文章编号: 1004-0609(2006)06-1064-06

纳米CeO2的醇水法制备及其对GaAs晶片的抛光性能

陈志刚1, 李霞章2, 陈 杨1, 陈建清3, 倪超英4

(1. 江苏工业学院 材料科学与工程系, 常州 213016; 2. 江苏大学 材料科学与工程学院, 镇江 212013;

3. 河海大学 材料科学与工程系, 南京 210098; 4. 特拉华大学 材料科学与工程系, 纽华克19711, 美国)

摘 要: 在醇-水体系中以HMT为缓释沉淀剂制备了纳米CeO2粉体, 并用TEM、 SAD、 XRD对其进行了表征, 将制备的不同粒径纳米CeO2粉体配制成抛光液, 对GaAs晶片进行了化学机械抛光。 研究了醇的引入及煅烧温度对粉体性能的影响, 并就纳米CeO2磨料尺寸对GaAs晶片抛光后表面粗糙度的影响机理进行了探讨。 结果表明: 醇水体系中制备的纳米CeO2颗粒较水溶液中制备的颗粒粒径小, 且分散性好; 随着煅烧温度的升高, 颗粒逐渐增大, 不同尺寸的纳米颗粒具有不同的抛光效果; 随着磨料粒径的增大, 表面粗糙度值也随之升高。

关键词: 纳米CeO2; GaAs; 醇水法; 抛光 中图分类号: TG146; TG356.28

文献标识码: A

Synthesis of nano-sized CeO2 via alcohol-water method and its polishing performance on GaAs wafer

CHEN Zhi-gang1, LI Xia-zhang2, CHEN Yang1, CHEN Jian-qing3, NI Chao-ying4

(1. Department of Materials Science and Engineering, Jiangsu Polytechnic University,Changzhou 213016, China;

2. School of Materials Science and Engineering, Jiangsu University,Zhenjiang 212013, China;

3. Department of Materials Science and Engineering, Hehai University,Nanjing 210098, China;

4. Department of Materials Science and Engineering, University of Delaware,Newark 19711, USA)

Abstract: Nano-sized CeO2 powders were synthesized by homogeneous precipitation method in alcohol-water solution with HMT as precipitator, the powders were characterized by TEM, SAD and XRD. The prepared powders were collocated into polishing slurry for chemical mechanical polishing of GaAs wafer. The effects of alcohol nature and calcine temperature on the resultant CeO2 nanoparticles were investigated, and the influence mechanism of nano-CeO2 size on the roughness of GaAs wafer was also discussed. The results show that the particles prepared by the above method are of smaller size and better dispersion than those obtained from the ordinary powders synthesized in water solution. The particle size become larger with the increase of calcination temperature. Various size of particles have the different polishing effect, of which the surface roughness rises with the increase of particle size.

Key words: nano-sized CeO2; GaAs; alcohol-water method; polishing

纳米CeO2是一种用途极广的材料, 广泛应用于气体传感器[1]、 燃料电池[2]、 化学机械抛光[3]、 汽车尾气净化催化 [4]等。 目前, 制备纳米CeO2的方法有很多, 归纳起来主要有固相法、 液相法、 气相法三大类, 其中液相法由于反应条件温和可控, 产物纯度高且粒径分布窄等优点而得到了广泛运用。

传统的液相合成纳米粉体遇到的普遍性问题是颗粒粒径尺寸大小及分布难以控制, 团聚严重, 单分散性差[5]。 为此, 国内外学者做了许多探索与改进。 其中用醇水混合溶液来替代传统的单一水溶液作为反应介质的方法——称之为醇水法, 由于其在纳米粉体制备中特有的粒径控制与反团聚方面的优势, 正越来越引起人们极大的研究兴趣[6-9], 而迄今用醇水法来制备纳米CeO2粉体的相关报道却很少。 同时CeO2作为抛光料的使用已经有了很多年的历史, 被广泛的应用于精密玻璃抛光和ULSI二氧化硅介质层的化学机械抛光, 表现出很强的抛光能力。 目前国际上在GaAs晶片化学机械抛光中普遍使用的是SiO2磨料, 尚未发现使用CeO2颗粒作为磨料抛光GaAs晶片的报道。 基于此, 本研究在醇水混合溶液中合成了纳米CeO2粉体颗粒, 对其进行了表征, 并配制成抛光液, 对GaAs晶片进行了抛光实验。

