文章编号:1004-0609(2007)06-0878-07

往复式喷射成形管坯沉积特性及运动参数优化

马万太1, 宋红媛1 , 张 豪2, 张 捷3

(1. 南京航空航天大学 机电学院,南京 210016;

2. 上海交通大学 金属基复合材料国家重点实验室,上海 200030;

3. 张家港华通喷射成形有限公司,张家港 215625)

摘 要:介绍基底往复式喷射成形制备大壁厚管坯的工艺原理。研究单层沉积轨迹特性及其数学模型,针对沉积轨迹螺旋特性,分析基底运动参数(ω, v)对单层沉积特性的影响。建立多旋转周期沉积轮廓叠加的单层沉积厚度模型,利用该模型在不同沉积轨迹螺距下,对沉积厚度进行计算仿真,获得保证均匀沉积面的运动参数优化条件。在此基础上,提出单层沉积厚度的简易计算方法,并通过实验进行了验证,测量结果与预测值一致性较好。将研究结果用于实际喷射成形管坯生产中,制备得到表面形貌良好、性能稳定的管坯。

关键词:管坯;往复式喷射成形;参数优化;沉积轨迹;沉积层厚度

中图分类号:TG 146 文献标识码:A

Deposition behavior and movement parameters optimization for reciprocating spray forming tubular

MA Wan-tai1, SONG Hong-yuan1, ZHANG Hao2, ZHANG Jie3

(1. College of Mechanical and Electrical Engineering, Nanjing University of Astronautics and Aeronautics,

Nanjing 210016, China;

2. State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University, Shanghai 200030, China;

3. Zhangjiagang Huatong Spray Forming Co. Ltd., Zhangjiagang 215625, China)

Abstract: Process principle of reciprocating spray forming large thickness-wall tubular was analyzed. Behavior of the deposit track and corresponding model of single layer were studied. Aiming at the helix characteristic of the deposit track, the influences of mandrel movement parameters (ω, v) on the deposit behavior were analyzed. A model used to simulating the deposit thickness overlapped by the deposit profiles of multiple circumrotate cycles was established. This model was applied to simulate the deposit thickness with different pitch of the deposit track, and the optimum condition of movement parameters was obtained under which homogeneous deposit surface can be prepared. Based on the above optimum condition, a simple method was presented to calculate the deposit thickness and was verified through spray experiments. It is indicated that the simulated values are in agreement with the measurements. The results were applied in spray forming tubular, and a serial of tubular with good profile and stable performance were prepared.

Key words: tubular; reciprocating spray forming; parameters optimization; deposit track; deposit thickness

喷射成形工艺是一个涉及传热、传质、冶金、气体动力学和众多工艺参数的复杂过程,为了缩短实验周期和深入地理解该过程,一般采用计算机数值模拟与实验相结合的方法[1]。其中,喷射成形特性(如形貌仿真及工艺参数影响)是一个主要研究内容。目前为止,对喷射成形坯件生长沉积模型的研究主要针对锭坯、环坯和板坯[2?6],文献[7?8]对喷射成形管坯形貌及传热模型进行了较为系统的研究,分析了主要运动参数(如基底转速、基底移动速度等)对管坯沉积特性的影响,但其研究对象是针对传统喷射成形工艺(即基底单向移动),该工艺适合制备薄壁管坯,对于制备大壁厚管坯,该工艺存在一定局限性。多层喷射成形是制备大壁厚管坯的理想工艺[9?13],基底往复式多层喷射成形工艺[12?13]由于设备结构、运动控制简单、连续自动移液实现方便等工艺优势更适合工业化生产。管坯多层喷射成形工艺的沉积特性及其形貌生长过程与传统喷射成形工艺有一定区别,其沉积层生长为动态变化过程。沉积密度[9]是影响沉积性能的重要综合参数,沉积层生长的变化导致沉积密度的变化,影响了材料微观组织和沉积过程的稳定和均匀性。管坯沉积特性的研究将有助于实现对喷射密度的控制以及可用于喷射高度实时控制中。

本文作者针对基底往复式喷射成形工艺,介绍了设备结构及其工作原理,分析了沉积轨迹特性及其运动参数的影响,建立了沉积厚度计算模型,为获得均匀沉积面,对运动参数进行了优化;提出了单层沉积厚度的简易计算方法,并进行了仿真及实验对比分析;在此基础上,讨论了工艺参数对管坯沉积层生长的影响。研究结果已应用于往复式喷射成形铝合金管坯制备生产控制中,对模型的预测结果进行了验证,并生产出一系列大尺寸沉积管坯。

