DOI: 10.11817/j.ysxb.1004.0609.2021-37969

废旧合金刀头中有价组分高效湿法分离技术研究

李良玉,韩俊伟,焦 芬,刘 维,覃文庆

(中南大学 资源加工与生物工程学院,长沙 410083)

摘 要:针对废旧金刚石刀头有价组分高效分离难的问题,提出“两段浸出-分步结晶-物理分选”的选冶联合清洁处理技术,即先通过低浓度硫酸溶液选择性浸铁,富铁液降温结晶获得七水合硫酸亚铁产品,铁浸渣通过酸性氧化浸出工艺提取铜,富铜液经净化后结晶可获得96%以上的五水硫酸铜产品,同时实现了浸铜尾渣中金刚砂和碳化钨的单体解离,再通过重选工艺可实现金刚砂和碳化钨的高效分离,最终实现废旧金刚石刀头的全量化利用。本文主要研究了浸铁过程和浸铜过程各工艺参数对有价金属浸出行为的影响,同时进行了金刚砂的物理分选试验研究。结果表明:在硫酸浓度130 g/L、液固比12:1、搅拌速度300 r/min、浸出温度60 ℃和时间36 h的条件下,废旧金刚石刀头中铁的浸出率为97.6%,且99%以上的铜和100%的金刚砂进入渣中,实现了铁的选择性分离。在硫酸浓度250 g/L、硝酸浓度23 g/L、液固比10:1、搅拌速度300 r/min、浸出温度80 ℃和时间26 h的条件下,铁浸渣中铜的浸出率达到99.9%以上,同时94%以上的锡和所有的金刚石进入尾渣中,实现了铜的高效浸出。浸铜尾渣经摇床分选可以实现金刚砂的高效回收。工业化试验不仅验证了实验室研究结果的正确性,还表明湿法过程中产生的废水可以循环利用,整个工艺过程无废水排除。

关键词:废旧合金;湿法浸出;资源回收;铜回收;金刚石

文章编号:1004-0609(2021)-xx-- 中图分类号:TD952 文献标志码:A

引文格式:李良玉, 韩俊伟, 焦 芬, 等. 废旧合金刀头中有价组分高效湿法分离技术研究[J]. 中国有色金属学报, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37969

LI Liang-yu, HAN Jun-wei, JIAO Fen, et al. High-efficiency hydrometallurgical separation of valuable components from waste alloy cutters[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37969

金刚石刀具有极高的耐磨性和硬度,较高的弹性模量、热导,较低的热膨胀系数和摩擦系数,以及与非铁金属亲和力小等优点[1],广泛用于石材和建筑行业、金属磨削、陶瓷和玻璃制造等行业[2-4]。我国天然金刚石资源比较贫乏,仅为世界产量的0.1%,工业用金刚石99%以上为国产人造金刚石[5]。金刚石刀具的切割材料为人造金刚石,胎体材料为碳化钨,粘结剂为金属粉,将这些组分混合均匀后,用热压成型加工工艺生产[6]。

全球工业金刚石有70%左右用于制造石材加工工具,其中绝大部分是金刚石圆锯片[7],我国金刚石总量的76%用于制造金刚石锯片[8]。金刚石锯片是石材加工行业的消耗品,在使用过程中,会产生一定量的刀头废料[9]。然而,在使用金刚石锯片过程中,为了保护基体,锯片中有10%左右的刀头和10%的金刚石颗粒不能用完[10-11]。一般在剩下1~2 mm的金刚石工作层和 1.5~2 mm的过渡层时就弃用[8]。仅四川雅安地区每年就有数十吨的废弃金刚石刀具需要回收[6]。废旧刀头中约10%的金刚石未得到利用而留在刀头中,此外,在金刚石刀头的生产过程中也有2%的残次品需要回收处理[11-13]。与此同时,金刚石刀头的应用趋势持续上升发展,相应的废旧金刚石刀头也逐渐增多,废旧合金刀头中的金刚石和铜、锌、锡等有色金属是日常生活的基础性材料,是新科技发展、国防军工必须的战略性物资,而我国有色金属生产原料对外依存度较高,有色金属生产产能与自给资源供应的矛盾非常突出[14],综合利用有色金属二次资源[15-18],高效清洁的回收废旧合金刀头中的有价组分具有重要意义[19]。

