文章编号:1004-0609(2015)02-0534-11

以脱铝赤泥-脱铝粉煤灰为原料制备硬硅钙石

郭曦尧1, 2,马淑花2,吕松青2, 3,郑诗礼2,邹 兴1

(1. 北京科技大学 冶金与生态工程学院,北京 100083;

2. 中国科学院 过程工程研究所 绿色过程与工程重点实验室

湿法冶金清洁技术国家工程实验室,北京 100190;

3. 北京化工大学 化学工程学院,北京 100029)

摘 要: 以脱铝赤泥和脱铝粉煤灰为原料,采用水热法制备硬硅钙石,考察原料配比、液固比及反应时间对硬硅钙石生成及形貌的影响。结果表明:在220 ℃、钙硅比为1.0时,脱铝粉煤灰掺入量的增加、液固比的提高和反应时间的延长均促进了硬硅钙石的生成。最佳反应条件为:脱铝粉煤灰加入量大于总质量40%、液固比35 mL/g、反应时间9 h。在该条件下获得了由直径为25~50 nm,长径比大于20的硬硅钙石单晶晶须缠绕而成的球形粒子。通过扫描电镜(SEM)、透射电镜(TEM)和背散射电子图像(BSE)分析晶须生长、成球机理及粒子内部结构,证实了球形粒子的中空结构可能与反应初期形成的前驱体包裹晶态SiO2有关。

关键词:硬硅钙石;脱铝赤泥;脱铝粉煤灰;晶须;球形粒子;水热反应

中图分类号:TU521 文献标志码:A

Preparation of xonotlite using red mud and fly ash after removal alumina as raw materials

GUO Xi-yao1, 2, MA Shu-hua2, L Song-qing2, 3, ZHENG Shi-li2, ZOU Xing1

Song-qing2, 3, ZHENG Shi-li2, ZOU Xing1

(1. School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing, Beijing 100083;

2. National Engineering Laboratory for Hydrometallurgical Cleaner Production Technology,

Key Laboratory of Green Process and Engineering, Institute of Process Engineering,

Chinese Academy of Sciences, Beijing 100190, China;

3. College of Chemical Engineering, Beijing University of Chemical Technology, Beijing 100029, China)

Abstract: The xonotlite was prepared by hydrothermal method using sub-molten salt red mud (SRM) and sub-molten salt fly ash (SFA) as raw materials, and the effects of ratio of raw materials, liquid-solid ratio and reaction time on the synthesis and morphology of the xonotlite were examined. The results show that the synthesis of xonotlite is promoted with the increase of doping amount of SFA incorporation, liquid-solid ratio and reaction time under the condition of 220 ℃ and n(CaO)/n(SiO2) of 1.0. The optimal conditions are as follows: doping amount of SFA greater than 40% of the total mass, liquid-solid ratio 35 mL/g and reaction time 9 h. Under such conditions, the spherical particles are formed by the winding of xonotlite single crystal whiskers with diameter of 25-50 nm, length-diameter ratio over 20 are synthesized. The mechanisms of the growth of xonotlite whisker, formation of spherical particles and the internal structure characteristics of the spherical particles were analyzed by scanning electron microscopy (SEM), transmission electron microscopy (TEM) and back-scattered electron imaging (BSE). The results show that the forming of hollow structure of the spherical particles is probably related to the wrapped crystalline state SiO2 by precursor formed in the initial reaction stage.

Key words: xonotlite; sub-molten salt red mud; sub-molten salt fly ash; whisker; spherical particle; hydrothermal reaction

赤泥是氧化铝工业生产时排出的固体废渣,每生产1t氧化铝产生1.0~1.5t的赤泥[1-2]。我国是世界第一大氧化铝生产国,每年排出五千万吨左右的赤泥。由于赤泥结合的化学碱难以脱除且含量大,又含有钛、铝及其他多种杂质等原因,对于赤泥的无害化利用一直难以进行。国外多是排入海中[3],我国采用堆存处理,既占用了大量土地,又造成土地碱化、地下水污染[4]。虽然烧结法实现了工业上对赤泥中氧化铝的回收,但由于反应温度在1000 ℃以上[5],因此能耗较高。中国科学院过程工程研究所利用亚熔盐介质处理拜耳法赤泥,回收其中有价值铝盐,在200 ℃下,实现87.8%的氧化铝回收率[6-7],通过上述方法处理后得到的终渣,即为亚熔盐脱铝赤泥,将其进一步脱钠,虽然实现了氧化钠的回收,但是终渣主要成分为硅酸二钙,一般只能作为水泥的填料,其附加值很低,且其中碱含量较高,从而限制了其大规模利用。

粉煤灰是锅炉燃煤后由烟气带出、经除尘的粉尘,与赤泥一样也是属大宗工业固体废弃物,预计到2015年,我国粉煤灰的排放量可达5.8亿t[8]。因部分地区粉煤灰中氧化铝含量高达40%以上,相当于中等品位的铝土矿,所以我国对粉煤灰提取氧化铝有诸多研究[9],马淑花等[10]利用亚熔盐技术,提出了一种湿法从粉煤灰中提取氧化铝的方法。而提铝后的亚熔盐脱铝粉煤灰在高值化利用方面已经取得了突破,唐振华[11]已将其开发成为托贝莫来石晶须产品,产品性能优异。

