CNTs和Nb 纳米颗粒提高电力传输线用放电等离子体烧结铝合金的摩擦和热性能

来源期刊:中国有色金属学报(英文版)2020年第2期

论文作者:Chika O. UJAH Patricia POPOOLA Olawale POPOOLA Victor AIGBODION Philip OLADIJO

文章页码:333 - 343

关键词:摩擦;热导率;放电等离子体烧结;Al-CNTs-Nb复合材料;摩擦因数

Key words:tribology; thermal conductivity; spark plasma sintering; Al-CNTs-Nb composite; coefficient of friction

摘 要:用放电等离子体烧结法(SPS)制备铝合金,以碳纳米管(CNTs)和Nb纳米颗粒作为增强相,提高合金的摩擦性能和热性能。SPS工艺参数为:630 °C、30 MPa、10 min和200 °C/min。而且,以钢球为对磨件,采用球-盘式摩擦试验机对样品进行摩擦学试验。用热重分析仪(TGA)和激光导热仪(LFA)进行热性能分析。结果表明,分别添加8 wt.% 的CNTs和Nb纳米颗粒使复合材料的摩擦因数(COF)降低79%。磨损量和磨损率也降低23%,且复合材料的热导率提高44%。摩擦性能的改善是由于CNTs的加入导致材料表面形成C薄膜,以及由于Nb纳米粉末的加入而生成起保护作用的Nb2O5。导热性能的改善是由于Nb的晶粒细化作用和CNTs的高导热性。因此,这些结果表明,Al-CNTs-Nb 复合材料是高压输电导线用的坚固材料,能够减小下垂并保证材料的使用寿命。

Abstract: This study aimed at improving the tribological and thermal properties of Al alloy using CNTs and Nb nanopowder as reinforcements and spark plasma sintering (SPS) as the fabrication method. The SPS was conducted at 630 °C, 30 MPa, 10 min, and 200 °C/min. The tribology test was run with ball-on-disc tribometer using steel ball as the counter body. And the thermal test was processed with thermogravimetric analyzer (TGA) and laser flash apparatus (LFA). Results showed that the addition of 8 wt.% CNTs and 8 wt.% Nb reinforcements respectively decreased the coefficient of friction (COF) of the composite by 79%. The wear volume of the composite was decreased by 23%, and so was the wear rate. However, the thermal conductivity of the composite was equally improved by 44%. The tribology improvement was stimulated by a C film generated by CNTs and a protective Nb2O5 formed by Nb nanopowder. The thermal conductivity was improved by the grain refining property of Nb and the high thermal conductivity of CNTs. Therefore, these results indicated that Al-CNTs-Nb composite is a robust material for high transmission conductor capable of reducing sag and ensuring the durability of the composite.

Trans. Nonferrous Met. Soc. China 30(2020) 333-343

Chika O. UJAH1, Patricia POPOOLA1, Olawale POPOOLA2, Victor AIGBODION1,3, Philip OLADIJO4,5

1. Department of Chemical, Metallurgical and Materials Engineering, Tshwane University of Technology, Pretoria 0001, South Africa;

2. Department of Electrical Engineering, Tshwane University of Technology, Pretoria 0001, South Africa;

3. Department of Metallurgical and Materials Engineering, University of Nigeria, Nsukka 410001, Nigeria;

4. Department of Chemical, Materials and Metallurgical Engineering, Botswana International University of Science and Technology, Palapye 12345, Botswana;

5. Department of Mechanical Engineering, University of Johannesburg, Johannesburg 2000, South Africa

Received 23 March 2019; accepted 25 November 2019

Abstract: This study aimed at improving the tribological and thermal properties of Al alloy using CNTs and Nb nanopowder as reinforcements and spark plasma sintering (SPS) as the fabrication method. The SPS was conducted at 630 °C, 30 MPa, 10 min, and 200 °C/min. The tribology test was run with ball-on-disc tribometer using steel ball as the counter body. And the thermal test was processed with thermogravimetric analyzer (TGA) and laser flash apparatus (LFA). Results showed that the addition of 8 wt.% CNTs and 8 wt.% Nb reinforcements respectively decreased the coefficient of friction (COF) of the composite by 79%. The wear volume of the composite was decreased by 23%, and so was the wear rate. However, the thermal conductivity of the composite was equally improved by 44%. The tribology improvement was stimulated by a C film generated by CNTs and a protective Nb2O5 formed by Nb nanopowder. The thermal conductivity was improved by the grain refining property of Nb and the high thermal conductivity of CNTs. Therefore, these results indicated that Al-CNTs-Nb composite is a robust material for high transmission conductor capable of reducing sag and ensuring the durability of the composite.

Key words: tribology; thermal conductivity; spark plasma sintering; Al-CNTs-Nb composite; coefficient of friction

1 Introduction

One of the most difficult challenges encountered in power transmission is conductor sag which is primarily due to the inelastic expansion of the conductor as a result of high thermal and electrical loading. To forestall this, conductors are made of central cores synthesized with materials of good thermal conductivity, low coefficient of thermal expansion (CTE) and high tribological properties. So, researches on developing a robust material for the conductor and its core capable of operating at a high temperature with very low sag are under way. Monolithic Al1000 alloy possesses light mass, good corrosion and electrical properties necessary for power transmission conductor, but it is poor in tribological and thermal characteristics. To boost this alloy, CNTs which have thermal conductivity of 3 kW/(m·K), low CTE, high strength and good wear resistance [1] should serve as a good reinforcement. Moreover, Nb is a good grain refiner, a superconductor, and a fracture toughening additive [2] which could contribute immensely to the enhancement of Al alloy for the purpose in question. In this modern era of high energy cost and demand, conservation of energy plays a paramount role in the production process.

