强变形诱导析出相回溶后的Al-Cu合金再时效行为

张孜昭1,许晓嫦1, 2,胡楠1,屈啸1,陈振湘1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 有色金属材料与工程教育部重点实验室,湖南 长沙,410083)

摘 要:采用透射电镜观察与分析,探讨含析出相的Al-Cu合金经多向压缩变形诱导析出相回溶后形成的过饱和固溶体的再时效行为。研究结果表明:Al-Cu合金由强塑性变形诱导析出相回溶形成的过饱和固溶体,在变形停止后再时效时显著加速时效析出过程;析出相的析出顺序与加热温度、变形量及变形后的晶粒尺寸有关;若加热温度足够消除强变形产生的高应力,则析出顺序为过渡相→稳定相;若加热温度不能消除变形产生的高应力,且晶粒超细化,则再析出时过渡相被抑制,直接生成稳定相。

关键词:Al-Cu合金;多向压缩;析出相;回溶;再时效

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2010)05-1782-09

Re-ageing behavior of Al-Cu alloy after re-dissolution of precipitated phases caused by severe plastic deformation

ZHANG Zi-zhao1, XU Xiao-chang1, 2, HU Nan1, QU Xiao1, CHEN Zhen-xiang1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: Supersaturated solid solution was formed after re-dissolution of precipitated phases during multi-axial compression in aged Al-Cu alloy. The re-ageing behavior of strain-induced supersaturated solid solution was investigated by transmission electron microscopy. The results show that the precipitation process of the strain-induced supersaturated solid solution is significantly accelerated during re-ageing. The precipitation sequence is related to heating temperature, degree of deformation and grain size after deformation. When the heating temperature is high enough to counteract the high internal stress resulting from severe plastic deformation, the precipitation sequence is from metastable phase to stable phase; when the heating temperature is not high enough to counteract the high internal stress and the grains are ultra-refined, the precipitation sequence is that equilibrium phases are formed directly instead of metastable phases.

Key words: Al-Cu alloy; multi-axial compression; precipitated phases; re-dissolution; re-ageing

强塑性变形作为细化晶粒的有效手段,已成为材料领域的研究热点。目前其主要加工方法有等径角挤压(ECAP)[1-3]、扭转变形(HPT)[4-5]、累积轧制(ARB)[6-7]、多向压缩变形(MAC)[8-10]等。大量的实验结果表明:强变形材料的一个重要特征是晶界处于高能非平衡态[11-13]。因此,必须经退火处理后才能应 用。但在退火过程中,随着温度升高,保温时间的延长,晶粒必然发生长大,这将使强塑性变形细化晶粒的效果达不到目标要求。有细小析出相存在的变形组织在高温下可以使再结晶晶粒尺寸基本保持不变[14],在含有Al3Sc析出相的Al-3%Mg-0.2%Sc合金[15]和含有Al3Zr和MgZn2相的Al-Zn-Mg合金[16]中出现这样的结果。有文献报道[17-19],强塑性变形在诱导材料获得大角度晶界等轴细晶粒时,也使其组织结构及性能演变规律与常规塑性变形时不同,如导致合金中出现第二相质点低温回溶、基体重新成为过饱和固溶体等新现象,这样,这种处于过饱和态的强塑性变形材料再加热时,应该存在再析出行为。这种再析出如果形成文献[15-16]中所述相同的大量细小析出相,将有利于提高合金的热稳定性。目前,人们对有关强变形诱导形成的过饱和固溶体加热再析出的研究很少,而且观点也存在分歧。Murayama等[17-18, 20]认为,强塑性变形改变了铝合金的再析出的顺序,不析出介稳相,而是直接现出稳定相;但Segal[21]则认为,强塑性变形不改变再析出的顺序,只是促使析出相的析出速度加快。为了进一步了解强变形诱导析出相回溶后形成的过饱和固溶体在加热时的再时效行为,本文作者利用透射电镜观察,探讨含析出相的Al-Cu合金在多向压缩变形诱导析出相回溶形成过饱和固溶体在加热时的再析出行为。

