文章编号:1004-0609(2014)12-2978-07

往复挤压工艺对Mg-5Sn-1.5Al-1Zn-1Si合金组织演变的影响

张建新1, 3,高爱华2,郭学锋1,崔红保1

(1. 河南理工大学 材料科学与工程学院,焦作 454000;

2. 河南理工大学 机械与动力工程学院,焦作 454000;

3. 河南理工大学 文法学院,焦作 454000)

摘 要:研究挤压温度、挤压速度及道次对铸态Mg-5Sn-1.5Al-1Zn-1Si合金显微组织的影响。结果表明:合金显微组织的均匀性随着挤压温度的升高表现出先提高后降低的趋势。当温度较低时,动态再结晶过程缓慢,晶粒尺寸不均匀;当温度较高时,动态再结晶过程速度加快,晶粒较粗大。晶粒尺寸随着挤压速度的增加表现出先减小后增大的趋势,速度较小或较大均会造成合金显微组织的不均匀。当挤压速度较小时,容易出现二次再结晶过程;当挤压速度较大时,再结晶过程不充分。随着挤压道次的增加,合金显微组织的均匀性逐渐提高,晶粒尺寸表现出先减小后增大的趋势。往复挤压超过7道次后,晶粒细化效果减弱,合金显微组织中重新出现大尺寸的晶粒,位错组态由位错墙向位错胞转化。

关键词:镁合金;往复挤压;工艺参数;组织演变

中图分类号:TG146.2 文献标志码:A

Effect of reciprocating extrusion process on microstructure evolution of Mg-5Sn-1.5Al-1Zn-1Si magnesium alloy

ZHANG Jian-xin1, 3, GAO Ai-hua2, GUO Xue-feng1, CUI Hong-bao1

(1. Institute of Materials Science and Engineering, Henan Polytechnic University, Jiaozuo 454000, China;

2. Institute of Mechanical and Power Engineering, Henan Polytechnic University, Jiaozuo 454000, China;

3. Institute of Liberal Arts and Law, Henan Polytechnic University, Jiaozuo 454000, China)

Abstract: The effects of extrusion temperature, extrusion speed and extrusion passes on microstructure of the as-cast Mg-5Sn-1.5Al-1Zn-1Si magnesium alloy were studied. The results indicate that the uniformity of alloy microstructure increases firstly, and then reduces with the increase of extrusion temperature. When temperature is lower, the dynamic recrystallization is slow and the grain sizes are uneven; when the temperature is higher, the dynamic recrystallization process is accelerating and grains are coarse. With the increase of extrusion speed, the grain size decreases firstly and then increases, a slower or faster extrusion speed will cause inhomogeneous distribution of the microstructure. When the extrusion speed is slower, the secondary recrystallization processes occur easily, while the faster extrusion speed causes insufficiency of recrystallization process. With the increase of extrusion passes, the microstructure uniformity improves gradually and the grain size decreases firstly and then increases. After reciprocating extrusion (REX) for more than 7 passes, the refining effect becomes weaken and large grains appear in the microstructure again, and the dislocation configuration transforms from dislocation walls to dislocation cells.

Key words: magnesium alloy; reciprocating extrusion; technological parameter; microstructure evolution

镁合金材料由于具有轻质环保和可再生利用的特点,近几年发展速度较快,在航空航天、轨道交通、机械电子等领域得到广泛应用,是目前发展较快的金属材料[1-4]。然而,随着时代的进步,普通镁合金已不能满足市场需求,其研发方向已朝着高性能发展,如高强韧、高耐热性等[5-7]。往复挤压包括挤压和镦粗两个连续过程,它能显著改善合金的组织性能,是获得高性能材料的重要手段[8-12]。这方面的报道很多,如宋佩维[13]研究了往复挤压Mg-4Al-2Si-0.75Sb镁合金的显微组织与力学性能,重点分析了基体组织和Mg2Si相的细化机制;WANG等[14]研究了往复挤压AM60B镁合金的组织与力学性能,着重探讨了挤压道次对合金组织细化及力学性能的改善;杨文朋等[15]研究了往复挤压镁合金再结晶组织表征,阐明了变形组织及晶粒分布与再结晶的关系。然而,目前关于往复挤压工艺参数对往复挤压合金的系统研究较少。本文作者研究了挤压温度、挤压速度和挤压道次对以Mg-5Sn- 1.5Al-1Zn-1Si镁合金显微组织的影响,为开发高性能镁合金提供了理论依据。

