文章编号:1004-0609(2016)-07-2166-08

铸铁干式加工过程中钎焊金刚石圆锯片磨损机理

刘思幸,肖 冰,张子煜,陈雨果

(南京航空航天大学 机电学院 江苏省精密与微细制造技术重点实验室,南京 210016)

摘 要:采用Ni-Cr合金活性钎料,在高真空炉中实现金刚石与钢基体牢固的钎焊连接。借助扫描电镜、能谱分析仪和X射线衍射仪阐述真空钎焊金刚石的钎焊机理和界面特征,分析钎焊金刚石圆锯片在干式加工铸铁过程中磨粒的磨损特性。结果表明:在铸铁管加工方面,钎焊金刚石圆锯片表现出优越的高效切割性能,磨粒磨损主要以破碎为主,磨削高温引起切屑粘附在破碎磨粒表面;揭示在铸铁干式加工过程中金刚石磨粒表面出现轻微的石墨化磨损等现象;实验表明磨粒的强度依然能满足加工要求。研制出适用铸铁材料高效加工用的高锋利度、高强度、安全的钎焊金刚石切割片。

关键词:金刚石圆锯片;铸铁管;真空钎焊;磨损机理;干式加工

中图分类号:TG732;TG743 文献标志码:A

传统的电镀、烧结和树脂结合剂等磨料工具的磨料与结合剂之间通过物理结合作用连接,在重负荷加工过程中磨粒易从母体材料层中脱落,直接影响工具的加工效率、使用寿命和操作安全性等。鉴于钎焊金刚石工具在焊接机理方面实现了磨粒、活性钎料与钢基体之间的化学冶金结合,显著提高了结合剂对磨粒的把持强度,能够满足高强度、重负荷、高效加工的要求[1-3]。本课题组成员及国内外相关学者在钎焊超硬磨料工具的机理研究方面所涉及的界面微观结构、反应机理、钎焊工艺等方面开展了大量深入研究[4-12],其应用领域包括硬脆材料、陶瓷材料与有色金属等材料的加工等。

黑色金属由于其优越的力学性能在机械、建筑、交通、桥梁、船舶和石油化工等领域有着广泛的应用前景,相关结构件的磨切削加工目前多采用树脂基磨料砂轮、锯片等工艺,虽然可以满足加工要求,但加工效率低、安全性低。天然单晶金刚石作为切削刀具材料在常规条件下因其磨损速率太快而不能用于黑色金属的切削[13],TANAKA和IKAWA等[14]通过化学热腐蚀试验,提出了金刚石切削刀具热化学腐蚀机理。LANE和DOW等[15]建立了热化学磨损分析模型,研究了单晶金刚石刀具在切削低碳钢时的刀面磨损形式。涉及黑色金属材料的应用加工过程中钎焊金刚石磨料工具的磨损分析还未见深层次的报道[16]。关于立方氮化硼(CBN)磨料钎焊工具在黑色金属加工应用方面少有研究,所用钎料多为铜基或银基合金,钎焊温度为900~950 ℃,钎料的强度低于镍基钎料的,而且银基钎料较镍基钎料成本高,CBN较金刚石成本高,故基于拓宽金刚石磨料工具的应用范围、工具的耐用性和性价比等为出发点,对CBN钎焊工具在黑色金属加工方面不做相关的对比研究[4, 17-19]。

本文作者通过对钎焊金刚石圆锯片切割铸铁过程中磨粒表面的形貌进行观察,深入研究了磨粒表面碳化物的形貌、磨损方式和磨损机理,以期对钎焊金刚石工具在黑色金属(大型工程、建筑钢和轨道交通等结构件)的切割应用领域做一些有益的探索尝试。