1 实验

试样材料是以工业纯Al(99.9%)和Al-49.3%Cu中间合金为原料,在石墨坩埚中精炼,铁模铸造。铸锭经过485 ℃,12 h均匀化处理,在470 ℃预热1 h后热轧成厚12 mm的板材,加工成长×宽×高为10 mm×10 mm×15 mm的长方体试样。其化学成分如表1所示。

表1 Al-Cu合金试样化学成分(质量分数)

Table 1 Chemical composition of tested Al-Cu alloy %

为了获得实验所需的含θ″,θ′ 和θ共3种析出相的试样,采用热处理工艺如表2所示。

多向压缩变形(Multi-axial Compression,MAC)在自行设计的多向压缩模具上进行,模具采用Cr12 模具钢制备,如图1所示。

采用型号为WE60,最大负荷60 t的液压式万能材料试验机,按应变轴x→y→z→x进行换方向压缩。

表2 试样的热处理工艺及析出相

Table 2 Phases and heat-treatment processes of Al-Cu alloy

图1 多向压缩变形模具示意图

Fig.1 Schematic of MAC

其等效应变根据公式ε=ln(h0/h)计算(其中:h0为原始高度,h为变形后高度)。每次挤压的应变量ε约为0.4,变形速率为5~10 mm/s。

Al-Cu合金经多向压缩变形后,采用透射电子显微镜观察其析出相的演变。透射电子显微镜观察试样在MAC变形后垂直于压缩方向取样,试样先机械减薄到0.1 mm,随后在MTP-1电解双喷仪上进行减薄,电解温度为-25 ℃。电解液为30% HNO3+70% CH3OH (体积分数)。在菲利浦TECNAI-G2透射电镜下观察试样,其加速电压为200 kV。

2 实验结果

根据文献[10, 19]中的结果,含θ″相和θ′相的试样分别经多向压缩变形8道次和16道次后,试样中的析出相已基本回溶于基体,使基体转变成强变形诱导的过饱和固溶体;含θ相的试样经多向压缩变形16道次析出相已部分回溶于基体中,使基体有一定的过饱和度。因此,本文中的试验选用了多向压缩变形大于8道次与16道次的试样进行再时效研究。

2.1 1号试样强塑性变形停止后的再时效

表3列出了1号试样经不同道次强塑性变形后,再加热至190 ℃保温不同时间的再析出相。其对应的透射电镜像如图2~4所示。

表3 1号试样经不同道次MAC变形后加热至190 ℃时的再析出相

Table 3 Re-precipitation of sample 1 after different MAC deformations at 190 ℃

从表2可知:本次实验的1号试样是在190 ℃保温16 h的工艺参数下制备的。而经MAC变形8道次后的试样,加热至190 ℃保温30 min时可观察到θ′相;经MAC变形16道次后,加热至190 ℃保温90 min时可观察到θ相;经MAC变形30道次后,加热至 190 ℃保温60 min时可观察到θ相。由此可推断:强塑性变形诱导析出相回溶形成的过饱和固溶体,在再加热时,析出相的析出速度比固溶处理形成的过饱和固溶体析出速度快。

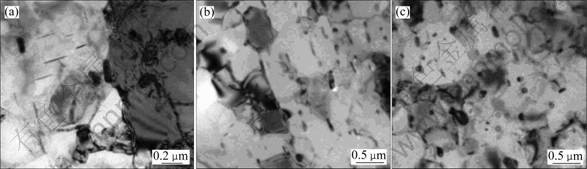

图2(a)~(c)所示分别为1号试样经MAC变形8道次后,再加热至190 ℃保温不同时间的透射电镜像。从图2可见:于190 ℃保温30 min时的试样中已出现极少量且非常细小的针状析出物。根据文献[22],可认为此析出相为θ′相(图2(a))。于190 ℃保温60 min后,θ′相数量比图2(a)中增多,且尺寸增大(图2(b));保温90 min,θ′相数量比图2(b)中的数量进一步增多,尺寸更大,且有明显的析出方向(图2(c))。

