TC8钛合金等温压缩变形过程中的不连续屈服特征

来源期刊:中国有色金属学报(英文版)2016年第6期

论文作者:王柯 李淼泉

文章页码:1583 - 1588

关键词:钛合金;流动应力;不连续屈服;动态理论

Key words:titanium alloy; flow stress; discontinuous yielding; dynamic theory

摘 要:基于TC8钛合金的等温压缩实验,对其高温变形过程中的不连续屈服现象(DYP)进行研究。首先引入上、下屈服点差值(△σUL)和应力振荡结束时的应变(εOSC)两个参数,根据应力-应变曲线,对TC8钛合金的不连续行为进行数值表征;然后,分析变形工艺参数对△σUL值和εOSC值的影响。结果表明:△σUL值和εOSC 值随着应变速率的增大而增大;在不同的应变速率下,变形温度对△σUL值的影响不同。最后,透射电子显微镜(TEM)观察结果为不连续屈服行为的动态理论提供了证据,不连续屈服行为归因于晶界产生的移动位错。同时,光学显微镜(OM)观察结果表明,初生α相和β相的晶粒尺寸随应变速率的增大而减小,从而揭示了变形工艺参数对△σUL和εOSC值的影响机制。

Abstract: The discontinuous yielding phenomenon (DYP) during high temperature deformation was investigated based on the isothermal compression of TC8 titanium alloy. The DYP of TC8 titanium alloy was characterized by quantifying the yield drop of the DYP (△σUL) and ending strain of flow oscillation (εOSC) based on the flow stress-strain curves, and then the effect of deformation parameters on the △σUL and εOSC values was analyzed. The results show that the △σUL and εOSC values increase with the increase of strain rate. The effect of deformation temperature on the △σUL value depends on the strain rate. Finally, the transmission electron microscope (TEM) observation shows the evidence for the dynamic theory, which ascribes the DYP to the generation of mobile dislocation at the grain boundary. Meanwhile, the optical microscope (OM) observation shows that both the primary α grain and β grain become smaller with the increase of strain, which well interprets the effect of deformation parameters on the △σUL and εOSC values.

Trans. Nonferrous Met. Soc. China 26(2016) 1583-1588

Ke WANG, Miao-quan LI

School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China

Received 7 June 2015; accepted 11 September 2015

Abstract: The discontinuous yielding phenomenon (DYP) during high temperature deformation was investigated based on the isothermal compression of TC8 titanium alloy. The DYP of TC8 titanium alloy was characterized by quantifying the yield drop of the DYP (△σUL) and ending strain of flow oscillation (εOSC) based on the flow stress-strain curves, and then the effect of deformation parameters on the △σUL and εOSC values was analyzed. The results show that the △σUL and εOSC values increase with the increase of strain rate. The effect of deformation temperature on the △σUL value depends on the strain rate. Finally, the transmission electron microscope (TEM) observation shows the evidence for the dynamic theory, which ascribes the DYP to the generation of mobile dislocation at the grain boundary. Meanwhile, the optical microscope (OM) observation shows that both the primary α grain and β grain become smaller with the increase of strain, which well interprets the effect of deformation parameters on the △σUL and εOSC values.

Key words: titanium alloy; flow stress; discontinuous yielding; dynamic theory

1 Introduction

Titanium alloys have been widely used in the aeronautical industries due to their low density, high strength, high toughness and good high-temperature properties [1-3]. However, titanium alloys are not easy to be deformed at high temperatures because the resistance of deformation is sensitive to temperature, which results in the narrow temperature range of hot deformation. Flow stress represents the deformation resistance and reflects the microstructure evolution in the deformation process. Many investigators [4-8] studied the flow stress behavior to optimize the deformation parameters and control the microstructure of titanium alloys.

