文章编号:1004-0609(2010)04-0688-07

AZ31B铸轧镁合金板材的预变形温热拉深

刘志民,邢书明,鲍培玮,李 楠,姚淑卿,张密兰

(北京交通大学 机械与电子控制工程学院,北京100044)

摘 要:针对AZ31B铸轧镁合金板材温热拉深性能差的问题,提出预变形温热拉深工艺。对AZ31B铸轧镁合金板材在20~220 ℃进行预变形温热拉深实验研究。结果表明:预变形使铸轧镁合金板材的拉深性能明显改善,使AZ31B铸轧镁合金板材具有最佳拉深性能的冲头温度范围(20~95 ℃);凹模温度选择在160~220 ℃范围内,铸轧镁合金板材具有良好的拉深性能,极限拉深比可达到2.26;随着拉深成形温度的升高,工件中动态再结晶晶粒数量逐渐增加,220 ℃拉深成形时工件中再结晶晶粒分布趋于均匀。

关键词:AZ31B合金;镁合金板材;双辊铸轧;预变形;温热拉深;极限拉深比

中图分类号:TG 146 文献标志码:A

Deep drawing of twin-roll cast AZ31B Mg alloy sheets at

warm temperatures by pre-forming

LIU Zhi-min, XING Shu-ming, BAO Pei-wei, LI Nan, YAO Shu-qing, ZHANG Mi-lan

(School of Mechanical, Electronic and Control Engineering, Beijing Jiaotong University, Beijing 100044, China)

Abstract: In order to solve the problem of the poor warm deep drawability of the twin-roll cast AZ31B Mg alloy sheet, a warm deep drawing process by pre-forming was proposed. The warm deep drawing experiments of twin-roll cast AZ31B Mg alloy sheets were examined by pre-forming at temperature of 20-220 ℃. The results indicate that the deep drawing performance is significantly improved by pre-forming. The punch temperature range of 20-95 ℃ is recommended to obtain the best drawability for the twin-roll cast AZ31B Mg alloy sheet. The twin-roll cast AZ31B Mg alloy sheets have good deep drawing formability at die temperature of 160-220 ℃ with the limit drawing ratio up to 2.26. The dynamic recrystallization (DRX) grains of the workpieces increase gradually with increasing temperature. And the DRX grains of the materials distribute evenly, when the workpieces are obtained at temperature of 220 ℃.

Key words: AZ31B alloy; Mg alloy sheet; twin-roll casting; pre-forming; warm deep drawing; limit drawing ratio

镁合金是目前最轻的结构金属材料,它具有比强度和比刚度高、阻尼减震性好、电磁屏蔽效果好等优点,在航空、航天、汽车和电子领域具有很高的应用前景[1-3]。但由于镁合金晶体结构是密排六方晶体结构,滑移系少,低温塑性差,传统轧制板材工艺困难,成材率低,成本高,制约其应用[4-5]。铸轧工艺是将材料的连续铸造和轧制结合在一起,以液态金属为原料,直接在短时间内完成熔体的凝固和热轧,具有流程短、成本低和组织细化等优点,已经受到国内外学者的广泛关注[6-7]。由于冷却速度快,镁合金铸轧板带在晶粒得到细化的同时,还可改善凝固组织、减少宏观偏析,提高铸轧板带材的力学性能[8-9]。近年来,随着镁合金铸轧技术不断提高,铸轧板材的质量越来越高,使得进一步生产铸轧镁合金板材深加工产品成为可能。