图3(a)~(c)所示分别为1号试样经MAC变形16道次再加热至190 ℃保温不同时间的透射电镜像。从图3可见:含1号试样经MAC变形16道次后在190 ℃保温30 min的试样中已出现少量、细小的针状析出物(图3(a))。根据文献[22]可认为针状析出相为θ′相,颗

保温时间/min: (a) 30; (b) 60; (c) 90

图2 1号试样经MAC变形8道次后于190 ℃保温不同时间的透射电镜像

Fig.2 TEM images of sample 1 subjected to 8 passes of MAC deformation annealed at 190 ℃ for different time

保温时间/min: (a) 30; (b) 60; (c) 90

图3 1号试样经MAC变形16道次后于190 ℃保温不同时间的透射电镜像

Fig.3 TEM images of sample 1 subjected to 16 passes of MAC deformation annealed at 190 ℃ for different time

保温时间/min: (a) 30; (b) 60; (c) 90

图4 1号试样经MAC变形30道次后于190 ℃保温不同时间的透射电镜像

Fig.4 TEM images of sample 1 subjected to 30 passes of MAC deformation annealed at 190 ℃ for different time

粒状析出相为θ相。对比图2(a)与图3(a)发现,图3(a)中θ′相数量明显增多,且析出相尺寸也增大。说明1号试样经MAC变形16道次后加热时,再析出速度比经MAC变形8道次的试样快;对比3(a)与图3(b)可发现:图3(b)中的θ′相数量比图3(a)中增多,且尺寸增大。在图3(c)中可同时观察到针状θ′相和颗粒状θ相。

图4(a)~(c)所示分别为1号试样经MAC变形30道次后,再加热至190 ℃保温不同时间的透射电镜像。保温30 min后的试样,从图4(a)观察不到析出相,但保温60和90 min后,则可从图4(b)和图4(c)中观察到平衡颗粒状θ相。θ相随着保温时间延长,数量增多,尺寸增大。在图4(b)和图4(c)中没有发现针状析出相。

2.2 2号试样强塑性变形停止后再加热过程中的再 时效

表4列出了2号试样经不同道次的强塑性变形后,加热至200 ℃保温不同时间的再析出相,其对应的透射电镜像如图5~7所示。

表4 2号试样经不同道次MAC变形后加热至200 ℃时的再析出相

Table 4 Re-precipitation of sample 2 subjected to different MAC deformations at 200 ℃

从表2可知:本次实验的2号试样是在200 ℃保温96 h的工艺参数下制备的。而经MAC变形16道次后的试样,加热至200 ℃保温30 min可观察到θ′相;保温60 min后可观察到θ相;经MAC变形22道次后加热至200 ℃保温30 min可观察到θ相;实验结果证明:强塑性变形诱导析出相回溶形成的过饱和固溶体,再加热时析出相的析出速度比固溶处理形成的过饱和固溶体的析出速度快。

图5(a)~(c)所示分别为2号试样经MAC变形16道次后,再加热至200 ℃保温不同时间的透射电镜像。从图5可见:于200 ℃保温30 min的试样中已出现少量细小的针状析出物(图5(a));随着保温时间的延长,针状θ′相析出相数量增多,尺寸变化不大,同时可观察到细小颗粒状θ相(图5(b));随着保温时间的延长,θ′和θ相数量增多,尺寸增大(图5(c))。

图6(a)~(c)所示分别为2号试样经MAC变形22道次后,再加热至200 ℃保温不同时间的透射电镜像。由图6可见:于200 ℃保温30 min和60 min的试样中出现针状θ′相和颗粒状θ相(图6(a), (b))。图6(b)中θ′相和θ相数量比图6(a)中的数量增多,尺寸几乎没有变化。于200 ℃保温90 min的试样中θ′相减少,而θ相尺寸稍增大(图6(c))。