Hence, spark plasma sintering (SPS) stands out in terms of energy conservation, cost and time effective fabrication technique. Besides these, SPS generates improved composites through ensuring cohesive grain boundaries, control of grain growth, inhibition of porosity and homogenous dispersion of the reinforcements [3,4]. Studies have shown that most metals except gold have free energy of oxidation. However, the growth of oxide layer at static state is lower than that at dynamic state where there is rubbing of surfaces. Oxidation generates micro pores, voids, dislocations and vacancies in the microstructure of material. Incidentally, CNTs incorporated into metal matrix composites (MMCs) ameliorate oxidation of contacting surfaces [5]. Moreover, BEDIR [6] noted that incorporation of secondary phase reinforcement which normally increases the hardness of the composite, improves the wear resistance. Hence, these reinforcements (CNTs and Nb) would improve the wear characteristics of the Al alloy. Improving the tribology of Al composites was studied by ABOU- BAKREL et al [7] and ZHOU et al [8] who discovered that wear rate of the composite was inversely proportional to the volume fraction of CNTs reinforcement, and that when the applied load increased, the wear loss increased and the coefficient of friction decreased. WANG et al [9] reinforced Al alloy with SiC, while YILMAZ [10] reinforced Al alloy with Al2O3, and both observed that the additions reduced wear loss, but when the applied load increased the wear rate and coefficient of friction (COF) increased, and they decreased with increasing sliding speed. DEMIRKOL et al [11] showed that Nb induced the formation of Nb2O5 in MMCs which reduced the wear loss. And since it is a good toughening agent, it prevents material deformation caused by friction.

Meanwhile, studies showed that the thermal behaviour of MMCs depends on the nature, volume fraction and dispersion of the reinforcement together with the densification of the composite since thermal conductivity is higher in continuous phases than that in discontinuous phases [12,13]. That is, since Al matrix is a continuous phase, and Al composite is a discontinuous phase, it is necessary to consolidate the composite with a technique and the material that will give the composite a nearly continuous phase for the maximum thermal conductivity. Accordingly, PIETRAK and WISNIEWSKI [14] disclosed that the interfacial thermal resistance (ITR) is one of the major causes of thermal conductivity drop in a composite. This is because there is scattering of phonons and electrons at the matrix/reinforcement interface that is not held cohesively. It was further revealed that ITR consists of thermal contact resistance (TCR) which is caused by weak bonding in the boundary layer and thermal boundary resistance (TBR) caused by differences in physical properties of the constituent materials in the composite. By this, it could be observed that a good fabrication technique can control TCR and good choice of reinforcement can handle TBR. All these form the basis of choosing SPS as the synthesis technique and CNTs/Nb as the reinforcements so as to generate a composite with enhanced thermal conductivity and tribology. Works on the enhancement of thermal and tribological properties of Al alloy using CNTs binary system abound in the literature. However, very few or none has looked into the synergistic effect that CNTs and Nb would have in the ternary composite system in improving its microstructure, thermal and tribological properties. Therefore, the aim of this study is to synthesize improved Al-CNTs-Nb composite using SPS and analyze its tribological and thermal characteristics for engineering application especially in the power transmission conductor and its core.

2 Experimental

2.1 Materials

Al1000 alloy powder with purity of 99.9% and particle size of 40 nm was the base metal. This was reinforced with multi-walled carbon nanotubes (MWCNTs) with purity of 99.5%, 10-30 nm in diameter, 5-20 μm in length and niobium nano powder with purity of 99.9% and 40-50 nm in particle size. Masses of the powders were weighed in accordance with the design of experiment (DOE) shown in Table 1 and mixed in a dry mode using a tubular shaker mixer at a rotation speed of 101 r/min for 10 h. Prior to this general blending of the whole powders, the CNTs were first disentangled by putting inside a bottle and shaking them inside the tubular shaker mixer for 7 h under a rotation speed of 69 r/min. Then, they were transferred into the container having other powders and blended together for another 10 h as stated above. Some steel balls (diameter of 6 mm) were incorporated into the powder container during the mixing operation (at the ball-to-powder ratio of 3:5) for a better dispersion of the CNTs and Nb reinforcements following CHIEH et al [15].

2.2 Taguchi design of experiment (DOE)

In the present work, SPS operation was designed with Taguchi (L9 32) orthogonal arrays as shown in Table 1. Two factors which included CNTs and Nb reinforcements were randomized at three levels of 1 wt.%, 4 wt.% and 8 wt.% to give a total of 9 experimental runs.