镁合金低温塑性差,室温下难以成形,而当成形温度升高至225~400 ℃时,镁合金的塑性变形能力明显提高,超过体心立方晶格的金属。但成形温度的提高给模具加热、润滑带来诸多困难,特别是高温下成形易导致晶粒异常长大,影响产品性能[10-11]。因此,研究225 ℃以下的镁合金温热成形工艺是未来镁合金板材成形的发展方向。近几年来,国内外学者对于镁合金板材的温热冲压成形进行大量的研究,并取得许多成果,但在成形过程中,主要是通过反复的交叉轧制和热处理对板材微结构进行改善,或者采用极低成形速率来提高极限拉深比[2, 10-13]。因此,工艺流程长、能耗大、生产效率低,难以满足未来材料成形发展的短流程、低成本的要求。近年来,预变形拉深工艺做为一种特种成形技术在汽车和航空工业获得应用。其工作原理是先给板料预展变形,使之发生超过屈服点的伸长,在应力充分传递给板料各部分后,再用压力机进行最终成形。预先产生超过屈服点的伸长可以带来很多好处[14-16],例如:1) 拉深力可降低1/2~2/3;2) 使金属材料各部分均处于塑性变形状态,所以成形后回弹小,残余应力小;3) 诱导镁合金发生动态再结晶形核,细化晶粒,使板料和成品的力学性能提高;4) 可以改变板料在冲头接触部分的应力状态,减小拉深初期的开裂和起皱可能,提高其成形性能;5) 工艺装备可以简化。由此可见,利用镁合金材料在热力共同作用下容易发生动态再结晶的特点,将预变形成形技术与在线热处理有机地给合起来,运用再结晶动力学原理对生产工艺参数进行优化,可以提高镁合金板材在温热条件下的成形性能,并可以降低能耗、提高生产效率和改善产品性能。因此,预变形成形技术将成为镁合金材料成形的一个新的发展方向。如果这种预变形成形技术能够在铸轧镁合金板材的深加工中得到应用,对于推广铸轧镁合金板材在各领域中应用,促进镁工业发展有着重要的意义。

然而,目前还没有关于利用预变形技术对铸轧镁合金板材进行冲压成形的报道。为此,本文作者以圆筒形件为例,首次采用预变形技术对镁合金铸轧板材的温热拉深成形工艺进行研究,确定适合AZ31B镁合金铸轧板材温热成形的温度范围,分析预变形、冲头温度和凹模温度对圆筒形件成形质量的影响,并分析铸轧镁合金圆筒形件的微观组织演变,探讨铸轧镁合金动态再结晶形核机制,为镁合金铸轧板材深加工探索一条可行的应用路线。

1 实验

拉深实验选用商用铸轧镁合金AZ3lB的板坯, AZ31B板坯采用双辊铸轧技术生产。AZ31B镁合金的合金成分如表1所列。拉深所用实验样品从铸轧板坯直接机械切割得到,样品为厚3.3 mm、直径96 mm的圆片。

表1 实验用镁合金的化学成分

Table 1 Chemical composition of experimental Mg alloy (mass fraction, %)

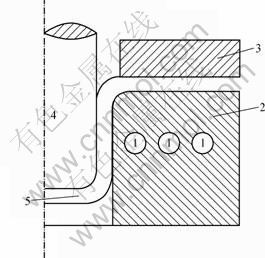

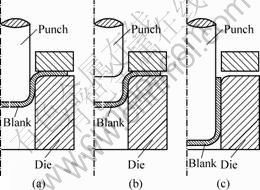

铸轧镁合金板材温热拉深成形实验在THP200液锻机上进行,液锻机为200 t。采用刚性压边装置对压边力进行调整。镁合金板料加热方式为内部加热,即将板料放入凹模中随模加热到设定的成形温度。凹模埋有环形电热环,用于模具加热,电热环采用控温仪控温,测温用热电偶点接触测量,冲头采用随模加热方式,模具结构及电加热系统设置如图1所示。工作部分尺寸如下:冲头直径42.5 mm,冲头圆角半径9 mm,凹模中心孔径52.4 mm,凹模中心孔径的圆角半径9.5 mm。预变形温热拉深的工艺原理图如图2所示。预变形时,冲头先下行一定的行程,即给板料一定的变形量;冲头停留一段时间待应力传递至板料各部分后,再上行,板料留在凹模中进行在线热处理,退火温度230 ℃,保温时间40 min;热处理完成后再继续进行温热拉深成形。

