DOI:10.19476/j.ysxb.1004.0609.2019.07.10

激光选区熔化Inconel 718合金高温腐蚀性能

滕 庆,李 帅,薛鹏举,田 健,魏青松,史玉升

(华中科技大学 材料成形与模具技术国家重点实验室,武汉 430074)

摘 要:研究激光选区熔化(Selective laser melting, SLM)制备Inconel 718合金的高温腐蚀性能,揭示了不同热处理工艺对腐蚀性能的影响规律。利用超景深显微镜、XRD、SEM表征了腐蚀后的形貌及产物。结果表明:SLM态的高温腐蚀质量损失速率远大于热处理态的,经标准热处理与均匀化热处理的合金其高温耐腐蚀性能与锻件的相当,时效热处理合金在经过25 h腐蚀后,原始态熔池边界消失,元素均匀化程度提高,氧、硫元素扩散通道关闭,抗腐蚀性能提高;经过75 h后,合金表面产物包括氧化物和硫化物,各热处理态合金表面的氧化物成分没有发生变化。重点分析和讨论SLM制备Inconel 718 合金的高温腐蚀机理,建立了SLM态Inconel 718 合金的高温腐蚀过程中元素扩散模型。

关键词:增材制造;激光选区熔化;Inconel 718;热处理;高温腐蚀

文章编号:1004-0609(2019)-07-1417-10 中图分类号:TG172.82 文献标志码:A

Inconel 718是一种含钼、铌的沉淀硬化型镍铬铁合金,主要强化相为 (Ni3Nb)和

(Ni3Nb)和 (Ni3(Al, Ti, Nb)),在700 ℃时具有高强度、良好的韧性和良好的耐腐蚀性能[1-3],被广泛应用于航空航天、石油化工和汽车工业等重要领域。该合金可通过调整热处理工艺获得不同的晶粒尺寸和性能,满足不同应用场合的性能要求。但是,镍基合金广泛存在机械加工性能差、铸造和锻造工艺难以控制的突出问题,在制造复杂结构零件时尤为突出。

(Ni3(Al, Ti, Nb)),在700 ℃时具有高强度、良好的韧性和良好的耐腐蚀性能[1-3],被广泛应用于航空航天、石油化工和汽车工业等重要领域。该合金可通过调整热处理工艺获得不同的晶粒尺寸和性能,满足不同应用场合的性能要求。但是,镍基合金广泛存在机械加工性能差、铸造和锻造工艺难以控制的突出问题,在制造复杂结构零件时尤为突出。

增材制造是近年来快速发展的先进制造技术之一,在制造复杂结构方面具有突出优势。其中激光选区熔化(Selective laser melting, SLM)技术被认为是最具潜力的金属增材制造工艺之一[4-6]。SLM利用高能束激光逐层熔化微细金属粉末,可制造近全致密的复杂金属零件,特别适合具有复杂结构、小批量零件的生产[7- 8],现已在医疗、航空等领域得到了应用[9]。SLM过程激光束快速扫描,形成微小熔池,其最大冷却速率可达1×106~1×107 K/s,获得微米级细晶[10],保证零件具有良好的宏观力学性能[11]。现阶段,已有不少研究单位对Inconel 718 SLM成形工艺及成形件力学性能进行了研究[12-15],但相对于不锈钢、钛合金等材料,其SLM成形工艺还不是非常成熟。主要原因是镍基合金更容易产生裂纹等缺陷,而Inconel 718 这种沉淀强化合金更是难以达到冶金效果。然而,在SLM制造过程中,由于激光能量高度集中,高速移动的激光会在粉末和凝固材料内产生复杂热流和非平衡相变,从而产生明显的微观偏析和热应力[16-17]。因此,SLM后续热处理对产品性能有重要影响。

镍基高温合金通常为航空发动机、燃气涡轮发动机等热端部件,由于燃油中有S、Al、V、Na等的杂质,燃烧过程中Na与S反应生成Na2SO4(熔点884 ℃),V和氧气会生成V2O5(熔点670 ℃)以及其他复杂的钒酸盐类物质[18-19]。这些物质沉积在部件表面形成盐膜,在持续高温下,盐膜发生物理化学变化,会加速金属材料的腐蚀。