1 实验

在井式坩埚炉中熔炼相应的合金试样,采用体积分数为0.5%的SF6+Ar混合气体保护,主要原料为高纯Mg、纯Sn、99.9% Al和99.9% Zn(质量分数),采用Mg-10Si中间合金形式加入Si。将直径为20 mm的铸态合金加工成d 17.8 mm×80 mm规格的挤压试样,在ZZSM-MY-100型液压机上进行多道次往复挤压,得到d 18.0 mm的往复挤压态合金材料。从加工态合金的中间部位切割相应的金相试样,经过打磨、预磨、抛光处理后,使用体积分数为4%的硝酸酒精溶液腐蚀,然后采用金相显微镜(OM)和扫描电子显微镜(SEM)观察合金显微组织形貌及合金相分布特征,采用JEM-2100型透射电子显微镜(TEM)观察合金的亚晶结构及位错组态。

2 结果与分析

2.1 挤压温度对合金显微组织的影响

镁合金的挤压温度范围很宽,多在300~400 ℃之间进行多道次加工[16-18]。为了分析挤压温度对Mg-Sn-Al-Zn-Si合金挤压组织的影响规律,实验中设定挤压比为12.96,挤压道次为5道次,在一定的挤压速率下,分别在320、340和360 ℃下把合金挤压成一定尺寸的棒材,各样品的显微组织如图1所示。

图1 不同温度下往复挤压Mg-5Sn-1.5Al-1Zn-1Si合金的显微组织

Fig. 1 Microstructures of reciprocating extruded Mg-5Sn- 1.5Al-1Zn-1Si alloys at different temperatures

由图1可知,Mg-5Sn-1.5Al-1Zn-1Si合金在320~ 360 ℃范围内往复挤压后,合金组织进行完全动态再结晶,合金组织较均匀,随着挤压温度的变化,晶粒尺寸在8~10.5 μm范围内波动。当温度较低时,合金元素扩散较慢,相同时间内发生动态再结晶的速度变缓,新晶粒吸收和消耗位错的速度减弱,造成组织中位错密度不一样、晶粒大小不均匀的现象(见图1(a));当温度升高到340 ℃时,合金元素扩散速率变快,动态再结晶较充分,晶粒细化较容易通过晶界滑移的途径实现,塑性变形过程中晶粒不断吸收晶界处的位错,并通过有利转动协调周围晶粒的位向,所以组织中的位错密度不高,晶粒大小趋于一致,晶粒平均尺寸基本维持在8 μm(见图1(b));当挤压温度较高时,合金动态再结晶过程加快,晶粒更容易长大,虽然新晶粒的形成也消耗一定数量的位错,但晶粒长大占据优势,为主要控制机制,最终晶粒较粗大(见图1(c))。同时,温度较高时容易出现二次再结晶,少数晶粒处于长大的有利条件,吞食其周围的小晶粒,最后形成晶粒大小极不均匀的组织,这对合金的力学性能不利,一般合金组织中应避免出现二次再结晶过程。因此,在其他挤压条件确定时,随着挤压温度的升高,Mg-5Sn- 1.5Al-1Zn-1Si显微组织有粗化趋势,合理的温度也有利于动态再结晶的进行。

与单挤压相比,往复挤压的变形量大,使合金组织均匀性得到大幅度提高,尤其是试样经过多道次加工后,合金组织均匀性更高。从图1可以看出,往复挤压过程中,合金相的分布对温度并不敏感,颗粒尺寸与加工道次关系密切,挤压道次越多,晶粒尺寸越小,晶粒分布较均匀。

图2所示为实验合金在340 ℃经过5道次挤压后Mg-5Sn-1.5Al-1Zn-1Si合金的SEM像,其中的白色物质为第二相颗粒(主要为Mg2Si、Mg2Sn和Mg32(Al,Zn)49)。由图2可知,往复挤压后第二相颗粒均匀细小,呈现弥散分布,晶粒尺寸大多小于3 μm。

