文章编号:1004-0609(2010)12-2412-07

复杂硫化铜矿热活化-加压浸出工艺

徐志峰1,李 强2,王成彦2

(1. 江西理工大学 材料与化学工程学院,赣州 341000;

2. 北京矿冶研究总院 冶金研究设计所,北京 100044)

摘 要:针对以黝铜矿为主体矿物的复杂硫化铜矿开展热活化-加压浸出工艺研究。结果表明:复杂铜精矿经573 K温度热活化1~2 h后,在浸出温度453 K,氧分压0.6 MPa,初始硫酸浓度1.23 mol/L,液固比5:1,木质素磺酸钙用量为精矿质量的1.25%等条件下,浸出仅2 h就可使铜和锌浸出率分别高达94.08%和96.95%,而铁浸出率仅为22.37%;在复杂铜精矿热活化预处理过程中,未见铅、锌、硫和砷等元素挥发损失,并探讨了复杂铜精矿的热活化机理。

关键词:硫化铜矿;黝铜矿;热活化;预处理;加压浸出

中图分类号:TF111 文献标志码:A

Heat activation pretreatment and pressure leaching of

complex copper sulfide ores

XU Zhi-feng1, LI Qiang2, WANG Cheng-yan2

(1. School of Materials and Chemical Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China;

2. Institute of Metallurgical Research and Design, Beijing General Research Institute of

Mining and Metallurgy, Beijing 100044, China)

Abstract: The heat activation-pressure leaching of complex copper sulfide ores with tetrahedrite as the main mineral was studied. The results show that the leaching rates of copper and zinc are as high as 94.08% and 96.95%, respectively, while that of iron is limited at 22.37% in the following conditions: the heat activation temperature 573 K, the heat activation time 1-2 h, the leaching temperature 453 K, the oxygen partial pressure 0.6 MPa, the initial sulfuric acid concentration 1.23 mol/L, the liquid to solid ratio 5:1, the calcium lignosulphonate dosage of 1.25% of the mass of the ores, the leaching time 2 h. No loss of lead, zinc, sulfur and arsenic in the ores occurs during the heat activation pretreatment. The heat activation mechanism of complex copper sulfide ores is further discussed.

Key words: copper sulfide ores; tetrahedrite; heat activation; pretreatment; pressure leaching

随着全世界铜资源的逐渐减少和贫化,湿法炼铜技术及相关研究日渐活跃[1-2]。作为一种清洁的湿法冶金新技术,加压浸出在复杂硫化铜矿处理方面具有广阔的应用前景[3-4]。目前,加压浸出工艺仅在次生辉铜矿处理方面成功实现工业化。原生黄铜矿、黝铜矿结构稳定,分解困难,其浸出“钝化”[5]问题目前尚未彻底解决。如何克服黄铜矿和黝铜矿浸出“钝化”,提高浸出速率,在较低温度及压力条件下实现高效浸出,已成为复杂硫化铜矿浸取研究的中心课题。

为克服浸出“钝化”,复杂硫化铜矿直接加压浸出时往往需要较高温度和较大压力(T>493 K,p>3.0 MPa)。高温高压条件[6]不仅对浸出设备及操作提出比较苛刻的要求,且在高温高压浸出条件下精矿中绝大部分硫化物形态的硫将氧化生成硫酸,导致浸出液硫酸“膨胀”,需进一步中和处理。HNO3催化氧化浸出[7-8]虽能明显降低浸出温度和压力,但在HNO3强氧化作用下,精矿中绝大部分硫也将氧化生成硫酸,而且浸出液脱硝也是一难题;加氯活化浸出工艺[9-10]虽能有效克服硫化铜矿浸出“钝化”,但氯离子对浸出设备的腐蚀不容忽视。