预变形温热拉深试验条件为:凹模温度20~220

图1 模具结构示意图

Fig.1 Schematic diagram of warm deep drawing: 1—Electric heating elements; 2—Die; 3—Blank holder; 4—Punch; 5—Blank

图2 预变形拉深工艺示意图

Fig.2 Schematic diagram of pre-forming deep drawing (punch 20-110 ℃, die 20-220 ℃): (a)—Punch moval to one location; (b)—Annealing online; (c)—Deep drawing

℃,冲头速度45 min,预变形量16%,冲头表面温度设定在20~110 ℃。润滑剂采用石墨+机油混合液。

2 结果与分析

2.1 预变形对成形质量的影响

预变形可以改善镁合金板料显微组织,从而提高板料的力学性能。图3所示为预变形前、后板料的显微组织。由图3可见,预变形前铸轧板的表层为粗大晶粒,心部为细小等轴晶(见图3(a));当板料预变形后,首先在位错密度高的晶界与“三叉点”处发生部分动态再结晶,然后通过在线热处理热激活,再结晶晶粒不断生成,由于退火温度低,晶粒长大速率小,保温时间合适,再结晶形成的晶粒细小,数量多,显微组织趋于均匀(见图3(b))。图4所示为预变形处理和未经预变形处理的板料在220 ℃拉深得到的工件照片。由图4可知,预变形处理使得板料的成形性能大大提高,能得到极限拉深比为2.26的完整圆筒件;而未经预变形处理的工件无法得到完整的圆筒件,其极限拉深比仅为1.55。图5所示为经220 ℃拉深时,冲头拉深力与冲头行程(40 mm)的关系。由图5可知,未经预变形处理的板料在冲头下行到13 mm时,便发生脆性断裂,拉深力迅速增大,且仅达到23 kN;而经预变形处理后,拉深时的最大拉深力可达43 kN,拉深能够顺利进行。

预变形提高铸轧镁合金板成形性能的原因在于:首先,预变形改变板料在冲头接触部分的应力状态,减小拉深初期冲头对板料的冲击力,有效避免拉深早期开裂和起皱现象。此外,最主要的是,对于镁合金来说,一定的预变形能使晶粒内部的位错密度大幅度增加,储存大量的畸变能,为后续的再结晶退火处理时再结晶晶粒形核与长大提供主要的驱动力。此外,镁合金的{10 2}á10

2}á10 1?锥面拉伸孪晶是最易激活的孪晶系,其临界剪切应力CRSS 远小于压缩孪生和ác+a?锥滑移,因此,通过一定的预变形量就可以激活{10

1?锥面拉伸孪晶是最易激活的孪晶系,其临界剪切应力CRSS 远小于压缩孪生和ác+a?锥滑移,因此,通过一定的预变形量就可以激活{10 2}á10

2}á10 1?拉伸孪晶;同时,由于{10

1?拉伸孪晶;同时,由于{10 2}á10

2}á10 1?拉伸孪晶使晶粒转动86.3?,孪晶内的所有基面在变形后近似平行于拉深方向,调节晶体的取向,进一步激发滑移和孪生,使滑移和孪生交替进行,从而获得较大的变形[17],且它可以成为动态再结晶的形核点,增大动态再结晶的温度范围[18-19]。在后续的再结晶热处理过程中,只要温度控制合理,避免因温度过高而产生的晶粒异常长大就可以使变形晶粒与细小的动态再结晶晶粒被热激活,经过较长一段时间的孕育期后,也会有晶核形成并缓慢长大,再结晶晶核的形核数量多,完成整个再结晶过程的时间较长,最后形成的组织细小而且均匀[1, 20]。因此,通过预变形可以对板料再结晶晶粒组织的尺寸大小和分布进行控制。对于板料的危险截面,如冲头圆角和凹模圆角处,在预变形热处理后,该部分晶粒在预变形应力诱导和热激活的共同作用下,首先发生动态再结晶,细化晶粒,并且不断向板材其余部分发展,从而使整个板材特别是危险截面处的组织得到改善,应力集中得以松弛,这样就可以提高铸轧镁合金板材的力学性能,得到比较高的极限拉深比。

