文章编号:1004-0609(2013)S1-s0391-07

热处理对TC4钛合金风扇叶片动态性能的影响

裴传虎,李臻熙,黄 旭,李四清,丁建山

(北京航空材料研究院 钛合金研究室,北京 100095)

摘 要:研究退火温度对TC4钛合金风扇叶片动态力学性能的影响。结果表明:在普通退火温度范围内(700~800 ℃),随着退火温度的升高,材料的绝热剪切敏感性逐渐降低,吸收冲击的能量逐渐提高。采用两种固溶时效热处理工艺,在TC4风扇叶片的临界失效应变率下(3 000 s-1),研究固溶后的冷却速度对TC4钛合金风扇叶片显微组织和动态力学性能的影响。研究发现,采用较低的冷却速度使α相几乎完全等轴化,能保证叶片锻件在强度降低不明显的前提下,一定程度的提高动态应变,降低绝热剪切敏感性。

关键词:TC4钛合金;风扇叶片;绝热剪切敏感性;动态力学性能;热处理工艺

中图分类号:TG146.2 文献标志码:A

Effect of heat treatment on dynamic properties of TC4 titanium fan blade

PEI Chuan-hu, LI Zhen-xi, HUANG Xu, LI Si-qing, DING Jian-shan

(Titanium Alloys Laboratory, Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The effects of annealing temperature on the dynamic properties of TC4 titanium fan blade were investigated. The results show that the adiabatic shear susceptibility is decreased and the absorbed energy is increased with increasing annealing temperature in normal heat treatment temperature range (700~800 ℃). With heat treatments, the influence of cooling rate from the solution treatment on the microstructure and dynamic mechanic properties was studied at the critical fracture strain rate of the TC4 titanium (3 000 s-1). It is found that the α phase almost completely equated and the grain size increased with decreasing cooling rate. Therefore, the dynamic strain is increased and the adiabatic shear susceptibility is decreased with the dynamic strength decrease slightly.

Key words: TC4 titanium alloy; fan blade; adiabatic shear integrality; dynamic properties; heat treatment processing

TC4钛合金具有较高的比强度,断裂韧性、疲劳强度等优良的综合力学性能,大量应用于工作温度在400 ℃以下的发动机风扇叶片。对于大涵道比涡扇发动机,大尺寸TC4风扇叶片是关键的转动部件之一,其工作条件非常苛刻。除了需要承受高速旋转产生的巨大的离心力和叶片振动产生的疲劳载荷,还需要承受砂石、飞鸟等外来物的冲击等,因此要求叶片材料在高应变率(>1×103 s-1)下具有优异的动态力学性能。国内外针对导弹战斗部壳体用钛合金在高应变率下的动态力学行为进行过研究[1-3],但对于航空发动机风扇叶片用钛合金在高应变率下的动态力学性能的研究很少。国内非常缺乏针对风扇叶片用钛合金抗外物冲击时损伤能力的评定参数和评定方法的系统研 究[4-5],因此,本文作者采用Hopkinson压杆装置,针对目前国内最大的航空发动机用TC4钛合金风扇叶片,研究热处理工艺对其动态力学行为的影响规律,为航空发动机用钛合金风扇叶片的选材和工艺优化提供一定的理论基础。

1 实验方法

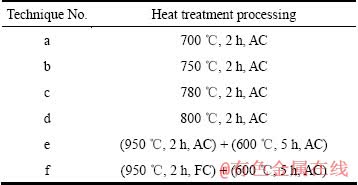

本研究采用TC4钛合金风扇叶片模锻件,研究四种普通退火和两种固溶时效热处理工艺对TC4风扇叶片锻件动态压缩性能的影响,6种热处理工艺如下表 1所示。

表1 热处理工艺

Table 1 Heat treatment processing

对经过6种工艺热处理后的TC4叶片锻件,沿叶身受外物冲击方向加工动态压缩试样。在分离式Hopkinson压杆(SHPB)上进行动态力学性能试验,其试验装置和试验原理如文献[6-7]所述。根据应力波理论,3种波形的宽度,△t,均由打击杆的长度决定,如公式(1)所示。

(1)

(1)