1 管坯喷射成形设备结构及工艺原理

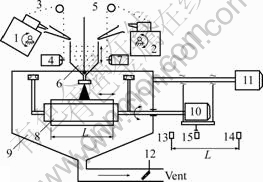

基底往复式喷射成形管坯设备结构如图1所示,其工作原理为:通过由中间包1、2及相应的传动机构3、4、7构成的移液装置将金属熔体连续、稳定地注入到漏包6中,在此过程中,采用PID控制算法控制漏包液面稳定;漏包中的金属熔体通过漏嘴流入喷嘴,被高压气体(N2)雾化成锥状液滴喷射液,喷嘴水平方向固定,垂直方向受控提升以控制喷嘴喷射高度,收集基底8作匀速旋转运动及往复运动,雾化锥液滴扫描沉积在收集基底上,经过雾化液流的多次往返扫描沉积, 最终成形管坯。沉积室保持微正压环境,使大气中的氧被隔离在沉积室之外,通过控制排气管中的电控蝶阀12的开口量使沉积室内压力于设定状态。

图1 往复式喷射成形管坯制备原理及结构

Fig.1 Process principle of reciprocating spray forming take: 1, 2—Left and right ladles; 3—Transmission chain; 4, 7—Transduce motor; 5—Stop rod; 6—Tundish; 8—Mandrel; 9—Deposit chamber; 10—Rotating transduce motor; 11—Reciprocating transduce motor; 12—Dishing valve; 13, 14—Left and right approximate switch; 15—Trigger approximate switch

2 单层沉积轨迹特性及运动参数优化

2.1 单层沉积轨迹

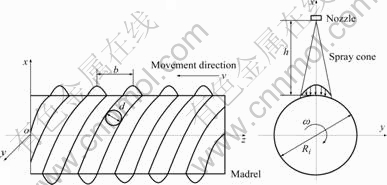

假设基底为均匀圆柱,根据图1中喷嘴与基底的相对运动关系可知,一次往复单层沉积中,当基底旋转速度和往复运动速度恒定时,雾化锥在基底上的沉积轨迹为螺旋轮廓,如图2所示。

图2 单层沉积的轨迹轮廓

Fig.2 Track profile of single layer deposit

单层沉积轨迹轮廓及其物质分布主要特征有以下两点。

1) 沉积轨迹为螺旋轮廓

螺旋方向由基底往复运动方向以及旋转方向确定。在图2所示的坐标系中,沉积轨迹方程为

根据螺旋线特性,螺旋沉积轨迹取决于基底运动参数ω和ν,该参数决定了螺旋线螺距b,存在以下关系:

沉积轨迹直接影响后续往复沉积条件。螺距b太大,产生断续的沉积面,不利于后续沉积及形貌控制;螺距b太小,则会造成沉积层的堆积。

2) 单层沉积轮廓的影响因素

运动参数ω和ν影响沉积轨迹螺距,喷射高度、金属液总质量流率、喷嘴结构等影响沉积轮廓的物质分布状态。

基底往复式喷射成形工艺可获得总体表面形貌优良的管坯,这由如下运动方式保证:1) 虽然各层喷射成形轨迹为螺旋轮廓,但由于基底为往复两个方向交替运动,且旋转方向不变,因而任意相邻两层沉积轨迹螺旋方向相反,同时,每个往复中沉积轨迹起始点是随机的,沉积层物质相互啮合,因而不存在各层沉积轨迹的耦合现象;2) 基底旋转速度和往复运动速度在整个过程中恒定,虽然在往复换向过程中存在短暂的变速阶段,但可以通过缩短变频器的加减速时间设置,使该变速阶段带来的影响忽略不计。多次喷射实验表明管坯两端不存在明显的直径增大现象。

2.2 均匀单沉积面的运动参数优化

单层沉积轨迹的螺旋线形状对沉积条件有较大影响,喷射成形过程中,在喷嘴结构、喷射高度、导液管直径、漏包液面高度等影响物质分布的工艺参数保持不变的前提下,基底旋转速度和往复运动速度是影响沉积轨迹轮廓的关键。优化运动参数(ω,ν)的目的是为了获得具有单层均匀沉积层厚度的沉积面,使金属均匀沉积在基底上。