硬硅钙石(6CaO×6SiO2×H2O)在水化硅酸钙类物质当中,是最具热稳定性的一类,广泛用作于制备高附加值保温材料。目前,国内外在制备硬硅钙石的过程中,使用的钙质和硅质原料多以成本较高的纯试剂为主,而且均采用动态水热化合法合成[12-15]。近年来,为了实现固废的综合利用,LIU等[16]和郭明武[17]利用电石渣、石英尾渣-锆渣分别代替了钙质原料和硅质原料,通过水热化合法合成了性能优良的硬硅钙石,但在他们的研究中,固废只替代了硅质和钙质原料其中的一种,另一种原料仍然采用分析纯试剂。制备原理如下:

6CaO+6SiO2+H2O=6CaO×6SiO2×H2O (1)

截至目前,以工业固废为原料,同时替代纯试剂作为钙源和硅源,并采用非化合法制备硬硅钙石的研究还未见报道。

考虑到我国很多氧化铝生产企业具有自备电厂,这为上述两种大宗工业固废同时综合利用提供了可能。因此,本研究拟以亚熔盐法脱铝后得到的赤泥和粉煤灰为原料,在220 ℃,n(Ca)/n(Si)=1的条件下[15, 18],采用动态水热法制备硬硅钙石,考察了亚熔盐粉煤灰掺入量、液固比及时间对硬硅钙石生成及其形貌的影响。此外,通过不同阶段产物的微观形貌、组成及微观结构,分析了杂质相的分布、晶须生长和成球的机理。本文作者间接地为两种大宗固废的再利用提供新的思路,同时通过晶须及成球机理的研究,实现对微观形貌的控制,为制备高附加值的新型材料提供依据。

1 实验

1.1 主要原料

实验所用的赤泥为河南某厂拜耳法赤泥经亚熔盐法提铝处理后得到的废渣,简称亚熔盐脱铝赤泥(SRM),实验掺加的粉煤灰为内蒙古某电厂煤粉炉灰经亚熔盐法提铝处理后的废渣,简称亚熔盐脱铝粉煤灰(SFA),两种原料主要化学成分如表1所列。

本文作者所有实验所用分析纯 SiO2,纯度≥99.5%(国药集团化学试剂有限公司生产),去离子水由Millipore纯水仪(电阻高于18.2 MW×cm,密理博中国有限公司生产)制备,分析用标样来自北京矿冶研究总院。

1.2 实验装置与分析仪器

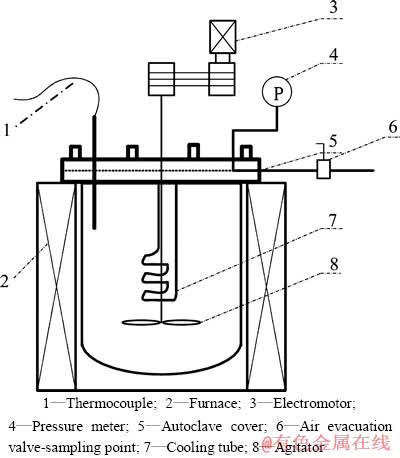

动态水热反应实验过程中,在容积为1 L的高压釜(威海鑫泰化工机械有限公司生产)内进行,该实验装置图如图1所示,釜腔为不锈钢材料,内衬耐碱腐蚀的镍衬,并带有温度控制系统。

表1 SRM和SFA的化学成分

Table 1 Chemical component of SRM and SFA

图1 高压实验装置示意图

Fig. 1 Schematic diagram of high-pressure experimental apparatus

分析仪器如下:美国Perkin-Elmer公司Optima 5300DV电感耦合等离子体原子发射光谱仪(ICP-OES),荷兰PANAlyticalB.V公司Empyrean型X射线衍射仪(XRD),日本电子株式会社JSM-7001F热场发射扫描电子显微镜与能谱分析仪(SEM),日本电子珠式会社JEM-2100F透射电子显微镜(TEM)。

1.3 实验方法及分析方法

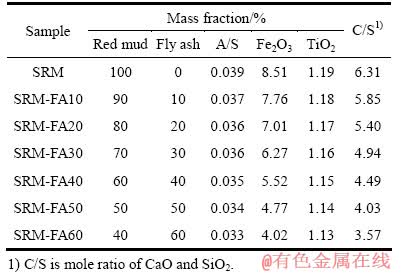

硬硅钙石的制备。首先将SRM和SFA分别用高速万能粉碎机充分打碎磨细,随后将SFA按二者总质量0~60%掺入SRM中形成的化合物分别为SRM、SRM-FA10、SRM-FA20、SRM-FA30、SRM-FA40、SRM-FA50、SRM-FA60,混合后的成分见表2。

表2 SRM和SFA按不同比例混合的试验配方

Table 2 Description of tested formulations in terms of content of SRM and SFM

由于初始钙硅摩尔比均大于1,而且根据硬硅钙石的化学式易知其钙硅为1时有利于其生成,因此按n(CaO)/n(SiO2)=1加入分析纯SiO2,充分混合后加入列带有磁力搅拌和温控系统的高压釜中,按液固比为25~40 mL/g加入去离子水,以250 r/min的转速在220 ℃下水热反应2~9 h。然后通入冷却水结束反应,待温度降至100 ℃以下,开釜出料。料液趁热保温抽滤以液固分离,滤饼用80 ℃去离子水充分淋洗,将洗后的湿渣置于105 ℃烘箱中烘干12 h,研磨得到粉体。