1 实验

1.1 实验条件和工艺过程

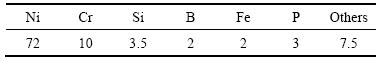

基体采用30CrMo不锈钢,活性钎料选用Ni-Cr合金粉末,其熔化温度为980 ℃,主要成分如表1所列。金刚石选用黄河旋风牌HSD90等级,磨料的平均颗粒直径为0.55 mm。分别选用不同粒径的碳化硅颗粒对基体顶端进行喷丸打磨处理,用工业酒精等有机溶剂对其表面进行清洗。金刚石磨料浸在配有工业酒精的容器中进行超声清洗,然后烘干去除磨粒表面的油污。通过树脂基环保粘结剂将钎料均匀布置在钢基体表面,在钎料表面排布金刚石磨粒。将制作完毕的试件放入高真空炉中进行钎焊,加热温度为1035 ℃,保温适宜时间,然后随炉自然冷却。

表1 Ni-Cr合金钎料的成分

Table 1 Chemical compositions of Ni-Cr filler alloy (mass fraction, %)

钎焊制作完毕的金刚石工具,以外径355 mm的圆锯片的形式对燃气管道用大型铸铁管道进行切割试验,铸铁管的尺寸为外径1800 mm、内径1764 mm,与其进行实验对比的树脂砂轮锯片外径为508 mm。

1.2 测试方法

加工试验后进行取样:沿着锯片刀头磨粒表面的垂直面进行线切割,断面分别用不同目数的碳化硅砂纸进行打磨;粘附切屑的刀头磨粒表面用油石修整,清除磨粒表面残留的熔融铁屑;用王水对刀头磨粒进行腐蚀,取出金刚石磨粒。上述试验样品在配有丙酮等工业有机溶剂的容器中进行超声清洗,烘干以去除表面残留杂质。通过Hitachi S-3400型扫描电镜、EDAX能谱仪和XD-3A型X射线Cu靶衍射仪,观察金刚石与钎料的钎焊接头界面的微观形貌和金刚石磨粒的界面生成物微观形貌,对C、Cr、Fe、Si等元素进行线扫描分析,并对钎焊接头进行X射线衍射相谱分析。

2 结果与讨论

2.1 钎焊金刚石界面微观结构分析

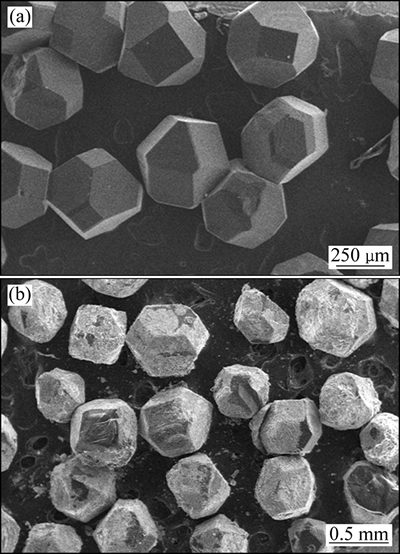

图1所示分别为在高真空钎焊炉中空烧后的金刚石磨粒和钎焊后经王水腐蚀后的金刚石磨粒的显微照片。空烧后金刚石的棱角未发生破碎、表面折射率正常、磨粒的强度损伤幅度较小(见图1(a));而钎焊后的金刚石表面存在一层明显的反应物,如同粘附了一层胶糊状物质(见图1(b))。

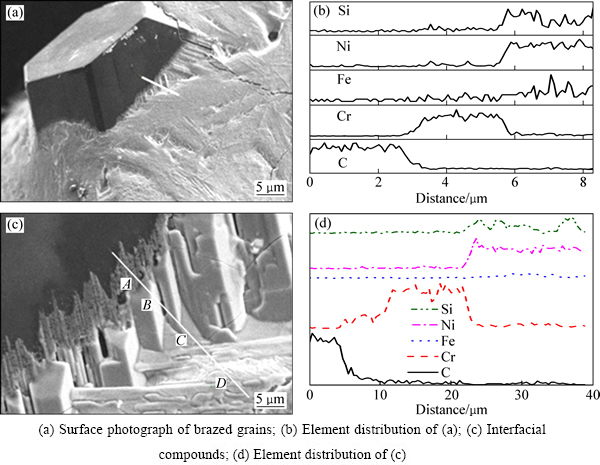

图2所示为金刚石与Ni-Cr合金钎料的钎焊连接显微照片。从图2(a)观察可得钎料对金刚石表面有较好的润湿性,且界面结合完好;沿其钎焊界面处白线进行线扫描分析可得存在元素C和Cr的相互扩散(见图2(b))。图2(a)中界面生成物的局部放大如图2(c)所示,观察可得柱状化合物以一定方式沿界面规律的排列,从图中观察可得柱状化合物的外径为0.2~4 μm不等,分别沿图2(c)中的白线进行选定点的能谱分析和线扫描。