为使沉积面不出现断续现象,轨迹螺距b与螺旋轮廓宽度d(喷射高度h处的雾化锥直径)须满足如下基本条件:

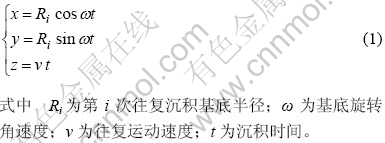

由于雾化质量流率的分布特性,式(3)所示的基本条件并不能保证沉积物在基底上的均匀分布,因此,应采用合适的运动参数使基底不同旋转周期的轨迹部分重叠,且轨迹叠加为平滑沉积面。图3所示为相邻两周轨迹重叠状态。后一周沉积轨迹3与前一周沉积轨迹1部分重叠,重叠区物质增长弥补了物质分布两边低、中间高的问题,从而避免了单层轨迹物质分布出现峰、谷交叉状态,有效地改善了物质在基底上分布均匀性。

图3 相邻两周沉积轨迹重叠状态

Fig.3 Overlap of two deposit tracks of conterminous circumrotate cycles

质量流率反映了雾化锥中的金属液滴的质量分布,不同结构的雾化器将产生不同质量流率分布的雾化锥。 但对于形状对称性好的雾化器,其雾化锥内的质量流率基本符合高斯分布[14?15],喷射高度h处的质量流率M可表示为

根据基底往复式喷射成形工艺运动特点,基底沉积轨迹叠加过程可分解为两个独立部分:1) 基底独立旋转一周时物质沉积轮廓(表现为沉积层厚度的分布);2) 单周沉积层轮廓依次平移螺距b后的多周沉积轮廓的叠加。

1) 单周沉积厚度计算

在图2所示的xoz截面内,第i次基底往复、距雾化锥中心r处的沉积厚度可表示为

式(5)的计算结果表明,单周沉积层厚度在xoz截面内同样满足高斯分布。

2) 多周平移沉积轮廓的叠加

根据式(5)可计算第j周沉积厚度Tij,以第1周(j=1)雾化锥中心为参考点,距参考点r处P点的叠加沉积厚度为各单周沉积厚度在该处的叠加:

由于各周间的轮廓依次平移了螺距b的距离,因此,在计算Tij时,P点相对第j周雾化锥中心的径向距离rj为

根据上述模型,在不同沉积轨迹螺距b下,对沉积层厚度进行了计算仿真以获得满足均匀沉积条件的运动参数。本计算采用的喷射工艺条件为:Laver缝隙式雾化器,雾化压力7.0 MPa ,导液管直径为d 4.5 mm,材料为7075铝合金,喷射温度为710 ℃,喷射高度h为380 mm,该实验条件下,式(4)中的Mmax=0.031 g/(mm2?s),a=0.000 9 mm?2。雾化锥角为15?,粘附系数ξ为0.75,第i次往复基底半径Ri为200 mm。图4所示是b为5、13、15、30 mm/r时的沉积层厚度仿真结果,图中反映了沉积轮廓叠加前后的沉积厚度变化情况,以及在不同螺距下沉积层厚度变化状态。

图4 不同螺距下轨迹叠加前后沉积层厚度仿真

Fig.4 Simulation of overlapped deposit thickness with different pitch

仿真结果表明:

1) 叠加后的沉积厚度较单周沉积厚度大。不同运动参数下,沉积轮廓的叠加造成不同的沉积表面形状,螺距越小,沉积层厚度增大,反之,沉积层厚度越小,同时会产生断续沉积面,当螺距b大于沉积轮廓d时,不产生叠加。

2) 在文中工艺参数条件下,当b在12~13 mm/r时(图4(b)),可获得表面平滑、均匀沉积面,该参数即为优化沉积条件。

3) 满足均匀沉积面的运动参数优化条件与雾化锥角、喷射高度、质量流率、基底半径等工艺参数有关。

3 单层沉积层厚度的简易计算方法

3.1 平铺计算法

上述模型既可用以优化运动参数,也可对各种工艺运动参数下的沉积层厚度进行计算和仿真,但该方法计算过程复杂、计算量大,难以用于实时控制系统应用程序(如PLC,可编程逻辑控制)中以对工艺参数(如喷射高度)进行控制。

通过运动参数优化可获得平滑的沉积轮廓,这是保证往复式多层沉积工艺沉积条件的关键,在此基础上,本文作者提出单层沉积层厚度的简易计算方法—平铺计算法,该方法假设基底为均匀外圆柱面,且单层沉积层物质均匀分布在基底外圆柱面上,则第i次往复单层沉积厚度 可通过往复一次的沉积物质总体积以及总圆柱面积近似获得:

可通过往复一次的沉积物质总体积以及总圆柱面积近似获得:

由式(2)可以看出,在满足均匀沉积面运动参数前提下,单层沉积厚度与旋转速度ω无关,只与总的金属量流率M、往复速度v及当前沉积基底半径Ri有关。

3.2 单层沉积厚度计算仿真及其验证

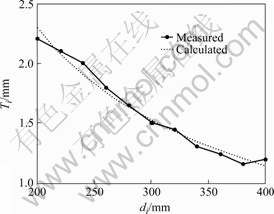

基于平铺计算法对单层沉积厚度进行计算和仿真,并通过实际测量结果进行对比(单层沉积厚度测量技术将在另文介绍)。计算仿真及实验采用的工艺参数为:总的金属流率M=133 g/s,旋转速度n=80 r/min,旋转角速度ω=8.4 rad/s,往复速度v=16.67 mm/s,初始基底半径R0=200 mm。此条件下,b=12.5 mm/r,运动参数ω和v满足优化条件。

单层沉积厚度的仿真和测量结果如图5所示。

图5 单层沉积厚度仿真与测量结果对比

Fig.5 Comparison between data of simulated and measured deposit thickness

从仿真和实验对比结果可以看出:

1) 平铺计算法与图4(b)的沉积厚度仿真结果基本相同,说明平铺计算法的可行性,也证明了在优化条件下可获得均匀沉积面。

2) 仿真值为一系列离散点,表明沉积厚度增长过程是非连续的,每一点表示某一基底直径Ri(第i次往复)下的沉积层厚度Ti。

3) 单层沉积层厚度随基底半径的增大而减小。

4) 测量点选取了连续10个往复单层沉积厚度测量值,仿真结果与测量结果一致性较好。

3.3 管坯壁厚计算

根据沉积层厚度间断增长的特点,可得到管坯沉积壁厚T:

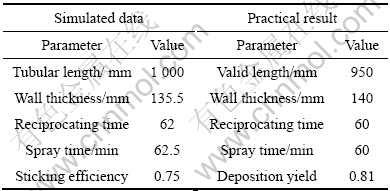

4 生产实例

上述研究结果已应用于喷射成形生产中,制备出了表面光滑、性能优异、具有不同内径、长度和壁厚的管坯。以内径为200 mm,长度为1 000 mm的管坯生产为分析对象,共投料500 kg 7075铝合金,其余工艺参数及运动参数与文中的仿真参数相同。制备的管坯照片如图6所示。从图中可看出,往复式喷射成形制备的管坯形状分为3个部分:左端过渡区、中间平稳生长区和右端过渡区,中间部分管坯为均匀圆柱,各截面直径尺寸一致,表面光滑,未出现螺旋轮廓。

图6 制备的管坯实物

Fig.6 Photo of prepared tubular

计算仿真与实际喷射生产的相关工艺数据对比如表1所示。

表1 工艺数据的计算仿真与实际结果对比

Table 1 Comparison between simulated data and practical results

5 结论

1) 基底往复喷射成形工艺中,单层沉积轨迹为螺旋轮廓,运动参数对轮廓形状有较大影响,沉积轨迹螺距b太大或太小均会造成不良沉积条件。

2) 基底和喷嘴的相对运动特性决定了不会形成各层沉积轨迹耦合,可以获得总体上表面形貌良好的管坯。

3) 在本文喷射工艺参数下,如果运动参数(ω,v)满足b=12~13 mm/r,可以获得单层均匀沉积面。在不同工艺参数下,该条件不同。

4) 在满足均匀沉积条件下,单层沉积厚度与旋转速度ω无关,只与总的金属流率M、往复速度v和沉积基底半径Ri有关。沉积层间断增长,单层沉积厚度随基底直径的增大而减小。

REFERENCES

[1] Lawley A, Leatham A G. Spray forming commercial products: principles and practice[J]. Material Science Forum, 1999, (6)299/300: 407?415.

[2] Hattel J H, Pryds N H. A unified spray forming model for the prediction of billet shape geometry[J]. Acta Materialia, 2004, 52(18): 5275?5288.

[3] Pryds N H, Hattel J H, Pedersen T B, Thorborg J. An integrated numerical model of the spray forming process[J]. Acta Materialia, 2002, 50(16): 4075?4091.