图7(a)~(c)所示分别为2号试样经MAC变形30道次后,再加热至200 ℃保温不同时间的透射电镜像。从图7可见:变形30道次后的试样加热至200 ℃保温30 min时,没有新析出相析出(图7(a));保温60 min和90 min的试样,有颗粒状θ平衡相,但没有发现针状析出相(图4(b), 4(c));随着保温时间延长,θ相数量增多,尺寸增大。

保温时间/min: (a) 30; (b) 60; (c) 90

图5 2号试样经MAC变形16道次后于200 ℃保温不同时间的透射电镜像

Fig.5 TEM images of sample 2 subjected to 16 passes of MAC deformation annealed at 200 ℃ for different time

保温时间/min: (a) 30; (b) 60; (c) 90

图6 2号试样经MAC变形22 道次后于200 ℃保温不同时间的透射电镜像

Fig.6 TEM images of sample 2 subjected to 22 passes of MAC deformation annealed at 200 ℃ for different time

保温时间/min: (a) 30; (b) 60; (c) 90

图7 2号试样经MAC变形30道次后于200 ℃保温不同时间的透射电镜像

Fig.7 TEM images of sample 2 subjected to 30 passes of MAC deformation annealed at 200 ℃ for different time

2.3 3号试样强塑性变形停止后再加热过程中的再 时效

表5列出了3号试样经不同道次的强塑性变形后,加热至200 ℃保温不同时间的再析出相,其对应的透射电镜像如图8~10所示。

图8(a)~(c)所示分别为3号试样经MAC变形16道次后加热至200 ℃保温不同时间的透射电镜像。从表2可知:本次实验的3号试样是在420 ℃保温2 h的工艺参数下制备的。

从图8(a)可观察到:保温30 min的试样中存在较

表5 3号试样经不同道次MAC变形后加热至200 ℃时的再析出相

Table 5 Re-precipitation of sample 3 subjected to different MAC deformations at 200 ℃

大尺寸的短杆状θ相,这是强变形后破碎但未溶解的析出相,同时存在非常细小的针状θ′相;保温60 min的试样随着保温时间的延长,针状θ′相数量增多、尺寸变化不大,未溶解的颗粒状θ相数量减少、尺寸变小(图4(b));保温90 min的试样中可观察到细小弥散的针状θ′相和颗粒状θ相(图4(c))。

图9(a)~(c)所示分别为3号试样经MAC变形22次后加热至200 ℃保温不同时间的透射电镜像。从图9(a)可见:保温30 min的试样中存在针状θ′相与强变形后破碎但未溶解的颗粒状θ相,与图8(a)相比,试样中的未溶解颗粒状θ相数量减少、尺寸变小。试样保温60 min后,从图9(b)中已观察不到强变形后破碎但未溶解的颗粒状θ相,但可观察到细小的颗粒状θ相和针状θ′相。对比图9(c)与9(b)可知:随着保温时间延长,析出相数量增多,尺寸稍有长大。

图10(a)~(c)所示分别为3号试样经MAC变形30道次后加热至200 ℃保温不同时间后的透射电镜像。从图10(a)可见:变形30道次后的试样加热至200 ℃保温30 min后仍有破碎未溶解的颗粒状θ相,但此时已成球状;从图10(b)和10(c)中只能观察到平衡颗粒状θ相,且θ相随着保温时间延长,数量增多,尺寸增大,并没有发现针状析出相。

保温时间/min: (a) 30; (b) 60; (c) 90

图8 3号试样经MAC变形16道次后于200 ℃保温不同时间的透射电镜像

Fig.8 TEM images of sample 3 subjected to 16 passes of MAC deformation annealed at 200 ℃ for different time

保温时间/min: (a) 30; (b) 60; (c) 90

图9 3号试样经MAC变形22道次后于200 ℃保温不同时间的透射电镜像

Fig.9 TEM images of sample 3 subjected to 22 passes of MAC deformation annealed at 200 ℃ for different time

保温时间/min: (a) 30; (b) 60; (c) 90

图10 3号试样经MAC变形30道次后于200 ℃保温不同时间的透射电镜像

Fig.10 TEM images of sample 3 subjected to 30 passes of MAC deformation annealed at 200 ℃ for different time