分析方法。采用电感耦合等离子体原子发射光谱仪测定固相元素含量并计算其对应氧化物的含量;采用X射线衍射仪分析固相样品物相组成;采用热场发射扫描电子显微镜与能谱分析仪的二次电子成像系统观察固体形貌;采用背散射电子成像系统观察固相内部刨面结构;采用透射电子显微镜观测固相纤维的尺寸及衍射图。

2 结果与分析

2.1 反应原理

SRM的主要物相为硅酸钠钙(NaCaHSiO4)和铁铝榴石(Ca3(Fe0.87Al0.13)2(SiO4)1.65(OH)5.4)[19],但是由于湿渣长时间未烘干,其中硅酸钠钙(NaCaHSiO4)已全部分解为无定形水化硅酸钙。因此,通过X射线衍射仪分析后得到的物相仅有铁铝榴石相,根据SRM中Fe2O3的含量可估算出铁铝榴石相约占30%(质量分数);而SFA的主要物相为硅酸钠钙(NaCaHSiO4)[20],由表1可知,由于SFA中Fe、Al和Ti等杂质元素含量极少,因此,通过X射线衍射仪分析也未见其他杂质物相。将二者混合后,同时加入少量SiO2用以调节钙硅比。在水热条件下,首先SRM附着的苛碱迅速溶于水中为液相提供了大量OH-离子,于是SFA中的易分解物相发生以下反应[21]:

NaCaHSiO4+OH-=SiO32-+Na++Ca(OH)2 (2)

Ca(OH)2+5H2O=Ca(H2O)5OH++OH- (3)

Ca(H2O)5OH++SiO32-→CSHgel (4)

而加入的SiO2在含OH-离子的液相中发生如下反应:

SiO2+OH-+H2O=H3SiO4- (5)

H3SiO4-+Ca(H2O)5OH+→CSHgel (6)

水化硅酸钙凝胶在水热过程中随着温度的升高,晶化形成水化硅酸钙CSH(Ⅱ),由于其结构与天然托贝莫来石矿物接近,且晶化程度不高因此可称为半结晶托贝莫来石[22]。随着水热反应的进行,当CSH(Ⅱ)晶化成为托贝莫来石(简称To)后,由热力学可知[23],该物相在高温下不稳定,尤其是长时间在220 ℃时,其层间水易解离成为OH-离子,并吸引结合Ca2+离子,发生如下反应:

5CaO×6SiO2×5H2O+Ca2++2OH-=6CaO×6SiO2×H2O+5H2O (7)

同时,由于反应体系液固比较大,硅酸钙过饱和度低,为其一维生长提供了环境。因此,经过220 ℃的动态水热反应,便可得到晶型完整、结构稳定,其化学式为6CaO×6SiO2×H2O的硬硅钙石(简称Xo)晶须,在搅拌作用下相互缠绕,形成孔隙率高的球形粒子。

2.2 SFA掺入量对硬硅钙石生成的影响

在硬硅钙石的制备过程中,外加物对其生成有一定的影响,如Al3+和Fe3+等[24-25]。从表2可以看出,随着SFA的加入,铁铝两种元素都有一定程度的下降,虽然SRM中的铁铝两种元素在水热过程中主要以铁铝榴石稳定存在于固相中,但作为一种杂质相势必对硬硅钙石的生成有一定影响,为此本实验在220 ℃下水热反应9 h,控制液固比在25 mL/g,搅拌转速250 r/min,考察SFA掺入量对硬硅钙石生成的影响。

图2所示为不同SFA掺入量下反应产物的XRD谱。由图2看出,首先无论是否加入SFA,产物中都存在未发生相变的铁铝榴石相,只是随之SFA加入量的增多,其特征衍射峰的强度有所下降。除了铁铝榴石外,其余物相有较大变化,当SFA未掺入时,产物的物相为具有类托贝莫来石结构的水化硅酸钙C2SH(A)和特征峰不明显的托贝莫来石,其中C2SH(A)分子式为2CaO×SiO×H2O,当体系中C/S大于1时,溶解的过量钙离子会促进部分水化硅酸钙凝胶向C2SH(A)转变[22];当SFA掺入量达到20%时,C2SH(A)几乎消失,而位于2θ≈30°的(222)属于托贝莫来石的特征峰(次强峰)开始出现,同时属于该物相的其他特征峰的强度也逐渐增大;当SFA掺入量达到40%时,出现了明显的硬硅钙石的特征峰,而托贝莫来石的特征峰的强度变弱,但位于2θ≈30°的(222)属于托贝莫来石的次强峰变得明显,说明虽然托贝莫来石含量由于硬硅钙石的生成大量减少,但其晶化程度有所提高;当粉煤灰掺入量达到60%时,各物相均与RMFA40一致,且强度没有明显的变化。

图2 不同SFA掺入量下反应产物的XRD谱

Fig. 2 XRD patterns of product synthesized with different amounts of SFA as admixture