SLM态金属组织与传统的铸造和锻造组织有明显差异。使用传统方法制备的Inconel 718合金的腐蚀性能已有不少的研究[20-22],但是针对激光选区熔化成形Inconel 718合金的腐蚀性研究比较少。JIA等[23]研究了SLM成形Inconel 718合金在空气中的氧化行为,实验表明氧化速率和材料的致密度密切相关;SLM态合金中的孔隙为氧气提供了传输通道,可观察到沿柱状晶晶界腐蚀的现象。宰雄飞等[24]研究了SLM成形Inconel 718 在酸性条件下腐蚀性,实验表明,经时效热处理后的合金比轧制态合金具有更正的腐蚀电位和更小的自腐蚀电流密度,其抗腐蚀性能较优。但是,有关SLM成形镍基高温合金的腐蚀机理特别是高温腐蚀性还未见报道。

为此,本研究表征SLM制备Inconel 718 合金在NaCl、Na2SO4条件下的高温(650 ℃)腐蚀特性。同时,研究SLM态和实施了不同热处理后合金的耐腐蚀性的变化规律,利用超景深显微镜、XRD和SEM等手段表征腐蚀形貌和产物,分析其腐蚀机理,为SLM制备Inconel 718镍基合金的工程应用提供理论基础。

1 实验

1.1 粉末材料

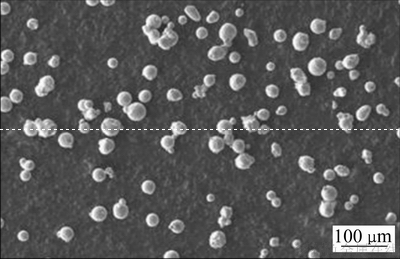

采用气雾化的镍基高温合金Inconel 718合金粉末(Hega-nars, Belgium),化学成分如表1所示。粉末微观形貌如图1所示,粉末多为球形或近球形,保证了在铺粉过程具有良好的流动性。实验前在烘箱中烘干10 h,以去除粉末中的水分。采用激光粒度仪(MAALVERN, Master Mini)检测粉末粒度,D10、D50和D90分别为20.4、30.63和45.6 μm,粉末的粒度大小整体呈现为正态分布。

图1 Inconel 718合金粉末形貌

Fig. 1 Morphology of Inconel 718 powder particles

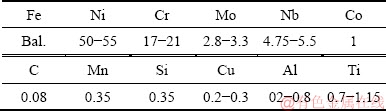

表1 Inconel 718粉末的化学成分

Table 1 Chemical composition of Inconel 718 powder particles (mass fraction, %)

1.2 设备及工艺

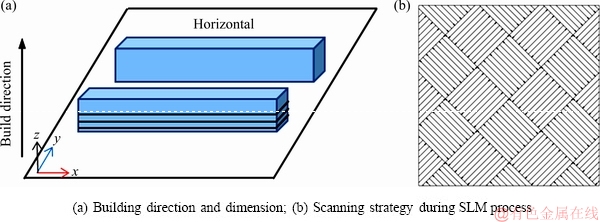

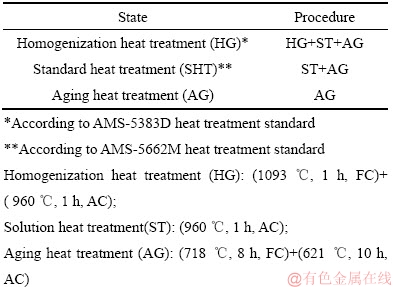

采用德国SLM Solution公司生产的SLMHL 250设备。采用氩气保护,氧含量为0.2%,基板预热100 ℃。实验中采用优化工艺参数:激光功率为180 W,扫描间距0.09 mm,铺粉层厚0.03 mm,成形样品尺寸为85 mm×10 mm×10 mm,分块扫描策略,如图2所示。采用真空热处理炉对SLM制备合金实施热处理,热处理制度如表2所示。

热腐蚀采用坩埚全浸法,动力学测定采用不连续失重法。将成形的样品采用线切割方式制备成10 mm×10 mm×10 mm大小的试样,用于热腐蚀实验。热腐蚀前,用游标卡尺测量每个立方块体的长、宽、高,计算其表面积。腐蚀盐成分(质量分数)为Na2SO4(75%)+ NaCl(25%)。实验过程中,将不同热处理态的样品埋入混合盐中,放入马弗炉,温度设置为650 ℃。分别在5、10、25、50和75 h取出样品清洗后去除表面腐蚀产物并称量,计算其质量变化。

1.3 检测方法

采用OM、SEM(JSM 7600F, JPN)观察显微组织和腐蚀后的形貌,利用EDS分析腐蚀产物的化学成分。采用日本岛津公司的X射线衍射仪(XRD-700S)完成物相测试,扫描角度30°~120°,扫描速度为10 (°)/min。