图1 金刚石磨粒的显微照片

Fig. 1 Micrographs of heated grains (a) and brazed grains (b)

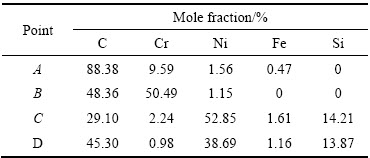

表2所列为图2(c)中A、B、C、D各点界面能谱分析结果。由表2可知,Ni、Cr、C元素都具有明显的扩散,其中靠近金刚石表面B点的Cr元素有较高的浓度分布,达到50%(摩尔分数),高于钎料中Cr的含量(10%);而Ni元素的浓度仅为1.15%,远低于钎料中Ni的含量(72%),而远离界面上D点的Cr含量(仅为0.98%)。由此推测可得,C和Cr在界面相互扩散,结合C-Cr相图可知,界面处发生了Cr和C的化学冶金结合,易生成CrxCy化合物,反应层的长度约为15 μm,为形成牢固的冶金结合提供了依据[1, 7, 11]。图2(d)所示为图2(c)界面处沿白线的线扫描分析,从分布趋势可以看到C、Cr两种元素在界面处存在明显的扩散现象,其扩散幅度在10 μm,这一结果与定点能谱分析结果相吻合。由此可以认为,C与Cr元素之间所形成的碳化物使得金刚石与合金钎料牢固结合。分别通过图1(a)、图2(a)观察可得,空烧及钎焊后出露部分的金刚石晶体棱角没有明显的破碎现象、表面折射率正常,也未出现明显的晶体腐蚀、剥落等石墨化现象。

图2 金刚石钎焊界面微观形貌

Fig. 2 Microstructures of brazed diamond

在自然环境下,金刚石晶体在800℃左右因氧化作用会发生石墨化现象,会显著降低磨粒的强度。在高真空环境中,氧分子的含量极少,经过高温作用仅在金刚石表面出现金刚石从共价键结构向石墨状结构的转变,从而有轻微的表面石墨化现象,对金刚石造成的热损伤不影响其强度在机械加工中的应用。上述结论与本课题组陈燕发表在焊接学报的结论相符[20]。

表2 选定点的元素能谱射线分析

Table 2 EDS analysis of elements at different points shown in Fig. 2(c)

钎焊金刚石表面化合物的微观形貌,如图3所示。图3(a)所示为单颗磨粒表面化合物形貌,可见表面生成一层柱状化合物;图3(b)~(d)所示分别为其逐级放大图。借助扫描电镜观察可见化合物的形状呈规则的条状沿一定方向规律的排列,如图3所示。条状生成物外径的差异是不同晶粒成分导致,对其进行能谱分析可得组成可能为Cr7C3,Cr3C2[1, 7],采用X射线衍射分析证实上述假设。