式中:L为撞击杆长度,C0为SHPB杆中的弹性纵波的波速。对于马氏体时效钢,C0为5.19 km/s,本实验所用打击杆长度为200 mm,因此,正常加载脉冲宽度约为80 μs。

2 结果及讨论

2.1 不同工艺热处理后TC4叶片的绝热剪切敏感性

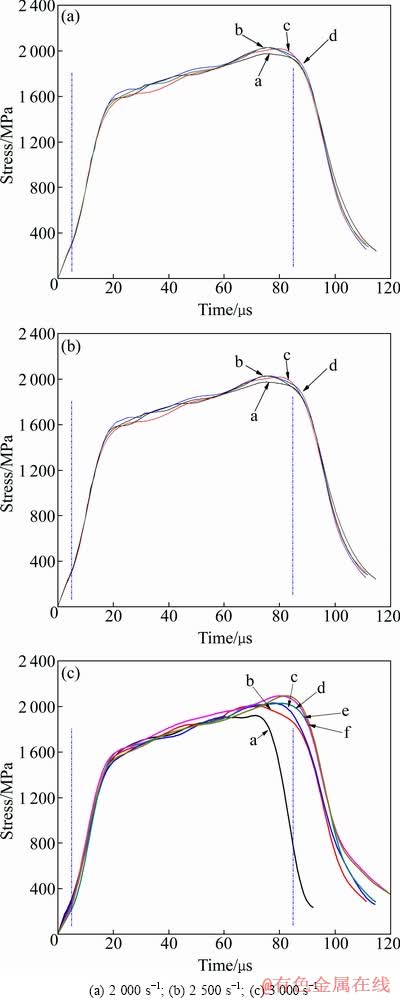

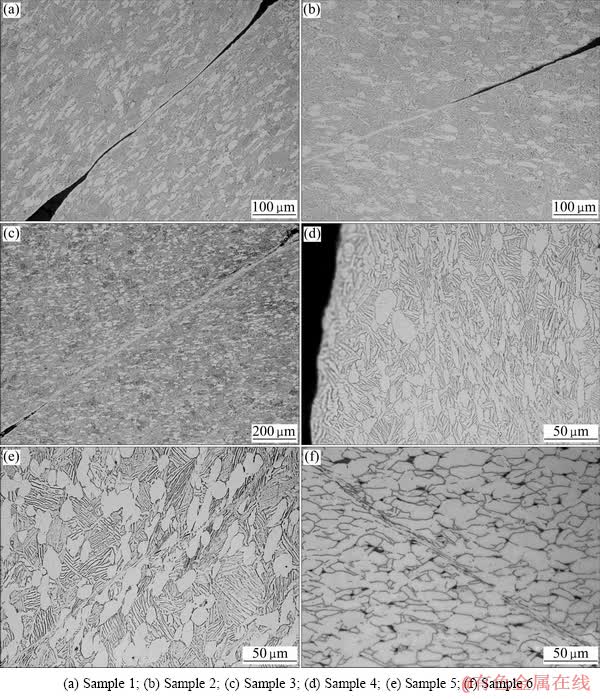

采用SHPB装置,将经过不同工艺热处理的TC4叶片锻件,在不同应变率下(2 000,2 500,3 000 s-1)进行动态加载,处理采集到的数据可以得到试样在高应变率下的动态应力—时间关系,如图1所示,动态压缩的承载时间如表2所示。6种不同工艺热处理的TC4叶片锻件试样在2 500 s-1和3 000 s-1变形材料在高应变、高应变速率条件下的变形特点由两个互相竞争的因素来决定:一是由于应变增加导致后局域化变形区域的微观组织如图2~3所示。

图1 不同工艺热处理的TC4叶片铸件在不同应变率下的应力—时间关系曲线

Fig. 1 Stress—time curves of TC4 fan blade by different heat treatments at different strain rates

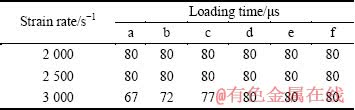

表2 不同工艺热处理的TC4叶片铸件在不同应变率下的承载时间

Table 2 Loading time of TC4 fan blade by different heat treatments at different strain rates

