Trans. Nonferrous Met. Soc. China 23(2013) 2276-2282

Influence of forging process on microstructure and mechanical properties of large section Ti-6.5Al-1Mo-1V-2Zr alloy bars

De-ming HUANG1, Huai-liu WANG2, Xin CHEN2, Yong CHEN1, Hua GUO1

1. State Key Laboratory of Vanadium and Titanium Resources Comprehensive Utilization, Pangang Group Research Institute Co.,Ltd., Panzhihua 617000, China;

2. Pangang Group Jiangyou Changcheng Special Steel Co., Ltd., Jiangyou 621700, China

Received 10 July 2012; accepted 23 March 2013

Abstract: The mechanical properties, microstructure and tensile fracture of Ti-6.5Al-1Mo-1V-2Zr large section bars produced by three diffrent forging processes were investigated. The results show that when billet forging and finish forging were conducted by means of fullering at high and low temperature of β-region, respectively; the microstructure of forged bar is coarse Widmanstaten structure; the mechanical properties, especially the reduction of cross-sectional area, are poor, and the room temperature tensile fracture presents a brittle feature. While billet forging was carried out by upset-fullering at high temperature of the β-region, and finish forging was proceeded through fullering at (α+β)-region, the microstructure of forged bar was a duplex structure, the bar has better comprehensive mechanical properties, and the room temperature tensile fracture reveals a ductile feature. In order to obtain qualified Ti-6.5Al-1Mo-1V-2Zr alloy bar, it is the key that as-cast microstructure should be completely broken during billet forging, and the forging temperature and deformation are also well controlled upon finishing forging.

Key words: Ti-6.5Al-1Mo-1V-2Zr; bar; forging; microstructure; mechanical properties

1 Introduction

Due to its high specific strength and good thermal stability, Ti-6.5Al-1Mo-1V-2Zr alloy has been widely used in aircraft industry. It is a near α titanium alloy similar to Russia alloy BT20 with a combination of good hot-working plasticity of (α+β) titanium alloy and excellent weldability of α titanium alloy. The as-annealed structure composes of an α solid solution matrix and about 6% β phase. This alloy is mainly used to manufacture sheet bank, sectional bar and forging workpiece [1].

The properties of a material are determined by its microstructure, which in turn depends on the encountered processing history. Thus, it is important to understand the relationships among the deformation process, microstructure and properties. In recent years, extensive researches have been carried out on Ti-6.5Al-1Mo-1V-2Zr alloy in China. The mechanism of heat treatment strengthening and its effect on microstructure and properties were discussed [2-5]. The effect of multiple thermomechanical treatment on microstructure and properties was investigated [6,7]. The hot deformation behaviors at different temperatures and strain rates were studied [8-11]. The dynamic globularization kinetics during hot working of colony microstructure was researched by WU et al [12]. ZHU et al [13] and GUO et al [14] studied the influence of deformation parameters on the microstructure and mechanical properties. These work mainly focused on laboratory theory research. However, the effect of deformation process on the microstructure and properties under practical industrial production conditions were seldom reported [15,16]. In addition, the microstructures of titanium alloys are complicated and sensitive to deformation process. Therefore, more researches are needed.

In this work, the microstructure and properties of Ti-6.5Al-1Mo-1V-2Zr alloy bars manufactured by different forging techniques during actual industrial production were discussed.