图3所示为不同SFA掺入量下反应产物的扫描电镜照片。由图3可以看出,当粉煤灰加入量为0和20%(质量分数)时,形貌为粗大的针状纤维及附着在其表面的花簇状和片层状颗粒,其中粗大的针状纤维、扁平片状颗粒为托贝莫来石[26],花簇状颗粒应为水化硅酸钙类物质及铁铝榴石;当粉煤灰加入量为40%和60%(质量分数)时,花簇状的铁铝榴石相减少,主要形貌以生长良好的纤维和扁平状颗粒存在,纤维相互交错缠绕,并存在微米级别的孔洞。

以上结果表明,当SRM未掺入SFA时,由于杂质物相较多,抑制了C2SH(A)向托贝莫来石及托贝莫来石向硬硅钙石的转化;随着SFA掺入量的增加,间接地降低了铁铝榴石杂质相的含量,一方面促进了C2SH(A)相的晶化过程,使其转化为托贝莫来石;另一方面,当粉煤灰加入量达到40%~60%时,不仅降低了CSH(Ⅱ)上面附着的榴石杂质相,提高了其比表面积,使其不经过C2SH(A)而直接晶化形成托贝莫来石甚至是硬硅钙石[22]。同时,也大大降低了托贝莫来石纤维上铁铝榴石的含量,增大了托贝莫来石与钙接触的机会,使托贝莫来石大量转化为硬硅钙石。因此,最优的SFA掺入量为40%~60%。

2.3 液固比对硬硅钙石生成及其形貌的影响

在制备硬硅钙石的过程中,CSH(II)作为硬硅钙石形成的前驱体,对其形成及其形貌,起了重要的作用。刘飞[27]的研究表明,若反应物浓度过大,前驱体浓度增高会产生爆发式的成核,短时间消耗大量前驱体,导致最终的产物在成核后的生长过程中因缺少原料而终止生长,导致其长径比减少。另一方面,由于本研究所中用原料含有榴石杂质相,会影响硬硅钙石形成过程中纤维成长时粒子的迁移及传质过程。为了进一步提高硬硅钙石的纯度并改善最终形貌,本研究中使用SRM-FA50作为原料,在220 ℃下水热反应9 h,控制为搅拌转速250 r/min,考察液固比对硬硅钙石生成的影响。

图3 不同SFA掺入量时反应产物的SEM像

Fig. 3 SEM images of product synthesized with different SFA incorporations

图4所示为在不同液固比(L/S)下反应产物的XRD谱。由图4可看出,2θ≈29°处的衍射峰不仅是硬硅钙石的次强特征峰,也是托贝莫来石和铁铝榴石的最强特征峰,多峰叠加作用使得其强度明显高于其他衍射峰,也导致无法通过该峰判别托贝莫来石和硬硅钙石的存在,故选择2θ≈30°即托贝莫来石的次强特征峰来判断其存在。从图4中还可以看出,随着液固比的提高,该衍射峰慢慢减弱,当液固比达到35 mL/g时,属于托贝莫来石的次强衍射峰完全消失,此时只剩下硬硅钙石和铁铝榴石两相。同时,由于托贝莫来石相的消失使得2θ≈29°的衍射峰也有一定程度的减弱;另一方面,硬硅钙石的特征衍射峰强度随着液固比的提高,均有一定程度的提高,这表明由于液固比的增大使得托贝莫来石完全转化为硬硅钙石,提高了硬硅钙石的纯度。而液固比为40和35 mL/g时,所得到的衍射峰相比几乎没有变化,因此综合考虑,合理的液固比为35 mL/g。

图4 不同液固比下反应产物的XRD谱

Fig. 4 XRD patterns of product synthesized at different liquid-solid ratios

图5所示为不同液固比下产物的SEM像。从图5可以看出,在液固比为25和30 mL/g时,均可看到片层状和纤维状结构,其中片层状形貌为托贝莫来石相[26],而花簇状的铁铝榴石杂质粒子不规则地分布在纤维周围;当液固比增大到35 mL/g及>35 mL/g时,花簇状粒子几乎消失,同时纤维的长径比增大。说明较大的液固比可以为水化硅酸钙凝胶(CSHgel)提供一个适宜的过饱和度,避免了爆发式的成核。在该条件下,CSHgel晶化形成适量的晶核,开始定向生长并形成晶须,最终形成晶型良好、长径比大的硬硅钙石;另一方面,随着液固比的增大,硅酸钠钙分解后产生的钠离子及反应物中铁铝榴石的杂质相的相对浓度降低,杂质相影响逐渐减弱,有利于托贝莫来石向硬硅钙石的转化,最终得到高纯度的硬硅钙石。

