Influence of serpentine channel pouring process parameters on semi-solid A356 aluminum alloy slurry

CHEN Zheng-zhou, MAO Wei-min, WU Zong-chuang

School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China

Received 28 June 2010; accepted 8 October 2010

Abstract: Semi-solid A356 aluminum alloy slurry was prepared by using serpentine channel pouring process, and the influences of the channel diameters and pouring temperatures on the semi-solid A356 aluminum alloy slurry were investigated. The experimental results show that when the channel diameter is 20 and 25 mm, respectively, and the pouring temperature is 640-680 °C, the average diameter of primary α(Al) grains in the prepared A356 aluminum alloy slurry is 50-75 and 55-78 μm, respectively, and the average shape factor of primary α(Al) grains is 0.89-0.76 and 0.86-0.72, respectively. With the decline in the pouring temperature, the microstructure of semi-solid A356 aluminum alloy slurry is more desirable and a serpentine channel with smaller diameter is also advantageous to the microstructure improvement. During the preparation of semi-solid A356 aluminum alloy slurry, a large number of nuclei can be produced by the chilling effect of the serpentine channel, and owing to the combined effect of the chilled nuclei separation and melt self-stirring, primary α(Al) nuclei can be multiplied and spheroidized finally.

Key words: semi-solid; A356 aluminum alloy; serpentine channel; primary α(Al)

1 Introduction

Semi-solid forming of metals offers numerous advantages over the conventional liquid forming of metals, such as reduction of solidification shrinkage, lower processing temperature, improved mechanical properties and prolonged die life[1]. The key in semi-solid forming technology is to produce metal slurry with non-dendritic microstructure. A number of slurry preparation methods have been developed, among which the controlled nucleation method[2-3] has received a lot of attention. A controlled nucleation method does not need any stirring and is simple, practical and inexpensive. According to this theory, several practical techniques have been developed, including the inclined cooling plate[4-6], rotating duct[7], cooling chute process[8] and DCT-damper cooling tube method[9-10]. The liquid alloy is poured over an inclined plate or into a tube in these techniques so that the nucleation can occur during the liquid flow, and then the produced fine primary phase is spheroidized by controlling the process parameters.

In this work, an innovative processing technique of semi-solid metal slurry, namely the serpentine channel pouring process, is introduced, and the effects of pouring process parameters on the microstructure of semi-solid A356aluminum alloy slurry are investigated.

2 Experimental

In the experiment, a commercial A356 aluminum alloy was used. Its chemical composition is Si 7.1%, Mg 0.31%, Fe <0.20%, Mn <0.10%, Zn <0.10% and balance Al. Its liquidus temperature is 615 °C, and the binary eutectic temperature is 577 °C.

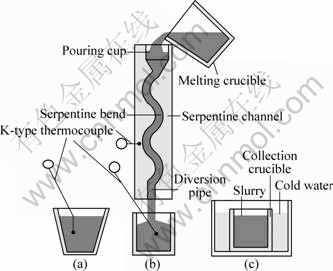

The serpentine channel was made of graphite and consisted of a pouring cup, four bends and a diversion pipe. The melting equipment was a crucible resistance furnace. The collection crucible was made of stainless steel, and its dimension was d127 mm×250 mm. A Ni-Cr/Ni-Si thermocouple was used to measure the temperatures of the liquid aluminum alloy, the serpentine channel inner wall and the semi-solid slurry. The temperature displaying accuracy was ±1 °C. The schematic of the slurry preparation process is shown in Fig.1 and the process parameters are shown in Table 1. The serpentine channel and the collection crucible were at room temperature (18 °C) before slurry preparation.