2.2 铸铁管高效切割实验

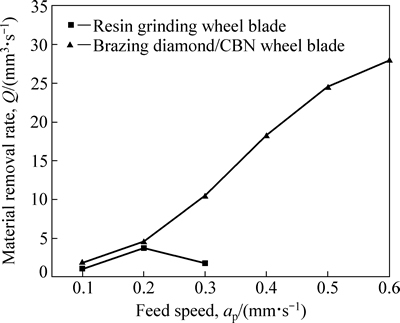

圆锯片切割铸铁管道(壁厚18 mm)的现场实验如图4(a)所示;图4(b)所示为连续切割一定数量的铸铁管后锯片的刀头数码照片,观察可得残留的切屑覆盖住部分磨粒的表面,产生此现象的原因与切割过程中的切削高温及切屑的强度有关。采用树脂砂轮片和钎焊片切割铸铁管的对比实验如图5所示。由图5中可得,当进给速率小于0.3 mm/s时树脂砂轮片的切割效率低于钎焊片的,高于此进给速率时树脂片无法正常工作,而钎焊片却充分发挥了其高效切割的优势,切割效率和进给速率呈正相关。其原因是钎焊过程中通过结合剂和金刚石的冶金结合将金刚石磨粒牢固的把持在钢基体表面,金刚石出露高度高,从而能满足大切深高负荷工作的要求,树脂片的磨粒是通过树脂材料将其机械固定,结合强度低,磨粒出露高度低,无法高效切割。

图3 钎焊金刚石表面生成化合物的微观形貌

Fig. 3 Microtopographs of compounds on brazed diamond surface

图4 铸铁管切割实验

Fig. 4 Machining experiments of cast iron pipes

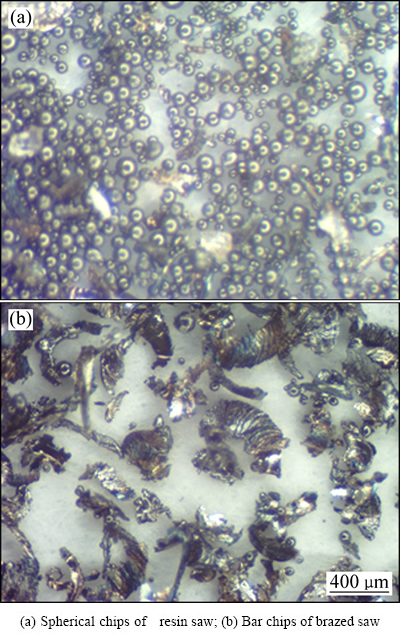

图6所示为两种锯片切割铸铁管过程中产生的切屑采集样本,观察可得树脂片产生的切屑为规则的熔球型切屑,粒度范围为50~100 μm(见图6(a));钎焊片产生的切屑为条形状剪切屑,长度尺寸范围为300~450 μm(见图6(b))。其原因是树脂片采用酚醛树脂做结合剂将磨料混合均匀后在模具内加热加压后制得,磨料粒度较小且出露高度低,在工作过程中单颗磨粒锯切深度小,切屑厚度小,磨粒之间的熔屑空间小,切屑容易断裂,排屑困难使得弧区摩擦增大而升高切削温度,相关研究表明切屑形成温度为1500 ℃[21],如此高的温度下自然很容易形成熔球型的切屑。钎焊片的磨粒结合强度大,磨粒出露高,容屑空间大,切屑的厚度大,散热性能好,锯切弧区的温度较树脂片切割时要小,因此不容易形成熔球屑而是以剪切屑为主。然而在图6(b)中存在部分小颗粒的切屑,近似熔球屑,分析其原因是随磨粒磨损的加剧,磨粒发生破碎,磨粒韧角钝化,强度低的切屑粘附在磨粒周围,降低了容屑空间,降低了磨粒的锋利度,导致弧区温度升高,切屑断裂,高温下形成了部分近似熔球屑的碎屑,同时在磨粒周围也粘附了一层切屑(见图4(b))。在切割区域的高温作用下,切屑与金刚石磨粒的接触,怀疑有切屑中的Fe元素和金刚石表面的腐蚀扩散现象发生,导致金刚石在触媒元素Fe的作用下发生石墨化,下面将对其进行深入分析。

图5 钎焊片与树脂片切割效率对比

Fig. 5 Cutting efficiency contrast test between brazing diamond and resin grinding wheel blade