图5 不同液固比下产物的SEM像

Fig. 5 SEM images of product synthesized at different liquid-solid ratios

2.4 硬硅钙石晶须及球形粒子形成机理

以水热法合成的硬硅钙石,多以晶须[28]或者纤维缠绕而成的球形粒子存在[14-15],但其形成的机理及历程因硅质原料的不同而产生很大的区别。刘飞[27]的研究以K2SiO3为原料,发现硬硅钙石晶须的生成是由水热反应前期大量的硅酸根阴离子团与溶在水中的钙的水合离子发生共棱反应,然后经历CSHgel→CSH(Ⅱ)→ Xo的核相变,最后晶体单向生长产生的;吴梅梅[29]的研究发现硬硅钙石中空二次球形粒子形成的机理是在水热反应初期,在石英粉的表面形成网状CSH(Ⅱ)和纤维状CSH(Ⅰ),然后随着石英粉溶解不仅使得内部结构中空,同时物相经历由CSH(Ⅱ)、CSH(Ⅰ)→ To→Xo转变的历程,最终形成由针状硬硅钙石晶体交织合成的中空二次粒子球,该历程也与KUBO等[30]的研究结果类似;郑远林等[31]以晶质SiO2为硅源,认为Xo是由中间产物C2SH(A)转化生成的,整个过程未出现To。为了探究以SRM和SFA为原料形成硬硅钙石晶须及成球机理,本研究使用SRM-FA50作为原料,在220 ℃下,控制液固比在35 mL/g、搅拌转速250 r/min,观察在不同的水热反应阶段各个物相及其形貌的变化。

图6所示为不同水热反应阶段产物的物相变化图。由图6可看出,在水热反应的初期即1h时,物相以托贝莫来石和榴石为主,同时还有少量残余的水化硅酸钙及未反应的二氧化硅,由于铁铝榴石相在反应前后未发生相变,因此,在反应的各个阶段均存在其特征峰。当反应进行到3 h时,托贝莫来石相由于高温条件下不稳定大量转化为硬硅钙石,因此,在此阶段物相以硬硅钙石为主并残留少量的托贝莫来石;在之后水热反应过程中,硬硅钙石相晶化程度逐步增大,其特征衍射峰不断增强;当反应进行到9 h时,水热产物中已找不到托贝莫来石的任何特征衍射峰。

图6 不同保温时间下产物的XRD谱

Fig. 6 XRD patterns of product synthesized at different reaction times

结合图7中水热反应过程中产物的形貌变化。由图7可以清楚地看到,在反应的第1 h,虽然看到纤维,但纤维大多短而粗,呈薄片状,这些纤维依靠结晶不好的水化硅酸钙及榴石结合在一起;当反应进行到3 h时,粘结在一起的组织开始团聚,并出现不明显的边界,而团聚体表面的纤维未有明显变化;当反应进行到5 h时,团聚体边界逐渐明晰,但团聚体的周围仍分布着大量的散纤维,纤维周围的无定型组织变少,而纤维则在变长;当反应进行到7 h时,团聚体清晰可见,虽然形状不规则,但其体积较5 h团聚体有所增大,同时其周围的散纤维几乎消失;当反应进行到9 h,团聚体体积没有明显变化,但其形状更为规则,以球形为主,球形粒子是由细而长的晶须缠绕而成。因此,可以确定水热反应时间应当在9 h以上,结合考虑经济因素,以水热反应9 h为最佳。同时,由于在反应9 h后,产物只剩下硬硅钙石和榴石,根据铁元素在反应前后未进入液相,可大致计算出杂质榴石相约占15%(质量分数),因此,制得到硬硅钙石含量约为85%(质量分数)。

图7 不同保温时间下产物的SEM像

Fig. 7 SEM images of product synthesized at different reaction times

为了研究晶须的长度及其生长方式,对反应9 h的水热产物进行TEM分析(见图8)。从图8(a)和(b)可以计算出,晶体直径为30~70 nm,长径比大于20,符合晶须的定义[32],通过观察图(c)的特征XRD谱(d),虽然图(c)中几根晶须重合在一起,但得到的XRD谱中点阵结构依然明显。由此可知,硬硅钙石晶须的形成是随着反应物在水中的分解,由CSHgel作为Xo的前驱体沿着一定的晶轴方向生长,最终形成具有单晶结构的硬硅钙石晶须。

为深入研究球形粒子的形成机理,对水热反应反应9 h的产物冷镶磨抛后进行背散射电子成像(BSE)分析,从而了解球形粒子的内部结构及杂质相的分布情况,其结果如图9所示。由于样品表面平均原子序数较高的区域在BSE中会呈现较亮的灰度[33],所以在图9中可以看到明亮不同的区域。根据这个原理,将球形粒子刨面的BSE中的灰度值粗略地对应于3大类物相,从暗到亮依次为孔道、硬硅钙石晶须和铁铝榴石。从图9可以看出,球形粒子主要呈两种结构:其中图9(a)和图9(b)中的球形粒子为内部多孔的中空结构,图(c)中的球形粒子为纤维缠绕结构松散但无空洞的结构。两者的杂质物相铁铝榴石则都不规则地分布在球形粒子的内部,且比较集中。

图8 220 ℃水热反应9 h后硬硅钙石晶须的TEM像及SAD谱

Fig. 8 TEM image of xonotlite whiskers produced at 220 ℃ for 9 h from SRM-FA50 and SAD pattern of crystal in TEM image