的加工硬化效应,二是由于绝热温升而引起的热软化效应。随着应变率的提高,材料的绝热温升提高,热软化超过了应变硬化和应变率硬化的总和,使材料的热粘塑性本构失稳过程加快并表现为材料的高度局域化,最终形成绝热剪切破坏[8-9]。应力—时间曲线表征了材料从动态加载开始到产生绝热剪切带破坏的承载时间;承载时间越长,说明材料对绝热剪切越不敏感,反之则越敏感[10]。

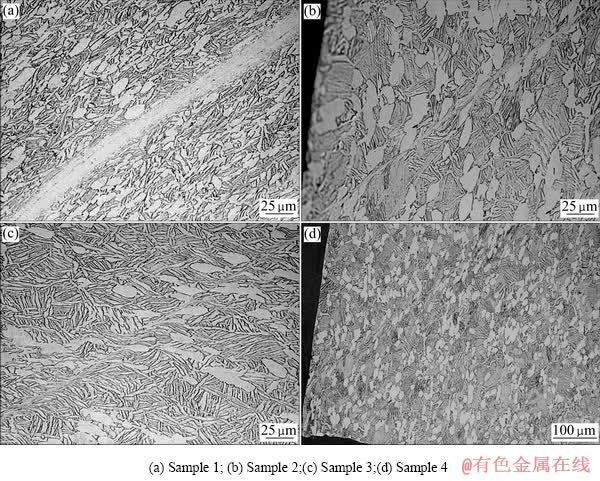

由图1~3和表2分析可知,在2 500 s-1应变速率下,四种普通退火热处理后的TC4叶片锻件试样均能稳定承载80 μs。试样4为均匀塑性变形,在局域化变形区域没有产生绝热剪切带或裂纹。但是,试样1、2和3的局域化变形区域均产生了绝热剪切带并已开始扩展,由于绝热剪切带具有一定的承载能力[11-12],因此在应力—时间曲线上,试样1、2和3并没有发生应力塌陷而失效。对比分析可知,试样1的绝热剪切带已扩展至约20 μm宽,若继续进行塑性加载,绝热剪切带将在局域化变形区域迅速扩展为裂纹,进而导致材料的应力塌陷失效。试样2和3的绝热剪切带刚刚萌生扩展至3~5 μm宽,表明材料随着后续的塑性变形加载,绝热剪切带会沿着局域化变形区域发生长度和宽度方向的扩展,而不会迅速扩展为裂纹失效。因此,试样1的绝热剪切敏感性最大,试样2和3相当,而4试样的绝热剪切敏感性最小。

在3 000 s-1应变率下,试样1、2、3已发生明显的应力塌陷卸载,承载时间分别为67、72、77 μs,而试样4、5、6依然能够稳定承载80 μs不发生应力塌陷。由图3分析其显微组织可知,试样1在局域化变形区域产生了非常明显的裂纹,裂纹边缘有较明显的绝热剪切带,且贯穿整个试样,材料已破坏失效。试样2和3在局域化变形区域的绝热剪切带已沿着两端扩展为裂纹,材料已发生应力塌陷而失效破坏,但是裂纹并未完全贯穿整个试样,其承载时间较试样1长。试样4、5和6的局域化变形区域均产生了绝热剪切带并已开始扩展,但剪切带并未贯穿整个试样,而且并未扩展为裂纹。

由以上分析可知,对于普通退火热处理工艺,随着退火温度的升高,材料的绝热剪切敏感性逐渐降低,发生绝热剪切断裂失效时所需要的驱动力逐渐增大,即叶片承受外物冲击能力逐渐增强。采用固溶时效和普通退火热处理的TC4叶片,其显微组织差别不明显,但是经固溶时效处理后材料的绝热剪切敏感性更小。在固溶处理后采用较低的冷却速度,使α相几乎完全等轴化,能够有效降低材料的绝热剪切敏感性。