图2 SLM成形Inconel 718示意图

Fig. 2 Schematic diagram of Inconel 718 parts fabricated by SLM

表2 Inconel 718 真空热处理规范

Table 2 Specification for vacuum heat treatment of Inconel 718 fabricated by SLM

2 结果与讨论

2.1 腐蚀动力学

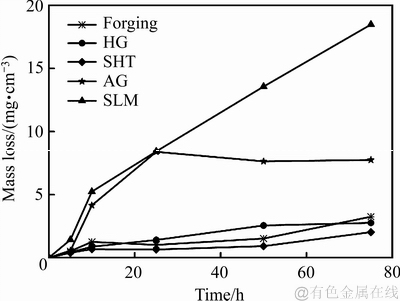

图3所示为SLM成形Inconel 718合金及热处理条件后的高温腐蚀曲线,可以看出,SLM态的高温腐蚀质量损失速率远大于热处理态的,SLM成形的Inconel 718合金经均匀化处理和标准热处理后的热质量损失率与同质锻件相当。SLM态合金的高温腐蚀过程明显分为两个阶段:腐蚀孕育阶段和加速腐蚀阶段。在5 h前合金质量基本不变,5 h后合金质量损失速率增大。75 h后,SLM态合金质量损失速率达到18 mg/cm3,是时效热处理的2.5倍,标准热处理的9倍。因此,可以看出SLM态的Inconel 718合金耐高温腐蚀性能不足,经热处理后其腐蚀性能明显增强[25-27]。

图3 SLM成形Inconel 718合金高温腐蚀曲线

Fig. 3 High-temperature corrosion curve of Inconel 718 alloy under various conditions

2.2 腐蚀产物相分析

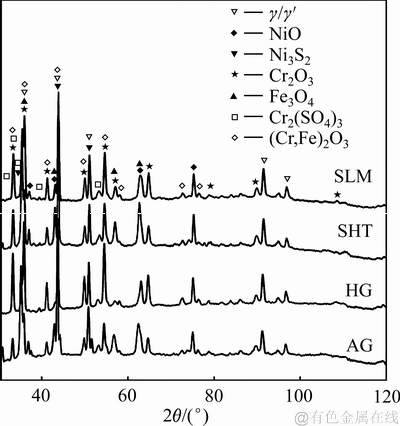

图4所示为经过75 h高温盐浴腐蚀后表面产物的XRD谱,经分析发现,除了基体相外,主要产物为Cr2O3、NiO、Fe3O4和Ni3S2,其中O和S元素主要来自于腐蚀盐Na2SO4,而不同热处理后合金腐蚀产物没有明显变化。

图4 高温腐蚀75 h后表面腐蚀产物的XRD谱

Fig. 4 XRD patterns of corrosion products after 75 h high- temperature corrosion test

2.3 腐蚀表面形貌分析

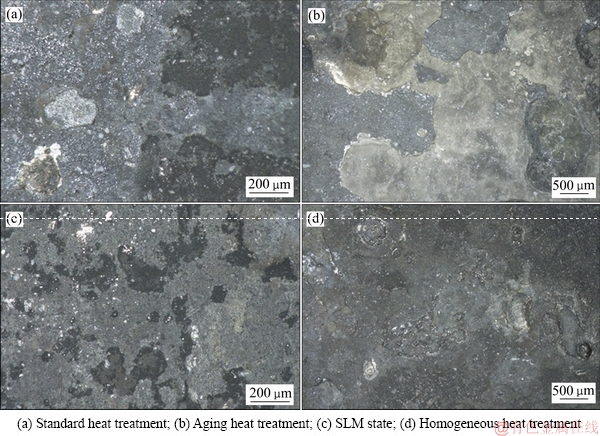

图5所示为SLM态和各个热处理态试样表面的腐蚀形貌,在经高温腐蚀后,试样表面生成了氧化膜。经不同热处理后,氧化膜的均匀程度也存在差异,同时,试样表面也存在明显的腐蚀坑。腐蚀开始时,腐蚀产物会聚集,同时接触面积增大,进一步加快了腐蚀过程。在样品表面覆盖着一层黑绿色的氧化皮,主要为NiO,底下有一层浅色的过渡层,最底层是镍基高温合金基体。腐蚀坑的最大深度达到了1 mm,在表面氧化皮脱落之后,镍基合金基体腐蚀依然存在。经过标准热处理的样品,经高温腐蚀后,表面氧化层存在剥落现象,内部微观的局部腐蚀依然存在,三维测量结果显示,表面腐蚀坑的深度在100 μm左右。经时效热处理样片表层剥落程度严重,但不存在大的腐蚀坑。对于均匀化处理的样品,其表面腐蚀程度整体与标准化样品类似,但在局部区域存在较深的腐蚀坑。