图9 220 ℃水热反应9 h后产物的BSE像

Fig. 9 BSE image of product synthesized at 220 ℃ for 9 h from SRM-FA50

由此可以得出,硬硅钙石晶须生成及成球的大概历程:对于SRM而言,由于反应原料中已含有水化硅酸钙凝胶(CSHgel-I),因此,在反应初期,这些(CSHgel-I)会与游离氧化钙反应形成水化硅酸二钙(C2SH(A)),除了与其粘结一起的榴石外,凝胶内部不会包裹后加入的SiO2。虽然具有较大的液固比,但由于榴石杂质较多,抑制了C2SH(A)的进一步转化。随着反应时间的延长,二氧化硅逐渐溶解并凝胶化后,这些C2SH(A)再与凝胶态二氧化硅结合形成富钙类水化硅酸钙(CSH(Ⅱ)),并逐渐晶化成托贝莫来石。同时,由于SFA的加入,榴石等杂质含量降低,杂质对晶型转化影响逐渐减弱。因此,这些托贝莫来石随着时间的延长逐渐转化为结构更为稳定的硬硅钙石,成为以图9(c)为主的无空心硬硅钙石。

而在SFA中,硅酸钠钙首先分解形成了大量的水合钙离子和硅酸根离子,因此,二者反应形成的初晶会以未溶的SiO2及杂质榴石为晶核而逐渐形成包裹晶态SiO2的水化硅酸钙凝胶(CSHgel-II),随着温度的进一步上升及SiO2的溶解,部分CSH(Ⅱ)晶化形成托贝莫来石,当水热反应1 h时,可以看到长度短的薄片状的托贝莫来石晶体和晶化不完全的CSH(Ⅱ)以及少量残余的SiO2。在反应中期,即保温阶段1 h至5 h的过程中,伴随着晶须的生长,二次球形粒子开始团聚长大。首先,较大的液固比为晶须的生长提供了适宜的过饱和度,于是CSH(Ⅱ)主要是沿着一维方向上进行生长发育;而球形粒子的形成则由于搅拌的作用,CSH(Ⅱ)不仅随流体一起运动,而且自身也做旋转运动[34],由于表面受到剪切力作用,促使片状的CSH(II)和托贝莫来石形成不规则的毛栗状颗粒,随着初期包裹在其内部的SiO2逐渐溶解,一方面,使得颗粒出现了中空的现象;另一方面,为颗粒表面晶须的一维生长提供了硅质原料的补给。随着晶须的生长及相互缠绕,毛栗状颗粒团聚在一起,之后从保温阶段3~5 h内,团聚体形成的形状不规则的二次粒子在搅拌作用下,轮廓逐渐明晰;在反应终期,即保温阶段5~9 h的过程中,由于搅拌产生的剪切力,使得二次粒子更加规则,结构也更加疏松,同时,该阶段硬硅钙石晶须的晶化程度也随时间的增长得以提高,最终得到由(CSHgel-II)发展形成的由晶须缠绕、结构松散的二次中空球形粒子,其内部结构主要以中空结构形态存在。

3 结论

1) 在亚熔盐脱铝赤泥中加入总质量40%以上的亚熔盐脱铝粉煤灰,在220 ℃下水热反应9 h,液固比为35 mL/g时,可以得到以硬硅钙石为主、少量铁铝榴石为辅的晶须产品,硬硅钙石含量约占85%。

2) 获得的硬硅钙石晶须长径比大于20,系单晶结构且表面无杂质。

3) 硬硅钙石球形粒子的中空结构可能与前驱体水化硅酸钙凝胶是否包裹晶态SiO2有关,从而会形成内部结构不同的球形粒子。若前驱体包裹晶态SiO2,反应完成后会形成中空的球形粒子,否则为非中空球形粒子,两种粒子均包裹着分布不均匀的铁铝榴石杂质。

REFERENCES

[1] AYRES R U, JOHN H, BJORN A. Utilisation of the wastes in the new millennium[J]. MRSI Bull, 2001, 7: 477-480.

[2] LI Xiao-bin, XIAO Wei, LIU Wei. Recovery of alumina and ferric oxide from Bayer red mud rich in iron by reduction sintering[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(5): 1342-1347.

[3] DETHLEFSEN V, ROSENTHAL H. Problems with dumping of red mud in shallow waters. A critical review of selected literature[J]. Aquaculture, 1973, 2: 267-280.

[4] 刘万超, 杨家宽, 肖 波. 拜耳法赤泥中铁的提取及残渣制备建材[J]. 中国有色金属学报, 2008, 18(1): 187-192.

LIU Wan-chao, YANG Jia-kuan, XIAO bo. Recovering iron and preparing building material with residues from Bayer red mud[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 187-192.

[5] 马淑花, 郑诗礼, 张 懿. 赤泥中氧化钠和氧化铝的回收[J]. 矿产综合利用, 2008(1): 27-31.

MA Shu-hua, ZHENG Shi-li, ZHANG Yi. Recovery of soda and alumina from red mud[J]. Multipurpose Utilization of Mineral Resources, 2008(1): 27-31.

[6] ZHONG Li, ZHANG Yi-fei, ZHANG Yi. Extraction of alumina and sodium oxide from red mud by a mild hydro-chemical process[J]. Journal of Hazardous Materials, 2009, 172(2): 1629-1634.

[7] 钟 莉, 张亦飞. 亚熔盐法回收赤泥[J]. 中国有色金属学报, 2008, 18(1): 70-73.