图2 在2 500 s-1应变率变形后的剪切带形貌

Fig. 2 Microstructures of adiabatic shear band at strain rate of 2 500 s-1

图3 在3 000 s-1应变率变形后的剪切带形貌

Fig. 3 Microstructures of adiabatic shear band at strain rate of 3 000 s-1

2.2 不同工艺热处理后TC4叶片锻件在高应变率下的吸能

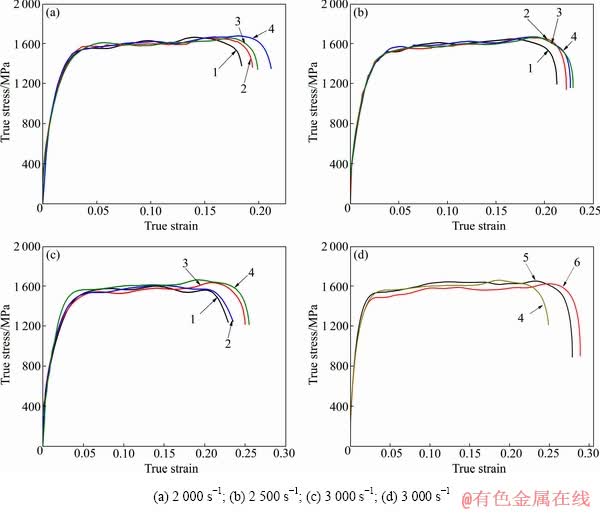

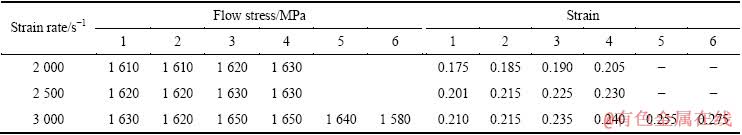

图4所示为6种工艺热处理后的TC4叶片锻件试样在3个应变率下的动态应力—应变曲线。不同应变速率下的流变应力和最大应变如表3所列。

由图4和表3可知,随着塑性变形的增加,经过6种工艺热处理后的叶片锻件试样的流变应力无明显增加,说明材料在高应变率变形时的应变强化效应不明显。此外,随着应变率的增加,流变应力亦无明显提高,说明其应变率强化效应也不明显。因此,在高应变率下变形时,经过这6种工艺热处理后的TC4钛合金叶片锻件的应变强化效应和应变率强化效应均不明显。由于TC4钛合金的温度敏感性较高,因此在高应变率下具有较高的绝热剪切敏感性[13-14]。

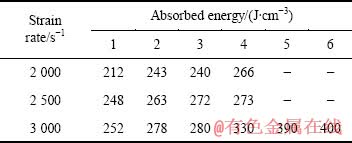

MAZEAU等[15]采用绝热剪切局域化的能量来衡量不同等级钛合金的绝热剪切敏感性。材料在冲击变形过程中所吸收的能量,也是衡量材料动态力学性能的一个重要指标,表达式如下:

(2)

(2)

叶片锻件试样在不同应变率下的吸收能如表4所列。由图4、表3和表4可知,在2 000~3 000 s-1应变率冲击加载下,随着普通退火温度的提高,材料的流变应力变化不明显,而动态应变和吸收能逐渐增大。相对于普通退火热处理,采用固溶时效处理后材料的流变应力相当,但是动态应变和吸收能显著增加,材料的动态力学性能明显提高。

由图2可知,TC4叶片模锻件经四种普通退火热处理后的初生α相和β相转变组织的尺寸、形态、分布和含量没有显著的差别,均为双态组织。但是,由于TC4风扇叶片采用的是高能螺旋压力机模锻成型,应变速率较高(约为0.1-1~1 s-1)。因此在锻件中存在大量的残余应力、形变能和位错。随着退火温度的升高,应力和位错的消除和回复进行的更加彻底,在随后的高应变率动态加载过程中越不容易发生应力集中,进而降低了绝热剪切带的萌生和扩展,降低了材料的绝热剪切敏感性。