为提高复杂硫化铜矿浸出效率,焙烧预处理是常用方法,目前已开展多项研究[11]。张振健[12]针对汤丹铜精矿提出先在823~873 K温度下焙烧脱硫,使不易浸出的硫化铜转变成易溶解的氧化物或硫酸铜,进而密闭氨浸;AKCIL[13]采用913 K温度下焙烧方法对黄铜矿进行预处理,然后进行低温压浸。上述“焙烧-加压浸出”联合工艺必须回收焙烧过程中释放的SO2以解决烟气污染问题。近年有学者研究提出硫化铜矿焙烧预处理新工艺,如固硫焙烧工艺[14-15]和硫化相变焙烧工艺[16-17]。固硫焙烧工艺通过引入Ca2+使硫在焙烧过程中以CaSO4形式固化在焙砂中,从而有效避免SO2烟气污染问题;而硫化相变焙烧工艺则在惰性气体保护下在623~673 K温度条件下使黄铜矿发生相变反应并转变成易浸出的铜蓝矿,该工艺同样可以有效回避SO2烟气污染问题。

本文作者提出复杂硫化铜矿“热活化-加压浸出”工艺思想,即在一个较低的火法焙烧温度条件下使黝铜矿和黄铜矿晶格活化,而在热活化预处理过程中控制精矿中的S、Zn、As和Pb等元素挥发损失为零,最终使原本难以浸出的复杂铜精矿在中等温度和压力条件下得以顺利浸出。“热活化-加压浸出”工艺为复杂硫化铜矿资源高效利用提供一种新的可选方案。

1 实验

1.1 实验原料

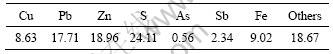

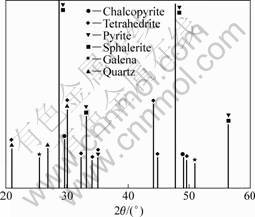

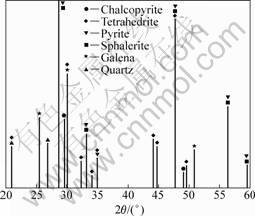

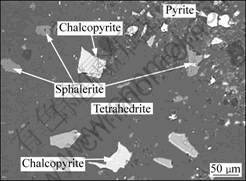

复杂硫化铜矿原料中99.7%粒度小于44 μm,主要元素含量见表1。进一步由铜精矿XRD谱(见图1)可知,铜精矿中主要金属矿物有闪锌矿、黄铜矿、黝铜矿、黄铁矿以及方铅矿,脉石矿物主要为石英。经显微镜下观察可知,该铜精矿中闪锌矿多,含铜矿物中黝铜矿数量多。在含铜矿物中,黝铜矿占35%~40%。

表1 复杂铜精矿主要化学成分

Table 1 Chemical composition of copper concentrate (mass fraction, %)

图1 铜精矿XRD谱

Fig.1 XRD pattern of copper concentrate

1.2 试验方法

复杂铜精矿热活化预处理在实验室用马弗炉中完成。加压浸出试验在1.0 L磁力搅拌衬钛高压釜中完成。将预处理后的铜精矿按一定液固比与硫酸浸出剂混合并加入钛胆中,然后放入高压釜中加盖密封,当升温至设定温度时开始通入氧气并计时,在浸出过程中保持搅拌转速恒定。浸出结束后通水冷却,待釜内压力降为零后开启高压釜,分别将浸出液和浸出渣送样分析。Cu、Zn、Fe等元素浸出率计算均按渣计。

2 结果与讨论

复杂硫化铜精矿未经热活化预处理,直接进行加压浸出[18]时,在温度453 K、氧分压0.6 MPa、初始硫酸浓度1.41 mol/L、液固比5:1(其中液体体积为5 mL,固体质量为1 g)、搅拌速度500 r/min、木质素磺酸钙用量1.25%(相对于精矿质量)等条件下,即使浸出时间延长至6 h,Cu浸出率仍低至68.22%。此时,Zn浸出率可达91.84%,杂质Fe浸出甚微(浸出率4.37%)。虽然Zn和Fe浸出结果相对理想,但难以实现Cu的高效溶出。