Fig.1 Schematic diagram of preparing semi-solid A356 Al-alloy slurry by serpentine channel pouring process: (a) Controlling superheat of A356 Al-alloy; (b) Preparing semi-solid A356 Al-alloy slurry; (c) Quenching slurry

The metallographic specimens were cut from the centre of the quenched slurries and then roughly ground, finely ground, polished and etched with 0.5% HF aqueous solution finally. The metallographic specimens were investigated with a Neuphoto 21 optical microscope. The diameter of primary α(Al) grains was directly measured with the microscope, and the shape factor of primary α(Al) grains was calculated as:

F=4πA/P2 (1)

where A and P represent the area and perimeter of a grain, respectively.

3 Results and discussion

3.1 Microstructure of quenched slurry

When the A356 aluminum alloy melts flow into the collection crucible from the diversion pipe, the slurry temperature (the measured positions are shown in Fig.1) varies between the liquidus and the binary eutectic temperature, as listed in Table 1, which indicates that the

A356 aluminum alloy melts have become semi-solid slurries.

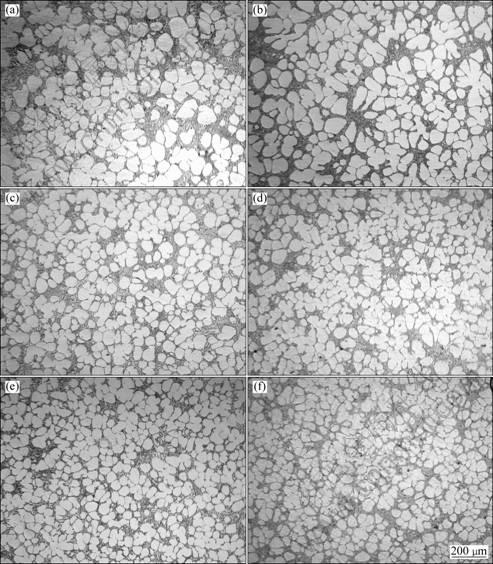

Figure 2 shows the microstructures of these quenched slurries. The shape factor and the grain diameter of the primary α(Al) grains are listed in Table 1. In the experiments, two serpentine channels with diameters of 20 and 25 mm were used. When the liquid A356 aluminum alloy is poured at 680 °C, the primary α(Al) grains are mainly spherical and near-spherical ones with a small amount of rosette, as shown in Figs.2(a) and (b). The shape factor and the grain diameter of primary α(Al) grains are 0.76, 0.72 and 75, 78 μm, respectively. When the liquid A356 aluminum alloy is poured at 660 °C, the primary α(Al) grains are still spherical and near-spherical ones with a slight amount of rosette, as shown in Figs.2 (c) and (d). The shape factor of primary α(Al) grains increases to 0.86 and 0.82, respectively, and the grain diameter is reduced to 55 and 60 μm, respectively. When the liquid A356 aluminum alloy is poured at 640 °C, most primary α(Al) grains are spherical, as shown in Figs.2(e) and (f). The shape factor and the grain diameter of the primary α(Al) grains reach 0.89, 0.86 and 50, 55 μm, respectively. The results show that if both the pouring temperature and channel diameter are reasonable, excellent semi-solid A356 aluminum alloy slurry can be produced by serpentine channel pouring process.

3.2 Influence of pouring temperature on slurry microstructure

Based on different preparation processes, the influence of pouring temperature on the microstructure of semi-solid alloy slurry was investigated[11-13]. In order to further understand the formation of spherical primary α(Al) grains during the serpentine channel pouring process, the influence of pouring temperature on the microstructure of the semi-solid A356 aluminum alloy slurry was discussed.

As shown in Fig.2, when the serpentine channel has the same diameter, the primary α(Al) grains become more spherical and finer with decreasing pouring temperature. It is generally believed that the lower the superheat of the alloy melt is, the shorter the time needed for the liquid alloy to reach the liquidus temperature. Therefore, the alloy melt in the serpentine channel has more time to nucleate by the chilling effect of the serpentine channel and can produce more primary α(Al) nuclei. Many studies showed that sufficient primary α(Al) nuclei in the semi-solid metal slurry is the necessary condition for the primary α(Al) nuclei to further spheroidize and prevent from growing too large[14].