图6 铸铁管切割时产生的切屑

Fig. 6 Chips of cutting cast iron pipes

2.3 金刚石磨料磨损腐蚀机理分析

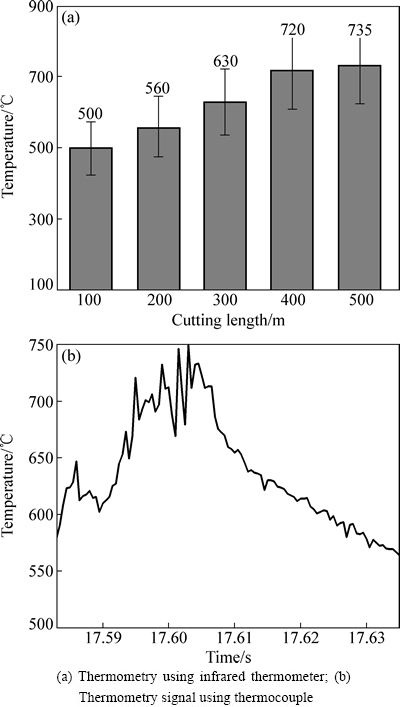

对图4(b)所示的切割铸铁后表面粘附有铁屑的金刚石磨粒用油石进行修复得出其表面形貌,结果如图8所示。从图8观察可得,金刚石出现了磨损、破碎和断裂等现象,金刚石周围粘附部分切屑。对其表面进行能谱分析表明成分主要是C元素,Fe元素的含量极少,由此可以判断在工作过程中的切削温度没有达到Fe元素急剧扩散的临界点,金刚石表面受到Fe的催化作用仅发生轻微的石墨化腐蚀现象。在干式加工铸铁的过程中,钎焊锯片在切削过程中接触面所产生的高温时间短、散热性好,准确测量磨粒点及弧区温度的难度较大,本实验中从多方面探究磨粒磨损腐蚀现象,测量磨粒及弧区温度这一因素作为衡量指标之一,在综合常用测温方法的基础上选用非接触手持式红外测温法(HCJYET-HT-8965型)和接触式半人工热电偶测温法(选用NI-6211数据采集卡)。上述两种方法的测试结果存在一定误差,起到相互补充的作用,测温结果如图7所示。图7(a)所示为手持式红外测温法所得数据结果,采用瞬时测量切削弧区温度的方法选取平均值。图7(b)所示为半人工热电偶测温,对采集卡的数据进行分析得出切削弧区温度,其外包络线为磨粒温度,内包络线为切削弧区工件温度。从图中可以得出接触区瞬间温度范围在500~750 ℃左右,对比图6中的切屑可得切削磨粒弧区温度没有达到使得金刚石严重石墨化的程度。但随着局部磨粒的逐渐破碎、容屑空间的减小,切削弧区会发生瞬时高温,图7(a)也体现出随着切削行程的增加,切削弧区温度有增加的趋势。因此金刚石磨粒表面轻微的石墨化在所难免,但是并不会出现特别严重的石墨化现象,图8可以充分的阐述上述解释。