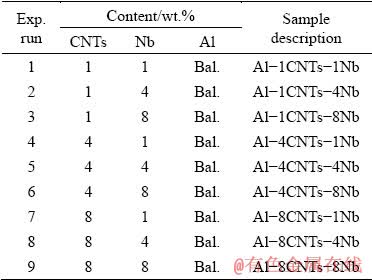

Table 1 Taguchi DOE for sintering Al-CNTs-Nb with sample description

2.3 Spark plasma sintering operation

SPS machine (KCE-FCT-HHPD 25, Germany) was initially calibrated with the following operating parameters: vacuum pressure of 60.5 Pa, relative pressure of -5×104 Pa, and an absolute pressure of 120 Pa. The as-mixed powders were weighed (using the guide of Table 1) as required for producing samples with 20 mm in diameter and 5 mm in thickness. The sintering parameters were initially optimized elsewhere [3] with optimal values of 630 °C, 30 MPa, 10 min and 200 °C/min and were used throughout the sintering process. The blended powder was weighed and put into a graphite die, pressed lightly with a hydraulic press and placed inside the sintering chamber. Subsequently, the sintering parameters were inputted into the machine to commence the operation. At the completion of sintering and cooling, the sample was removed from the die. For easy removal of sintered samples and reduction of a temperature gradient across the sample, graphite sheets were used to shield the powders from the die and also from the upper and lower punches. A total of 10 samples were produced, the 9 designed samples and 1 control sample of pure 100 wt.% Al alloy.

2.4 Microstructural characterization

The sintered samples were prepared for characterization by cutting, grinding with 120 grit sand paper, polishing with 0.3 μm fumed silica lubricant and emery cloth. They were etched with Keller’s reagent. Transmission electron microscope (JEOL, USA) was used to analyze the grain morphology of the start-up powder. Field emission scanning electron microscope (FE-SEM, TESCAN, Brno, Czech Republic) was used to analyze the microstructure of the sintered samples. Optical microscope (Olympus BX 53, Japan) was used to analyze the worn surfaces of the material.

2.5 Friction and wear tests

Transmission conductor and its core being developed have wear and friction challenges. During installation, they are pulled on the ground to expose to erosion and abrasion. In service, during expansion and contraction at peak temperature and off-peak temperature respectively, they rub against the connectors which induce erosion and abrasion on the points of contact. These two scenarios call for a wear resistant material for the conductor and its core. The 10 samples were prepared for wear test by cutting them to pieces with the sizes of 20 mm × 20 mm × 2 mm, ground with 120-grit size sand- paper and polished with 320 grit size emery sandpaper and 0.1 μm fumes silica lubricant. The test was conducted at room temperature and based on dry sliding mode using a ball-on-disc tribometer (RTEC 2441, USA) connected to software that generates the COF of the samples. The ball is made of Grade 25 alloy steel E52100, with 6.35 mm in diameter. The ball holder points normal to the sample holder fixed firmly on a disc. The sliding distance of the machine (stroke length) and sliding velocity were set to be 5 mm and 3 mm/s, respectively. Time was 60 s, and normal loads of 10, 20 and 30 N were systematically applied. The masses of the sample before and after wear test were used to compute the wear volume as shown below

Vw=(m1–m2)/ρ (1)

where Vw (mm3) is the wear volume, m1 (g) and m2 (g) are masses obtained before and after wear test, respectively, and ρ (g/cm3) is the actual density of the composite material. The machine generates the coefficient of friction of the samples automatically. The wear rate is obtained with the following equation:

η=V/t (2)

where η is the wear rate (mm3/s); V is the wear volume (mm3) and t is the time (s).

2.6 Thermal conductivity test

A laser flash apparatus (LFA 427) connected to the NETZSCH Proteus software, USA, was used in this test. The samples were cut to smaller dimensions of 10 mm × 10 mm × 4 mm. The samples were polished and coated with graphite to enhance thermal conductivity, diffusivity and absorptivity. The test was run in an argon atmosphere, with laser voltage of 450 V and laser pulse width of 0.8 ms. The thermal diffusivity of each sample was gotten by sending a laser (energy pulse) to the surface of a sample and generating the time interval for the energy to reach other side of the sample, and recording the value. The thermal conductivity was computed with the relationship between the diffusivity, specific heat capacity and density of the material given in Eq. (3):

λ=αρcp (3)

where λ is the thermal conductivity (W/(m·K)), α is the thermal diffusivity (m2/s) (given by the machine), ρ is the density of the composite (kg/m3), and cp is the specific heat capacity of the material (J/(kg·K)).

2.7 Thermogravimetric analysis (TGA)

A TGA (Universal V4.5A TA Instruments, Japan) was used to test the thermal stability of the sintered samples. The samples’ masses were cut down to 5-10 mg. The test was conducted in nitrogen environment, a temperature range of 27-1000 °C and time of 120 min. The mass response of the samples to temperature increase was obtained.