LI Zhong, ZHANG Yi-fei. Recovery of Al2O3 and Na2O from red mud by sub-molten salt[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 70-73.

[8] 姚志通, 李海晏, 夏枚生, 叶 瑛, 张 路. 由粉煤灰水热合成方钠石及其表征[J]. 中国有色金属学报, 2009, 19(2): 366-371.

ZHAO Zhi-tong, LI Hai-yan, XIA Mei-sheng, YE Ying, ZHANG Lu. Hydrothermal synthesis of sodalite from coal fly ash and its property characterization[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(2): 366-371.

[9] 蒋家超, 赵由才. 粉煤灰提铝技术的研究现状[J]. 有色冶金设计与研究, 2008, 29(2): 40-43.

JIANG Jia-chao, ZHAO You-cai. Current research situation of Al extraction from fly ash[J]. Nonferrous Metals Engineering & Research, 2008, 29(2): 40-43.

[10] 马淑花, 杨权成, 郑诗礼. 一种湿法从粉煤灰中提取氧化铝的方法. 中国专利: 201010565571.1[P]. 2012-05-30.

MA Shu-hua, YANG Quan-cheng, ZHENG Shi-li. A hydrometallurgy method of extracting Al from fly ash. China Patent: 201010565571.1[P]. 2012-05-30.

[11] 唐振华. 亚熔盐法粉煤灰提铝工艺硅渣制保温材料工艺及其性能[D]. 北京: 北京科技大学, 2013: 32-47.

TANG Zhen-hua. Manufacturing technology and properties of insulation materials from Si-rich slag generated in the cleaner process of extracting alumina from fly ash by sub-molten salt method[D]. Beijing: University of Science and Technology Beijing, 2013: 32-47.

[12] 张寿国, 谢红波, 李国忠. 硅酸钙保温材料研究进展[J]. 建筑节能, 2006, 34(1): 28-30.

ZHANG Shou-guo, XIE Hong-bo, LI Guo-zhong. Research advances in calcium silicate insulation material[J]. Energy Saving Material, 2006, 34(1): 28-30.

[13] YANAGISAWA K, FENG Q, YAMASAKI N. Hydrothermal synthesis of xonotlite whiskers by ion diffusion[J]. Journal of Materials Science Letters, 1997, 16(11): 889-891.

[14] 李懋强, 陈玉峰, 夏淑琴, 李建辉, 粱宏勋. 超轻微孔硅酸钙绝热材料的显微结构和工艺控制[J]. 硅酸盐学报, 2000, 28(5): 401-406.

LI Mao-qiang, CHEN Yu-feng, XIA Shu-qin, LI Jian-hui, LIANG Hong-xun. Microstructure and processing of ultra-light calcium silicate insulation material[J]. Journal of the Chinese Ceramic Society, 2000, 28(5): 401-406.

[15] 唐振华, 马淑花, 王月娇, 郭曦尧, 郑诗礼. 硬硅钙石晶须的水热合成[J]. 过程工程学报, 2013, 13(6): 1047-1051.

TANG Zhen-hua, MA Shu-hua, WANG Yue-jiao, GUO Xi-yao, ZHENG Shi-li. Synthesis of xonotlite whisker with hydrothermal method[J]. The Chinese Journal of Process Engineering, 2013, 13(6): 1047-1051.

[16] LIU Fei, WANG Xiao-dan, CAO Jian-xin. Effect of ultrasonic process on carbide slag activity and synthesized xonotlite[J]. Physics Procedia, 2012, 25: 56-62.

[17] 郭武明. 利用固体废弃物制备硅酸钙绝热材料及性能研究[D]. 南京: 南京理工大学, 2013: 28-41.

GUO Wu-ming. Investigation on preparation and properties of calcium silicate thermal insulation material by solid waste[D]. Nanjing: Nanjing University of Science and Technology, 2013: 28-41.

[18] LI Mao-qiang, LIANG Hong-xun. Formation of micro-porous spherical particles of calcium silicate (xonotlite) in dynamic hydrothermal process[J]. China Particuology, 2004, 2(3): 124-127.

[19] ZHANG Ran, ZHENG Shi-li, MA Shu-hua, ZHANG Yi. Recovery of alumina and alkali in Bayer red mud by the formation of andradite-grossular hydrogarnet in hydrothermal process[J]. Journal of hazardous materials, 2011, 189(3): 827-35.

[20] 孙振华, 包炜军, 李会泉, 回俊博, 王晨晔, 唐 清. 高铝粉煤灰预脱硅碱溶提铝过程中的物相转变规律[J]. 过程工程学报, 2013, 13(3): 403-408.

SUN Zhen-hua, BAO Wei-jun, LI Hui-quan, HUI Jun-bo, WANG Chen-ye, TANG Qing. Mineral phase change of high-alumina fly ash during desilication and extraction of Al2O3 by alkali dissolution process[J]. The Chinese Journal of Process Engineering, 2013, 13(3): 403-408.

[21] ZHANG Ran, MA Shu-hua, YANG Quan-cheng, ZHENG Shi-li, ZHANG Yi, KIM N, HONG S. Research on NaCaHSiO4 decomposition in sodium hydroxide solution[J]. Hydrometallurgy, 2011, 108(3/4): 205-13.