3 讨论与分析

由文献[22]可知:在Al-Cu合金的析出相中,θ″相与基体是共格关系,其析出形态是平行分布;θ′相与基体是半共格关系,其析出形态是呈针状,只有平衡相θ与基体非共格,其形态是颗粒状。根据实验结果发现:含析出相的Al-Cu合金在强塑性变形停止后再加热过程中,变形程度较低的试样在加热后都可观察到θ′过渡相先析出、θ平衡相后析出的现象,不存在析出顺序的改变,且随着变形程度的增加,θ′相和θ相的析出速度大幅度提高。如1号试样经MAC变形16道次后,在190 ℃保温90 min时再析出相中含θ相,但固溶处理获得的过饱和固溶体190 ℃保温16 h,其析出相为θ″相。2号试样经MAC变形22道次后,在200 ℃保温90 min时,再析出相中含θ相,但固溶处理获得的过饱和固溶体200 ℃保温96 h,其析出相为θ′相。3号试样经MAC变形22道次后,在200 ℃保温90 min时,再析出相中含θ相,但固溶处理获得的过饱和固溶体420 ℃保温2 h,其析出相为θ相。因此可得出:含析出相的Al-Cu合金在强塑性变形诱导析出相回溶后再加热过程中的再析出不出现析出顺序变化,仍然是过渡相→平衡相,但随着变形程度的增加,析出相的析出速度大幅度提高。但当变形程度较大时,在实验温度下析出顺序发生改变。如3种变形30道次的试样,在实验温度下再加热时,抑制了针状θ′过渡相的析出,直接生成颗粒状θ平衡相。据文献 [20]报道,采用ECAP制备的超细晶粒合金再时效时稳定相在等轴晶界上存在直接析出的现象。

Al-Cu合金在强变形诱导析出相回溶后形成的过饱和固溶态在强塑性变形停止后再加热过程中的再析出,与加热温度及变形程度相关。当加热温度高至足够消除基体晶格的畸变,使基体处于低应力状态时,再析出顺序与常规状态相同,但大大加快了析出过程;当合金变形程度很高,基体晶粒超细化,且加热温度不足以消除基体晶格的畸变,使基体处于高应力状态时,再析出顺序发生变化。其原因是:在强变形过程中,由于形变能的储存及析出相破碎粒子造成表面能提高,导致析出相的自由能提高,当达到所需的临界能量后,则出现回溶现象。析出相的回溶使基体重新出现过饱和度,导致合金在外界能量的作用下仍要发生溶质原子的偏聚及析出相的重新形核析出。由于这时存在大量的空位和晶界被位错饱和,使溶质原子的扩散速度显著提高(体积扩散系数可增大8个数量 级[23]),从而大大加快析出过程。当变形程度很大时,在低温时效过程中试样仍于高应力状态时则出现再时效析出顺序的改变。原因是强烈塑性变形使材料内部各相原子间距变大[24],析出相产生大量位错[25-26]和晶格畸变[27])使变形合金的畸变能剧增,因此,强塑性变形诱导析出相回溶后形成的过饱和固溶体产生严重晶格畸变,此时基体处于高能态。而处于高能状态下的母体内部无法自发产生溶质原子偏集,生成具有与母体共格和半共格关系的GP区和过渡相,因为GP区、过渡相与基体的界面关系会引起母相内的应力能进一步增大,导致自由能变高,使析出不能自发进行。但通过在晶界形成与母相没有共格关系的平衡相有利于减少母相内的应变,降低自由能,所以,出现基本上不存在应变的平衡相直接在晶界上析出的自发过程。此外,在高能态下再时效,使与基体具共格或半共格关系的过渡相难以析出,造成平衡相θ相在晶界和滑移带等晶格缺陷处不均匀形核。而强塑性变形程度很大的试样,晶粒已经超细化, 晶界和位错等晶格缺陷呈几何级数增加,因此,平衡相θ相的非均匀形核也呈几何级数增加,晶内基体的溶质原子迅速扩散到非均匀形核处以满足非均匀形核的稳定相的生长,从而导致相变驱动力急剧下降,因为晶内形成GP区、亚稳相所需的溶质过饱和度迅速消失。在上述因素的共同作用下,变形程度大的超细晶粒合金在加热再析出时,均匀形核的θ平衡相抑制GP区、 亚稳相等前期粒子的析出。因此,在本实验中,当试样的变形程度小于22道次时,在200 ℃左右低温时效过程中,基体晶格的畸变基本上被消除,因而,试样恢复了正常的析出顺序,仅大大加快析出过程;当试样变形30道次时,于200 ℃加热不足消除其高应力状态,导致析出顺序发生改变。