一般采用酸溶的工艺回收废旧合金刀头中的有价成分,利用刀头中Fe、Cu、Zn等有价金属溶于酸,金刚石、碳化钨不溶于酸而达到分离[20]。这些有价金属转化为可溶性的盐,进入溶液然后进行后续的处理[6, 10, 20-25]。已有学者通过热力学分析,证明了在酸性条件、有氧化剂存在下可分解废旧合金刀头[13]。针对废旧合金刀头有价组分高效分离难的问题,本文作者以废旧合金刀头为研究对象,提出“两段浸出-分步结晶-物理分选”的选冶联合清洁处理技术,即先用低浓度硫酸溶液选择性浸出废旧合金刀头中的铁,废旧合金刀头中的铁易转化为硫酸亚铁而溶解于溶液中,而铜在不加氧化剂的低浓度硫酸溶液中几乎不反应,富铁液经过滤、降温结晶获得七水合硫酸亚铁产品;然后铁浸渣通过酸性氧化浸出工艺提取铜,富铜液经净化后结晶可获得96%以上的五水硫酸铜产品;同时实现了浸铜尾渣中金刚砂和碳化钨的单体解离,再通过摇床分选可实现金刚砂和碳化钨的高效分离,最终实现废旧金刚石刀头的全量化利用。

1 实验

1.1 试验原料

本研究的废旧合金刀头取自江西一元再生资源有限公司。废旧合金刀头主要化学成分组成和XRD谱分别如表1和图1所示。表1原料化学成分通过化学分析进行测定,该废旧合金刀头主要含有Fe(73.58%)、Cu(16.42%)、Zn(1.59%)、Sn(0.28%)等成分,铁元素含量高至73.58%,属于铁基金刚石刀头,同时铜、锌、锡等有价金属元素含量较高,属于一种高价值的二次资源,应将有价成分进行综合回收利用。

表1 废旧合金刀头的主要化学成分

Table 1 Main chemical composition of waste alloy cutters (mass fraction, %)

图1 废旧合金刀头的XRD谱

Fig. 1 XRD pattern of waste alloy cutters

1.2 试验方法与工艺流程

综合考虑废旧合金刀头的组分特点,设计废旧合金刀头的工艺流程如图2所示。用低浓度硫酸为浸出剂浸出处理废旧合金刀头,原料中铁易转化为硫酸亚铁而溶解于溶液中,而铜在低浓度硫酸浸出体系中不加氧化剂几乎不反应,锌元素少量溶解于浸出液中,富铁液经过过滤结晶得到七水合硫酸亚铁产品,结晶后的浸出液返回浸铁过程,实现循环利用,减少浸出剂的消耗,降低生产成本。经过滤后铁浸渣进入浸铜工艺,铁浸渣含少量铁,而铜、锌和锡等得到富集且铜含量较高,考虑使用较高浓度硫酸作浸出剂并加入氧化剂来处理该铁浸渣,铜在该条件下转化为硫酸铜溶解于溶液中,锌和锡等溶解于浸出液中,随着反应进行,溶液的酸度降低,锡离子发生水解生成锡泥(氧化锡),富铜液经过一次过滤结晶,得到粗硫酸铜结晶,锡泥和浸出渣,结晶后的浸出液返回浸铜的过程,减少浸出剂的消耗;将粗硫酸铜结晶进一步纯化结晶得到精制五水硫酸铜产品,纯化过程可以通过萃取的方式回收锌和镍等,锡泥经处理可回收其中的锡;浸铜尾渣通过摇床分选,得到金刚石和碳化钨。

图2 试验工艺流程图

Fig. 2 Experimental flow chart of proposed process

废旧合金刀头为块状长方体,其切割面平整,基体面呈锯齿状,基体中掺有金刚石颗粒,质地坚硬,不易破碎,因其粉碎条件困难,不作粉碎,直接以块状废旧合金刀头进行浸出[22, 26]。浸出试验装置主要包括数显型顶置式电子搅拌器,电热恒温水浴锅,铁架台和烧杯等。在进行铁选择性浸出试验时,称取一定质量的废旧合金刀头,倒入盛有浸出液的烧杯中开始铁选择性浸出试验。当铁选择性浸出试验结束后,用真空泵将浆液过滤,用量筒测量滤液的体积,最后采用ICP-AES 方法分析浸出液中铁、锌和铜元素的含量,并计算铁、锌和铜的浸出率。铁浸渣烘干后称取质量,用于分析和铜高效浸出试验。铜高效浸出试验的操作过程与铁选择性浸出试验基本相似。