鉴于复杂铜精矿在中等温度及压力条件下难以直接高效浸出,以下进行“热活化-加压浸出”工艺实验。

2.1 热活化温度的影响

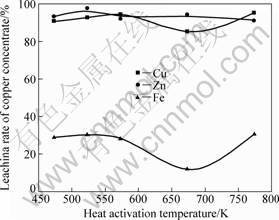

考察热活化温度对复杂铜精矿加压浸出的影响(各批次热活化时间恒定为3 h),浸出试验条件为:T=453 K,p(O2)=0.6 MPa,t=4.0 h,液固比5:1,c(H2SO4)ini=1.33 mol/L,搅拌速度500 r/min,木质素磺酸钙用量1.25%。热活化温度对Cu、Zn和Fe浸出率的影响见图2。

图2 热活化温度对铜精矿浸出率的影响

Fig.2 Effect of heat activation temperature on leaching rate of copper concentrate

由图2可见,经热活化预处理后,铜精矿浸出有显著改善。Cu和Fe浸出率随热活化温度变化的规律类似。当热活化温度为573 K时,Cu和Zn浸出率可分别达到94.37%和92.06%,Fe浸出率为28.32%,此时,浸出液中Fe浓度4 g/L左右,经浸出条件调整,有可能进一步降低浸出液中Fe浓度。

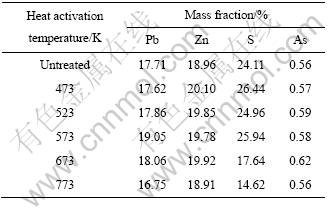

进一步考察热活化温度对铜精矿中S、Zn、As和Pb等元素含量的影响,结果见表2。由表2可见,当在573 K及以下温度进行热活化预处理时,S、Zn、As、Pb等元素的挥发损失为零;当活化温度高于673 K时,虽然Zn、As、Pb等元素未见挥发,但元素S开始出现明显挥发。673 K时,S挥发损失率为26.84%;773 K时,S的挥发损失率达到39.36%。

表2 热活化温度对铜精矿中S、Zn、As和Pb等元素含量的影响

Table 2 Effect of heat activation temperature on S, Zn, As and Pb of in copper concentrate

综上所述,热活化温度取573 K为宜,此时不会出现SO2烟气污染问题。

2.2 浸出温度的影响

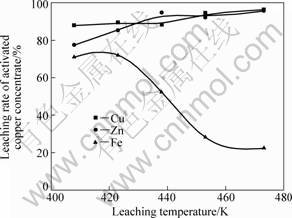

在复杂铜精矿573 K热活化3 h基础上,考察浸出温度对铜精矿加压浸出的影响,试验条件如下:p(O2)=0.6 MPa,t=4.0 h,液固比5:1,c(H2SO4)ini=1.33 mol/L,搅拌速度500 r/min,木质素磺酸钙用量1.25%。浸出温度对Cu、Zn和Fe浸出率的影响见图3。

图3 浸出温度对活化铜精矿浸出的影响

Fig.3 Effect of leaching temperature on leaching rate of activated copper concentrate

由图3可见,当浸出温度由408 K升高至473 K时,Cu浸出率由87.80%增大至96.67%;随浸出温度升高,Zn浸出率总体上也呈增大趋势,当浸出温度由438 K进一步升高时,Zn浸出率趋于平衡,保持在95%左右;当浸出温度高于427 K以后,Fe浸出率急剧降低,这可能是由于Fe发生了明显的水解沉淀之故。当浸出温度为453 K时,Cu、Zn和Fe浸出率分别为94.37%、92.06%和28.32%。

综上所述,浸出温度取453 K为宜。

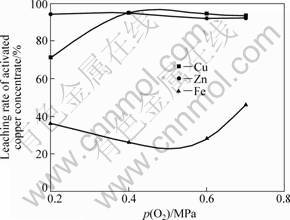

2.3 氧分压的影响

在试验3.2的基础上,考察氧分压对活化铜精矿加压浸出的影响,试验条件如下:T=453K,t=4.0 h,液固比5:1,c(H2SO4)ini=1.33 mol/L,搅拌速度500 r/min,木质素磺酸钙用量1.25%。氧分压对Cu、Zn和Fe浸出率的影响见图4。