It is worth noting that the flow stress had a dramatic drop after the peak value under some deformation conditions, which is named as discontinuous yielding phenomenon (DYP) [9-12]. Generally, the DYP reflects the characterization of flow behavior and microstructure evolution in the initial deformation period, and arouses many investigations which focus on the understanding of the deformation mechanism and processing of titanium alloys. LI et al [9] studied the flow stress behavior in the isothermal compression of Ti-3Al-5V-5Mo alloy, and found that the DYP occurred at the deformation temperatures above 700 °C and strain rates above 15 s-1. BALASUBRAHMANYAM and PRASAD [10] studied the deformation behavior of beta titanium alloy Ti-10V- 4.5Fe-1.5Al in hot upset forging, and found that the DYP occurred at the deformation temperatures above 850 °C and strain rates above 10 s-1. ZHU et al [11] studied the hot deformation behavior during hot compression of Ti40 titanium alloy and pointed out that the magnitude of DYP increased with the increase of deformation temperature and strain rate. JIA et al [12] studied the high-temperature deformation behavior of Ti60 titanium alloy and pointed out that the DYP was observed for all deformation tests performed at temperatures above 990 °C and strain rates of 0.01- 10 s-1. It can be seen from these investigations [9-12] that the DYP occurred at the high strain rate and high deformation temperature. Based on the microstructure observation, PHILIPPART and RACK [13] found that the new mobile dislocation was generated at the grain boundary, providing clear support for the dynamic theory. The dynamic theory ascribes the DYP to the generation of new mobile dislocation which arouses a dramatic yield drop [14,15]. The dynamic theory is accepted widely for the DYP in the titanium alloy [11,12]. However, the DYP is not characterized well, and the effect of strain rate and temperature on the DYP is not interpreted well.

In the recent research works, WANG and LI [16] studied the flow behavior in the isothermal compression of TC8 titanium alloy (corresponding to Russia titanium alloy BT8), and found the apparent DYP which was not discussed in Ref. [16]. Compared with Ref. [16], the deformation temperature range and height reduction range for the isothermal compression of TC8 titanium alloy were widened. After the isothermal compression, the DYP occurring in the isothermal compression of TC8 titanium alloy firstly was characterized, and then the effects of strain rate and temperature on the DYP were studied in detail. Finally, the evolution and generation mechanism of DYP were discussed with the help of the microstructure examination of TC8 titanium alloy.

2 Experimental

The TC8 titanium alloy used in this work was received in the form of a rod with a diameter of 25 mm and with the chemical composition (mass fraction) of 6.5% Al, 3.3% Mo, 0.3% Si, 0.06% Fe, 0.01% C, 0.002% H, 0.075% O, 0.005% N, and a balance of Ti [16,17]. Cylindrical specimens with 8.0 mm in diameter and 12.0 mm in height were machined from the TC8 titanium alloy rod, and the axial direction of specimen was parallel to that of as-received rod. The cylindrical specimens were isothermally compressed on a Gleeble 3500 thermal simulator. The compressed parameters are listed in Table 1. Before isothermal compression, the specimens were heated to the compressed temperature and held for 3 min to ensure a uniform temperature in the specimens. After compression, the specimens were cooled in wind to room temperature. Meanwhile, a specimen was only heated to 940 °C and held for 3 min followed by cooling in wind to compare the difference in the microstructure between the compressed and uncompressed TC8 titanium alloys.

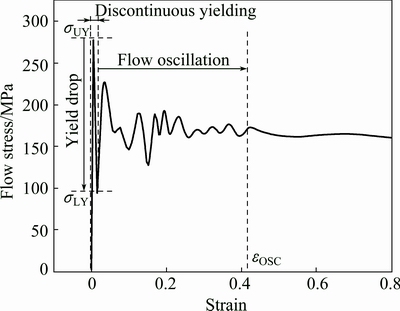

Table 1 Parameters of isothermal compression for TC8 titanium alloy

Following isothermal compression, the specimens were sectioned along the compression axis and prepared for microstructure examination using standard techniques. For the optical microscope (OM) examination, the sectioned specimen was prepared following standard grinding/polishing procedures and etched in a solution of 5% HF, 15% HNO3 and 80% H2O (volume fraction). For the transmission electron microscopy (TEM) examination, the sectioned specimen was ground to 60-80 μm in thickness followed by twin-jet electropolishing. An OLYMPUS GX71 OM and a Tecnai F30 G2 TEM were used to examine the microstructure.