图2 往复挤压Mg-5Sn-1.5Al-1Zn-1Si合金的SEM像

Fig. 2 SEM image of reciprocating extruded Mg-5Sn-1.5Al- 1Zn-1Si magnesium alloy

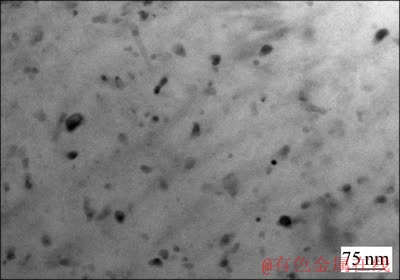

在往复挤压过程中,由于变形量大,晶粒参与位错增值,同时,各晶粒间需要相互协调共同完成塑性变形。图3所示为在340 ℃条件下往复挤压5道次Mg-5Sn-1.5Al-1Zn-1Si的TEM像。由于晶粒内部不同区域滑移系开动情况不同,造成图3中各区域独立分割,形成小胞块,同时位错组态自发向低能状态下转化,形成位向差极小的亚结构,这就是合金形变过程中出现的亚晶。由此可见,动态再结晶对位错迁移和重排起关键作用,位错组态所引起的变化主要是多边化和亚晶形成。

图3 往复挤压Mg-5Sn-1.5Al-1Zn-1Si合金中的亚晶结构

Fig. 3 Subgrain microstructure of reciprocating extruded Mg-5Sn-1.5Al-1Zn-1Si alloy

2.2 挤压速度对合金显微组织的影响

在往复挤压过程中,由于合金组织随着挤压道次的增加而变化,因此各道次的挤压力不同,实验中挤压力的变化范围是300~500 kN。一般通过改变挤压速度的方式控制挤压时间的长短。挤压速度对合金组织性能的影响较大,当挤压速度较小时,挤压时间较长,组织中容易出现晶粒粗化及二次再结晶;当挤压速度较大时,挤压时间较短,晶界的迁移速度加快,变形热扩散不均匀,致使再结晶组织不均匀。为了分析挤压速度对合金组织的影响规律,实验中设定挤压比为12.96,挤压道次为5,挤压温度为340 ℃,采用3、5和7 mm/min 3种不同的速度对合金进行往复挤压。各试样的挤压组织如图4所示。

对比3种不同挤压速度下的金相组织,可以得出以下结论:随着挤压速度的增加,平均晶粒尺寸呈现出先降低后升高的趋势,合理的挤压速度对组织细化具有重要作用,挤压速度较小或较大均能造成挤压合金晶粒粗化。当挤压速度较小时,挤压时间过长,再结晶中产生的细小晶粒生长时间较充足,最终得到晶粒粗大的合金组织,少数晶粒的尺寸大于30 μm,变形过程中出现了二次再结晶现象,晶粒尺寸均匀性明显较低(见图4(a));当挤压速度增加到5 mm/min时,挤压时间缩短,合金的再结晶时间适中,再结晶过程充分,最终得到的晶粒不仅均匀细小,而且平整度较高,平均晶粒尺寸约为8 μm(见图4(b)),是3种挤压速度下最为理想的合金组织;当挤压速度较大时,挤压时间较短,热量分布不均匀,而温度高的地方再结晶过程充分,晶粒迅速长大,温度低的地方再结晶过程不完全,晶粒来不及长大(见图4(c))。另外,从图4(c)还可以看出,由于挤压速度较快,第二相颗粒的均匀度明显下降(见图5),因此,挤压速度过快对颗粒相分布也有负面影响。

图4 不同挤压速度下往复挤压Mg-5Sn-1.5Al-1Zn-1Si合金的显微组织

Fig. 4 Microstructures of reciprocating extruded Mg-5Sn- 1.5Al-1Zn-1Si alloy at different extrusion speeds

图5 合金在快速挤压下Mg-5Sn-1.5Al-1Zn-1Si合金的SEM像

Fig. 5 SEM image of Mg-5Sn-1.5Al-1Zn-1Si alloy at rapid extrusion speed

图6所示为在快速挤压Mg-5Sn-1.5Al-1Zn-1Si合金的显微组织。采用较大的挤压速度对组织的均匀性不利,不仅晶粒出现狭长变形,而且亚晶结构也呈现长条状。主要原因在于金属流动过快,晶粒在较短的时间内来不及转动或协调变形,最终沿挤压力方向被拉长。