由图3可知,对试样5进行的为固溶时效热处理,由于固溶温度与叶片模锻温度相同,因此其显微组织与普通退火热处理后的组织差别不大,均为初生α相含量约40%(体积分数)的双态组织。但是由于普通退火热处理为不完全再结晶,材料依然保留了部分锻态的组织特性,存在一定的组织不均匀性。而固溶时效热处理后,材料的初生α相等轴化程度更好,β转变组织的尺寸、形态和分布更均匀。因此,在高应变率动态加载过程中,材料内部的协调变形能力更好,更不容易发生局域化变形,绝热剪切带更不容易萌生和扩展。所以,相对于普通退火热处理,固溶时效热处理在保证材料流变应力相当的前提下,动态应变和吸收能显著增加。因此,其绝热剪切敏感性更小,抗外物冲击性能更好。

图4 不同应变率下的真应力—应变曲线

Fig. 4 True stress—strain curves at different strain rates

表3 不同应变率下的流变应力和应变

Table 3 Flow stress and strain at different strain rates

表4 不同应变率下的吸收能

Table 4 Absorbed energy at different strain rates

试样6采用固溶处理后炉冷,与试样5空冷后的组织差别较大,炉冷后α相几乎完全等轴化,已经不存在片层β转变组织,且晶粒发生了一定程度的长大。TC4钛合金等轴组织抗裂纹萌生的能力较强,但是抗裂纹扩展能力较差,强度较低。而片层组织抗裂纹萌生能力较差,但是抗裂纹的扩展能力较强[16-17]。研究结果表明[10-11],具有一定比例初生等轴α相的双态组织的动态力学性能匹配最好。而本研究针对TC4钛合金风扇叶片锻件的研究结果表明,采用固溶后炉冷的工艺获得的等轴组织,在动态强度下降不明显的前提下,可以显著提高材料的动态应变和吸收能。因此,对于不同的材料和锻件,应选用合适的热处理工艺,以获得优良的动态力学性能。

3 结论

1) 随着普通退火温度的提高,材料的绝热剪切敏感性逐渐降低,动态应变和吸收冲击的能量逐渐提高,抗外物冲击能力逐渐增强。

2) 对于固溶时效热处理工艺,在固溶处理后采用较低的冷却速度,使α相几乎完全等轴化,且使晶粒发生一定程度的长大,能够有效降低材料的绝热剪切敏感性,提高材料的动态力学性能。

3) 固溶时效与普通退火热处理后TC4风扇叶片锻件的显微组织差别不大,但是固溶时效处理后材料的初生α相的等轴化程度更好,β相转变组织的尺寸、形态和分布更均匀,动态力学性能更加优越。

REFERENCES

[1] 才鸿年, 王 鲁, 李树奎. 战斗部材料研究进展[J]. 中国工程科学, 2002, 4(12): 21-27.

CAI Hong-nian, WANG Lu, LI Shu-kui. Research progress in warhead materials [J]. Engineering Science, 2002, 4(12): 21-27.

[2] CHICHILI D R, RAMESH K T, HEMKER K J. The high-strain-rate response of alpha-titanium: Experiments, deformation mechanisms and modeling [J]. Acta Materialia, 1998, 46(3): 1025-1043.

[3] LIU Xin-qin, TAN Cheng-wen, ZHANG Jing, HU Yang-guang, MA Hong-lei, WANG Fu-chi, CAI Hong-nian. Influence of microstructure and strain rate on adiabatic shearing behavior in Ti-6Al-4V alloys [J]. Materials Science and Engineering A, 2009, 501: 30-36.

[4] 关玉璞, 陈 伟, 高德平. 航空发动机叶片外物损伤研究现状[J]. 航空学报, 2007, 28(4): 851-857.

GUAN Yu-pu, CHEN Wei, GAO De-ping. Present status of investigation of foreign object damage to blade in aeroengine [J]. Acta Aeronautica ET Astronautica Sinica, 2007, 28(4): 851-857.

[5] 黄志勇, 陈 伟, 赵海鸥, 阎成鸿. 评定叶片鸟撞击损伤的参数与方法[J]. 航空发动机, 2005, 31(1): 28-30.

HUANG Zhi-yong, CHEN Wei, ZHAO Hai-ou, YAN Cheng-hong. Parameters and methods for evaluating bird impact damage of fan/compressor blade [J]. Aeroengine, 2005, 31(1): 28-30.

[6] MEUNIER Y, BEATTY J H. Shock-waves and high strain rate phenomena in metas [M]. New York: Marce Dekker Inc, 1992: 637.