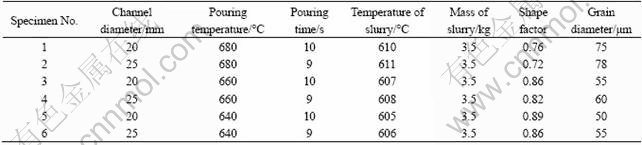

Table 1 Processing parameters and characteristic size of semi-solid slurries

Fig.2 Microstructures of quenched semi-solid A356 aluminum alloy slurries prepared by serpentine channel pouring process under conditions of different channel diameters and pouring temperatures: (a) 20 mm, 680 °C; (b) 25 mm, 680 °C; (c) 20 mm, 660 °C; (d) 25 mm, 660 °C; (e ) 20 mm, 640 °C; (f) 25 mm, 640 °C

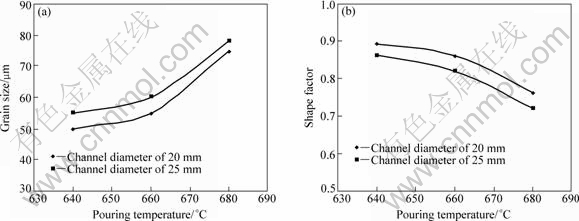

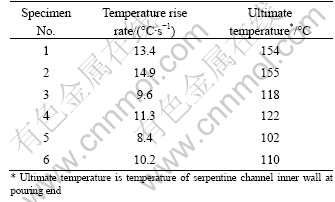

Comparing the microstructure of A356 alloy poured at 680 °C with that poured at 660 °C, it is seen that the grain diameter and shape factor of the primary α(Al) grains vary a little sharply. However, when the pouring temperature changes from 660 to 640 °C, the relevant variation is somewhat gentle, as shown in Fig.3. It indicates that this variation may have certain relationship with the temperature rise rate of the serpentine channel inner wall. The measured position for the serpentine channel temperature is shown in Fig.1. Figure 4 shows the curves of temperature of the serpentine channel inner wall vs the pouring time. It can be seen that the temperature rise rate of the serpentine channel inner wall increases with increasing pouring temperature. If the channel diameter is 20 mm and the pouring temperatures are 680, 660 and 640 °C, respectively, the temperature rise rates of the serpentine channel inner wall are 13.4, 9.6 and 8.4 °C/s, respectively, as shown in Table 2. The change of the temperature rise rate is 3.8 °C/s when the pouring temperature changes from 680 to 660 °C. However, the change of the temperature rise rate is 1.2 °C/s in the case that the pouring temperature changes from 660 to 640 °C.

Fig.3 Curves of pouring temperature vs grain diameter (a) and shape factor (b)

Fig.4 Curves of channel wall temperature vs pouring time with different channel diameters: (a) 20 mm; (b) 25 mm

Table 2 Temperature rise rate and ultimate temperature of serpentine channel inner wall

The chilling ability of the graphite channel is affected by its temperature. The higher the temperature of the graphite channel is, the weaker its chilling ability is. If the temperature rises faster, it is deteriorated faster. Based on the analysis, the former (from 660 to 680 °C) changes faster or more obviously, so the number of primary α(Al) grains in the semi-solid slurry changes faster as well and the changes of the grain diameter and shape factor are more markedly. When the channel diameter is 25 mm, the relevant change is also similar.

The higher the pouring temperature is, the faster the temperature rise rate of the serpentine channel inner wall is, and the higher the ultimate temperature of the serpentine channel inner wall is. As a result, the chilled nuclei can be reduced more markedly, and thus the morphology and size of the primary α(Al) grains are not satisfactory. Relevant studies also showed that the more the chilled nuclei in the semi-solid slurry are, the more desirable the microstructures of the primary grains are[15-16].