图6 快速挤压Mg-5Sn-1.5Al-1Zn-1Si合金的TEM像

Fig. 6 TEM image of Mg-5Sn-1.5Al-1Zn-1Si alloy at rapid extrusion speed

2.3 挤压道次对合金显微组织的影响

关于挤压道次对合金显微组织的影响,目前的研究结果不够统一,如王渠东等[19]研究了往复挤压变形对ZK60镁合金力学性能的影响,指出往复挤压8道次后塑性大幅度提高,轴向拉伸强度下降;徐春杰等[20]研究了往复挤压高韧Mg-Zn-Y合金,发现2道次后,合金晶粒细化与强度改善已不明显;12道次时合金的拉伸强度下降。可见,对于不同成分合金,挤压道次影响不尽相同,需要深入研究。为了探索挤压道次对Mg-5Sn- 1.5Al-1Zn-1Si合金的影响规律,实验中设定挤压比为12.96,温度为340 ℃,挤压速度为5 mm/min,对合金进行不同道次的往复挤压各试样的显微组织如图7所示。

由图7可知,随着挤压道次的增加,合金显微组织得到明显细化,晶粒尺寸呈现出先减小后增大的趋势。在一定条件下,合金经过1道次往复挤压后,平均晶粒尺寸约为10.0 μm,其中伴随着少量尺寸为20 μm的粗晶粒,合金相的分布呈现网状聚集,显微组织的均匀性不高(见图7(a));合金经过3道次挤压后,平均晶粒尺寸为9.0 μm,显微组织中很难找到相对粗大的晶粒,合金相的网状聚集得到改善,组织均匀性得到提高(见图7(b));合金经过5道次挤压后,显微组织与3道次试样的十分相似,但晶粒尺寸和颗粒相尺寸略有减小,平均晶粒尺寸大小为8.1 μm,颗粒相尺寸小于3 μm(见图7(c))。随着挤压道次的增加,7道次挤压试样组织更加优异,不仅晶粒尺寸的均匀性较高,而且颗粒相分布更加弥散,细化效果较为显著,晶粒尺寸约为7.7 μm(见图7(d))。而经过9道次往复挤压后,细化效果开始减弱,显微组织中重新出现了少量大晶粒,但颗粒相的分布依然较均匀(见图7(e))。以上分析可知,在一定的条件下,对于Mg-5Sn-1.5Al- 1Zn-1Si合金,随着挤压道次的增加,合金显微组织逐渐得到细化,颗粒相均匀度得到改善,7道次达到最佳挤压效果,之后,合金晶粒出现粗化现象。

图7 往复挤压不同道次的Mg-5Sn-1.5Al- 1Zn-1Si合金的显微组织

Fig. 7 Microstructures of REXed Mg-5Sn- 1.5Al-1Zn-1Si alloy at different passes

图8所示为不同挤压道次Mg-5Sn-1.5Al-1Zn-1Si合金位错的分布及塞积情况。由图8可知,在一定的条件下,随挤压道次增加,合金获得的应变量逐渐增大,位错在颗粒处发生塞积的数目增多,位错密度逐渐增大,如图8(b)可知,已经产生了明显的位错胞。在塑性变形初期,组织中各种缺陷修复速度较快,位错运动阻力小,变形容易,此时,位错密度处于上升阶段;在塑性变形中期,随着变形量的累积,位错减少的速度和位错增加的速度处于动态平衡,变形相对稳定;在塑性变形后期,随着位错密度升高,应力集中加剧,位错运动变缓,并在晶界、第二相颗粒以及不动位错处发生塞积,位错组态由位错墙向位错胞方向发展,变形抗力增加。这解释了关于化合物相不能无限细化的原因,当颗粒相破碎所需要的应力大于外加应力时,就不可能再继续细化。

图9所示为经过7道次往复挤压后Mg-5Sn-1.5Al- 1Zn-1Si合金的TEM像。由图9可看出,经过往复挤压后,组织均匀性较高,合金相经过多次破碎,有的颗粒相更加细小,仅有20~30 nm左右,并均匀分散到基体之中,颗粒相的这种分布特征更加有利于改善挤压合金的组织性能。

图8 Mg-5Sn-1.5Al-1Zn-1Si合金往复挤压7和9道次的位错结构

Fig. 8 Dislocation structures of Mg-5Sn-1.5Al-1Zn-1Si reciprocating extruded alloys

图9 经过7道次往复挤压后Mg-5Sn-1.5Al-1Zn-1Si合金的TEM像

Fig. 9 TEM image of reciprocating extruded Mg-5Sn-1.5Al- 1Zn-1Si alloy after 7 passes

3 结论

1)对于Mg-5Sn-1.5Al-1Zn-1Si合金,合金相分布对挤压温度不敏感,随着温度的升高,组织尺寸均匀性出现先增加后降低的趋势。当温度较低时,动态再结晶缓慢,晶粒大小不均匀;当温度较高时,动态再结晶加快,晶粒较粗大。