由图4可见,随氧分压由0.2 MPa增大至0.4 MPa,Cu浸出率由71.33%增大至95.03%,渣含Cu由3.56%降至0.64%,Fe浸出率由36.43%降至26.17%;当氧分压进而提高至0.6 MPa并进一步增大时,Cu浸出率

图4 氧分压对活化铜精矿浸出的影响

Fig.4 Effect of oxygen partial pressure on leaching rate of activated copper concentrate

趋于平衡,而随氧分压由0.6 MPa增至0.7 MPa时,Fe浸出率呈增大趋势。总体而言,氧分压变化对Zn浸出率无明显影响。

综合考虑,氧分压最终选取0.6 MPa为宜。

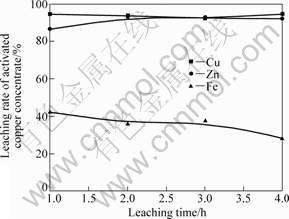

2.4 浸出时间的影响

在试验3.3的基础上,考察了浸出时间对活化铜精矿加压浸出的影响,试验条件如下:T=453 K,p(O2)=0.6 MPa,液固比5:1,c(H2SO4)ini=1.33 mol/L,搅拌速度500 r/min,木质素磺酸钙用量1.25%。浸出时间对Cu、Zn和Fe浸出率的影响如图5所示。

由图5可见,当浸出时间由1 h延长至4 h时,Zn的浸出率由86.58%增至92.06%,Cu浸出率无明显变化,保持在92%~95%之间,而Fe浸出率则由42.28%

图5 浸出时间对活化铜精矿浸出的影响

Fig.5 Effect of leaching time on leaching rate of activated copper concentrate

降至28.32%。当浸出时间为2 h时,Cu、Zn和Fe浸出率分别为93.79%、92.82%和35.99%,通过浸出初酸浓度调整,有可能将Fe浸出率进一步降低。

因此,在保证Cu和Zn高效浸出的前提下尽可能缩短浸出时间,浸出时间选取2 h即可。

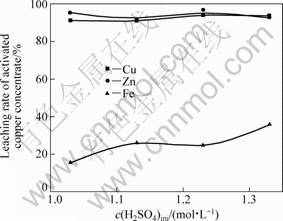

2.5 初始硫酸浓度的影响

在试验3.4的基础上,考察了初始硫酸浓度对活化铜精矿加压浸出的影响,试验条件为T=453 K,p(O2)=0.6 MPa,液固比5:1,搅拌速度500 r/min,t= 2.0 h,木质素磺酸钙用量1.25%。初始硫酸浓度对Cu、Zn、Fe浸出率的影响见图6。

图6 初始硫酸浓度对活化铜精矿浸出的影响

Fig.6 Effect of initial sulfuric acid concentration on leaching rate of activated copper concentrate

由图6可见,当初始酸浓度由1.03 mol/L增大至1.23 mo/L时,Cu浸出率由91.37%略增至94.08%;随初始酸浓度进一步增大,Cu浸出率无明显变化。初始酸浓度对Zn浸出无明显影响,在试验范围内,Zn浸出率保持在95%左右。随着初始酸浓度的升高,Fe浸出率呈明显增大趋势,浸出初酸浓度的降低有利于降低杂质Fe浸出率。

综合考虑,c(H2SO4)ini选取1.23 mo/L为宜。

2.6 液固比的影响

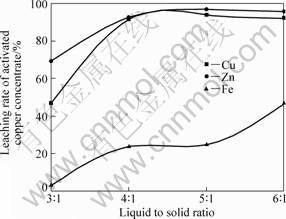

在试验3.5的基础上,考察液固比对活化铜精矿加压浸出的影响,试验条件为T=453 K,p(O2)= 0.6 MPa,c(H2SO4)ini=1.23 mo/L,搅拌速度500 r/min,t=2 h,木质素磺酸钙用量1.25%。液固比对Cu、Zn和Fe浸出率的影响如图7所示。