3 Results

3.1 Characterization of DYP

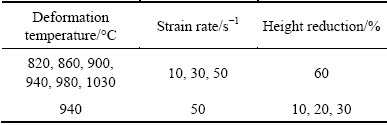

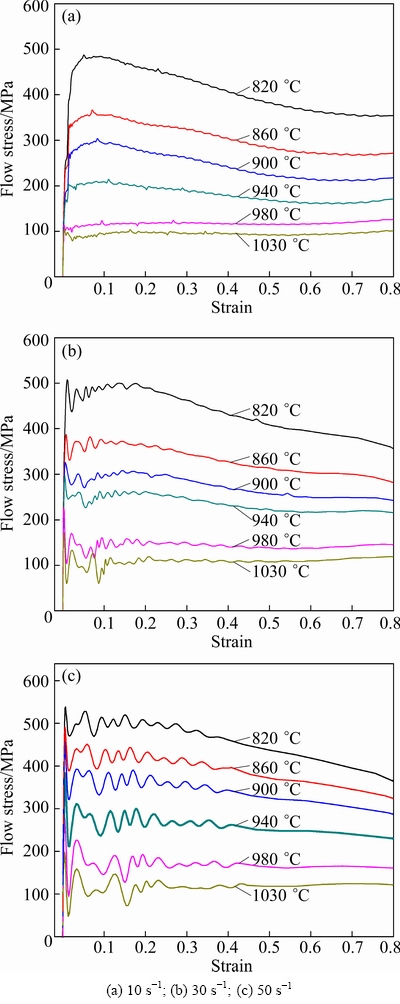

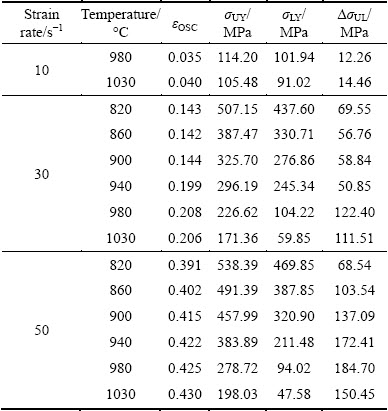

The typical flow stress-strain curves in the isothermal compression of TC8 titanium alloy are shown in Fig. 1, which shows that the DYP occurs under some deformation conditions, as listed in Table 2. Figure 2 shows the schematic diagram of DYP in the isothermal compression of TC8 titanium alloy. As shown in Fig. 2, at the initial strain, the flow stress increases rapidly to the upper yield stress point (σUY), and then the flow stress drops rapidly to the lower yield stress point (σLY) with the increase of strain. Meanwhile, a flow oscillation follows the DYP. The yield drop is defined as △σUY=σUY-σLY, and the ending strain of the flow oscillation is defined as εOSC. The values of εOSC, σUY, σLY and △σUY in the isothermal compression of TC8 titanium alloy are listed in Table 2.

Fig. 1 Flow stress-strain curves in isothermal compression of TC8 titanium alloy at different strain rates

3.2 Evolution of DYP

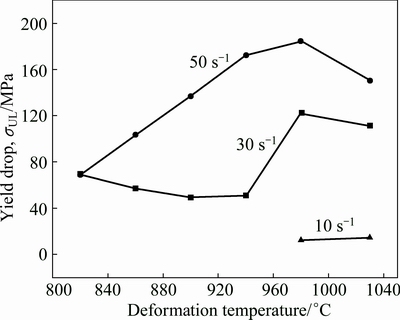

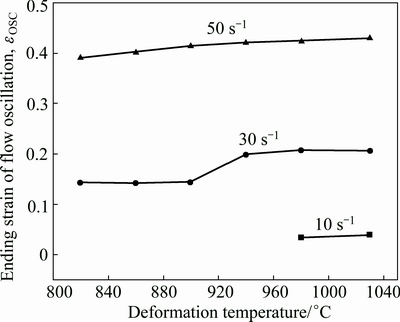

Figures 3 and 4 show the evolution of △σUL and εOSC values with the variation of deformation temperature and strain rate in the isothermal compression of TC8 titanium alloy. The effects of deformation temperature and strain rate on the △σUL and εOSC values can be drawn as follows.

1) The DYP occurs only at high deformation temperatures or high strain rates. It can be seen from Table 2 and Fig. 3 that, the DYP exhibits remarkably as the strain rate increases to 30 s-1, while it occurs only as the deformation temperature increases to 980 °C at a strain rate of 10 s-1.

2) The △σUL value increases remarkably with the increase of strain rate at deformation temperatures above 820 °C. As shown in Table 2 and Fig. 3, when the strain rate increases from 10 to 30 and 50 s-1, the △σUL values increase from 14.46 MPa to 122.40 MPa and 184.70 MPa respectively at the deformation temperature of 980 °C.