1 实验

1.1 纳米CeO2的制备与表征

所用试剂与材料为: Ce(NO3)3·6H2O(分析纯), 六亚甲基四胺(简称HMT, 分析纯), 无水乙醇(分析纯), 蒸馏水(自制), 双氧水(质量浓度30%, 分析纯), KOH(分析纯), GaAs(111)晶片(已用粗粉经过预抛光)。 称取一定量的Ce(NO3)3·6H2O溶于无水乙醇中, 再称取一定量的HMT溶于蒸馏水中, 分别加以搅拌, 将两种溶液混合并用电动搅拌器搅拌均匀, 其中HMT与Ce(NO3)3摩尔比为20∶1, 醇水体积比为3∶1。 混合溶液放入75℃水浴中恒温加热约1h, 反应完全后取出在循环水下快速冷却, 静置1h, 倒出上层清液, 将沉淀物水洗2遍, 乙醇洗涤2遍, 放入70℃鼓风干燥箱中干燥10h左右, 在200~600℃煅烧2h, 得到淡黄色的纳米CeO2粉体。

采用JEM-2010F型透射电子显微镜观察颗粒形貌并进行选区电子衍射, 用Rigaku X-Ⅲ射线衍射仪对粉体进行物相分析。

1.2 GaAs晶片的抛光与表面性能测试

称取一定量粉体超声分散于蒸馏水中配制成质量浓度为1%的抛光液, 再加入一定量的氧化剂双氧水, 用KOH调节溶液pH值至9, 并搅拌均匀。 在一定抛光压力(2N)、 转速(200r/min)和时间(30min)下, 使用美国Buehler PHOENIX BETA型抛光机进行抛光实验。

抛光完后随机切下一小片GaAs晶片并用丙酮清洗, 置于原子力显微镜下观察表面微观形貌并测量其表面微观粗糙度。 AFM型号为: Nanoscope Ⅲa, Mutimode SPM, 美国DI公司, 纵向分辨率为0.1nm, 横向分辨率为0.01nm。

2 结果与讨论

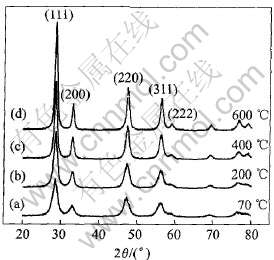

由于HMT是种缓释沉淀剂, 在受热的条件下能缓慢水解成氨和甲醛, 氨再水解产生沉淀剂OH-, 同时HMT还具有氧化性, 能将溶液中的Ce3+氧化成Ce4+[10], 这就为Ce4+沉淀前驱体的产生提供了更为有利的条件。 上述过程涉及到的化学反应可以表述为

湿沉淀前驱体经过烘干后, 表面吸附水及乙醇分子逐渐挥发, 即可得到较纯的CeO2粉体。

2.1 醇对粉体性能的影响

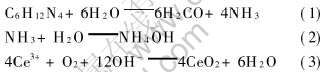

为做比较, 作者在同样的Ce(NO3)3和HMT用量的条件下以单一的水为溶剂制备了CeO2沉淀前驱体, 同样也经过70℃烘干, 其透射电镜观测图如图2所示。 可以看出, 醇水溶液中制备出的CeO2颗粒较水溶液中制备的颗粒尺寸小, 且分散性好, 对应的选区电子衍射花样表明两者均是立方萤石结构的CeO2。 同时可以发现, 醇水溶液中制备颗粒的衍射花样较水溶液中的展宽略大。 根据X射线理论, 粉末衍射峰的锐利程度与衍射粉末的颗粒大小有关, 衍射颗粒尺寸越小, 则衍射峰越展宽, 这也与TEM观察的结果相吻合。 晶体成核的热力学原理表明, 在液相环境中, 得到稳定最小晶体的粒径与过饱和比的关系可以用Keivin公式来表示, 即:

式中 r为临界颗粒半径; σs-l为新生的晶体与溶液间的固液表面自由能; M为结晶物质的相对分子质量; v为每分子溶质中离子的数目, 对自由分子构成的晶体; v=1, R为摩尔气体常数; T为形成晶体时系统的绝对温度; 忽略以上参数的影响, 其中过饱和比S为主要的影响因素, S为溶液实际浓度c与溶质溶解度cl的比值, 可表示为

溶液的溶剂化效应理论[11]认为, 溶液的介电常数越低, 则溶液的溶剂化能力越差。 由于醇的介电常数小于水, 当醇加入时, 溶液的介电常数随之降低, 导致过饱和比S增大, 从而促进生成形核半径更小的颗粒。 另一方面, 由于醇带有羟基, 溶液中大量醇的存在也能起到一定的空间位阻作用[12], 降低了颗粒间碰撞的几率, 在一定程度上起到了分散保护的作用, 这都有利于生成尺寸小、 分散性好的颗粒。

图1 不同溶液中制备粉体的TEM形貌及其衍射花样

Fig.1 TEM micrographs and SAD patterns of powders prepared in different solvents

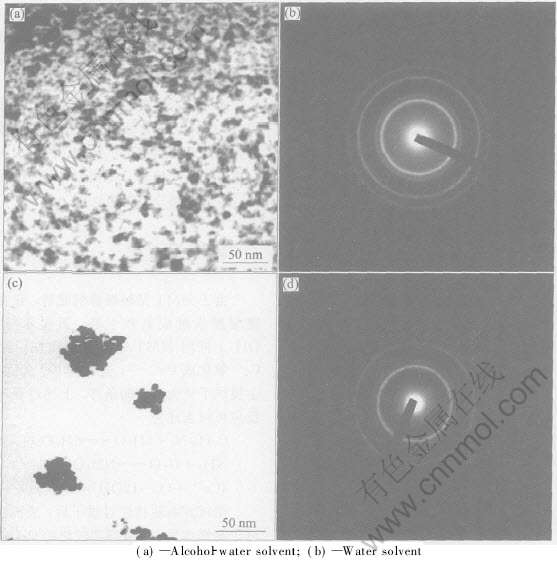

图2 不同温度处理后粉体的X射线衍射谱

Fig.2 XRD patterns of CeO2 powders treated at different temperatures

2.2 煅烧温度对粉体性能的影响

粉体烘干后分别在200, 400, 600℃进行煅烧, X射线衍射谱如图2所示。 可以发现, 随着煅烧温度的提高, 粉体没有发生物相的转变, 均是立方萤石结构的氧化铈, 这也与SAD结果相一致。 同时可以看出衍射峰逐渐变得尖锐, 说明煅烧过程使得粉体结晶性能更为完好, 另一方面也促进了晶粒的长大。

用透射电镜分别对烘干及煅烧后粉体的微区形貌进行观察, 如图3所示。 其中图3(a)为烘干后粉体样品的高分辨电子显微图(HREM), 可以发现其颗粒分界清晰, 单分散性好, 平均尺寸在8nm左右; 经200℃, 400℃温度煅烧后略有长大, 12nm左右; 600℃煅烧下颗粒长大显著, 平均粒径达到30nm, 同时分散性变差, 有一定程度的团聚。