由图7可见,当液固比由3:1增大至5:1,Cu浸出率由46.95%增大至94.08%,Zn浸出率由69.33%增

图7 液固比对活化铜精矿浸出的影响

Fig.7 Effect of liquid to solid ratio on leaching rate of activated copper concentrate

大至96.89%,Fe浸出率由3.48%增大至24.99%。随液固比进一步增大,Cu和Zn浸出率无明显变化,而Fe浸出率则呈明显增大趋势。因此,液固比选取5:1为宜。

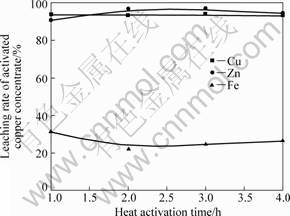

2.7 热活化预处理条件优化

基于上述试验,可初步确定活化铜精矿加压浸出的较优工艺如下:T=453 K,p(O2)=0.6 MPa,c(H2SO4)ini=1.23 mo/L,液固比5:1,搅拌速度500 r/min,t=2.0 h,木质素磺酸钙用量1.25%。为缩短热活化时间以优化热活化预处理工艺,进一步考察热活化时间对复杂铜精矿加压浸出结果的影响(各批次热活化温度恒定为573 K),加压浸出试验条件同上。热活化时间对铜精矿Cu、Zn和Fe浸出率的影响如图8所示。

图8 热活化时间对铜精矿浸出的影响

Fig.8 Effect of heat activation time on leaching rate of copper concentrate

由图8可见,在上述试验条件下,热活化时间对Cu浸出率无明显影响。复杂硫化铜矿热活化1 h后,Cu浸出率即可达到93.78%,渣含Cu降至0.76%;随热活化时间由1 h延长至2 h后,Zn浸出率由90.87%升高至96.95%,Fe浸出率由31.37%降至22.37%;随热活化时间进一步延长,Cu、Zn、Fe浸出率无明显 变化。

由上述分析可知,热活化预处理工艺可以进一步优化,活化时间可缩短至1~2 h。

2.8 热活化机理

以黝铜矿为主要含铜矿物的复杂硫化铜矿经热活化预处理后,在中等温度和压力条件下可以取得比较理想的浸出结果。在此,对复杂硫化铜矿热活化机理进行探讨。

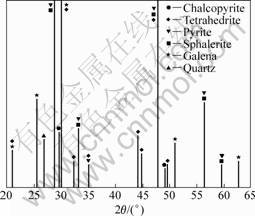

分别对523 K及573 K温度条件下热活化预处理后铜精矿进行了XRD分析,所得谱如图9和10所 示。

将图9和10与图1比较可见,铜精矿热活化预处理前后在物相上无本质差异,未见有新相产生。热活化预处理后,铜矿物谱线相对变弱。这可能是因为热活化预处理后,铜矿物晶体结构发生一定程度的畸变,晶格缺陷增大。

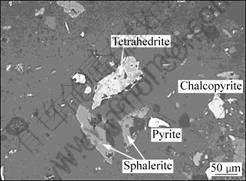

另外,对热活化前后的铜精矿分别进行显微镜下观察,其形貌如图11和12所示。对比图11和12可见,经573 K热活化预处理后,黄铜矿、黝铜矿、闪锌矿和黄铁矿抛光面上未见明显变化,抛光面颜色和原料相比稍有差异,虽未见明显相变,但矿物颗粒表面有一些很薄的氧化层。由此推测,经573 K温度热活化预处理后,矿物颗粒表面有部分Fe或S氧化,这可能导致Cu—Fe—S键或Cu—S键去稳定化。