[7] HU Shi-sheng, DENG De-tao, REN Xiao-bin. A study on impact tensile test of materials [J]. Journal of Experimental Mechanics, 1998, 3: 9.

[8] 李 强, 徐永波. 钛合金(Ti-17)的动态力学性能和损伤特性[J]. 金属学报, 1999, 35(5): 491-494.

LI Qiang, XU Yong-bo. Dynamic mechanical properties and damage characteristics of titanium alloy(Ti-17) [J]. Acta Metallurgica Sinica, 1999, 35(5): 491-494.

[9] NEMAT S, GUO W G, CHENG J Y. Mechanical properties and deformation mechanisms of a commercially pure titanium [J]. Acta Materialia, 1999, 47(13): 3705-3720

[10] 刘新芹, 谭成文, 才鸿年, 张 静, 胡阳光, 陈志永, 王富耻. 应力状态对Ti-6Al-4V绝热剪切敏感性的影响[J]. 稀有金属材料与工程, 2008, 37(10): 1522-1525.

LIU Xin-qing, TAN Cheng-wen, CAI Hong-nian, ZHANG Jing, HU Yang-guang, CHEN Zhi-yong, WANG Fu-chi. Influence of stress-state on adiabatic shear sensitivity of Ti-6Al-4V [J]. Rare Metal Materials and Engineering, 2008, 37(9): 1522-1525.

[11] 孙 坤, 程兴旺, 王富耻, 苗 普, 赵双赞. TC6钛合金不同组织绝热剪切带的形成机理[J]. 稀有金属材料与工程, 2009, 38(1): 34-37.

SUN Kun, CHENG Xing-wang, WANG Fu-chi, MIAO Pu, ZHAO Shuang-zan. Formation mechanics of adiabatic shear band for the different microstructures of TC6 alloy [J]. Rare Metal Materials and Engineering, 2009, 38(1): 34-37.

[12] 孙 坤, 程兴旺, 王富耻, 苗 普, 赵双赞. 组织及应变率对TC6钛合金绝热剪切敏感性的影响[J]. 稀有金属材料与工程, 2008, 37(9): 1856-1860.

SUN Kun, CHENG Xing-wang, WANG Fu-chi, MIAO Pu, ZHAO Shuang-zan. Study on sensitivity of adiabatic shear of TC6 alloy under different strain rate and morphology [J]. Rare Metal Materials and Engineering, 2008, 37(9): 1856-1860.

[13] RANC N, TARAVELLA L, PINA V, HERVE P. Temperature field measurement in titanium alloy during high strain rate loading-Adiabatic shear bands phenomenon [J]. Mechanics of Materials, 2008, 40(4/5): 255-270.

[14] TENG X, WIERZBICKI T, COUQUE H. On the transition from adiabatic shear banding to fracture [J]. Mechanics of Materials, 2007, 39(2): 107-125.

[15] MAZEAU C, BEYLAT L, LONGERE P, LOUVIGNE P F. On the quantitative evaluation of adiabatic shear banding sensitivity of various titanium alloys [J]. Journal De Physique IV, France, 1997, 7(3): 429-434.

[16] 李建崇, 范群波, 裴传虎, 李树奎. 锻造工艺对Ti6Al4V4ZrMo合金绝热剪切敏感性的影响[J]. 稀有金属材料与工程, 2010, 39(1): 60-63.

LI Jian-chong, FAN Qun-bo, PEI Chuan-hu, LI Shu-kui. Effects of forging processing on adiabatic shearing sensitivity of Ti6Al4V4ZrMo alloy [J]. Rare Metal Materials and Engineering, 2010, 39(1): 60-63.

[17] LEE D G, LEE H L, LEE S H, LEE C S, HUR S M. Dynamic deformation behavior and ballistic impact properties of Ti-6Al-4V alloy having equiaxed and bimodal microstructures [J]. Metallurgical and Materials Transactions A, 2004, 35(10): 3103-3112.

(编辑 方京华)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:裴传虎,工程师;电话:13520946579;传真:010-62496640;E-mail:chuanhupei@163.com