2 Experimental

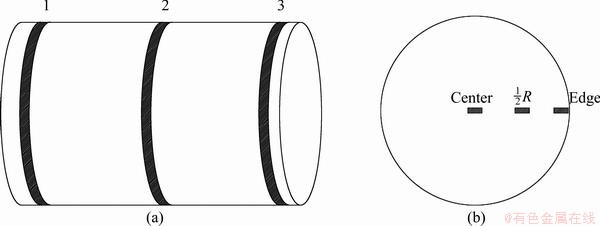

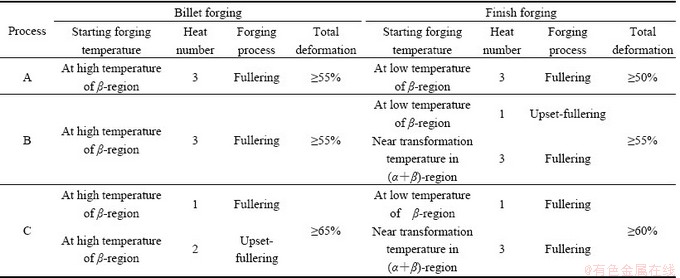

Ti-6.5Al-1Mo-1V-2Zr alloy ingot with diameter of 750 mm was remelted three times in an industrial vacuum consumable electrode arc furnace. The chemical composition of ingot in different positions (Fig. 1(a)) is listed in Table 1. The forged bars were manufactured by three different forging techniques, as listed in Table 2. The as-forged bars were air-cooled to room temperature and subsequently annealed at 800 °C for 1 h. The mechanical properties were tested by universal material testing machine at room temperature and 500 °C, respectively. Metallographic samples were prepared as shown in Fig. 1(b), and metallographic analysis was carried out by a DM600 microscope. The JSM-7001 scanning electron microscopy (SEM) equipped with INCA energy disperse spectroscopy (EDS) was used for analyzing room temperature tensile fracture appearance, microstructure and chemical composition of the forged bars.

3 Results

3.1 Mechanical properties

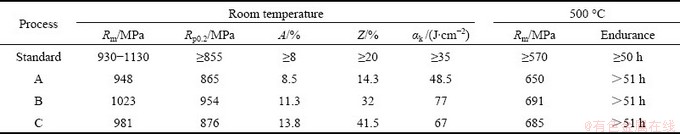

The mechanical properties of forged bars produced by different processes are listed in Table 3. It is seen that the tensile strength, yield strength and impact toughness of bar generated from process A meet the specified requirements at room temperature, and the tensile strength and endurance meet the specified elevated temperature performance requirements. But the area reduction fails to meet the standard requirements. The properties of bar from process B have a significant improvement compared with that from process A and meet the standard requirements at room temperature and 500 °C, respectively. The strength of bar from process C is lower than that of from process B, but higher than that from process A, and its plasticity gives the highest level. It is obvious that the plasticity of bars keeps improved from process A to process C, and the strength indexes of bars satisfy the standard requirements. The bar produced from process C has a better comprehensive performance.

Fig. 1 Schematic diagram of sampling positions of chemical composition analysis of ingot (a) and metallographic observation in cross-section of forged bar (b)

Table 1 Chemical composition of Ti-6.5Al-1Mo-1V-2Zr alloy ingot in different positions (mass fraction, %)

Table 2 Forging process scheme of Ti-6.5Al-1Mo-1V-2Zr alloy bar

3.2 Microstructure

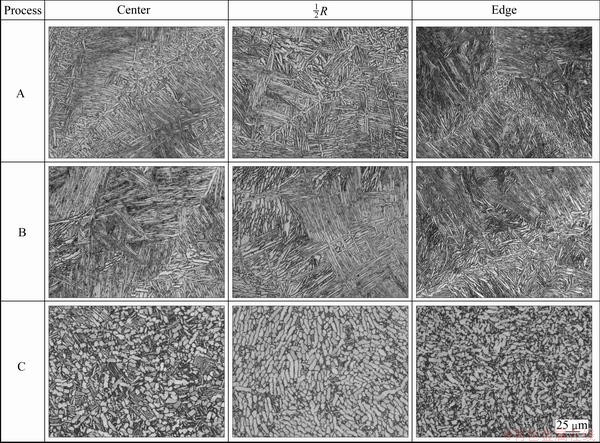

Figure 2 shows the microstructures of bars produced by different processes. It is evident that the bars from processes A and B have a similar microstructure, where coarse prior β gains are not completely broken, shaft-shape α exists in the grain boundaries, and bulky lamellar clusters appear in the center of grain. This is typical of Widmanstaten structure. The difference in microstructure between processes A and B lies in the bigger area of shaft-shape α phases in the grain boundaries of process A. Meshy α phases distributing continuously along grain boundaries appear in the center, 1/2 radius and edge of cross-section of forged bar. However, the microstructure from process B is relatively bulky, and the region of shaft-shaped α phase is narrower than that from process A in the grain boundaries. Except for continuous meshy α phases in the grain boundaries appearing on the edge of cross-section, there is no α phases network in the center and 1/2 radius of cross-section. For all these, the microstructures from processes A and B can not meet the standard requirements. The microstructure from process C is significantly different from that from process A or B, where initial β grains are completely broken, and the microstructure is composed of equiaxial α phases and transformed β phases. It is typical of a duplex structure.