图7 铸铁干式切削区温度测量结果

Fig. 7 Temperature measurement results of cast iron during dry cutting

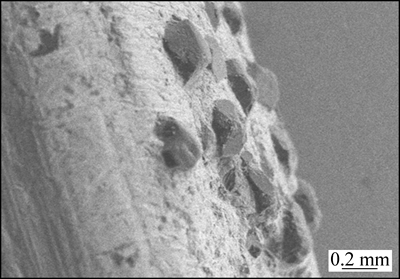

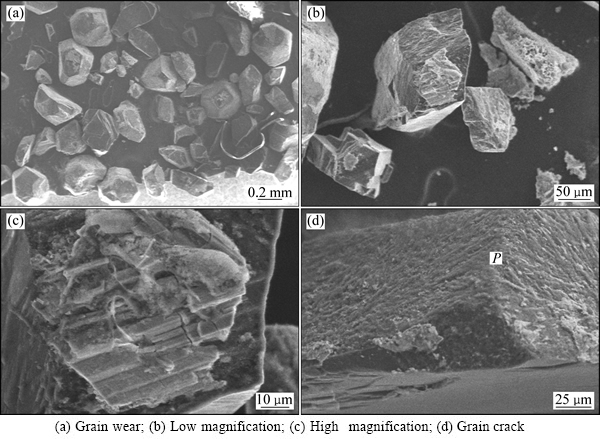

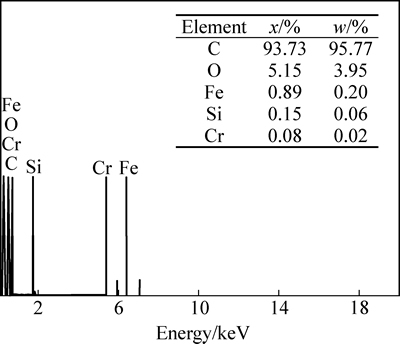

对图8中的金刚石采用化学腐蚀的方法得到磨粒,其微观形貌如图9所示。从图9(a)中可以看出,金刚石颗粒中有破碎、断裂及细小颗粒的金刚石存在,分析其原因为切割过程的金刚石破碎所致,而非整个颗粒从基体脱落。图9(b)和(c)所示分别为其中某颗破碎幅度较小的高倍率显微形貌。从图中可看出,金刚石表面生成的化合物磨损较为严重。图9(d)所示为断裂一半的金刚石磨粒,可以看出金刚石表面有微小的小孔,究其原因可能是所生成的条状碳化物与磨粒表面的接触部分为碳化物和磨粒的牢固冶金结合提供了可能,而此时条状碳化物因磨损使得小孔漏出。对图9(d)中金刚石的棱角部位P进行能谱分析,元素分布结果如图10所示。由图10可知,其中含有轻微的触媒元素Fe和Cr等,其余主要成分是C元素,而从其表面形貌观察可得磨粒的棱角明显,晶面完整,可以得出金刚石表面未发生严重的石墨化腐蚀现象,切屑温度也没有达到石墨化温度的极值点,不影响切割过程的正常工作,对以往金刚石磨料加工黑色金属易发生严重石墨化的观念提出了质疑,图4中所示的铸铁管的切割实验也验证了上述观点。

图8 切割后刀头金刚石形貌

Fig. 8 Surface photograph of brazed diamond grains after cutting cast iron

3 结论

1) 采用Ni-Cr合金钎料在高真空炉中将金刚石磨粒牢固地焊接在钢基体上,界面处生成的碳化物如Cr7C3及Cr3C2呈现规则的柱状形状并整齐的排列在磨粒周围将其牢牢把持住,能够充分满足钎焊切割片高负荷工作的要求。

图9 切割铸铁管后金刚石界面微观结构

Fig. 9 Interfacial microstructures of diamond grains after cutting cast iron pipes

图10 图9(d)中P点的能谱分析

Fig. 10 Energy dispersive spectroscopy of Point P in Fig. 9(d)

2) 钎焊金刚石切割片在高效加工铸铁管道等黑色金属材料较传统的树脂砂轮片有明显优势,表现在高效率、安全操作等方面。

3) 加工铸铁管道过程中金刚石磨料的磨损主要表现为磨粒的破损和断裂,磨粒和工件接触区的表面温度等因素不足以引起金刚石磨粒产生严重石墨化腐蚀磨损等现象,对以往认为金刚石工具加工黑色金属时容易出现严重石墨化的观点提出了质疑,拓宽钎焊金刚石工具在黑色金属加工领域中应用,具有重要的应用价值。

REFERENCES

[1] 肖 冰, 徐鸿钧, 武志斌, 徐西鹏. Ni-Cr合金真空单层钎焊金刚石砂轮[J]. 焊接学报, 2001, 22(2): 23-27.

XIAO Bing, XU Hong-jun, WU Zhi-bin, XU Xi-peng.Furnace brazing of diamond grinding wheel with Ni-Cr alloy under vacuum atmosphere[J]. Transactions of the China Welding Institution, 2001, 22(2): 23-27.

[2] BUHL S, LEINENBACH C, SPOLENAK R, WEGENER K. Failure mechanisms and cutting characteristics of brazed single diamond grains[J]. The International Journal of Advanced Manufacturing Technology, 2013, 66(5/8): 775-786.