图9 523 K下热活化后精矿的XRD谱

Fig.9 XRD pattern of copper concentrate after heat activation at 523 K

图10 经573 K热活化后精矿的XRD谱

Fig.10 XRD pattern of copper concentrate after heat activation at 573 K

图11 热活化前铜精矿中各硫化矿的形貌

Fig.11 Micrograph of minerals in concentrate before heat activation pretreatment

图12 经573 K热活化后铜精矿中各硫化矿的形貌

Fig.12 Micrograph of minerals in concentrate after heat activation pretreatment at 573 K

经热活化预处理后,无论是致密耐蚀的铜矿物晶格结构在一定程度上被破坏,还是稳定的共价键去稳定化,在宏观上都将表现出难浸的复杂硫化铜矿浸出过程得以改善。上述结论还有待进一步研究证实。

3 结论

1) 通过热活化预处理,可以实现以黝铜矿为主体矿物的复杂硫化铜比较理想的加压浸出结果。经试验确定,热活化预处理的较优工艺条件如下:热活化温度573 K,活化时间为1~2 h。在热活化预处理过程中,铜精矿中S、Zn、As和Pb等元素未见挥发损失,不产生SO2等有害气体。

2) 经试验确定,热活化预处理后复杂铜精矿加压浸出较优工艺条件如下:浸出温度453 K,氧分压0.6 MPa,初始硫酸浓度1.23 mol/L,液固比5:1,木质素磺酸钙用量为精矿质量的1.25%,浸出时间2 h。在上述工艺条件下,Cu和Zn浸出率分别高达94.08%和96.95%,而Fe浸出率仅22.37%,浸出效果理想。

3) 经热活化预处理,精矿中的黄铜矿或黝铜矿未见分解或生成其他易浸出的矿物。铜精矿浸出过程改善,可能是由于热活化使铜矿物的晶格结构发生畸变,或者是由于矿物表面部分Fe和S氧化,使得稳定的Cu—Fe—S键或Cu—S键变得不稳定的缘故。

致谢:在复杂铜精矿工艺矿物学分析过程中,得到了北京矿冶研究总院矿产资源所汤集刚教授的帮助,在此深表谢意!

REFERENCES

[1] 王海北, 蒋开喜, 邱定蕃, 卢惠民. 国内外硫化铜矿湿法冶金发展现状[J]. 有色金属, 2003, 55(4): 101-104.

[2] WANG Hai-bei, JIANG Kai-xi, QIU Ding-fan, LU Hui-min. Status of hydrometallurgical development on copper sulfide ores[J]. Nonferrous Metals, 2003, 55(4): 101-104.

[3] 刘大星. 湿法炼铜的发展与前景[J]. 有色金属再生与利用, 2005(7): 37-39.

[4] LIU Da-xing. Development trend of copper hydrometallurgy[J]. Regeneration and Utilization of Nonferrous Metals, 2005(7): 37-39.

[5] 邱定蕃. 加压湿法冶金过程化学与工业实践[J]. 矿冶, 1994, 3(4): 55-67.

[6] QIU Ding-fan. Process chemistry and industrial practice of pressure hydrometallurgy[J]. Mining & Metallurgy, 1994, 3(4): 55-67.

[7] BEREZOWSKY R M G S, COLLINS M J. The commercial status of pressure leaching technology[J]. JOM, 1991, 43(2): 9-15.

[8] HACKL R P, DREISINGER D B, PETERS E, KING J A. Passivation of chalcopyrite during oxidative leaching in sulfate media[J]. Hydrometallurgy, 1995, 39(1/3): 25-48.

[9] SOHN H Y, LIN H K, Oxygen pressure leaching of copper from primary chalcopyrite ore containing pyrite under simulated solution-mining conditions[J]. Minerals & Metallurgical Processing, 1990, 7(3): 163-168.

[10] DAVIES D S, LEUEDERS R E, SPITZ R A, FRANKIEWICS T C. Nitric-sulfuric leach process improvements[J]. Minerals Engineering, 1981, 33(8): 1252-1259.