3 Results and discussion

3.1 Microstructure

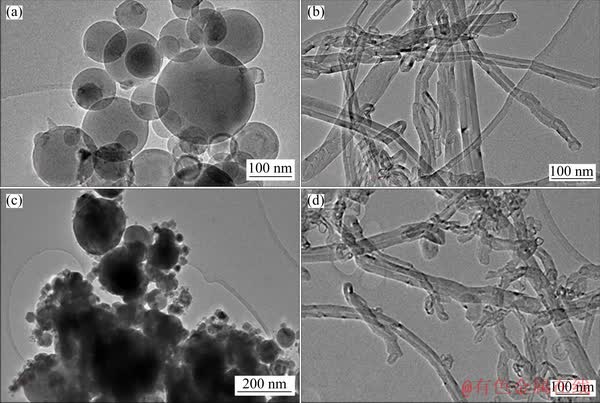

Figure 1 shows the TEM micrographs of the as-received powders. It can be seen that the nano particles are clustered (Figs. 1(a) and (c)) which may be from packaging and that is why they were blended for 10 h with steel balls in a tubular mixer to disperse the particles and homogenize the mixture. In Fig. 1(b), CNTs can be seen to be heavily entangled with one another. But when they are subjected to rigorous shake-up with tubular shaker for 7 h, they are able to disentangle as can be seen in Fig. 1(d), being looser than before, thus creating a room for better blending with other powders.

Fig. 1 TEM images of as-received powders of Al (a), CNTs (b), Nb (c) and CNTs shaken with tubular shaker mixer (d)

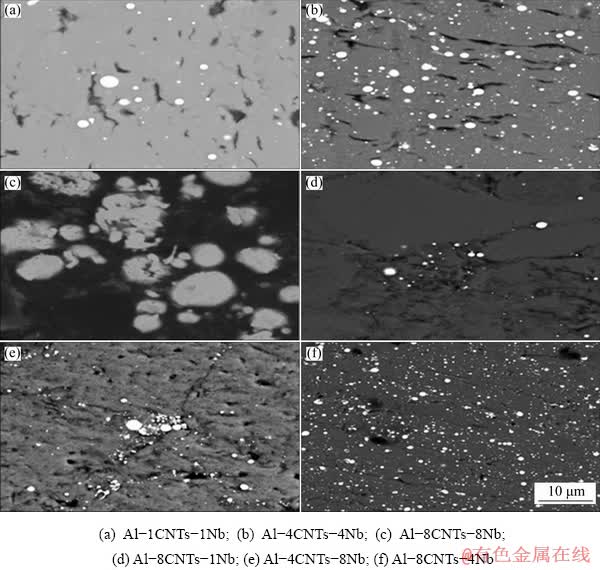

Figure 2 shows SEM micrographs of some sintered samples. It can be seen that the grain sizes were highly refined. They became smaller in size. This can be attributed to the grain refining propensity of SPS and Nb reinforcement [2-4]. In the micrograph, the white grains are the Nb particles while the dark coil-like objects are the CNTs. There is homogenous dispersion of reinforcements in most of the microstructures, though there is agglomeration of reinforcements in Fig. 2(e) (Al-4CNTs-8Nb). The microstructures give good fused grain boundaries with the absence of pores except for Fig. 2(d) (Al-8CNTs-1Nb) that has pores in the microstructure. The defect in Fig. 2(d) (micro pores) may be due to the low mass fraction of Nb which is a grain growth inhibitor.

3.2 Tribology results

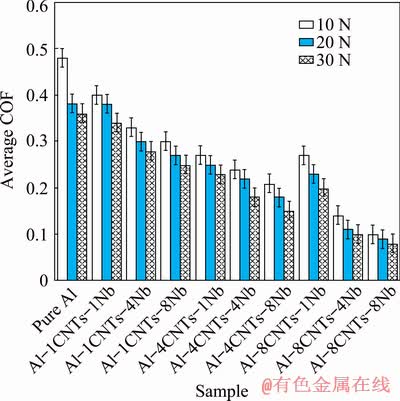

Figure 3 shows the coefficient of friction (COF) of pure Al and Al-CNTs-Nb composites subjected to dry sliding wear test at three loads of 10, 20 and 30 N, respectively. It can be seen that pure Al had the highest COF at the three loads while Al-8CNTs-8Nb had the least COF. The addition of 8 wt.% CNTs and 8 wt.% Nb to Al alloy decreased its COF by 79% (from 0.48 to 0.10 at applied load of 10 N). The decrease could be as a result of the solid lubrication property of CNTs [7] and the ability of Nb to form an oxide layer of Nb2O5 that acts as a solid lubricant too [11]. This was, likewise, observed in Ref. [16] where the COF of the matrix was 0.6 while the reinforced composite had COF of 0.26 because reinforcement reduced COF. It can be observed that the COF decreased with the increase in the applied load. This was because when the load increased, the heat generated increased as well, thereby softening the material and subsequently reducing the COF [7]. Moreover, Amonton’s first law of static friction states that COF is inversely proportional to the applied load (μ=F/R), where μ is the COF, F is the frictional force and R is the applied load. However, WANG et al [9] and YILMAZ [10] had a contrary view where they stated that COF increased with increase in applied load.

