin Institute of Chemical Technology, 1993, 10(3): 1-8.

[3] 黄澎. 高温煤焦油悬浮床加氢裂化研究[J]. 洁净煤技术, 2011, 17(3): 61-63.

HUANG Peng. Study on slurry-bed hydrocracking reactions of high temperature coal tar[J]. Clean Coal Technology, 2011, 17(3): 61-63.

[4] YANG Zhibin, ZHANG Yuwen, DING Weizhong. Investigation on the reforming reactions of coke-oven-gas to H2 and CO in oxygen-permeable membrane reactor[J]. Journal of Membrane Science, 2014, 470(11): 197-204.

[5] JOHANSSON M T, SODEERSTROM M. Options for the Swedish steel industry-energy efficiency measures and fuel conversion[J]. Energy, 2011, 36(1): 191-198.

[6] KOTHARI R, SINGH D P, TYAGI V V, et al. Fermentative hydrogen production: an alternative clean energy source[J]. Renewable and Sustainable Energy Reviews, 2012, 16(4): 2337-2346.

[7] MIURA K, KAWASE M, NAKAGAWA H, et al. Conversion of tar in hot coke oven gas by pyrolysis and steam reforming[J]. Journal of Chemical Engineering of Japan, 2003, 36(7): 735-741.

[8] LI Chunshan, SUZUKI K. Resources, properties and utilization of tar[J]. Resources, Conservation and Recycling, 2010, 54(11): 905-915

[9] WANG Xun, WANG Tianjiao. Hydrogen amplification from coke oven gas using a CO2 adsorption enhanced hydrogen amplification reactor[J]. International Journal Hydrogen Energy, 2012, 37(6): 4974-4986.

[10] ONOZAKI M, WATANABE K, HASHIMOTO T, et al. Hydrogen production by the partial oxidation and steam reforming of tar from hot coke oven gas[J]. Fuel, 2006, 85(2): 143-149.

[11] VICTOR Z, FREDERIC H. Coke oven carbon deposits growth and their burning off[J]. ISIJ International, 2007, 47(10): 1422-1431.

[12] ONOZAKI M, WATANABE K, HASHIMOTO T, et al. Hydrogen production by the partial oxidation and steam reforming of tar from hot coke oven gas[J]. Fuel, 2006, 85(2): 143-149.

[13] CHEN W H, LIN Murong, YU A B, et al. Hydrogen production from steam reforming of coke oven gas and its utility for indirect reduction of iron oxides in blast furnace[J]. International Journal of Hydrogen Energy, 2012, 37(16): 11748-11758.

[14] BERMUDEZ J M, FIDALGO B, ARENILLAS A, et al. Dry reforming of coke oven gases over activated carbon to produce syngas for methanol synthesis[J]. Fuel, 2010, 89(10): 2897-2902.

[15] 张宇晨, 孙业新. 焦炉上升管荒煤气显热回收技术探讨[J]. 冶金能源, 2011, 30(3): 46-48.

ZHANG Yuchen, SUN Yaxin. Discussion about the technology of sensible heat recovery of raw coke oven gas in ascension pipe[J]. Energy for Metallurgical Industry, 2011, 30(3): 46-48.

[16] RAZZAQ R, LI Chunshan, ZHANG Suojiang. Coke oven gas: Availability, properties, purification, and utilization in China[J]. Fuel, 2013, 113(11): 287-299.

[17] 张增亮, 林柏泉. 焦炉煤气的爆炸特性[J]. 燃烧科学与技术, 2012, 18(6): 499-503.

ZHANG Zenglian, LIN Baiquan. Explosion characteristics of coke oven gas[J]. Journal of Combustion Science and Technology, 2012, 18(6): 499-503.

[18] 杨卫宏, 赖亚欣, 萧泽强. 余热锅炉流场温度场数值计算[J]. 中国有色金属学报, 2000, 10(2): 278-281.

YANG Weihong, LAI Yaxin, XIAO Zeqiang. Numerical simulation of flow and temperature fields in waste boiler[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(2): 278-281.

[19] 满奕, 杨思宇,项东, 等. 煤和焦炉气联供制烯烃过程的建模模拟与分析[J]. 化工学报, 2014, 65(12): 4850-4858.

MAN Yi, YANG Siyu, XIANG Dong, et al. Modeling, simulation and analysis for co-feed process of coal and coke-oven gas to olefins[J]. CIESC Journal, 2014, 65(12): 4850-4858.

[20] STEVAN N, VUKMAN B, SIMEON O. Experimental and numerical investigation of gaseous fuel combustion in swirl chamber[J]. International Journal of Heat and Mass Transfer, 2005, 48(21): 4623-4632.

[21] 冯明杰, 李德立, 王恩刚. 火焰长度可调式燃烧器的数值模拟[J]. 东北大学学报(自然科学版), 2014, 35(9): 1279-1283.

FENG Mingjie, LI Deli, WANG Engang, Numerical simulation of an adjustable length of flame gas burner[J]. Journal of Northeastern University (Natural Science), 2014, 35(9): 1279-1283.

[22] LI Chenyi, APPARI S, TANAKA R, et al. A CFD study on the reacting flow of partially combusting hot coke oven gas in a bench-scale reformer[J]. Fuel, 2015, 159(1):590-598.

[23] CHUNG T H, LEE L L, STARLING K E. Applications of kinetic gas theories and multi-parameter correlation for prediction of dilute gas viscosity and thermal conductivity[J]. Industrial and Engineering Chemistry Fundamentals, 1984, 23(1): 8-13.

[24] CHUNG T H, AJLAN M, LEE L L. Generalized multi-parameter correlation for non-polar and polar fluid transport properties[J]. Industrial and Engineering Chemistry Research, 1988, 27(4): 671-679.

[25] 房永征, 黄萍, 张琢. 焦炉石墨生成规律研究[J]. 洁净煤技术, 2011, 17(5): 36-39.

FANG Yongzheng, HUANG Ping, ZHANG Zhuo. Analysis on the growth mechanism of carbon deposit in coke oven[J]. Clean Coal Technology, 2011, 17(5): 36-39.

(编辑 陈爱华)

收稿日期:2016-03-11;修回日期:2016-06-28

基金项目(Foundation item):国家自然科学基金资助项目(200809123)(Project(200809123) supported by the National Natural Science Foundation of China)

通信作者:冯明杰,博士,副教授,从事能源与燃烧的研究;E-mail:fengmj@epm.neu.edu.cn