[3] 王美娟, 王日初, 彭超群, 冯 艳, 张 纯. 固结磨粒金刚石线锯的研究进展[J]. 中国有色金属学报, 2013, 23(5): 1368-1379.

WANG Mei-juan, WANG Ri-chu, PENG Chao-qun, FENG Yan, ZHANG Chun. Research progress on fixed diamond wire saw[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1368-1379.

[4] 李奇林, 苏宏华, 徐九华, 雷卫宁. 超高频感应连续钎焊立方氮化硼磨粒的界面反应机理[J]. 中国有色金属学报, 2015, 25(6): 1165-1170.

LI Qi-lin, SU Hong-hua, XU Jiu-hua, LEI Wei-ning. Interfacial reaction mechanism of CBN grain continuous brazed by ultra-high frequency induction[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1165-1170.

[5] MA Bo-jiang, PANG Qian, LOU Jian-peng. Rod-like brazed diamond tool fabricated by supersonic-frequency induction brazing with Cu-based brazing alloy[J]. Int J Refract Met Hard Mater, 2014, 43(3): 25-29.

[6] WANG Cheng-yong, ZHOU Yu-mei, ZHANG Feng-lin, XU ZC. Interfacial microstructure and performance of brazed diamond grits with Ni-Cr-P alloy[J]. Journal of Alloys & Compounds, 2009, 476(1): 884-888.

[7] 卢金斌, 徐九华. 真空钎焊金刚石界面碳化物的形貌[J]. 中国有色金属学报, 2007, 17(7): 1143-1148.

LU Jin-bin, XU Jiu-hua. Morphology of carbide on diamond interface by vacuum brazing[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1143-1148.

[8] 刘思幸, 肖 冰, 张子煜, 段端志, 徐风雷, 王 波. 铜锡钛合金钎焊金刚石及立方氮化硼磨粒界面特征分析[J]. 人工晶体学报, 2015, 44(5): 1161-1165.

LIU Si-xing, XIAO Bing, ZHANG Zi-yu, DUAN Duan-zhi, XU Feng-lei, WANG Bo. Microanalysis of interface characteristics of diamond and cubic boron nitride abrasive with Cu-Sn-Ti filler alloy[J]. Journal of Synthetic Crystals, 2015, 44(5): 1161-1165.

[9] 孙凤莲, 冯吉才, 刘会杰, 邱平善, 李 丹. Ag-Cu-Ti钎料中Ti元素在金刚石界面的特征[J]. 中国有色金属学报, 2001, 11(1): 103-106.

SUN Feng-lian, FENG Ji-cai, LIU Hui-jie, QIU Ping-shan, LI Dan. Characteristic of Ti in Ag-Cu-Ti filler in brazed joint of diamond[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 103-106.

[10] 卢金斌, 席艳君, 王志新. Ni-Cr合金真空钎焊金刚石的碳化物生长及位向关系[J]. 中国有色金属学报, 2010, 20(1): 137-142.

LU Jin-bin, XI Yan-jun, WANG Zhi-xin. Carbide growth and orientation relationship of vacuum brazing diamond with Ni-Cr alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 137-142.

[11] YAO Zheng-jun, SU Hong-hua, FU Yu-can High temperature brazing of diamond tools[J]. Transactions of Nonferrous Metals Society of China, 2005, 15(6): 1297-1302.

[12] WU Mao, CAO Che-zheng, Rafi-ud-din, HE Xin-bo, QU Xuan-hui. Brazing diamond/Cu composite to alumina using reactive Ag-Cu-Ti alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(6): 1701-1708.

[13] LI Z J, FANG F Z, GONG H, ZHANG X D. Review of diamond-cutting ferrous metals[J]. International Journal of Advanced Manufacturing Technology, 2013, 68(5/8): 1717-1731.

[14] TANAKA H, SHIMADA S, IKAWA N, YOSHINAGA M. Wear mechanism of diamond cutting tool in machining of steel[J]. Key Engineering Materials, 2001, 196(8): 69-78.