Fig. 2 SEM images of different sintered samples

Fig. 3 Average COF values of pure Al and Al-CNTs-Nb samples at applied loads of 10, 20 and 30 N

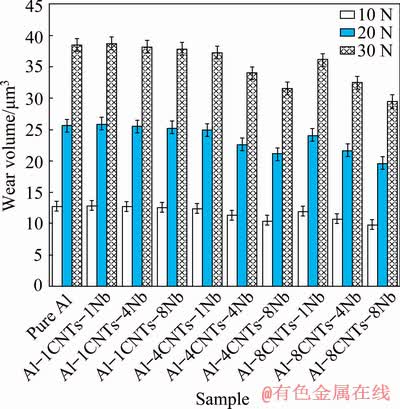

Figure 4 shows plot of wear volumes of the samples. It could be seen that the highest worn sample was pure Al while the least worn sample was Al-8CNTs-8Nb with a decrease of 23% (from 38.4 to 29.4 μm3 at applied load of 30 N). The decrease could be because the harder asperities of the reinforcements prevented the rubbing-off of the test material in contact with the steel ball as harder asperities reduced wear volume [10]. Moreover, Al reinforced with CNTs would experience a film of carbon which acted as a trilayer between the composite and the sliding ball which would reduce the contact of both, thereby reducing the wear volume of the reinforced composite [5,7]. Also, the Nb contributed to the reduction in the wear volume of reinforced samples since it was able to refine the grains since grain growth induced coarse and porous microstructure which made delamination easy and subsequently increased wear volume [2].

The fabrication method together with the optimized parameters contributed to the improvement in the wear volume reduction. This was because SPS had always been linked with improved microstructure, wear and friction properties [3,4]. Meanwhile, it could be observed that the wear volume increased when the applied load increased [9]. This could be because when the applied load increased, the asperities tended to penetrate more deeply into the surface of the material, causing more removal of the material [9]. Moreover, increased applied load tended to increase the shear force which acted on the surfaces, inducing higher removal of materials [10]. In addition, Archard’s law of wear volume stated that wear loss was proportional to the applied load, sliding distance and wear coefficient [17], hence, the higher the load was, the more the wear volume was. In the same vein, this could be likened to the observation made by YIN et al [18] where the wear volume increased with increase of the impact velocity because higher velocity increased material damage. The sudden increase in the wear volume of Al-8CNTs-1Nb in Fig. 4 could be linked with the porosity experienced in its microstructure in Fig. 2(d) which was the nucleating ground for most imperfections.

Fig. 4 Wear volume plots of pure Al and Al-CNTs-Nb composite samples at applied loads of 10, 20 and 30 N

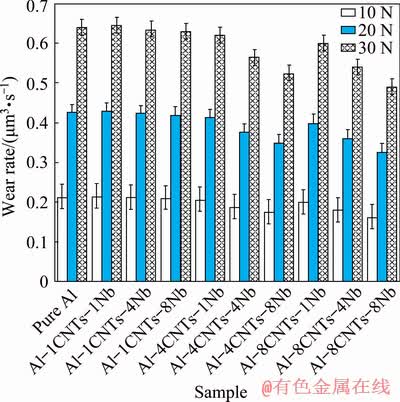

Figure 5 shows the wear rate plot of pure Al and Al-CNTs-Nb composite samples. Just like the wear volume, the wear rate was the highest for pure Al and the least for Al-8CNTs-8Nb. This gave a decrease of 23% as well (from 0.64 to 0.49 μm3/s). It could equally be observed that the wear rate increased when the applied load increased. This was also observed in Refs. [7,9,10]. The addition of CNTs and Nb into Al alloy improved the wear rate because the reinforcements increased the hardness of the material, improved grain boundaries bonding and refined microstructure devoid of micro pores [3,4].

Fig. 5 Wear rate plots of pure Al and Al-CNTs-Nb composite samples at applied loads of 10, 20 and 30 N

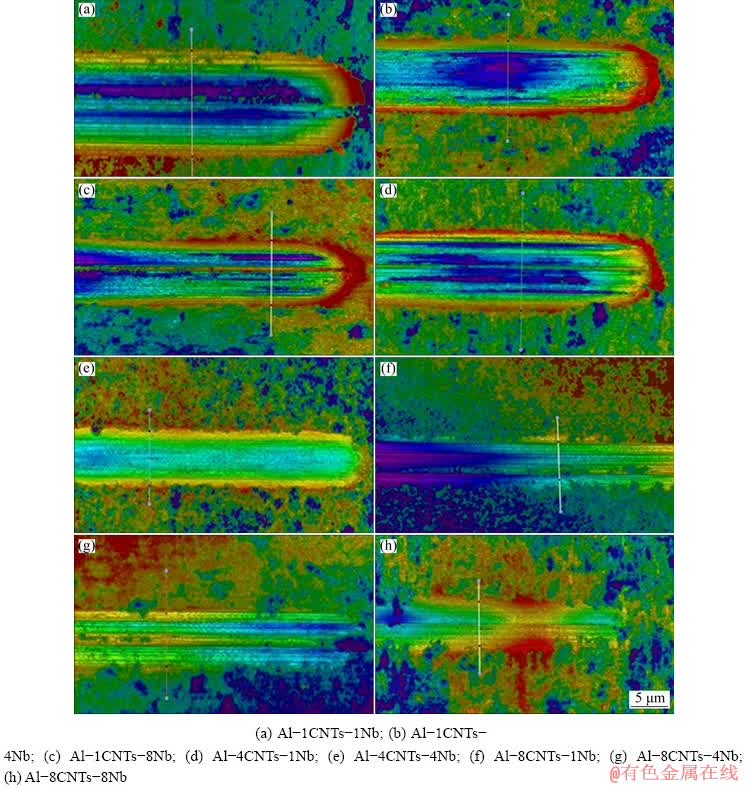

Figure 6 shows optical images of the wear track morphology of the samples loaded with 20 N. The observed wear mechanism included abrasive and adhesive wear. Figures 6(a-d) reveal some aggressive material removal with wide wear tracks. The ploughed debris was found to be sticking to the wear track; hence, these would be considered as adhesive wear.