1?拉伸孪晶使晶粒转动86.3?,孪晶内的所有基面在变形后近似平行于拉深方向,调节晶体的取向,进一步激发滑移和孪生,使滑移和孪生交替进行,从而获得较大的变形[17],且它可以成为动态再结晶的形核点,增大动态再结晶的温度范围[18-19]。在后续的再结晶热处理过程中,只要温度控制合理,避免因温度过高而产生的晶粒异常长大就可以使变形晶粒与细小的动态再结晶晶粒被热激活,经过较长一段时间的孕育期后,也会有晶核形成并缓慢长大,再结晶晶核的形核数量多,完成整个再结晶过程的时间较长,最后形成的组织细小而且均匀[1, 20]。因此,通过预变形可以对板料再结晶晶粒组织的尺寸大小和分布进行控制。对于板料的危险截面,如冲头圆角和凹模圆角处,在预变形热处理后,该部分晶粒在预变形应力诱导和热激活的共同作用下,首先发生动态再结晶,细化晶粒,并且不断向板材其余部分发展,从而使整个板材特别是危险截面处的组织得到改善,应力集中得以松弛,这样就可以提高铸轧镁合金板材的力学性能,得到比较高的极限拉深比。

图3 预变形前、后板料的金相组织

Fig.3 Metallographs of blank before (a) and after (b) pre- forming

图4 预变形对铸轧镁合金极限拉深比的影响

Fig.4 Influence of pre-forming on LDR of TRC Mg alloys: (a) Without pre-forming; (b) With pre-forming

图5 冲头拉深力与行程的关系

Fig.5 Relationship between punch force and punch stroke (within 40 mm)

2.2 冲头温度对成形质量的影响

在进行温热拉深时,由于冲头温度与板料温度不同,板料在冲头接触区与板料突缘变形区形成一定的温差,即使在拉深过程中,圆筒件的底部与侧壁温度始终低于板料突缘变形区,这种温度差导致变形区塑性高于传力区,有利于拉深进行。然而,在进行板料的温热拉深时,如果冲头温度过低,当冲头与较高温度的板料,特别是与具有低热容量和高热传导系数的镁合金板接触时很容易产生激冷现象,使得冲头圆角处板料的塑性急剧变差,进而使板料在冲头圆角处发生断裂,工件在拉深初期即发生脆性断裂;而若将冲头加热至较高温度甚至接近板料温度时,则由于冲头圆角接触,产生塑性变形热以及摩擦发热,使得板料软化,抗拉强度降低,在拉深坯料时,危险截面的等效应力随拉深力不断增大直至超过板料的抗拉强度,造成塑性失稳断裂[12-13]。因此,确定合适的冲头温度范围对于镁合金的温热拉深是非常重要的。

图6所示为在220 ℃预变形温热拉深时,冲头温度(θP)在20~95 ℃以及大于95 ℃时得到的拉深件。由图6(a)可知,板料在冲头圆角处产生开裂现象。这是由于冲头温度较高,温热拉深时板料与冲头接触部分的流动应力和凸缘部分的流动应力接近,拉深过程中随着所需拉深力的不断增加,冲头圆角处金属的等效应力将超过材料的屈服应力而产生变形,随着拉深力进一步增大,冲头圆角处等效应力超过抗拉强度,最终导致失稳开裂。当冲头温度在20~95 ℃变化时, 冲头圆角处没有出现脆性裂纹,得到极限拉深比为2.26的圆筒件的外形完整,表面无裂纹(见图6(b))。上述实验结果表明,20~95 ℃是使板料在预变形温热拉深时获得高极限拉深比的合理冲头温度。