图5 高温腐蚀75 h后表面(X-Y面)宏观形貌图

Fig. 5 Surface topography of Inconel 718 surface after 75 h high-temperature corrosion test under various heat treatment conditions

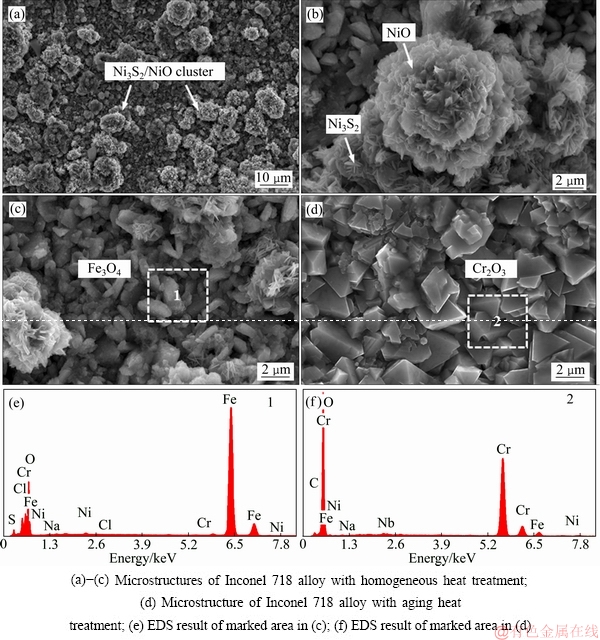

图6 SLM成形Inconel 718合金高温腐蚀100 h后表面产物显微形貌及EDS谱

Fig. 6 Surface morphology and element distribution of Inconel 718 alloy after 100 h high-temperature corrosion test

图6所示为Inconel 718 合金经均匀化处理后基体腐蚀产物微观形貌及元素分析。图6(a)中可以观察到岛状分布的团簇物质,呈现松散排布,表明这区域的腐蚀程度高。图6(b)所示为局部放大图,可以发现团簇主要由片层状的NiO和针状的Ni3S2组成[28-29]。片层状疏松多孔,为合金的加速腐蚀提供了条件。在腐蚀表面存在细棒状和尖晶石两种结构的物质,如图6(c)和(d)所示。能谱分析结果(见图6(e)和(f))表明,该区域的主要元素为Cr和O,可以确定主要物质为Cr2O3。这两种物质在合金中常作为阻碍腐蚀的物质[30],从图6(c)和(d)中可以看出,Cr2O3形成的氧化层结构致密,没有孔洞出现,抗氧化及腐蚀能力好,而Fe3O4形成的氧化物存在孔洞,其抗氧化腐蚀能力较Cr2O3形成的氧化层低。

2.4 腐蚀截面分析

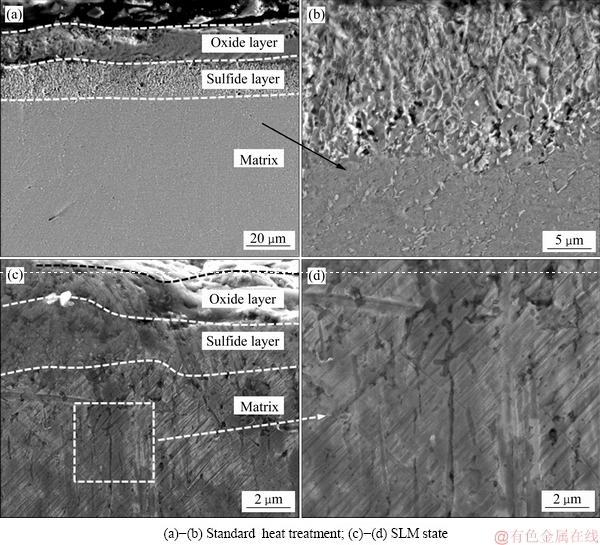

图7所示为SLM态及热处理试样腐蚀纵截面形貌。两种状态下腐蚀区域从外到内均分为三层:最外层为疏松的氧化物层,这一层主要是Cr2O3和Fe3O4等氧化物,第二层为网状的硫化层,主要成分为硫化物,如Ni3S2等,最内层为合金基体。从硫化层放大图(见图7(b))可以看出硫化物呈片状分布,与图6中SEM形貌相似。原始SLM态试样在渗硫层底部可以看到明显的条状腐蚀沟,相邻间距约3~5 μm,该间距与SLM成形Inconel 718合金形成的柱状亚晶粒间距接近[5]。因此可以推测亚晶粒的边界为渗硫过程提供了通道。