[4] Hattel J H, Pryds N H, Pedersen T B. An integrated numerical model for the prediction of Gaussian and billet shapes[J]. Mater Sci Eng A, 2004, 383(1): 184?189.

[5] Singha A K, Sivaramakrishnana C S, Panigrahib S C. Effect of processing parameters on physical properties of spray formed and stir cast Al-2Mg-TiO2 composites[J]. Mater Sci Eng A, 2005, 393(10): 196?203.

[6] 曹福洋, 崔成松, 范洪波, 李庆春. 喷射成形过程工艺参数作用规律的理论预测[J].中国有色金属学报, 1999, 9(2): 213?219.

CAO Fu-yang, CUI Cheng-song, FAN Hong-bo, LI Qing-chun. Theoretical analysis on effect of spray forming processing parameters[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(2): 213?219.

[7] CUI Cheng-song, Fritsching U, Alwin S, Li QING-chun. Mathematical modeling of spray forming process of tubular performs—Part 1: Shape evolution[J]. Acta Materialia, 2005, 53(4): 2765?2774.

[8] CUI Cheng-song, Fritsching U, Alwin S, Li QING-chun. Mathematical modeling of spray forming process of tubular performs—Part 2: Heat transfer[J]. Acta Materialia, 2005, 53(4): 2775?2784.

[9] 陈振华, 严红革, 陈 刚, 张福全, 胡仲勋, 傅杰新. 多层喷射沉积的装置和原理[J]. 湖南大学学报(自然科学版), 2001, 28(5): 20?28.

CHEN Zhen-hua, YAN Hong-ge, CHEN Gang, ZHANG Fu-quan, HU Zhong-xun, FU Jie- xin. Principle and setups of multi-layer spray deposition technology[J]. Journal of Hunan University (Natural Sciences Edition), 2001, 28(5): 20?28.

[10] 袁武华. 多层喷射沉积制备大尺寸耐热铝合金管坯的研究[D]. 长沙:中南工业大学, 2001.

YUAN Wu-hua. Study on multi - layer spray deposited large heat-resistant Al alloy pipe blank[D]. Changsha: Central South University of Technology, 2001.

[11] 陈振华, 陈 鼎, 康智涛, 严红革, 张福全, 袁武华, 王慧敏. 坩埚移动式喷射共沉积制取铝基复合材料的技术[J]. 湖南大学学报(自然科学版), 2002, 29(6): 23?30.

CHEN Zhen-hua, CHEN Ding, KANG Zhi-tao, YAN Hong-ge, ZHANG Fu-quan, YUAN Wu-hua, WANG Hui-min. Preparation technology of Aluminum alloy matrix composites by spray co-deposition with moving crucible[J]. Journal of Hunan University (Natural Sciences Edition), 2002, 29(6): 23?30.

[12] 张 豪. 控制往复喷射成形装置[P]. 中国专利 03230878.7, 2004.

ZHANG Hao. Setup of controlled reciprocating spray forming[P]. CN, 03230878.7, 2004.

[13] 张 豪, 张 荻, 张 捷, 宋 立. 控制往复喷射成形工艺[P]. 中国专利 03117066.8, 2004.

ZHANG Hao, ZHANG Di, ZHANG Jie, SONG Li. Process of controlled reciprocating spray forming[P]. CN, 03117066.8, 2004.

[14] 霍 光, 邓德国, 谢 明, 郑福前, 史庆南. 喷射成形棒坯中沉积距离和回缩速度的选择[J]. 粉末冶金技术, 2005, 23(2): 125?128.

HUO Guang, DENG De-guo, XIE Ming, ZHENG Fu-qian, SHI Qing-nan. The selection of deposition distance and withdrawal velocity in spray forming[J]. Powder Metallurgy Technology, 2005, 23(2): 125?128.

[15] 熊柏青, 朱宝宏, 张永安, 等. 喷射成形Al-Fe-V-Si系耐热铝合金的制备工艺和性能[J]. 中国有色金属学报, 2002, 12(2): 250?254.

XIONG Bai-qing, ZHU Bao-hong, ZHANG Yong, et al. Technique and property of heat resisting Al-Fe-V-Si alloys prepared by spray forming process[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(2): 250?254.

收稿日期:2006-10-23;修订日期:2007-02-26

通讯作者:马万太,副教授;电话:025-84892509;E-mail: mawantai@263.net

(编辑 陈爱华)