Table 3 Mechanical properties of Ti-6.5Al-1Mo-1V-2Zr alloy bars

Fig. 2 Microstructures of Ti-6.5Al-1Mo-1V-2Zr alloy bars under conditions of different forging processes

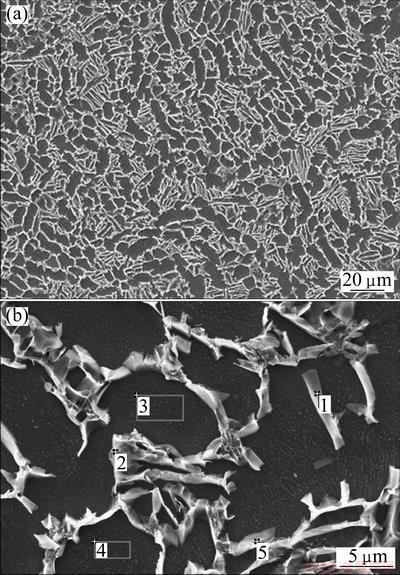

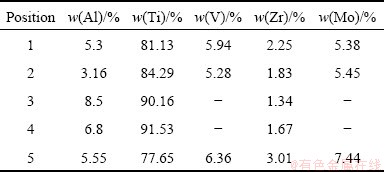

In order to better understand the microstructure and its corresponding phases of the forged bars, the microstructure in cross-section of forged bars was observed by SEM, as shown in Fig. 3. The SEM observations reveal that lamellar clusters dominate the white region in the center of grain and the black precipitated phases form network along the grain boundaries, and even black block phases exist in some areas, as marked by arrows in Fig. 3(a). The average grain size approximates 900 μm. It can clearly be found that the black areas around grain boundaries are precipitated phases, and the white areas in the center of grain are lamellar structure (Fig. 3(b)). The SEM image from process C shows black globular particles and skeletal from netting white substances exist among black particles (Fig. 4). The basic phases are α and β in microstructure of Ti-6.5Al-1Mo-1V-2Zr alloy. Using EDS for semi-quantitative analysis of these phases, the results show that Mo and V elements segregate in the white phases, and Al element content is higher in the black phases than in the white phase (Table 4). It indicates that the white phase in the SEM is β phase, and the black one is α phase. SEM analysis indicates that there are significant differences in the morphology of microstructure and phases under different forging processes.

Fig. 3 SEM images of bars under condition of process A

Fig. 4 SEM images of bars under condition of process C

Table 4 EDS analysis corresponding to Fig. 4(b)

3.3 Fracture morphology

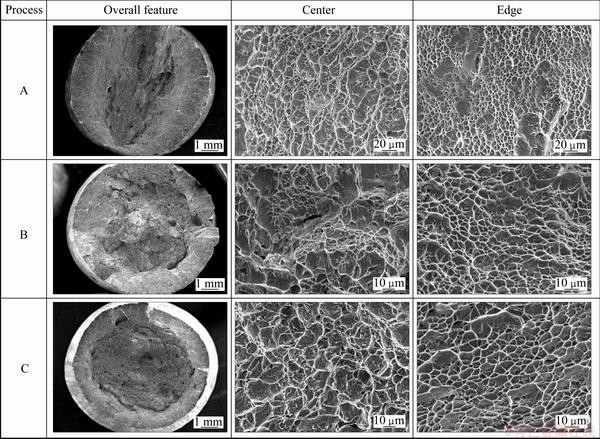

The morphologies of room temperature tensile fracture of bars manufactured by three kinds of processes are shown in Fig. 5. It is clear from Fig. 5 that there is no apparent necking in the tensile fractures from processes A and B. The morphology of fracture shows greatly irregular, and there is no fiber area in the macro fracture. It indicates a brittle fracture. The fracture microcosmic morphologies from processes A and B are dominated by dimples, and there are a small amount of cleavage planes in their fracture. In addition, the size of dimple is uneven. It is clear that the dimple size from process B is bigger than that from process A. There is noticeable necking phenomenon in the fracture from process C. The fracture morphology is regular, which composes of distinct shear lip on the edge and smooth center fiber zone in the center, without apparent radiate zone. It indicates a ductile fracture. The microscopic morphology of fracture from process C is dimple without cleavage plane. The size of dimple is uniform and the biggest in the three fractures. Fiber holes are found in the fracture from process C. The feature of fracture indicates that the plasticity of process C is the best.

Fig. 5 Feature of tensile fracture under conditions of different forging processes at room temperature

4 Discussion

The results manifest that the plasticity of forged bars increases from process A to process C, while the bar from process B has the highest strength value. Therefore, process C has produced a better combination of mechanical properties. The difference in properties of forged bars is caused by different microstructures generated under the different forging processes.