4 结论

(1) Al-Cu合金由强塑性变形诱导析出相回溶形成的过饱和固溶体,在变形停止后再时效时析出过程显著加速,析出相的析出顺序与加热温度、变形量及变形后的晶粒尺寸相关。

(2) 若加热温度足够消除变形量产生的高应力,则析出顺序为过渡相→稳定相;若加热温度不能消除高变形产生的高应力,且晶粒超细化,则再析出时过渡相被抑制,直接生成稳定相。

参考文献:

[1] Gao N, Starink M J, Furukawa M, et al. Evolution of microstructure and precipitation in heat-treatable aluminium alloys during ECA pressing and subsequent heat treatment[J]. Materials Science Forum, 2006, 503/504: 275-280.

[2] Valiev R Z, Langdon T G. Principles of equal-channel angular pressing as a processing tool for grain refinement[J]. Progress in Materials Science, 2006, 51(7): 881-981.

[3] Xu C, Furukawa M, Horita Z, et al. Influence of ECAP on precipitate distributions in a spray-cast aluminum alloy[J]. Acta Materialia, 2005, 53(3): 749-758.

[4] Cicek J, Prochazka I, Smola B, et al. Microstructure and thermal stability of ultra fine grained Mg-based alloys prepared by high-pressure torsion[J]. Materials Science and Engineering A, 2007, 462(1/2): 121-126.

[5] Zhilyaev A P, Langdon T G. Using high-pressure torsion for metal processing: fundamentals and applications[J]. Progress in Materials Science, 2008, 53(6): 893-979.

[6] Kwan C, Wang Z R, Kang S B. Mechanical behavior and microstructural evolution upon annealing of the accumulative roll-bonding(ARB) processed Al alloy 1100[J]. Materials Science and Engineering A, 2008, 480(1/2): 148-159.

[7] Min B K, Kim H W, Kang S B. Effect of Al3Sc precipitate on the microstructural evolution during accumulative roll bonding in Al-0.2%Sc alloy[J]. Journal of Materials Processing Technology, 2005, 162/163: 355-361.

[8] Cherukuri B, Nedkova T S, Srinivasan R. A comparison of the properties of SPD-processed AA-6061 by equal-channel angular pressing multi-axial compressions/forgings and accumulative roll bonding[J]. Materials Science and Engineering A, 2005, 410/411: 394-397.

[9] Cherukuri B, Srinivasan R. Properties of AA6061 processed by multi-axial compressions/forging (MAC/F)[J]. Materials and Manufacturing Processes, 2006, 21(5/6): 519-525.

[10] 党朋, 许晓嫦, 刘志义, 等. 铝合金等径角挤压和多向压缩变形中析出相的回溶研究[J]. 材料热处理学报, 2007, 28(5): 82-85.

DANG Peng, XU Xiao-chang, LIU Zhi-yi, et al. Investigation on dissolution of precipitates in Al alloy deformed by equal-channel angular pressing and multi-axial compression[J]. Transactions of Materials and Heat Treatment, 2007, 28(5): 82-85.

[11] Furukawa M, Horita Z, Zhilyaev A P, et al. Developing ultrafine-grained microstructures through the use of severe plastic deformation[J]. Materials Science Forum, 2003, 426/432: 2631-2636.