3.3 Influence of channel diameter on slurry microstructure

When the A356 aluminum alloy melt flows along the serpentine channel inner wall, copious chilled primary α(Al) nuclei are generated in the alloy melt layer contacting directly the inner wall. Then most or part of the chilled nuclei could separate from the inner wall and go into the melt because of the combined effect of alloy melt flowing motion and temperature fluctuation. Meantime, the alloy melt is continuously cooled during flowing, its temperature gradually decreases below the liquidus temperature, and most of the separating nuclei could survive and become the main part of the final multiplied nuclei in the alloy melt. So a wealth of multiplied nuclei in the A356 alloy melt is the main requirement for the transformation of spherical grains. But another part of the chilled nuclei may remain on the inner surface of the serpentine channel and grow up, and a layer of thin solidified shell can form.

It can be seen from Table 1 that when the pouring temperature is the same, the microstructure of the primary α(Al) grains is better with smaller channel diameter, because several advantages can be obtained as the channel diameter is reduced. Firstly, if the pouring temperature and the prepared slurry mass are the same, the pouring time can be longer, and the superheat and the latent heat of the A356 aluminum alloy can be easily absorbed by the channel, as a result, there will be more chilled nuclei. Secondly, the separating time for the chilled nuclei is longer and there will be more separating nuclei in the melt. Finally, the self-stirring effect of the melt in the serpentine channel is also more intense and it is helpful for the separating nuclei to spheroidize and distribute homogeneously. Based on the advantages mentioned, the channel diameter should be designed in a reasonable range.

4 Conclusions

1) When the channel diameter is 20 and 25 mm, and the pouring temperature is 640-680 °C, the average diameter of primary α(Al) grains in the prepared A356 aluminum alloy slurry is 50-75 μm and 55-78 μm, respectively, and the average shape factor of primary α(Al) grains is 0.89-0.76 and 0.86-0.72, respectively.

2) With the decreasing pouring temperature, the microstructure of semi-solid A356 aluminum alloy slurry is more desirable and a serpentine channel with smaller diameter is advantageous to the microstructure improvement.

3) During the preparing process of semi-solid A356 aluminum alloy slurry, a large number of nuclei can be produced by the chilling effect of the serpentine channel, and owing to the combined effect of chilled nuclei separating and melt self-stirring, primary α(Al) nuclei can be multiplied and spheroidized finally.

References

[1] ATKINSON H V. Modeling the semisolid processing of metallic alloys [J]. Prog Mater Sci, 2005, 50(3): 341-412.

[2] WANG H, St JOHN D H, DAVIDSON C J, NING Z. Controlled nucleation method for formation of feedstock [C]//ALEXANDROU A, APELIAN D. Proc of the 8th Int Conf on the Processing of Semi-Solid Alloys and Composite. Limassol, Cyprus: Worcester Polytechnic Institute, 2004: 269-276.

[3] APELIAN D, PAN Q Y, FINDON M. Low cost and energy efficient methods for the manufacture of semi-solid (SSM) feedstock [J]. Die Casting Engineer, 2004(1): 22-29.

[4] MEHRARA H, NILI AHMADABADI M, ASHOURID S, GHISINEJAD J. Modeling of inclined cooling plate semisolid processing by model alloy [J]. Diffusion and Defect Data Part B (Solid State Phenomena), 2008, 141-143: 785-790.

[5] KIDO F, MOTEGI T. Production of magnesium alloy billets by semisolid continuous casting [J]. Mater Sci Forum, 2009, 610-613: 1403-1406.

[6] TAN Jian-bo, LI Zhi-yong, WANG Ying-jie, LIU Jiang-cheng, GU Chao, ZHANFG Jiang-chao. Effects of parameters of incline cooling and shearing on microstructures of semi-solid AlSi9Mg alloy [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(4): 607-612. (in Chinese)

[7] GUO H M, YANG X J, HU B. Rheocasting of aluminum alloy A356 by low superheat pouring with a shear field [J]. Acta Metallurgica (Letters), 2006(5): 328-334.