2.3 成形温度对成形质量的影响

随着温度的升高,镁合金的非基滑移系被激活,塑性变形能力显著增强,拉深性能明显改善,例如,当温度在175 ℃以上时,原子密度仅次于基面的附加滑移面{1011}和{1012},也开始发生滑移,塑性明显提高;当温度在225 ℃以上时,则12个滑移系都可以参加变形[1],塑性很好。但随着温度升高,给实验中板料加热,润滑等方面带来诸多困难[10-11]。所以,开发镁合金温热成形技术是目前亟待进行的工作。研究表明,对于镁合金轧制板材,在120~170 ℃之间温热塑性变形能力就很好,尤其在170 ℃左右的变形能力已经很高,筒形件的极限拉深比可达1.8以上[10]。

图6 冲头温度对拉深成形的影响

Fig.6 Effect of punch temperature on deep drawing (forming temperature 220 ℃): (a) θp≥95 ℃; (b) 20 ℃≤θp≤95 ℃

对铸轧镁合金板材在20~170 ℃的预变形温热拉深进行研究表明,成形温度对板料的极限拉深比有很大的影响。得到的各温度下的极限拉深比如图7所示。由图7可知,铸轧镁合金板材极限拉深比(Limit drawing ration,LDR)随着变形温度的升高而增大。室温下的铸轧镁合金LDR仅为1.44;在80~130 ℃成形时,极限拉深比变化很小,为1.50~1.58;当温度提高至150 ℃时,极限拉深比急增至1.89;当温度升高至160 ℃时,已经能够得到极限拉深比为2.26的完整圆筒件。

2.4 微观组织的演变

铸轧镁合金板在不同成形温度下得到工件的显微组织如图8所示。由图8可看出,当在成形温度较低时(170 ℃)(见图8(a)),合金晶粒沿拉深方向伸长,晶粒呈现长条形,有较多的孪晶和少量的动态再结晶晶粒在晶界和“三叉点”处出现;在195 ℃成形时,在

图7 铸轧AZ31B镁合金在不同温度下的LDR

Fig.7 LDR of TRC AZ31B Mg alloy at various temperatures

大晶粒周围出现了越来越多的细小等轴晶,变形的大晶粒被细小的动态再结晶小晶粒包围,呈现出显著的项链状组织特征,整个材料的显微组织为变形的大晶粒与动态再结晶小晶粒共存的现象;且再结晶晶粒逐步取代原始大晶粒(见图8(b));在220 ℃成形时,再结晶晶粒略有长大,显微组织趋于均匀,以动态再结晶晶粒为主,仅有少量变形大晶粒存在(见图8(c))。

图8 在不同成形温度时板料的光学显微组织

Fig.8 Optical micrograph of blank formed at various temperatures: (a) 170 ℃; (b) 195 ℃; (c) 220 ℃

在不同成形温度下,镁合金动态再结晶晶粒表现出形态的多样性,这种多样性由镁合金动态再结晶机制决定,而动态再结晶机制与镁合金塑性变形机制之间有很密切的关系[1, 21]。在低温(<200 ℃)变形时,基面滑移和孪生是镁合金主要的变形机制。α位错基面滑移在孪晶界附近塞集并发生弹性畸变,弹性畸变引起的内应力可使晶界局部区域受到的应力超过低温下非基面滑移的临界剪切应力。位错的重排导致大角度晶界的形成,这些大角度晶界是由大量位错缠绕而成的位错墙。因而,动态再结晶首先在位错密度高的大角度晶界处形成晶核。在中温(200~250 ℃)变形时,Friendel-escaing机理下的交滑移控制着塑性变形和动态再结晶形核。α位错在非基面上的交滑移一般在原始晶界应力集中的地方发生,α位错的交滑移使螺位错部分转变成位刃位错并由基面滑移至非基面,刃位错沿非基面发生攀移。位错的交滑移和攀移可以使位错重组而在原始晶粒边界形成一小角度晶界网。并通过不断吸收新的位错转化成大角度晶界,从而形成新的晶粒。镁合金的这种动态再结晶形核机制即为连续动态再结晶[21]。因此,在220 ℃成形时,动态再结晶形核机制为连续动态再结晶(见图8(c)),大部分再结晶晶粒形貌上呈等轴状,且极为细小,晶界为波纹形,为典型的连续动态再结晶晶粒特征。