2.3 纳米CeO2磨料对GaAs晶片的抛光效果与机理分析

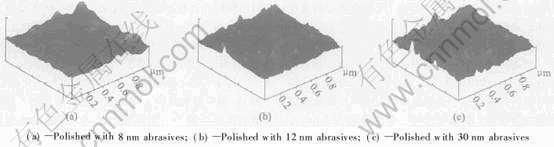

按照实验方法, 分别将制得的一次颗粒粒径在8, 12及30nm的CeO2粉体配制成相同质量浓度的抛光液, 对GaAs晶片进行了化学机械抛光, 抛光后表面微观形貌如图4所示。 可以看出, 8nm磨料的颗粒具有最好的抛光效果, AFM测试表明其表面粗糙度Ra值在1μm×1μm范围内达到了0.740nm, 随着颗粒粒径的增大, 晶片表面光洁度变差, Ra值分别升高到了1.117nm和1.605nm。

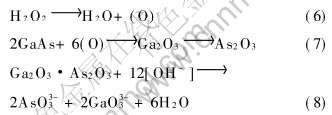

对于GaAs材料而言, 它易被活性氧氧化成Ga和As的三价氧化物, 而其氧化物具有两性, 易被酸和碱所溶解[13], 因此可以认为, 抛光液首先对GaAs产生了腐蚀作用, 化学反应过程如下:

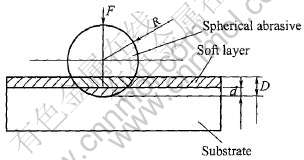

腐蚀后表面化学腐蚀层(称之为软质层)[14], 在磨料的机械磨削作用下不断被去除, 同时暴露出新鲜表面, 使整个过程循环进行。 在近似认为磨料颗粒为球形的前提下, 对单个颗粒与晶片表面的接触进行了简化, 如图5所示。 d=D-d0, 其中: D为纳米磨料颗粒嵌入到GaAs晶片表面的最大深度; d0为软质层的厚度(由腐蚀程度决定, 在本实验条件下可以认为是常数)。

图3 不同温度处理后粉体的TEM像

Fig.3 TEM images of CeO2 powders treated at different temperatures

图4 抛光后 GaAs表面微观形貌像

Fig.4 Morphologies of GaAs surface after polishing

图5 纳米磨料粒子与GaAs晶片间的接触模型

Fig.5 Contacting model between nano-sized abrasive particle onto GaAs wafer

由于前提是磨料具有的相同质量浓度, 因此可以认为, 颗粒粒径越大, 则参与研磨的有效粒子数越少, 在相同抛光压力的条件下, 单个颗粒承担的压力F则越大。 有文献表明, 抛光后表面粗糙度Ra值与切削深度d的平均值成正比[15], 即: Ra=kd。 在上述条件下, 当每个颗粒承担的压力F增大时, 则其嵌入到基体的最大深度D也必然增大并导致切削深度d的加大, 故表面粗糙度也会随之上升; 反之亦然。 这样就合理的解释了在相同的抛光工艺条件下, 磨料粒径增大后表面粗糙度随之上升的现象。

3 结论

1) 在醇水法制备纳米CeO2颗粒过程中, 醇的加入降低了溶液的介电常数从而降低了颗粒的形核半径, 并起到了一定的空间位阻作用, 提高了粉体的分散性。

2) 煅烧温度主要影响了颗粒的结晶性能, 随着煅烧温度的升高, 结晶性趋于完整, 同时晶粒长大, 但颗粒之间团聚程度也有所增大。

3) GaAs在抛光过程中表现为化学腐蚀与机械去除同时进行, 小颗粒的磨料表现出了较好的抛光效果, 相同的抛光工艺条件下, 随着纳米CeO2磨料粒径的增大, 表面粗糙度值随之升高, 原因在于粒径增大后单个颗粒承担的压力增大, 导致切削深度增加, 从而使得抛光后表面平整度下降。

REFERENCES

[1]Noriya I, Woosuck S, Norimitsu M, et, al. Resistive oxygen gas sensors based on CeO2 fine powder prepared using mist pyrolysis[J]. Sensors and Actuators B, 2002, 87: 95-99.

[2]Takashi H, Atsuko H, Takao I, et al. A lowoperating temperature solid oxide fuel cell in hydrocarbon-air mixtures[J]. Science, 2000, 288(16): 2031-2034.