The forging process of materials remarkably influences the microstructure, and further determines the mechanical properties. Under process A, the higher forging temperature and insufficient deformation cause coarse grains and non-uniform microstructure in the whole cross-section of forged bar. Initial β grains are not fully broken, α phase appears in the grain boundaries and networks form, and bulky lamellar clusters occur in the center of the grains. This kind of microstructure greatly deteriorates the mechanical properties of the bars under process A, which causes poor plasticity particularly. The research by WEI et al [17] also confirmed that the network α phases in grain boundaries deteriorated the plasticity of TB10 alloy. The mechanical properties improve to a certain extent under process B, because one heating-cycle upset-fullering practice has been carried out at lower temperature of β-region during finish forging, which increases effective deformation. At the same time, the forging temperature decreases and the deformation increases during finish forging, which causes the microstructure broken in some degree, and the network α phases in the center and 1/2 radius are eliminated. Therefore, the mechanical properties are improved. Under process C, the bars have been forged by two heating-cycles upset-fullering at the stage of billet forging, and the forging temperature further decreases and the deformation increases in (α+β)-region at the stage of finish forging, which makes the structure fully broken, microstructure smaller, and it presents a typical duplex structure. For duplex structure, shaft-shaped α phases can enhance the resistance of crack initiation, and the plasticity and impact toughness of titanium alloy are improved. Lamellar structure can improve the resistance of crack propagation, and the fracture toughness of titanium alloy is enhanced too. Because the motion direction change of crack in lamellar structure is more frequent, crack bifurcates to form secondary cracks, which causes the total crack length increasing, and needs more metal volume plastic deformation work done [18]. As a result, the comprehensive performance of forged bars is the best under process C. Thus, in order to obtain qualified microstructure and properties of forging bars, as-cast structure should be fully broken during billet forging, and the forging temperature and deformation are controlled during finish forging.

It is visible from the room temperature fracture appearance that the size and depth of dimple increase from process A to process C. The size and depth of dimple depend on the nucleation numbers and plastic deformation ability during the materials fracture. The much bigger and deeper dimples would bring materials more plasticity [19]. Thus, process C results in the best plasticity level in accordance with its fracture feature.

5 Conclusions

1) The high forging temperature and insufficient deformation cause the Ti-6.5Al-1Mo-1V-2Zr forged bars a typical Widmanstatten structure, which causes poor performance, especially poorer plasticity. The room temperature tensile fracture presents a brittle feature.

2) The duplex structure of forged bars is obtained through fully broking initial structure during billet forging, reducing forging temperature and increasing deformation upon finishing forging. The resulted mechanical properties are the best, and the room temperature tensile fracture appears a ductile feature.

3) It is key that in order to obtain qualified microstructure and properties of forged bars, as-cast microstructure should be completely broken during billet forging, and the forging temperature and deformation are also well controlled during finishing forging.

References

[1] HUANG Bo-yun, LI Cheng-gong, SHI Li-kai, QIU Guan-zhou, ZUO Tie-yong. Non-ferrous metal materials manual [M]. Beijing: Chemical Industry Press, 2009: 566. (in Chinese)

[2] ZHANG Wang-feng, WANG Yu-hui, MA Ji-min. Heat treatment strengthening and its mechanism of large forging for TA15 titanium alloy [J]. Chinese Journal of Rare Metals, 2010, 34(1): 1-5. (in Chinese)

[3] WANG Yu-hui, LI Yan, ZHANG Wang-feng, MA Ji-min. Heat treatment behavior of TA15 titanium alloy with different deformation degrees [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(s1): s641-s646. (in Chinese)

[4] LI Shi-kai, XIONG Bai-qing, HUI Song-xiao. Effect of heat-treatment on microstructure and properties of TA15 alloy [J]. Transactions of Materials and Heat Treatment, 2008, 29(6): 82-85. (in Chinese)

[5] LU Yi-fan, MENG Xiang-jun, LI Shi-kai, YU Wei. Effects of annealing heat treatment on microstructure and properties of TA15 titanium alloy [J]. Development and Application of Materials, 2009, 24(5): 7-11. (in Chinese)

[6] ZHU Jing-chuan, WANG Yang, YOU Feng-hai, LIU Yong, LAI Zhong-hong. Microstructure and mechanical properties of thermal deformed TA15 titanium alloy [J]. Transactions of Materials and Heat Treatment, 2007, 28(s): 106-106. (in Chinese)

[7] WANG Bin, GUO Hong-zhen, YAO Ze-kun, ZHAO Jing, ZHAO Zhang-long, ZHANG Ming-yuan. Effect of multiple thermomechanical heat treatment on microstructure and mechanical property of near-alpha TA15 titanium alloy [J]. Transactions of Materials and Heat Treatment, 2006, 27(5): 70-72. (in Chinese)

[8] XU Wen-cheng, SHAN De-bin, YANG Guo-ping, LU Yan. Flow behavior and microstructure evolution during hot compression of TA15 titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(s3): s2066-s2071.