2) 随挤压速度增加,Mg-5Sn-1.5Al-1Zn-1Si合金的晶粒尺寸呈现先减小后增大的趋势,挤压速度较小或较大均能造成合金晶粒尺寸不均匀。挤压速度较小时,合金组织中容易出现二次再结晶;挤压速度较大时,合金组织中再结晶过程不充分。

3) 对于Mg-5Sn-1.5Al-1Zn-1Si合金,随着挤压道次增加,合金组织的均匀性逐渐提高,晶粒尺寸呈现出先减小后增大的趋势,往复挤压超过7道次后,细化效果开始减弱,合金组织中重新出现大晶粒,位错组态由位错墙向位错胞转化。

4) 对于Mg-5Sn-1.5Al-1Zn-1Si合金,在挤压比一定的条件下,得到最佳晶粒尺寸的往复挤压工艺为在340 ℃的挤压温度下,采用5 mm/min的挤压速度,对试样进行7道次往复挤压。

REFERENCES

[1] FANG Xi-ya, YI Dan-qing, LUO Wen-hai, WANG Bin, ZHANG Xiao-juan, ZHENG Feng. Effects of yttrium on recrystallization and grain growth of Mg-4.9Zn- 0.7Zr alloy[J]. Journal of Rare Earths, 2008, 26(3): 392-396.

[2] ARR G, HUR I, VAI J, CIN C, DEV S, TOW J, MAH S, WEN A, WEI K, BEN A. Development of investment-casting process of Mg-alloys for aerospace applications[J]. Advanced Engineering Materials, 2007, 9(9): 751-756.

[3] EASTON M, SONG WQ, ABBOTT T. A comparison of the deformation of magnesium alloys with aluminium and steel in tension, bending and buckling[J]. Materials and Design, 2006, 27(10): 935-942.

[4] 张金山, 姬国强, 王 星, 张照光, 许春香, 王红霞, 陶卫建, 孙 勇. Sm对AM60合金显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2012, 41(4): 617-621.

ZHANG Jin-shan, JI Guo-qiang, WANG Xing, ZHANG Zhao-guang, XU Chun-xiang, WANG Hong-xia, TAO Wei-jian, SUN Yong. Effect of Sm on microstructure and mechanical properties of AM60 magnesium alloy[J]. Rare Metal Materials and Engineering, 2012, 41(4): 617-621.

[5] YUAN Y C, MA A B, JIANG J H, LU F M, JIAN W W, SONG D, ZHU Y T. Optimizing the strength and ductility of AZ91 Mg alloy by ECAP and subsequent aging[J]. Materials Science and Engineering A, 2013, 588: 329-334.

[6] 张 静, 袁付庆, 黄 浩. 铸态和挤压变形态Mg-Zn-Al-Re镁合金的室温和高温力学性能[J]. 稀有金属材料与工程, 2013, 42(3): 593-596.

ZHANG Jing, YUAN Fu-qing, HUANG Hao. Mechanical properties of as-cast and as-extruded Mg-Zn-Al-Re magnesium alloys at room temperature and elevated temperatures[J]. Rare Metal Materials and Engineering, 2013, 42(3): 593-596.

[7] ORLOV D, RALSTON K D, BIRBILIS N, ESTRIN Y. Enhanced corrosion resistance of Mg alloy ZK60 after processing by integrated extrusion and equal channel angular pressing[J]. Acta Materialia, 2011, 59(15): 6176-6182.

[8] RICHER T M,  H P, ZEHETBAUER M J, RICHERT J, PIPPAH R, MOTZ C, SCHAFLER E. Work hardening and microstructure of AlMg5 after severe plastic deformation by cyclic extrusion and compression[J]. Materials Science and Engineering A, 2003, 355(1/2): 180-185.

H P, ZEHETBAUER M J, RICHERT J, PIPPAH R, MOTZ C, SCHAFLER E. Work hardening and microstructure of AlMg5 after severe plastic deformation by cyclic extrusion and compression[J]. Materials Science and Engineering A, 2003, 355(1/2): 180-185.

[9] 李安涛, 王锦程, 司 林, 赖云亭, 杨根仓. 往复挤压对Mg-0.85Zn-0.15Y-0.6Zr铸态组织和力学性能的影响[J]. 稀有金属材料与工程, 2011, 40(3): 515-518.