图8所示为SLM态试样腐蚀纵截面元素分布结果,O元素主要分布在最外层,以氧化物形存在。在渗硫区可以观察到一部分O元素(见图8(b)),说明O元素可以扩散至基体内部。S元素主要在渗硫区域(见图8(c)),从外往内含量逐步降低,可观察到集束状的S元素聚集区,与图7对比可以判断这些区域就是S元素扩散的通道。Cr元素(见图8(d))的分布,在最外层氧化区比较集中,同时在基体中也分布一定量的Cr。在渗硫区,Cr元素含量较少,同时S与Cr会发生反应,形成硫化物,进一步消耗合金中的Cr元素。而这些生成的硫化物通过S通道扩散到外层氧化区后,会与O反应生成Cr2O3。但是这种氧化物是一种疏松多孔的物质,难以起到保护合金的作用。

2.5 腐蚀机理分析

图7 SLM成形Inconel 718合金高温腐蚀100 h后截面腐蚀形貌

Fig .7 Cross-section morphology of SLM fabricated Inconel 718 alloy after 100 h high-temperature corrosion test

图8 SLM成形Inconel 718合金纵截面元素分布图

Fig. 8 Element distribution of SLM fabricated Inconel 718 alloy on cross-section area

高温腐蚀实验用混合盐为Na2SO4(75%)+NaCl (25%),该混合盐的理论熔点为675 ℃[31]。在650 ℃条件下,该混合盐由液态熔盐和少量固态Na2SO4组成,在液态条件下,溶液中物质会发生如下变化[32]:

2Na2SO4=2Na2O+3O2+S2 (1)

在腐蚀前期,O会与Ni反应生成NiO附着在合金表面,随着O的消耗,溶液中S元素增多。当S含量达到一定程度时,会反应生成硫化物[33]:

Na2SO4+(7/2) Ni+(1/2)Cr2O3+(1/4)O2→Na2CrO4+2NiO+(1/2)Ni3S2 (2)

3Na2SO4+7Cr+(3/2) O2→3Na2CrO4+Cr2S3+Cr2O3 (3)

硫化物在高温和氧的作用下并不稳定,继续反应[34-35]:

2Cr2S3+9O2→2C2O3+SO2 (4)

SO2+5Fe+2O2→2Fe2O3+FeS (5)

3Fe2O3+O2→2Fe3O4 (6)

生成的气态SO2会沿着合金腐蚀通道扩散,进入金属内部,促进硫化作用:

7Ni+SO2→4NiO+Ni3S2 (7)

6Cr+3SO2→2Cr2O3+Cr2S3 (8)

硫化物会与O继续反应,生成SO2,由此一步步往合金基体内部渗透,腐蚀界面不断推进。研究表明,当Cl元素的浓度在10-6级别就会大大增加合金表面氧化膜的开裂和剥落倾向[22]。因为NaCl会发生如下反应:

4NaCl+2Cr2O3+3O2→2Na2CrO4+2CrO2Cl2 (9)

CrO2Cl2可能以气态存在,发生挥发或转变成铬酸盐。在此反应中具有保护作用的Cr2O3氧化膜被破坏从而加速合金的腐蚀。

除了晶粒边界外,SLM逐道熔池搭接和层层叠加还会产生特定空间拓扑的熔池边界,熔池边界是合金的性能弱区[5]。杂质元素通常处于熔池边界,导致熔池边界缺陷多。熔池边界和晶界为S和O元素的扩散提供了通道。而腐蚀性的熔盐则会沿着这些通道进入内部,加速了腐蚀进程(如图9所示)。SLM态合金在经过高温固溶处理后,材料的熔池边界基本消失,溶质元素分布也变得均匀,因此表现出与锻件相当的耐腐蚀性[12]。直接时效处理的样品,热处理温度为718 ℃,熔池边界并没有发生充分溶解,导致腐蚀初期与SLM态相似。由于腐蚀是在 650 ℃条件下进行,样品依然会发生在熔池边界的溶解和 Laves 元素均匀化的扩散,在经历 25 h 的扩散与溶解之后,熔池边界消失,元素得以均匀分布。由于S和O元素提供快速的通道关闭,抗腐蚀元素得到均匀分布,材料的抗腐蚀性能得到大幅度的提升,表现出类似标准热处理和均匀化样品的性质。经过高温热处理之后,材料的熔池边界完全消失,溶质得到了均匀分散,样品失重速率降低,表现出与锻件相当的耐热腐蚀性能。而SLM态样品由于存在大量的原始熔池边界,合金内部的腐蚀程度不断加大,在腐蚀后期其腐蚀程度随时间推移呈线性递增。