3) The deformation temperature significantly affects the △σUL value, and the effect of deformation temperature on the △σUL value depends on the strain rate. It can be seen from Table 2 and Fig. 3 that the △σUL value increases slightly with the increase of deformation temperature at a strain rate of 10 s-1. At a strain rate of 30 s-1, the △σUL value decreases slightly as the deformation temperature increases from 820 to 940 °C, and then increases remarkably as the deformation temperature increases from 940 to 980 °C, and finally decreases slightly as the deformation temperature increases from 980 to 1030 °C. At a strain rate of 50 s-1, the △σUL value increases remarkably as the deformation temperature increases from 820 to 980 °C, and then decreases remarkably as the deformation temperature increases from 980 to 1030 °C. It can be seen from the above analysis that the effect of deformation temperature on the △σUL value at a strain rate of 30 s-1 is different with that at 50 s-1, but the △σUL values for the two strain rates attain the maximum at the same deformation temperature of 980 °C.

Fig. 2 Schematic diagram of DYP in isothermal compression of TC8 titanium alloy at deformation temperature of 980 °C and strain rate of 50 s-1

Table 2 Values of εOSC, σUY, σLY and △σUL in isothermal compression of TC8 titanium alloy

Fig. 3 Illustration of △σUL values of DYP in isothermal compression of TC8 titanium alloy

4) The εOSC value increases remarkably with the increase of strain rate. It can be seen from Table 2 and Fig. 4 that, as the strain rate increases from 10 to 30 and 50 s-1, the εOSC value increases from 0.035 to 0.208 and 0.425 respectively at the deformation temperature of 980 °C. However, the εOSC value varies slightly with the variation of deformation temperature.

Fig. 4 εOSC values of DYP in isothermal compression of TC8 titanium alloy

4 Discussion

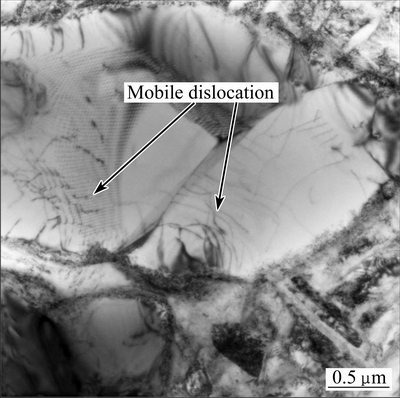

At the initial strain in the isothermal compression of TC8 titanium alloy, the rapid generation and tangling of dislocation make the flow stress increase rapidly to the σUY value. The dynamic theory suggests that the flow stress decreases rapidly to the σLY value due to the generation of new mobile dislocation at the grain boundaries. The TEM observation, as shown in Fig. 5, shows that a lot of new mobile dislocations are generated at the grain boundaries at a height reduction of 20%. This phenomenon indicates the possibility of the generation of mobile dislocation at the grain boundaries as the σUY value is attained, so it provides the indirect evidence for the dynamic theory, which agrees well with the previous investigation [13]. The generation of new mobile dislocation at the grain boundary requires the high stress concentration generated by the piling up of a large amount of dislocation at the grain boundary, and the high thermal activation generated by the high deformation temperature. This is the essential reason why the DYP occurs only at high deformation temperatures or high strain rates.

Fig. 5 TEM image showing generation of mobile dislocation at grain boundary in TC8 titanium alloy isothermally compressed at deformation temperature of 940 °C, strain rate of 30 s-1 and height reduction of 20%

As mentioned in Ref. [16], the increase of strain rate will induce the increase of dislocation density, which subsequently strengthens the stress concentration and promotes the generation of new mobile dislocations to make the stress decrease largely, i.e., make the △σUL value increase largely; whereas the increase of deformation temperature will induce the two results. Firstly, the increase of deformation temperature will provide the higher thermal activation to promote the generation of new mobile dislocations. Secondly, the increase of deformation temperature will make the dislocation decrease [16], and then weaken the stress concentration to restrain the generation of new mobile dislocations. Therefore, the effects of deformation temperature and strain rate on the △σUL values depend on each other.

At higher deformation temperatures of 860- 1030 °C, the increase of strain rate from 30 to 50 s-1 makes the increase of dislocation density and stress concentration, and then promotes the generation of new mobile dislocations and makes △σUL value increase. While the increase of dislocation density and stress concentration cannot promote the generation of new mobile dislocations due to the low thermal activation at lower deformation temperature (820 °C), so, the △σUL value varies slightly with the increase of strain rate at 820 °C.