LI An-tao, WANG Jin-cheng, SI Lin, LAI Yun-ting, YANG Gen-cang. Effects of reciprocating extrusion on microstructures and mechanical properties of as-cast Mg-0.85Zn-0.15Y-0.6Zr alloys[J]. Rare Metal Materials and Engineering, 2011, 40(3): 515-518.

[10] LEE SW, YEH JW. Superplasticity of 5083 alloys with Zr and Mn additions produced by reciprocating extrusion[J]. Materials Science and Engineering A, 2007, 460/461: 409-417.

[11] LEE S, CHEN Y L, WANG H Y, YANG C F, YEH J W. On mechanical properties and superplasticity of Mg-15Al-1Zn alloys processed by reciprocating extrusion[J]. Materials Science and Engineering A, 2007, 464(1/2): 76-84.

[12] 赖云亭, 王锦程, 司 林, 李安涛, 杨根仓. 往复挤压对Mg-6%Si合金组织与力学性能的影响[J]. 稀有金属材料与工程, 2011, 40(3): 519-521.

LAI Yun-ting, WANG Jin-cheng, SI Lin, LI An-tao, YANG Gen-cang. Effects of reciprocating extrusion on microstructures and mechanical properties of Mg-6%Si alloy[J]. Rare Metal Materials and Engineering, 2011, 40(3): 519-521.

[13] 宋佩维. 往复挤压Mg-4Al-2Si-0.75Sb镁合金的显微组织与力学性能[J]. 金属热处理, 2011, 36(3): 1-8.

SONG Pei-wei. Microstructure and mechanical properties of Mg-4Al-2Si-0.75Sb magnesium alloy by reciprocating extrusion[J]. Heat Treatment of Metals, 2011, 36(3): 1-8.

[14] WANG Li-ping, CHEN Tian, JIANG Wen-yong, FENG Yi-cheng, CAO Guo-jian, ZHU Yan. Microstructure and mechanical properties of AM60B magnesium alloy prepared by cyclic extrusion compression[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3200-3205.

[15] 杨文朋, 郭学锋, 任 昉, 梁世何. 往复挤压镁合金再结晶组织表征[J]. 中国有色金属学报, 2013, 23(10): 2730-2735.

YANG Wen-peng, GUO Xue-feng, REN Fang, LIANG Shi-he. Characterization of recrystallized microstructure of reciprocating extruded magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(10): 2730-2735.

[16] LIU Jun-wei, CHEN Zhen-hua, CHEN Ding, LI Gui-fa. Deformation mechanism and softening effect of extruded AZ31 magnesium alloy sheet at moderate temperatures[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1329-1334.

[17] 王 琪, 王 斌, 易丹青, 刘会群, 臧 冰, 文 智. 二次挤压对MB26镁合金棒材组织及性能的影响[J]. 中国有色金属学报, 2012, 22(6): 1527-1533.

WANG Qi, WANG Bin, YI Dan-qing, LIU Hui-qun, ZANG Bing, WEN Zhi. Effect of double extrusion on microstructure and properties of MB26 magnesium alloy rod[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1527-1533.

[18] WATANABE H, MUKAI T, ISHIKAWA K. Effect of temperature of differential speed rolling on room temperature mechanical properties and texture in an AZ31 magnesium alloy[J]. Journal of Materials Processing Technology, 2007, 182(1/3): 644-647.

[19] 王渠东, 林金保, 彭立明, 陈永军. 往复挤压变形对ZK60镁合金力学性能的影响[J]. 金属学报, 2008, 44(1): 55-58.

WANG Qu-dong, LIN Jin-bao, PENG Li-ming, CHEN Yong-jun. Influence of cycle extrution and compression on the mechanical property of Mg alloy ZK60[J]. Acta Metallurgica Sinica, 2008, 44(1): 55-58.

[20] 徐春杰, 郭学锋, 郑水云, 张忠明. 往复挤压高韧Mg-Zn-Y合金[J]. 材料工程, 2007(7): 16-20.

XU Chun-jie, GUO Xue-feng, ZHENG Shui-yun, ZHANG Zhong-ming. Mg-Zn-Y alloy with high elongation properties by reciprocating extrusion[J]. Journal of Materials Engineering, 2007(7): 16-20.

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51271073);国家大学生创新创业训练计划项目(72306/044)

收稿日期:2014-04-29;修订日期:2014-07-28

通信作者:张建新,副教授,博士研究生;电话:0391-3986659;E-mail: edu001@163.com