3 结论

1)铸轧镁合金板材能够在20~220 ℃条件下直接进行温热拉深成形,预变形技术能明显改善铸轧镁合金板料的显微组织,提高板料的极限拉深比。在冲头速度45 mm/min,预变形量16%,凹模温度220 ℃条件下能得到LDR为2.26的完整的圆筒形件;而未经预变形处理的板料无法得到完整的圆筒形件,其极限拉深比仅为1.55。

2) 20~95 ℃是使铸轧镁合金板料在预变形温热拉深时获得高极限拉深比的合理冲头温度;拉深力曲线变化表明,未预变形处理的板料在冲头下行到13 mm时,便发生脆性断裂,而预变形技术可以使拉深能够顺利进行;室温下铸轧镁合金板料的LDR仅为1.44,随着温度的升高,拉深性能明显改善,温度为150 ℃时,LDR提高至1.89,而在160 ℃拉深时已经可以获得LDR=2.26的完整圆筒件。

3) 镁合金动态再结晶晶粒体积分数随着成形温度的升高而提高;再结晶晶粒尺寸也随着成形温度升高而增大,且再结晶晶粒分布趋于均匀。镁合金塑性变形机制决定动态再结晶晶粒在形态上的不同。在220 ℃成形时,Friendel-Escaing机理下的交滑移控制着塑性变形和动态再结晶形核,动态再结晶形核机制为连续动态再结晶,得到的再结晶晶粒体积分数高,晶粒尺寸细小,显微组织均匀。

REFERENCES

[1] 黎文献. 镁及镁合金[M]. 长沙: 中南大学出版社, 2005: 1-10.

LI Wen-xian. Magnesium and magnesium alloys[M]. Changsha: Central South University Press, 2005: 1-10.

[2] 苌群峰, 彭颖红, 刘守荣, 李大永, 曾小勤. 镁合金板材温热成形性能[J]. 上海交通大学学报, 2006, 40(6): 887-880.

CHANG Qun-feng, PENG Ying-hong, LIU Shou-rong, LI Da-yong, ZENG Xiao-qin. Forming performance of magnesium sheet metal at elevated temperatures[J]. Journal of Shanghai Jiao Tong University, 2006, 40(6): 877-880.

[3] 余 琨, 黎文献, 王日初. 镁合金塑性变形机[J]. 中国有色金属学报, 2005, l5(7): 1081-1086.

YU Kun, LI Wen-xian, WANG Ri-chu. Plastic deformation mechanism of magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 1081-1086.

[4] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金研究、进展及应用[J]. 中国有色金属学报, 2003, 13(2): 277-287.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-287.

[5] SLOOFF F A, ZHOU J, DUSZCZYK J, KATGERMAN L. Constitutive analysis of wrought magnesium alloy Mg-Al4- Zn1[J]. Scripta Materialia, 2007, 57(8): 759-762.

[6] 娄花芬, 汪明朴, 唐 宁, 李 周, 郭明星, 雷 前. AZ31B镁合金的铸轧组织及其相关变形机制[J]. 中国有色金属学报, 2008, 18(9): 1584-1589.

LOU Hua-fen, WANG Ming-pu, TANG Ning, LI Zhou, GUO Ming-xing, LEI Qian. Microstructures of twin-roll cast AZ31B Mg alloy and its deformation mechanism[J]. The Chinese Journal of Nonferrous Metals. 2008, 18(9): 1584-1589.

[7] PARK S S, OH Y S, KANG D H, KIM N J. Microstructural evolution in twin-roll strip cast Mg-Zn-Mn-Al alloy[C]// Proceedings of the 12th International Conference on Rapidly Quenched & Metastable Materials. Cheongju: Mater Sci Eng A, 2007, 449/451: 352-355.

[8] PARK S S, BAE G T, KANG D H, JUNG I H, SHIN K S, KIM N J. Microstructure and tensile properties of twin-roll cast Mg-Zn-Mn-Al alloys[J]. Scripta Materialia, 2007, 57(9): 793-796.