Fig. 6 Optical images of wear track of sintered samples at applied load of 20 N

The wide wear tracks only implied that the samples were poor in tribology. The poor tribology may be because they have low mass fraction of CNTs. If mass fraction of the CNTs reinforcement was higher, it could have improved the hardness and wear resistance of the samples by obstructing dislocations, vacancies and other imperfection such as heavy wear loss [5]. Figures 6(e-h) show the abrasive wear tracks with less severity when compared with other samples described above. This could be due to the presence of sufficient CNTs and Nb reinforcements. It is thought that the sufficient reinforcements improved the wear resistance by eliminating porosity and increasing the hardness of the asperities [4,5]. It can be seen that Al-8CNTs-8Nb, shown in Fig. 6(h), had the lightest and narrowest wear track, which implied that it had the best wear characteristics. This was because it had excellent microstructure (Fig. 2(c)) with tightly bonded grains without micro pores.

3.3 Thermogravimetric analysis result

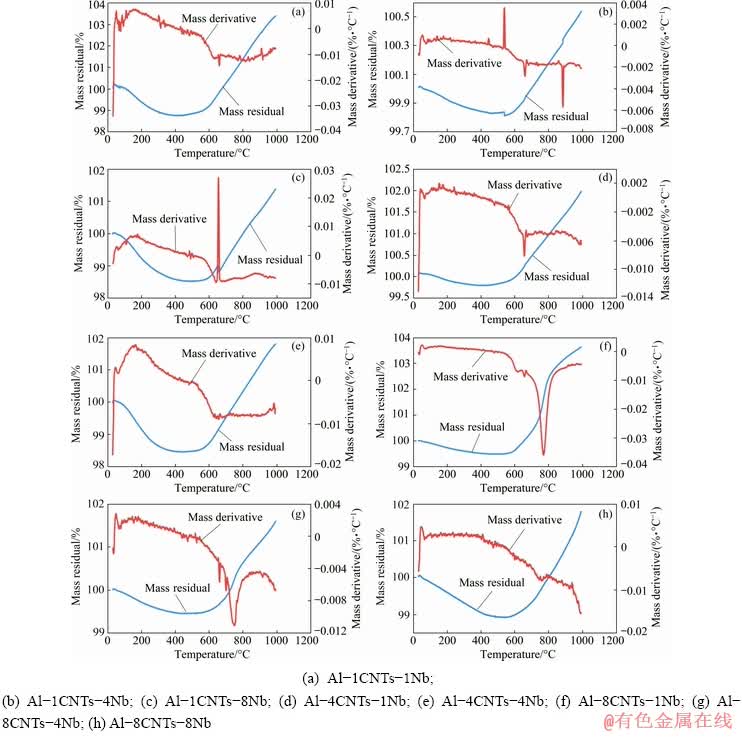

Fig. 7 Plots of mass residual and mass derivative versus temperature of sintered samples

Figure 7 shows TGA curves where the mass fraction of the composites is plotted against the temperature. This test helps to determine the stability of composites with respect to temperature increase. Thermally stable composites were determined by the nature of curves they produced. When their derivative curves (red lines) are without sharp peaks which depict oxidation, diffusion or thermal degradation, the samples are stable. It can be seen that Fig. 7(a) had smooth curves in both mass fraction and mass derivative, meaning that it was thermally stable. In Fig. 7(b) (Al-1CNTs-4Nb), there were sharp peaks at 500, 600 and 900 °C. Those peaks meant that there was thermal degradation at those temperatures. This could have been oxidation, diffusion or release of crystallized water. That made the sample thermally unstable. This is because that will be its response to temperatures if such a mass fraction is used to develop a conductor core. Samples that showed thermal stability include Al-1CNTs-1Nb, Al-4CNTs-4Nb and Al-8CNTs-8Nb. Their thermal stability can be attributed to the equal mass fractions of the reinforcements which supported homogenous dispersion of the reinforcements in their matrices, grain refinement and cohesive bonding of matrix/reinforcement interface [3,4,14]. The homogenous dispersion of reinforcements controlled the scattering of phonons, cohesive matrix/reinforcement interface reduced interfacial thermal resistance (ITR), which all synergized to improve the thermal properties. The microstructures of these three thermally stable composites could be seen in Figs. 2(a-c) to be made of refined and homogenously dispersed grains. The thermally unstable samples could also be judged from their microstructures. For instance, Al-8CNTs-1Nb decomposed at 790 °C, which could have been caused by poor dispersion of reinforcements that resulted in the agglomeration and subsequent growth of micro pores as observed in the microstructure (Fig. 2(d)).