[15] LANE B M, DOW T A, SCATTERGOOD R. Thermo-chemical wear model and worn tool shapes for single-crystal diamond tools cutting steel[J]. Wear, 2013, 300(1/2): 216-224.

[16] ZHANG Yuan-liang, ZHOU Zhi-min, WANG Jin-long, LI Xiao-yan. Diamond tool wear in precision turning of titanium alloy[J]. Materials and Manufacturing Processes, 2013, 28(10): 1061-1064.

[17] WANG Yi, QIU X M, SUN D Q. Influence of Ti on microstructure and strength of c-BN/ Cu-Ni-Sn-Ti composites[J]. Int J Refract Met Hard Mater, 2011, 29(2): 293-297.

[18] ELSENER H R, KLOTZ U E, KHALID F A, PIAZZA D, KISER M. The role of binder content on microstructure and properties of a Cu-base active brazing filler metal for diamond and CBN[J]. Adv Eng Mater, 2005, 7(7): 375-380.

[19] LIU Si-xing, XIAO Bing, ZHANG Zi-yu, DUAN Duan-zhi. Microstructural characterization of diamond/CBN grains steel braze joint interface using Cu-Sn-Ti active filler alloy[J]. Int J Refract Met Hard Mater, 2016, 54: 54-59.

[20] 陈 燕, 徐鸿钧, 傅玉灿, 苏宏华. Ni-Cr合金真空钎焊金刚石的表面石墨化[J]. 焊接学报, 2009, 30(9): 21-24.

CHEN Yan, XU Hong-jun, FU Yu-can, SU Hong-hua. Surface graphitization on brazed diamond with Ni-Cr alloy in vacuum brazing[J]. Transactions of the China Welding Institution, 2009, 30(9): 21-24.

[21] MALKIN S, ANDERSON R B. Thermal aspects of grinding: Part 1-Energy Partition[J]. Jour Manuf Sci Eng, 1974, 96(4): 1177-1183.

Wear mechanism of brazed diamond saws during dry-cutting cast iron

LIU Si-xing, XIAO Bing, ZHANG Zi-yu, CHEN Yu-guo

(Jiangsu Key Laboratory of Precision and Micro-manufacturing Technology,

College of Mechanical and Electrical Engineering,

Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China)

Abstract: Diamond grains were brazed onto steel (0.45%C) matrix in high vacuum furnace using Ni-Cr active powder filler alloy. Scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS) and X-ray diffracometry (XRD) techniques were applied to investigate the interface characteristics of brazing diamond abrasive crystals to steel substrate and the wear characteristics in dry cutting cast iron process. The results show that the brazing diamond saws have obvious advantages in terms of high efficiency cutting cast iron. The main wear of the grains is grits fracture from the brazed combined zone. The iron chips are adhered to the surface of the broken grains at high grinding temperature. The graphitization of diamond grits slightly occurred and the diamond strength is enough to meet the requirements of machining process when dry-cutting cast iron. The super sharp, high strength and safety brazed diamond saw was developed for the high efficiency machining cast iron materials.

Key words: diamond saws; cast iron pipe; vacuum brazing; wear mechanism; dry-cutting

Foundation item: Projects(BY2014003-02, BY2014003-18, BY2014003-11, BY2013003-14, BY2013003-04 and BY2013003-15) supported by the Industry-University-Research Cooperation Research Project of Jiangsu Province, China

Received date: 2015-05-06; Accepted date: 2016-01-20

Corresponding author: XIAO Bing; Tel: +86-25-84892901; E-mail: xbxiao@263.net

(编辑 龙怀中)

基金项目:江苏省产学研前瞻性联合研究项目(BY2014003-02,BY2014003-18,BY2014003-11,BY2013003-14, BY2013003-04,BY2013003-15)

收稿日期:2015-05-06;修订日期:2016-01-20

通信作者:肖 冰,教授,博士;电话:025-84892901;E-mail:xbxiao@263.net