[9] LI Miao-quan, LI Xiao-li, LONG Li, XU Guang-xing, YU Hao, CHI Cai-lou, WEN Guo-hua. Deformation behavior and processing map of high temperature deformation of TA15 alloy [J]. Rare Metal Materials and Engineering, 2006, 35(9): 1354-1358. (in Chinese)

[10] WANG Yang, YOU Feng-hai, ZHU Jing-chuan, LAI Zhong-hong, LIU Yong. Study on hot deformation behavior of TA15 alloy [J]. Materials for Mechanical Engineering, 2006, 30(11): 63-65. (in Chinese)

[11]  Yi-fan, MENG Xiang-jun, LI Shi-kai. Study on hot deformation behavioe of TA15 alloy [J]. Development and Application of Materials, 2010, 25(4): 28-32. (in Chinese)

Yi-fan, MENG Xiang-jun, LI Shi-kai. Study on hot deformation behavioe of TA15 alloy [J]. Development and Application of Materials, 2010, 25(4): 28-32. (in Chinese)

[12] WU Cheng-bao, YANG He, FAN Xiao-guang, SUN Zhi-chao. Dynamic globularization kinetics during hot working of TA15 titanium alloy with colony microstructure [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 1963-1969.

[13] ZHU Jing-chuan, WANG Yang, LIU Yong, LAI Zhong-hong, ZHAN Jia-jun. Influence of deformation parameters on microstructure and mechanical properties of TA15 titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(s1): s490-s494.

[14] GUO Zhi-jun, WANG Jian, WANG Hong-wu. Effects of deformation parameters on microstructure and mechanical properties of TA15 alloy plate [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(s1): s40-s42. (in Chinese)

[15] MIN Xin-hua, ZHU Yi-fan, LIU Jin-sheng. Forging processes of TA15 alloy large diameter bar [J]. Rare Metal Materials and Engineering, 2008, 37(s3): 250-252. (in Chinese)

[16] DONG Jie, GAO Bo, ZHANG Yong-qiang, QIAO Eng-li, MA Long, GAO Hui. The forging technology of the large-standard TA15 alloy bar [J]. Rare Metal Materials and Engineering, 2008, 37(s3): 155-156. (in Chinese)

[17] WEI Yan-guang, TAO Hai-ming, CHEN Hai-shan. Effect of solid solution temperature on mechanical property of TB10 titanium alloy [J]. Chinese Journal of Rare Metals, 2010, 34(1): 6-10. (in Chinese)

[18] LI Shi-kai, HUI Song-xiao, YE Wen-jun, YU Yang, XIONG Bai-qing. Effects of microstructure on damage tolerance properties of TA15 ELI titanium alloy [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1119-1123. (in Chinese)

[19] ZHU Bao-hui, HU Xiao-chen, WU Meng-hai, WANG Pei-jun, LIU Yan-chang. Tensile properties and fractographs of finish forged bar of TC1 titanium alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(s1): s144-s147. (in Chinese).

锻造工艺对Ti-6.5Al-1Mo-1V-2Zr合金大规格棒材的组织与性能的影响

黄德明1,王怀柳2,陈 鑫2,陈 永1,郭 华1

1. 攀钢集团研究院有限公司 钒钛资源综合利用国家重点实验室,攀枝花 617000;

2. 攀钢集团江油长城特殊钢有限公司,江油 621700

摘 要: 研究三种锻造工艺条件下Ti-6.5Al-1Mo-1V-2Zr合金大规格棒材的力学性能、微观组织和拉伸断口。结果表明:采用拔长方式在β区高温和低温分别进行开坯锻造和成品锻造,获得的棒材的组织为粗大的魏氏组织,力学性能特别是塑性差,室温拉伸断口为脆性断口;采用镦拔方式在β区高温进行开坯锻造,再采用拔长方式在α+β区进行成品锻造,获得棒材的组织为双态组织,具有最佳的综合力学性能,室温拉伸断口为塑性断口。要获得合格的Ti-6.5Al-1Mo-1V-2Zr棒材,关键是开在坯锻造阶段进行充分镦拔以破碎铸锭原始组织,并在成品锻造阶段控制锻造温度和变形量。

关键词: Ti-6.5Al-1Mo-1V-2Zr;棒材;锻造;微观组织;力学性能

(Edited by Jing-hua FANG)

Corresponding author: De-ming HUANG; Tel: +86-13540702017; E-mail: deming_huang 03@163.com

DOI: 10.1016/S1003-6326(13)62729-6