[3]Tetsuya H, Yasushi K, Yuuki T, et al. Mechanism of polishing of SiO2 films by CeO2 particles[J]. Journal of Non-crystalline Solids, 2001, 283: 129-134.

[4]Kaspar J, Fornasiero P, Graziani M. Use of CeO2 based oxides in the three-way catalysis[J]. Catalysis Today, 1999, 50(2): 285-298.

[5]陈雪梅, 陈彩凤, 陈志刚. 超声沉淀法制备纳米Al2O3[J]. 中国有色金属学报, 2003, 13(1): 122-126.

CHEN Xue-mei, CHEN Cai-feng, CHEN Zhi-gang. Al2O3 nanopowder prepared by precipitation under ultrasonic radiation[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 122-126.

[6]Moon Y T, Park H K, Kim D K, et al. Preparation of monodisperse and spherical zirconia powders by heating of alcohol-aqueous salt solution[J]. J Am Ceramic Soc, 1995, 78(10): 2690-2694.

[7]Michael Z C, Andrew E P, Charls H B, et al. Sol-gel and ultrafine particle formation via dielectric tuning of inorganic salt-alcohol-water solutions[J]. Journal of Colloid and Interface Science, 2000, 222(1): 20-36.

[8]Choi J Y, Kim D K. Preparation of monodisperse and spherical powders by heating of alcohol-aqueous salt solutions[J]. Journal of Sol-gel Science and Technology, 1999, 15(3): 231-241.

[9]Fang C S, Chen Y W. Preparation of titania particles by thermal hydrolysis of TiCl4 in n-propanolsolution[J]. Materials Chemistry and Physics, 2003, 78: 739-745.

[10]Chen P L, Chen I W . Reactive cerium (Ⅳ) oxide powders by the homogeneous precipitation method[J]. J Am Ceram Soc, 1993, 76(6): 1577-1583.

[11]张永敏. 物理有机化学[M]. 上海: 上海科学技术出版社, 2001. 49-62.

ZHANG Yong-min. Physical Organic Chemistry[M]. Shanghai: Shanghai Science and Technology Press, 2001. 49-62.

[12]陈建清. 超细二氧化铈制备及其化学机械抛光机理研究[D]. 镇江: 江苏大学, 2004.

CHEN Jian-qing. Study on the Preparation and CMP Mechanism of Ultrafine CeO2[D]. Zhenjiang: Jiangsu University, 2004.

[13]卜俊鹏, 郑红军, 何宏家, 等. GaAs晶片化学机械抛光的机理分析[J]. 固体电子学研究与进展, 1997, 17(4): 399-402.

BU Jun-peng, ZHENG Hong-jun, HE Hong-jia, et al. GaAs wafer chemomechanical polishing mechanism[J]. Research & Progress of SSE, 1997, 17(4): 399-402.

[14]陈杨, 陈建清, 陈志刚, 等. 纳米磨料对硅晶片的超精密抛光研究[J]. 摩擦学学报, 2004, 24(4): 332-335.

CHEN Yang, CHEN Jian-qing, CHEN Zhi-gang, et al. Study on ultra-precision polishing of silicon wafer by nanosized abrasives[J]. Tribology, 2004, 24(4): 332-335.

[15]袁巨龙. 功能陶瓷的超精密加工技术[M]. 哈尔滨: 哈尔滨工业大学出版社, 2000. 40-46.

YUAN Ju-long. Ultraprecision Machining of Functional Ceramics[M]. Harbin: Harbin Institute of Technology Press, 2000. 40-46.

基金项目: 江苏省自然科学基金资助项目(BK2002010); 江苏省高技术资助项目(BG2004022)

收稿日期: 2005-10-10; 修订日期: 2006-02-10

通讯作者: 陈志刚, 教授; 电话: 0519-3290002; E-mail: czg@ujs.edu.cn

(编辑陈爱华)