图9 Inconel 718合金热腐蚀过程中O和S原子在熔池边界和柱状晶扩散模型

Fig. 9 Diffusion model of O and S atoms in melt pool boundary and columnar crystals during high-temperature corrosion of Inconel 718 alloy fabricated by SLM

3 结论

1) 在高温腐蚀过程中,SLM态合金腐蚀质量损失速率远大于其他状态的,经过75 h的腐蚀后,质量损失速率达到18 mg/cm3,是时效热处理的2.5倍、标准热处理的9倍。而经标准和均匀化热处理的合金其耐腐蚀性能与锻件的相当,时效热处理的合金在经过25 h的扩散和溶解之后,抗腐蚀性能也得到了大幅度提升。

2) 经高温腐蚀后,腐蚀表面分布大量由片层状的NiO和针状的 Ni3S2组成的团簇物质。团簇物质呈松散排布,片层状疏松多孔,为合金的加速腐蚀提供了条件,当晶粒发生腐蚀时,S元素和O元素会先聚集在晶粒边界,形成Cr2O3、Fe3O4和Ni3S2,促使合金发生腐蚀。同时,在不同的热处理条件下,合金表面腐蚀产物主要成分并没有发生变化。

3) SLM 态熔池边界是合金的性能弱区,为S元素和O元素的扩散提供了通道,腐蚀性的熔盐会沿着熔池边界深入到合金的基体内部。同时快速凝固条件下的柱状晶晶界也为O和S的扩散提供了通道。

REFERENCES

[1] WANG Y, SHAO W Z, ZHEN L, ZHANG B Y. Hot deformation behavior of delta-processed superalloy 718[J]. Materials Science & Engineering A, 2011, 528(7): 3218-3227.

[2] NING Y Q, FU M W, CHEN X. Hot deformation behavior of GH4169 superalloy associated with stick δ phase dissolution during isothermal compression process[J]. Materials Science & Engineering A, 2012, 540: 164-173.

[3] WANG Y, ZHEN L, SHAO W Z, YANG L, ZHANG X M. Hot working characteristics and dynamic recrystallization of delta- processed superalloy 718[J]. Journal of Alloys & Compounds, 2009, 474(1/2): 341-346.

[4] ZHANG S, WEI Q S, CHENG L Y, LIU G C, LI S, SHI Y S. Effects of scan line spacing on pore characteristics and mechanical properties of porous Ti6Al4V implants fabricated by selective laser melting[J]. Materials & Design, 2014, 63(21): 185-193.

[5] LI S, WEI Q S, SHI Y S, ZHU Z C, ZHANG D Q. Microstructure characteristics of Inconel 625 superalloy manufactured by selective laser melting[J]. Journal of Materials Science & Technology, 2015, 31(9): 946-952.

[6] AMATO K N, GAYTAN S M, MURR L E, MARTINEZ E, SHINDO P W, HERNANDEZ J, COLLINS S, MEDINA F. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting[J]. Acta Materialia, 2012, 60(5): 2229-2239.

[7] SING S L, YEONG W Y, WIRIA F E, TAY B Y. Characterization of titanium lattice structures fabricated by selective laser melting using an adapted compressive test method[J]. Experimental Mechanics, 2016, 56(5): 735-748.

[8] GHANI S A C, ZAKARIA M H, HARUN W S W, ZAULKAFILAI Z. Dimensional accuracy of internal cooling channel made by selective laser melting (SLM) And direct metal laser sintering (DMLS) processes in fabrication of internally cooled cutting tools[C]//MATEC Web of Conferences, 2017, 90: 01058.

[9] REHME O, EMMELMANN C. Reproducibility for properties of selective laser melting products[C]// Proceedings of the Third International WLT-Conference on Lasers in Manufacturing, 2005: 227-232.

[10] WANG Z M, GUAN K, GAO M, LI X Y, CHEN X F, ZENG X Y. The microstructure and mechanical properties of deposited-IN718 by selective laser melting[J]. Journal of Alloys & Compounds, 2012, 513(2): 518-523.

[11] HUSSEIN A, HAO L, YAN C, EVERSON R. Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting[J]. Materials & Design, 2013, 52(24): 638-647.