[8] THAGA T, KAPRANOS P. Simple rheocasting processes [J]. J Mater Process Technol, 2002, 130-131: 594-598.

[9] YANG Hao-qiang, XIE Shui-sheng, LI Lei, HUANG Guo-jie. Numerical simulation and parameters optimization of preparation of AZ91D magnesium alloy semi-solid slurry by damper cooling tube method [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 488-494. (in Chinese)

[10] ZHANG Xiao-li, XIE Shui-sheng, LI Ting-ju, YANG Hao-qiang, JIN Jun-ze. A356 aluminum alloy semisolid slurry prepared by damper cooling tube process [J]. Rare Metal Materials and Engineering, 2007, 36(5): 915-919. (in Chinese)

[11] EASTON M A, KAUFMANN H, FRAGNER W. The effect of chemical grain refinement and low superheat pouring on the structure of NRC castings of aluminium alloy Al-7Si-0.4Mg [J]. Materials Science and Engineering A, 2006, 420(1-2): 135-143.

[12] JORSTAD J L. Interaction of key variables during rheocasting: importance of microstructure, fraction solid and flow velocity [J]. Solid State Phenomena, 2006(116-117): 24-33.

[13] MAO Wei-min, YANG Ji-lian, ZHAO Ai-min, CUI Cheng-lin, ZHONG Xue-you. Effect of pouring temperatures on the microstructure of the semi-solid AlSi7Mg alloy[J]. Journal of University of Science and Technology Beijing, 2001, 23(1): 38-41. (in Chinese)

[14] ZHAO Jian-xin, ZHU Ming-fang, KIM Jie-min, HONG Chun-pyo. Evolution of globular and dendritic structures in solidification of Al-Si alloys [J]. Physical testing and chemical analysis A: Physical testing, 2004, 40(9): 433-438. (in Chinese)

[15] GUO Hong-min, YANG Xiang-jie. Formation mechanism of spherical particles in undercooled melt [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(4): 651-659. ( in Chinese)

[16] PAN Y, AOYAMA S, LIU C. Spherical structure and formation conditions of semi-solid Al-Si-Mg alloy[C]//SUN G X, YUAN H. Proceedings of the 5th Asian Foundry Congress. Nanjing: Southeastern University Press, 1997: 443-451.

蛇形通道浇注工艺参数对半固态A356铝合金浆料的影响

陈正周,毛卫民,吴宗闯

北京科技大学 材料科学与工程学院,北京 100083

摘 要:采用蛇形通道浇注技术制备半固态A356铝合金浆料,并研究浇注温度和通道直径对半固态A356铝合金浆料的影响。结果表明:当通道直径为20和25 mm、浇注温度为640-680 ℃时,可以制备出初生相α(Al)的半固态浆料,其平均形状因子分别为0.89-0.76和0.86-0.72、平均晶粒直径分别为50-75 μm和55-78 μm。随着浇注温度的降低,半固态A356铝合金浆料中初生α(Al)晶粒的组织变得细小;较小的通道直径有利于组织的改善。在制备半固态A356铝合金浆料过程中,通道内壁的激冷能够产生大量的晶核。由于晶粒游离和合金熔体自搅拌的共同作用,初生α(Al)晶核能够在熔体内部增殖并且球化。

关键词:半固态;A356铝合金;蛇形通道;初生α(Al)

(Edited by FANG Jing-hua)

Foundation item: Project (2006AA03Z115) supported by the National High-tech Research and Development Program of China; Project (2006CB605203) supported by the National Basic Research Program of China; Project (50774007) supported by the National Natural Science Foundation of China

Corresponding author: CHEN Zheng-zhou; +86-10-62332882; E-mail: chzz19710425@126.com

DOI: 10.1016/S1003-6326(11)60810-8