[9] SONG S X, HORTON J A, KIM N J, NIEH T G. Deformation behavior of a twin-roll-cast Mg-6Zn-0.5Mn-0.3Cu-0.02Zr alloy at intermediate temperatures[J]. Scripta Materialia, 2007, 56(5): 393-395.

[10] ZHANG S H, ZHANG K, XU Y C, WANG Z T, XU Y, WANG Z G. Deep-drawing of magnesium alloy sheets at warm temperatures[J]. Journal of Materials Processing Technology, 2007, 185(1/3): 147-151.

[11] HUANG T B, TSAI Y A, CHEN F K. Finite element analysis and formability of non-isothermal deep drawing of AZ31B sheets[J]. Journal of Materials Processing Technology, 2006, 177(1/3): 142-145.

[12] ZHANG K F, YIN D L, WU D Z. Formability of AZ31 magnesium alloy sheets at warm working conditions[J]. International Journal of Machine Tools & Manufacture, 2006, 46(11): 1276-1280.

[13] 尹德良, 张凯锋, 吴德忠. AZ31镁合金非等温拉深性能的研究[J]. 材料科学与工艺, 2004, 12(1): 87-91.

YIN De-liang, ZHANG Kai-feng, WU De-zhong. Nonisothermal deep drawability of AZ31 magnesium alloy[J]. Materials Science & Technology, 2004, 12(1): 87-91.

[14] LUO Y, LUCHEY S G, FRIEDMAN PA, PENG Y. Development of an advanced superplastic forming process utilizing a mechanical pre-forming operation[J]. International Journal of Machine Tools & Manufacture, 2008, 48(12/13): 1509-1518.

[15] NGUYEN B N, BAPANAPALLI S K. Forming analysis of AZ31 magnesium alloy sheets by means of a multistep inverse approach[J]. Materials and Design, 2009, 30(4): 992-999.

[16] 郭 成, 储家佑. 现代冲压技术手册[M]. 北京: 中国标准出版社, 2005: 576-577.

GUO Cheng, CHU Jia-you. Modern technology manual of stamping[M]. Beijing: Chinese Standard Press, 2005: 576-577.

[17] 路 君, 靳 丽, 董 杰, 曾小勤, 丁文江, 姚真裔. 等通道角挤压变形AZ31镁合金的变形行为[J]. 中国有色金属学报, 2009, 19(3): 424-432.

LU Jun, JIN Li, DONG Jie, ZENG Xiao-qin, DING Wen-jiang, YAO Zhen-yi. Deformation behaviors of AZ31 magnesium alloy by equal channel angular extrusion[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(3): 424-432.

[18] BOHLEN J, CHMELIK F, DOBRON P, LUKAC P, LETZIG D,KAINER K U. Orientation effects on acoustic emission during tensile deformation of hot rolled magnesium alloy AZ31[J]. Journal of Alloys and Compounds, 2004, 378(1/2): 207-213.

[19] BEER A G, BARNETT M R. Microstructure evolution in hot worked and annealed magnesium alloy AZ31[J]. Mater Sci Eng A, 2008, 485(1/2): 318-324.

[20] 汪凌云, 黄光胜, 范永革, 黄光杰. 变形AZ31镁合金的晶粒细化[J]. 中国有色金属学报, 2003, 13(3): 594-598.

WANG Ling-yun, HUANG Guang-sheng, FAN Yong-ge, HUANG Guang-jie. Grain refinement of wrought AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 594-598.

[21] GALIYEV A, KAIBYSHEV R, GOTTSTEIN G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60[J]. Acta Materialia, 2001, 49(7): 1199-1207.

(编辑 李艳红)

基金项目:北京自然科学基金资助项目(3093024);北京交通大学十一五科技基金资助项目(2007XM035)

收稿日期:2009-06-03;修订日期:2009-09-15

通信作者:邢书明,教授,博士;电话: 010-51688614; E-mail: shumingxing1962@126.com