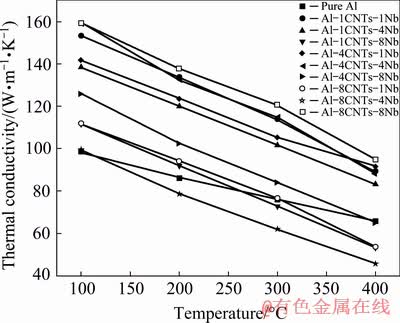

3.4 Thermal conductivity

Figure 8 shows the thermal conductivity of different samples. It could be seen that there was downward trend of the thermal conductivity as the temperature increased. This could be attributed to the scattering effect of electrons and phonons by the composite particles when agitated by the temperature rise [19]. However, the average thermal conductivity of pure Al was 89 W/(m·K) while the best thermally conductive composite was Al-8CNTs-8Nb with average thermal conductivity of 128 W/(m·K). This gave an improvement of 44%. The improvement obtained with higher mass fractions of CNTs and Nb can be explained by the fact that Nb is a superconductor and CNTs has a very high thermal conductivity, and both have the tendency of precipitating more crystals from the solid solution which boost the thermal conductivity. Judging from their microstructures, it can be seen that Al-8CNTs-8Nb had a compact grain boundaries (Fig. 2(c)), which helped in reducing the thermal resistivity of matrix/reinforcement interface as reported in Refs. [12,13,19]. However, the improvement goes in contradiction to MOHAND et al [13] who observed that reinforced alloys had lower conductivities than the metal matrix. In the present work, reinforced composite had higher conductivity than the matrix alloy.

Fig. 8 Thermal conductivity of different samples

4 Conclusions

(1) There was grain refinement and fairly homogenous dispersion of reinforcement in the matrix which induced improvements in the properties tested. The dispersion was enhanced by the turbular mixing of the powders and the SPS technique. However, the blending of CNTs with turbular mixer did not achieve total dispersion of the reinforcement. Therefore, other techniques are recommended.

(2) There was improvement in the tribological characteristics of Al-8CNTs-8Nb composite. The COF was decreased by 79% while wear volume and wear rate were decreased by 23% each. The COF decreased with increase in the applied load, while the wear volume and the wear rate increased with increase in the applied load. Hence, the addition of CNTs and Nb enhanced the tribological properties of Al matrix because the solid lubrication property of CNTs and the ability of Nb to form a protective oxide layer of Nb2O5 imparted positively on the samples.

(3) The thermal characteristics of Al alloy was improved with the addition of CNTs and Nb. The thermal stability of three samples, Al-1CNTs-1Nb, Al-4CNTs-4Nb and Al-8CNTs-8Nb were confirmed by the TGA to be good. Moreover, the thermal conductivity of Al-8CNTs-8Nb was the highest with an improvement of 44% and this was attributed to the ability of the composition to precipitate a high mass fraction of atoms from the solid solution in order to have more free electrons and phonons required for thermal conductivity.

(4) The SPS-treated Al-CNTs-Nb composite has shown its potential properties as a robust material for high transmission conductor with good microstructure, good tribological and thermal properties. It has better properties when compared to the conductors presently in use, and it will ameliorate the challenges of sag, wear and abrasion squarely.

Acknowledgments

The authors do hereby acknowledge Centre for Energy and Electric Power (CEEP), Tshwane University of Technology, Pretoria, NRF and DHET for providing financial aid to this project. There is no conflict of interest in the course of this work.

References

[1] GEORGE R, KASHYAP K T, RAHUL R, YAMDAGNI S. Strengthening in carbon nanotube-aluminium (CNT/Al) composites [J]. Scripta Materials, 2005, 53: 1159-1163.

[2] SAIRAM K, SONBER J K, MURTHY T S R C, SUBRAMANIAN C, FOTEDAR R K, NANEKAR P, HUBLI R C. Influence of spark plasma sintering parameters on densification and mechanical properties of niobium diboride (NbB2) [J]. Refractive Metals and Hard Materials, 2014, 42: 185-192.

[3] UJAH C O, POPOOLA A P I, POPOOLA O M, AIGBODION V S. Optimisation of spark plasma sintering parameters of Al-CNTs-Nb nano-composite using Taguchi design of experiment [J]. Advanced Manufacturing Technology, 2019, 100: 1563-1573. https://doi.org/10.1007/ s00170-018-2705-3.

[4] XIE G, OHASHI O, SONG M, FURUYA K, NODA T. Behaviour of oxide film at the interface between particles in sintered Al powders by pulsed electric-current sintering [J]. Metallurgical and Materials Transactions A, 2003, 34: 699-703.

[5] SELVAKUMAR N, GANGATHARAN K. Electrical resistivity, tribological behaviour of multi walled carbon nanotubes and nano boron carbide particles reinforced copper hybrid composites for pantograph application [J]. Advanced Material Science and Engineering, 2016, 2016: 1-18. Article ID 3432979. http://dx.doi.org/10.1155/2016/ 3432979.

[6] BEDIR F. Characteristic properties of Al-Cu-SiCp and Al-Cu-B4Cp composites produced by hot pressing method under nitrogen atmosphere [J]. Materials & Design, 2007, 28: 1238-1244.

[7] ABOUBAKREL S, KAMEL B M, KHATTAB A, OSMAN T A, AZZAM B, ZAKI M. Improved mechanical and tribological properties of A356 reinforced by MWCNTs [J]. Fullerene, Nanostructures and Carbon Nanostructures, 2018, 26: 185-194. DOI:10.1080/1536383X.2017.1415888.