[12] Heason C P, Prangnell P B. Grain refinement and texture evolution during the deformation of Al to ultra-high Strains by accumulative roll bonding (ARB)[J]. Materials Science Forum, 2002, 396/402: 429-434.

[13] Prangnell P B, Bowen J R, Apps P J. Ultra-fine grain structure in aluminum alloys by severe deformation processing[J]. Materials Science and Engineering A, 2004, 375/377: 178-185.

[14] Dobatkin S V. On the increase of thermal stability of ultrafine grained material obtained by severe plastic deformation[J]. Material Science Forum, 2003, 426/432: 2699-2704.

[15] Lee S, Utsunomiya A, Akamatsu H, et al. Influence of scandium and zirconium on grain stability and superplastic ductilities in ultrafine-grained Al-Mg alloys[J]. Acta Materialia, 2002, 50(3): 553-564.

[16] Xu C, Furukawa M, Horita Z, et al. Using ECAP to achieve grain refinement,precipitate fragmentation and high strain rate superplasticity in a spray-cast aluminum alloy[J]. Acta Materialia, 2003, 51(20): 6139-6149.

[17] Murayama M, Horita Z, Hono K. Microstructure of two-phase Al-1.7at% Cu alloy deformed by equal-channel angular pressing[J]. Acta Mater, 2001, 49(1): 21-29.

[18] Kang S B, Lim C Y, Kim H W, et al. Microstructure evolution and hardening behavior of 2024 aluminum alloy processed by severe plastic deformation[J]. Materials Science Forum, 2002, 396/402: 1163-1168.

[19] XU Xiao-chang, LIU Zhi-yi, LI Yun-tao, et al. Evolution of precipitates of Al-Cu alloy during equal-channel angular pressing at room temperature[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(5): 1047-1052.

[20] Gulnaz J V, Maria D B, Ruslan Z V. Thermal stability and microstructural evolution in ultrafine grained nickel after ECAP[J]. Metall Mater Trans A, 2002, 33(6): 1865-1871.

[21] Segal V M. Equal channel angular extrusion: from micromechanics to structure formation[J]. Materials Science and Engineering A, 1999, 271(1/2): 322-333.

[22] 郑子樵. 材料科学基础[M]. 长沙: 中南大学出版社, 2005: 403-406.

ZHENG Zi-qiao. Fundamental of material science[M]. Changsha: Central South University Press, 2005: 403-406.

[23] Straumal B B, Baretzky B, Mazilkin A A, et al. Formation of nanograined structure and decomposition of supersaturated solid solution during high pressure torsion of Al-Zn and Al-Mg alloys[J]. Acta Materialia, 2004, 52(15): 4469-4478.

[24] Alexandrov I V, Zhang K, Kilmametov A R, et al. The X-ray characterization of the ultrafine-grained Cu processed by different methods of severe plastic deformation[J]. Mater Science and Engineering A, 1997, 234/236: 331-334.

[25] FatayD, AstarashE, NyilasK, et al. X-ray diffraction study on the microstructure of an Al-Mg-Sc-Zr alloy deformed by high-pressure torsion[J]. Materials Research and Advanced Techniques, 2003, 94(7): 842-847.

[26] Ohashi K, Fujite T, Oh-ishi K, et al. Microstructural control of a precipitate-hardenable Al-Ag alloy using severe plastic deformation[J]. Materials Science Forum, 2003, 426/432: 2637-2642.

[27] Horita Z, Fujinami T, Nemoto M, et al. Improvement of mechanical properties for Al alloy using equal-channel angular pressing [J]. Journal of Materials Processing Technology, 2001, 117(3): 288-292.

(编辑 陈爱华)

收稿日期:2010-03-31;修回日期:2010-06-10

基金项目:湖南省自然科学基金资助项目(05JJ40005);湖南省科技攻关项目(2007FJ3085)

通信作者:许晓嫦(1963-),女,湖南湘乡人,教授,博士,从事新型铝合金材料和金属材料强韧性研究;电话:13787797327;E-mail: xxc12@126.com