[22] 王绍东, 蒲心诚. 灰沙系统水热反应动力学和反应过程的研究[J]. 硅酸盐学报, 1989, 17(6): 490-495.

WANG Shao-dong, PU Xin-cheng. Investigation on kinetics and mechanism of hydrothermal reaction in lime-sand system[J]. Journal of the Chinese Ceramic Society, 1989, 17(6): 490-495.

[23] 张瑞芝. 硬硅钙石型硅酸钙纤维的合成和应用[D]. 长沙: 长沙理工大学, 2010: 17-19.

ZHANG Rui-zhi. Synthesis and application of xonotlite-type calcium silicate hydrates fibers[D]. Changsha: Changsha University of Science and Technology, 2010: 17-19.

[24] 粱宏勋. 动态水热法合成硬硅钙石球形团聚体形成机理的研究[D]. 北京: 中国建筑材料研究院, 2001: 8-9.

LIANG Hong-xun. A study on the mechanism of formation of spherical xonotlite agglomerates during dynamic hydrothermal synthesis[D]. Beijing: China Building Materials Academy, 2001: 8-9.

[25] NOCU -WCZELIK W. Effect of Na and Al on the phase composition and morphology of autoclaved calcium silicate hydrates[J]. Cement and Concrete Research, 1999, 29(11): 1759-67.

-WCZELIK W. Effect of Na and Al on the phase composition and morphology of autoclaved calcium silicate hydrates[J]. Cement and Concrete Research, 1999, 29(11): 1759-67.

[26] 李光辉, 张吉清, 罗 骏, 陈浩远, 曾精华, 姜 涛. 硅酸钠溶液合成托贝莫来石晶须[J]. 硅酸盐学报, 2012, 40(12): 1721-1727.

LI Guang-hui, ZHANG Ji-qing, LUO Jun, CHEN Hao-yuan, ZENG Jing-hua, JIANG Tao. Preparation of tobermorite whisker from sodium silicate solution[J]. Journal of the Chinese Ceramic Society, 2012, 40(12): 1721-1727.

[27] 刘 飞. 水热合成硬硅钙石晶须及其在超轻质硅酸钙材料中应用的研究[D]. 广州: 华南理工大学, 2010: 27-28, 83-85.

LIU Fei. Study on hydrothermal synthesis of xonotlite whiskers and its application in ultra-light material of calcium Silicate[D]. Guangzhou: South China University of Technology, 2010: 27-28, 83-85.

[28] 刘 飞, 曾令可, 曹建新, 祝 博. 基于电石渣的硬硅钙石晶须的制备与表征[J]. 人工晶体学报, 2010, 39(2): 416-421.

LIU Fei, ZENG Ling-ke, CAO Jian-xin, ZHU Bo. Preparation and characterization of xonotlite whisker from carbide slag[J]. Journal of Synthetic Crystals, 2010, 39(2): 416-421.

[29] 吴梅梅, 蔡 红, 王贞尧. 硬硅钙石中空二次粒子球形成机理的探讨[J]. 耐火材料, 2000, 34(3): 151-153.

WU Mei-mei, CAI Hong, WANG Zhen-yao. Study on formation mechanism of hollow secondary particles of xonotlite[J]. Refractories, 2000, 34(3): 151-153.

[30] KUBO K, TAKEUCHI M, ESUMI M, YAMAGUCHI G, TAMURA H. Formation process of spherical secondary grain of xonotlite[J]. Yogyo-Kyokai-Shi, 1974, 82(8): 414-419.

[31] 郑远林, 张吉元, 蒋 智, 陈代清. 动态水热合成硬硅钙石的反应历程研究[J]. 中国建材科技, 1991, 3(4): 20-25.

ZHENG Yuan-lin, ZHANG Ji-yuan, JIANG Zhi, CHEN Dai-qing. Investigation of dynamical hydrothermal synthetic reaction course of xonotlite[J]. Journal of China Building Materials Academy, 1991, 3(4): 20-25.

[32] 徐兆瑜. 晶须的研究和应用新进展[J]. 化工技术与开发, 2005, 34(2): 11-17.

XU Zhao-yu. Research progress of whisker and its application[J]. Technology & Development of Chemical Industry, 2005, 34(2): 11-17.

[33] 王培铭, 丰曙霞, 刘贤萍. 背散射电子图像分析在水泥基材料微观结构研究中的应用[J]. 硅酸盐学报, 2011, 39(10): 1659-1665.

WANG Pei-ming, FENG Shu-xia, LIU Xian-ping. Application of backscattered electron imaging and image analysis in microstructure research on cement-based materials[J]. Journal of the Chinese Ceramic Society, 2011, 39(10): 1659-1665.

[34] 梁宏勋, 李懋强. 动态水热合成中搅拌对生成硅酸钙球形团聚体的作用[J]. 中国粉体技术, 2002, 8(4): 1-5.

LIANG Hong-xun, LI Mao-qiang. Effect of stirring on formation of spherical xonotlite agglomerates in dynamic hydrothermal process[J]. China Powder Science and Technology, 2002, 8(4): 1-5.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2011AA060701)

收稿日期:2014-06-12;修订日期:2014-11-15

通信作者:马淑花,副研究员,博士;电话:010-82544856;E-mail: shma@ ipe.ac.cn