[8] ZHOU S, ZHANG X, DING Z, MIN C, XU G, ZHU W. Fabrication and tribological properties of carbon nanotubes reinforced Al composites prepared by pressure less infiltration technique [J]. Composites Part A-Applied Sciences, 2007, 38: 301-306.

[9] WANG Y Q, AFSAR A M, JANG J H, HAN K S, SONG J I. Room temperature dry and lubricant wear behaviors of Al2O3f/SiCp/Al hybrid metal matrix composites [J]. Wear, 2010, 268: 863-870.

[10] YILMAZ S O. Comparison on abrasive wear of SiCrFe, CrFeC and Al2O3 reinforced Al2O24 MMCs [J]. Tribology International, 2007, 40: 441-452.

[11] DEMIRKOL N, OKTAR F N, KAYALI E S. Influence of niobium oxide on the mechanical properties of hydroxyapatite [J]. Engineering Materials, 2013, 529-530: 29-33. DOI:10.4028/www.scientific.net/KEM.529-530.29.

[12] RAMIREZ A M, ESPINOZA J B, YANEZ-LIMON J M, VOROBIEV Y V, GONZALEZ-HERNANDEZ J. Effects of porosity on the thermal properties of a 380-aluminum alloy [J]. Materials Research, 1999, 14: 10-19.

[13] MOHAN K S A, SHRIDHAR T N, KRISHNAMURTHY L. Experimental investigations on thermal analysis and thermal characterization of Al 6061-SiC-Gr hybrid metal matrix composites [J]. Materials Science, 2015, 5: 2-9. DOI: 10.12783/ijmsci.2015.0502.04.

[14] PIETRAK K, WISNIEWSKI T S. A review of models for effective thermal conductivity of composite materials [J]. Powder Technology, 2015, 95: 14-24.

[15] CHIEH K, TE T, KUO H, KUO Y C, MING S C. The influences of powder mixing process on the quality of W-Cu Composites [J]. Transactions of the Canada Society for Mechanical Engineering, 2009, 33: 3-11.

[16] WANG Jian-ying, FANG Jing-hua, YANG Hai-lin, LIU Zhi-lin, LI Rui-di, JI Shou-xun, WANG Yun, RUAN Jian-ming. Mechanical properties and wear resistance of medium entropy Fe40Mn40Cr10Co10/TiC composites [J]. Transactions of Nonferrous Metals Society of China, 2019, 29: 1484-1494.

[17] ARCHARD J F. Contact and rubbing of flat surfaces [J]. Applied Physics, 1953, 24: 981-988.

[18] YIN Mei-gui, CAI Zhen-bing, LI Zhen-yang, ZHOU Zhong-rong, WANG Wen-jian, HE Wei-feng. Improving impact wear resistance of Ti-6Al-4V alloy treated by laser shock peening [J]. Transactions of Nonferrous Metals Society of China, 2019, 29: 1439-1448.

[19] BAUDOUY B, FOUR A. Low temperature thermal conductivity of aluminium alloy 5056 [J]. Cryogenics, 2014, 34: 67-75. DOI: 10.1016/j.cryogenics.2013.12.008.

Chika O. UJAH1, Patricia POPOOLA1, Olawale POPOOLA2, Victor AIGBODION1,3, Philip OLADIJO4,5

1. Department of Chemical, Metallurgical and Materials Engineering, Tshwane University of Technology, Pretoria 0001, South Africa;

2. Department of Electrical Engineering, Tshwane University of Technology, Pretoria 0001, South Africa;

3. Department of Metallurgical and Materials Engineering, University of Nigeria, Nsukka 410001, Nigeria;

4. Department of Chemical, Materials and Metallurgical Engineering, Botswana International University of Science and Technology, Palapye 12345, Botswana;

5. Department of Mechanical Engineering, University of Johannesburg, Johannesburg 2000, South Africa

摘 要:用放电等离子体烧结法(SPS)制备铝合金,以碳纳米管(CNTs)和Nb纳米颗粒作为增强相,提高合金的摩擦性能和热性能。SPS工艺参数为:630 °C、30 MPa、10 min和200 °C/min。而且,以钢球为对磨件,采用球-盘式摩擦试验机对样品进行摩擦学试验。用热重分析仪(TGA)和激光导热仪(LFA)进行热性能分析。结果表明,分别添加8 wt.% 的CNTs和Nb纳米颗粒使复合材料的摩擦因数(COF)降低79%。磨损量和磨损率也降低23%,且复合材料的热导率提高44%。摩擦性能的改善是由于CNTs的加入导致材料表面形成C薄膜,以及由于Nb纳米粉末的加入而生成起保护作用的Nb2O5。导热性能的改善是由于Nb的晶粒细化作用和CNTs的高导热性。因此,这些结果表明,Al-CNTs-Nb 复合材料是高压输电导线用的坚固材料,能够减小下垂并保证材料的使用寿命。

关键词:摩擦;热导率;放电等离子体烧结;Al-CNTs-Nb复合材料;摩擦因数

(Edited by Wei-ping CHEN)

Corresponding author: Chika O. UJAH; E-mail: omega.ujah@gmail.com

DOI: 10.1016/S1003-6326(20)65216-5