[12] TILLMANN W, SCHAAK C, NELLESEN J, SCHAPER M, AYDINOZ M E, HOYER K P. Hot isostatic pressing of IN718 components manufactured by selective laser melting[J]. Additive Manufacturing, 2016, 13: 93-102.

[13] JIA Q B, GU D D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties[J]. Journal of Alloys & Compounds, 2014, 585(17): 713-721.

[14] WANG X, GONG X, CHOU K. Review on powder-bed laser additive manufacturing of Inconel 718 parts[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2017, 231(11): 1890-1903.

[15] LIU F C, LIN X, YANG G L, SONG M H, CHEN J, HUANG W D. Microstructure and residual stress of laser rapid formed Inconel 718 nickel-base superalloy[J]. Optics & Laser Technology, 2011, 43(1): 208-213.

[16] 宋 衎, 喻 凯, 林 鑫, 陈 静, 杨海鸥, 黄卫东. 热处理态激光立体成形Inconel 718高温合金的组织及力学性能[J]. 金属学报, 2015, 51(8): 935-942.

SONG Kan, YU Kai, LIN Xin, CHEN Jing, YANG Hai-ou, HUANG Wei-dong. Microstructure and mechanical properties of heat treatment laser solid forming superalloy Inconel 718[J]. Acta Metallurgica Sinica, 2015, 51(8): 935-942.

[17] 贾清波. Ni基高温合金及其复合材料选区激光熔化成形工艺、组织及性能[D]. 南京航空航天大学, 2015.

JIA Qing-bo. Selective laser melting fabrication of nickel-based superalloys and its composites: process, microstructure and property[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2015.

[18] KAMAL S, JAYAGANTHAN R, PRAKASH S, KUMAR S. Hot corrosion behavior of detonation gun sprayed Cr3C2-NiCr coatings on Ni and Fe-based superalloys in Na2SO4-60%V2O5 environment at 900 ℃[J]. Journal of Alloys & Compounds, 2008, 463(1/2): 358-372.

[19] SIDHU T S, PRAKASH S, AGRAWAL R D. Hot corrosion behaviour of HVOF-sprayed NiCrBSi coatings on Ni- and Fe-based superalloys in Na2SO4-60%V2O5 environment at 900 ℃[J]. Acta Materialia, 2006, 54(3): 773-784.

[20] 葛 锋, 王春光, 张玉碧, 何 璧, 李 念, 王东哲. Inconel718合金耐腐蚀性能研究及基于电化学方法的腐蚀评价综述[J]. 材料导报, 2013, 27(11): 102-106.

GE Feng, WANG Chun-guang, ZHANG Yu-bi, HE Bi, LI Nian, WANG Dong-zhe. A review on corrosion resistance properties and corrosion evaluation based on electrochemical method for Inconel718 alloy[J]. Materials Review, 2013, 27(11): 102-106.

[21] 王春光, 王东哲, 万 红, 莫 燕, 刘 虹, 向祥蓉, 金文勇, 葛 峰. Inconel718合金在高含H2S/CO2环境下的应力腐蚀行为[J]. 热加工工艺, 2015(10): 107-109.

WANG Chun-guang, WANG Dong-zhe, WAN Hong, MO Yan, LIU Hong, XIANG Xiang-rong, JIN Wen-yong, GE Feng. Stress corrosion behavior of Inconel718 alloy in high H2S and CO2 containing environment[J]. Hot Working Technology, 2015(10): 107-109.

[22] 魏 斌, 严密林, 白真权, 冯耀荣. 镍基合金Inconel 718与抗硫油套管钢在模拟气田地层水中的电偶腐蚀[J]. 腐蚀科学与防护技术, 2007, 19(5): 319-322.

WEI Bin, YAN Mi-lin, BAI Zhen-quan, FENG Yao-rong. Galvanic corrosion of nickel alloy Inconel 718 coupled with VM 80 SS steel in a simulated formation water[J]. Corrosion Science & Protection Technology, 2007, 19(5): 319-322.

[23] JIA Q B, GU D D. Selective laser melting additive manufactured Inconel 718 superalloy parts: High-temperature oxidation property and its mechanisms[J]. Optics & Laser Technology, 2014, 62(10): 161-171.

[24] 宰雄飞, 陈仕奇, 吴 宏, 任俊业, 刘 咏, 兰小东, 李清湘, 周少强, 刘 银. 激光近净成形Inconel 718高温合金的力学性能与耐腐蚀性能[J]. 粉末冶金材料科学与工程, 2017, 22(5): 680-686.