At a higher strain rate of 50 s-1, the high dislocation density induces the high stress concentration, so, the increase of deformation temperature plays a main role in enhancing the thermal activation to promote the generation of new mobile dislocation. Therefore, the △σUL value increases gradually as the deformation temperature increases from 820 to 980 °C at a strain rate of 50 s-1; whereas the dislocation density will decrease as the strain rate decreases from 50 to 30 s-1, making the increase of deformation temperature which plays a main role in weakening the stress concentration to restrain the generation of new mobile dislocations. So, the △σUL value decreases gradually as the deformation temperature increases from 820 to 940 °C at 30 s-1. However, the β phase content increases sharply as the deformation temperature increases from 940 to 980 °C [16]. The body-centered cubic (BCC) β phase has more operative slip systems than hexagonal close-packed (HCP) α phase, so, more dislocations are generated to enhance the stress concentration, inducing the increase of △σUL value as the deformation temperature increases from 820 to 940 °C at a strain rate of 30 s-1. As the deformation temperature increases from 980 to 1030 °C, the primary α phase totally transforms to β phase, so, the vanishing of the stress concentration on the α-β interphase boundary will make the △σUL value decrease at the strain rates of 30 and 50 s-1.

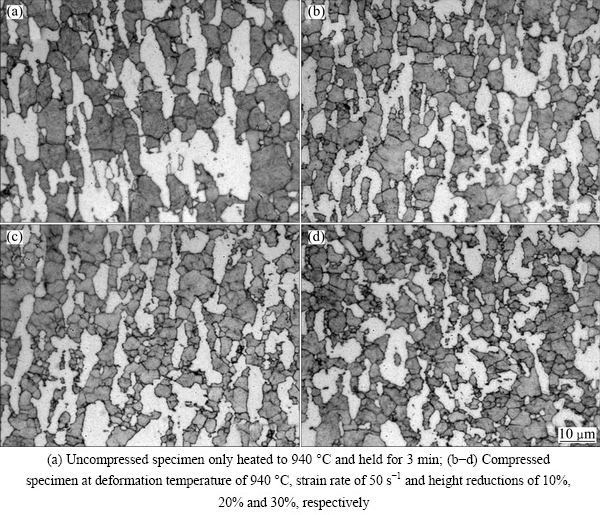

After the period of DYP, the new mobile dislocation will multiply and accumulate to induce the increase of stress, and then new mobile dislocations are generated again, making a flow oscillation. As seen from Fig. 6, due to the dynamic recrystallization of primary α phase and β phase, both the primary α grain and β grain become smaller with the increase of strain in the isothermal compression of TC8 titanium alloy. The decrease of grain size will weaken the stress concentration at the grain boundary, resulting in that the stress concentration is not high enough to generate the new mobile dislocations, so, the increase of strain leads to the disappearance of flow oscillation. The increase of strain rate will enhance the stress concentration and promote the generation of new mobile dislocations in the flow oscillation period, and then prolong the flow oscillation period, i.e., make the εOSC value increase. As the stress concentration decreases to a critical magnitude, the increase of deformation temperature cannot promote the generation of mobile dislocations, so, the εOSC value varies slightly with the increase of deformation temperature.

Fig. 6 OM images of TC8 titanium alloy

5 Conclusion

1) The DYP is characterized by the values of εOSC, σUY, σLY and △σUL in the isothermal compression of TC8 titanium alloy. The effects of deformation temperature and strain rate on the DYP were studied. Based on the dynamic theory and microstructure examination, the generation mechanism of DYP was interpreted well.

2) Due to the generation of new mobile dislocations at the grain boundary, the DYP occurs at the strain rates above 10 s-1 or the deformation temperatures above 940 °C in the isothermal compression of TC8 titanium alloy.

3) The △σUL value increases with the increase of strain rate because the increase of strain rate promotes the generation of new mobile dislocations.

4) The △σUL value varies at different strain rates with the increase of deformation temperature. The effect of deformation temperature and strain rate on the △σUL value depends on each other.

5) The increase of strain leads to the disappearance of flow oscillation. The εOSC value increases with the increase of strain rate, and varies slightly with the increase of deformation temperature.

References

[1] HUANG Liang, ZENG Rong, ZHANG Xiao-ting, LI Jian-jun. Study on plastic deformation behavior of hot splitting spinning of TA15 titanium alloy [J]. Materials & Design, 2014, 58: 465-474.

[2] FAN J K, KOU H C, LAI M J, TANG B, CHANG H, LI J S. Characterization of hot deformation behavior of a new near beta titanium alloy: Ti-7333 [J]. Materials & Design, 2013, 49: 945-952.

[3] SHI Zi-feng, GUO Hong-zhen, HAN Jin-yang, YAO Ze-kun. Microstructure and mechanical properties of TC21 titanium alloy after heat treatment [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(10): 2882-2889.