[11] 王永慧. 铜矿石及精矿氮类物催化加压浸出的应用与经济估算[J]. 中国有色冶金, 2009(1): 6-11, 43.

[12] WANG Yong-hui. The application and economics of NSC catalyzed pressure leaching of copper ores and concentrates[J]. China Nonferrous Metals Metallurgy, 2009(1): 6-11, 43.

[13] SKROBIAN M, HAVLIK T, UKASIK M. Effect of NaCl concentration and particle size on chalcopyrite leaching in cupric chloride solution[J]. Hydrometallurgy, 2005, 77(1/2): 109-114.

[14] LU Z Y, JEFFREY M I, LAWSON F. Effect of chloride ions on the dissolution of chalcopyrite in acidic solutions[J]. Hydrometallurgy, 2000, 56(2):189-202.

[15] SPASAD S, PANDEY B D. Alternative processes for treatment of chalcopyrite—A review[J]. Minerals Engineering, 1998, 11(8): 763-781.

[16] 张振健. 汤丹铜精矿焙烧-氨浸-萃取电积新工艺研究[J]. 有色金属(冶炼部分), 1999(4): 16-20.

[17] ZHANG Zhen-jian. Study on new technique of roasting-ammonia leaching-solvent extraction-electrowinning of Tangdan copper concentrates[J]. Nonferrous Metals(Extractive Metallurgy), 1999(4): 16-20.

[18] AKCIL A. A preliminary research on acid pressure leaching of pyritic copper ore in Kure Copper Mine, Turkey[J]. Minerals Engineering, 2002, 15(12): 1193-1197.

[19] 丁伟安. 硫化铜精矿石灰焙烧-浸出工艺研究[J]. 新疆有色金属, 1996(2): 23-26.

[20] DING Wei-an. Study on the process of lime roasting-leaching of copper sulfide concentrates[J]. Xinjiang Nonferrous Metals, 1996(2): 23-26.

[21] 蔡超君, 华一新, 梁铎强. 硫化铜精矿加碳酸钙焙烧表观动力学研究[J]. 有色金属(冶炼部分), 2004(3): 2-6.

[22] CAI Chao-jun, HUA Yi-xin, LIANG Duo-qiang. Non-isothermal kinetics of roasting of copper sulfide concentrate in the presence of calcium carbonate[J]. Nonferrous Metals(Extractive Metallurgy), 2004(3): 2-6.

[23] 宋 宁, 刘纯鹏. 黄铜矿加硫焙烧提铜新工艺[J]. 有色金属, 2005, 57(2): 84-87.

[24] SONG Ning, LIU Chun-peng. A New technique to make copper removing iron from chalcopyrite[J]. Nonferrous Metals, 2005, 57(2): 84-87.

[25] 宋 宁, 严继康, 杜景红. 黄铜矿硫化焙烧相变浸出的研究[J]. 有色金属(冶炼部分), 2005(3): 10-13.

[26] SONG Ning, YAN Ji-kang, DU Jing-hong. Study on sulfidation roasting and leaching process of chalcopyrite[J]. Nonferrous Metals(Extractive Metallurgy), 2005(3): 10-13.

[27] 徐志峰, 李 强, 王成彦. 复杂硫化铜精矿微波活化预处理-加压浸出工艺[J]. 过程工程学报, 2010, 10(2): 256-262.

[28] XU Zhi-feng, LI Qiang, WANG Cheng-yan. Microwave activation pretreatment and pressure leaching of complex copper sulfide concentrate[J]. The Chinese Journal of Process Engineering, 2010, 10(2): 256-262.

(编辑 李艳红)

基金项目:国家重点基础研究发展计划资助项目(2007CB613505);江西省自然科学基金资助项目(2007GQC0656)

收稿日期:2009-10-29;修订日期:2010-09-12

通信作者:王成彦,教授,博士;电话:010-88399551;E-mail:wchy3207@sina.com