ZAI Xiong-fei, CHEN Shi-qi, WU Hong, REN Jun-ye, LIU Yong, LAN Xiao-dong, LI Qing-xiang, ZHOU Shao-qiang, LIU Yin. Mechanical properties and corrosion resistance of laser rapid forming Inconel 718 superalloy[J]. Materials Science and Engineering of Powder Metallurgy, 2017, 22(5): 680-686.

[25] ZHANG D, NIU W, CAO X, LIU Z. Effect of standard heat treatment on the microstructure and mechanical properties of selective laser melting manufactured Inconel 718 superalloy[J]. Materials Science and Engineering A, 2015, 644: 32-40.

[26] CHLEBUS E, GRUBER K, KUZNICKA B, KURZAC J, KURZYNOWSKI T. Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting[J]. Materials Science and Engineering A, 2015, 639: 647-655.

[27] TUCHO W M, CUVILLIER P, SJOLYST-KVERNELAND A, HANSEN V. Microstructure and hardness studies of Inconel 718 manufactured by selective laser melting before and after solution heat treatment[J]. Materials Science and Engineering A, 2017, 689: 220-232.

[28] JIANG H, DONG J X, ZHANG M C, ZHENG L, YAO Z H. Hot corrosion behavior and mechanism of FGH96 P/M superalloy in molten NaCl-Na2SO4 salts[J]. Rare Metals, 2016: 1-8.

[29] ZHENG L, ZHANG M C, DONG J X. Hot corrosion behavior of powder metallurgy Rene95 nickel-based superalloy in molten NaCl-NaSO salts[J]. Materials & Design, 2011, 32(4): 1981-1989.

[30] CUI G J, HAN J R, WU G X. High-temperature wear behavior of self-lubricating Co matrix alloys prepared by P/M[J]. Wear, 2016, 346/347: 116-123.

[31] Data from FTsalt-FACT salt database[DB/OL]. http://www. factsage.com/

[32] GOEBEL J A, PETTIT F S, GOWARD G W. Mechanisms for the hot corrosion of nickel-base alloys[J]. Metallurgical Transactions, 1973, 4(1): 261-278.

[33] ORG.CAMBRIDGE.EBOOKS.ONLINE.BOOK.AUTHOR@ECA. Introduction to the high temperature oxidation of metals[M]. Cambridge: Cambridge University Press, 2006.

[34] LUTHRA K L, SHORES D A. Mechanism of Na2SO4 induced corrosion at 600-900 ℃[J]. Journal of the Electrochemical Society, 1980, 127(10): 2202-2210.

[35] ROMEO G, MCKEE D W. The Na2SO4 induced corrosion properties of Ni base superalloy phases[J]. 1975, 122(2): 188-199.

High-temperature corrosion resistance of Inconel 718 fabricated by selective laser melting

TENG Qing, LI Shuai, XUE Peng-ju, TIAN Jian, WEI Qing-song, SHI Yu-sheng

(State Key Laboratory of Materials Processing and Die & Mould Technology, Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract: The Inconel 718 was fabricated by Selective Laser Melting (SLM), and its high-temperaturecorrosion behavior under different heat treatment conditions was evaluated. The morphology and corrosion phases were observed by using ultra depth microscope, XRD and SEM. The results show that the heat treatment can effectively reduce high-temperature corrosion mass loss rate of this alloy. After standard heat treatment and homogenization heat treatment, the high-temperature corrosion resistance of this alloy is comparable with forgings. The corrosion resistance of samples with direct aging treatment increases after 25 h corrosion test, which can be attributed to the disappearance of the melt pool boundary and the improved homogeneity of solute elements. As a result, the corrosion resistance of this alloy also isimproved because the diffusion channels for O and S are closed. After 75 h test, the main phases on the alloy surface are two types of oxides and sulfides, and the composition of these phases has not change under different heat treatment conditions. The high-temperature corrosion mechanism of Inconel 718 alloy prepared by SLM was analyzed and discussed, and the elements diffusion model of Inconel 718 alloy in SLM state was established.

Key words: additive manufacturing; SLM; Inconel 718; heat treatment; high-temperature corrosion

Foundation item: Project(MJ-2015-H-G-104) supported by the Special Scientific Research Projects of Civil Aircraft, China

Received date: 2018-04-27; Accepted date: 2018-07-03

Corresponding author: WEI Qing-song; Tel: +86-13296512995; E-mail: wqs_xn@163.com

(编辑 何学锋)

基金项目:民用飞机专项科研项目资助(MJ-2015-H-G-104)

收稿日期:2018-04-27;修订日期:2018-07-03

通信作者:魏青松,教授,博士;电话:13296512995;E-mail:wqs_xn@163.com