[4] QIN Chun, YAO Ze-kun, NING Yong-quan, SHI Zhi-feng, GUO Hong-zhen. Hot deformation behavior of TC11/Ti-22Al-25Nb dual-alloy in isothermal compression [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(7): 2195-2205.

[5] LU Shi-qiang, LI Xin, WANG Ke-lu, DONG Xian-juan, FU Ming-wang. High temperature deformation behavior and optimization of hot compression process parameters in TC11 titanium alloy with coarse lamellar original microstructure [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(2): 353-360.

[6] SESHACHARYULU T, MEDEIROS S C, FRAZIER W G, PRASAD Y V R K. Unstable flow during supratransus working of Ti-6Al-4V [J]. Materials Letters, 2001, 47: 133-139.

[7] CHEN Hui-qin, CAO Chun-xiao. Characterization of hot deformation microstructures of alpha-beta titanium alloy with equiaxed structure [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(3): 503-509.

[8] LI Zhi-ming, FU Li-ming, FU Bin, SHAN Ai-dang. Yield point elongation in fine-grained titanium [J]. Materials Letters, 2013, 96: 1-4.

[9] LI L X, LOU Y, YANG L B, PENG D S, RAO K P. Flow stress behavior and deformation characteristics of Ti-3Al-5V-5Mo compressed at elevated temperatures [J]. Materials & Design, 2002, 23: 451-457.

[10] BALASUBRAHMANYAM V V, PRASAD Y V R K. Deformation behaviour of beta titanium alloy Ti-10V-4.5Fe-1.5Al in hot upset forging [J]. Materials Science and Engineering A, 2002, 336: 150-158.

[11] ZHU Yan-chun, ZENG Wei-dong, ZHAO Yong-qing, SHU Ying, ZHANG Xue-min. Effect of processing parameters on hot deformation behavior and microstructural evolution during hot compression of Ti40 titanium alloy [J]. Materials Science and Engineering A, 2012, 552: 384-391.

[12] JIA Wei-ju, ZENG Wei-dong, ZHOU Yi-gang, LIU Jian-rong, WANG Qing-jiang. High-temperature deformation behavior of Ti60 titanium alloy [J]. Materials Science and Engineering A, 2011, 528: 4068-4074.

[13] PHILIPPART I, RACK H J. High temperature dynamic yielding in metastable Ti-6.8Mo-4.5F-1.5Al [J]. Materials Science and Engineering A, 1998, 243: 196-200.

[14] JOHNSTON W G, GILMAN J J. Dislocation velocities, dislocation densities, and plastic flow in lithium fluoride crystals [J]. Journal of Applied Physics, 1959, 30: 129-144.

[15] LONG M, RACK H J. High temperature discontinuous yielding in β-phase Ti3Al (Nb, Mo) alloys [C]//Titanium 1995: Science and Technology. London: The Institute of Materials, 1996: 316-323.

[16] WANG Ke, LI Miao-quan. Flow behavior and deformation mechanism in the isothermal compression of the TC8 titanium alloy [J]. Materials Science and Engineering A, 2014, 600: 122-128.

[17] WANG Ke, LI Miao-quan. Morphology and crystallographic orientation of the secondary α phase in a compressed α/β titanium alloy [J]. Scripta Materialia, 2013, 68: 964-967.

王 柯,李淼泉

西北工业大学 材料学院,西安 710072

摘 要:基于TC8钛合金的等温压缩实验,对其高温变形过程中的不连续屈服现象(DYP)进行研究。首先引入上、下屈服点差值(△σUL)和应力振荡结束时的应变(εOSC)两个参数,根据应力-应变曲线,对TC8钛合金的不连续行为进行数值表征;然后,分析变形工艺参数对△σUL值和εOSC值的影响。结果表明:△σUL值和εOSC 值随着应变速率的增大而增大;在不同的应变速率下,变形温度对△σUL值的影响不同。最后,透射电子显微镜(TEM)观察结果为不连续屈服行为的动态理论提供了证据,不连续屈服行为归因于晶界产生的移动位错。同时,光学显微镜(OM)观察结果表明,初生α相和β相的晶粒尺寸随应变速率的增大而减小,从而揭示了变形工艺参数对△σUL和εOSC值的影响机制。

关键词:钛合金;流动应力;不连续屈服;动态理论

(Edited by Wei-ping CHEN)

Foundation item: Project (51275416) supported by the National Natural Science Foundation of China

Corresponding author: Ke WANG; Tel: +86-29-88460328; Fax: +86-29-88492642; E-mail: study_ke@163.com

DOI: 10.1016/S1003-6326(16)64234-6