2 试验结果与讨论

2.1 铁选择性浸出试验研究

2.1.1 主要工艺参数对铁的影响

在浸出温度60 ℃、浸出时间48 h、液固比12:1、搅拌速度300 r/min(充分搅拌),改变H2SO4浓度以考察其对废旧合金刀头中铁浸出率的影响,结果如图3(a)所示。由图3(a)可知,在同一浸出时间内,随着H2SO4浓度的升高,废旧合金刀头中铁的浸出率增大。当浸出时间超过36 h时,铁的浸出率增加速度变缓,延长浸出时间有利于铁的浸出,但是浸出时间过长会导致浸出效率降低,综合考虑,浸出时间确定为36 h。当浸出时间为36 h,当H2SO4浓度从90 g/L增加到130 g/L,铁的浸出率从82.15%逐渐增至96.54%,继续提高H2SO4浓度,铁的浸出率增长缓慢,并且反应后的浸出液中剩余酸量较多,不利于后续浸出液的结晶过程,为了满足工业生产要求,综合考虑,选择H2SO4浓度为130 g/L,浸出时间为36 h较合适。在H2SO4浓度130 g/L、浸出时间36 h、液固比12:1、搅拌速度300 r/min(充分搅拌)条件下,考察浸出温度对浸出率的影响,结果如图3(b)所示。由图3(b)可知,在80 ℃和90 ℃下,浸出12 h,铁的浸出率增加速度极快,铁的浸出率均达90%以上,当浸出时间超过12 h后,铁的浸出率增长缓慢,表明浸铁过程在80 ℃和90 ℃下12 h基本反应完成,但在80 ℃和90 ℃下浸出液蒸发量较大,并且在36 h时,90 ℃下铁的浸出率比80 ℃略低,这可能是生成了Fe2SO4·H2O沉淀,导致浸出液中Fe2+浓度降低。在60 ℃和70 ℃下,铁浸出率增加速度较快,且两者的浸出率接近;在50 ℃下,铁的浸出速率增加速度较慢;20 ℃和40 ℃下,浸出36 h,铁的浸出率达不到要求。综合考虑反应速率以及能耗,参考工业硫酸法制备Fe2SO4·7H2O,选择浸出温度为60 ℃较宜。在浸出温度60 ℃,浸出时间36 h,H2SO4浓度130 g/L,搅拌速度300 r/min(充分搅拌)条件下,考察液固比对铁浸出率的影响,结果如图3(c)所示。由图3(c)可知,随着液固比的增加铁浸出率逐渐增加。当浸出36 h,当液固比为10:1时,铁的浸出率较低,这可能是因为液固比较小,溶液中H2SO4量不足导致。液固比12:1和14:1时Fe的浸出率接近,而液固比16:1时浸出速率较大,但浸出液中剩余酸量较大,不利于后期的结晶,综合考虑,选择液固比为12:1较合适。

图3 浸出过程的主要工艺条件参数对铁浸出率的影响

Fig. 3 Main technological parameters in leaching process on Fe leaching efficiency

2.1.2 主要工艺参数对铁、锌、铜浸出率的影响

在浸出温度60 ℃、浸出时间36 h、液固比12:1、搅拌速度300 r/min(充分搅拌)条件下,考察硫酸浓度对铁、铜、锌浸出率的影响,结果如图4(a)所示。由图4(a)可知,硫酸浓度对铜浸出率的影响较小,铜的浸出率较低,维持在1%以下;铁、锌的浸出率随着硫酸浓度的升高逐渐增大,通过控制硫酸浓度可以使铁的浸出率保持在较高水平而锌的浸出率较小。 在H2SO4浓度130 g/L、浸出时间36 h、液固比12:1、搅拌速度300 r/min(充分搅拌)条件下,考察浸出温度对铁、铜、锌浸出率的影响,结果如图4(b)所示。由图4(b)可知,浸出温度对铜浸出率的影响较小,铜的基本保持在1%以下;铁和锌浸出率随浸出温度的提高而增大,通过控制浸出温度可以使锌的浸出率较小而铁的浸出率保持较高水平。在H2SO4浓度130 g/L,浸出时间36 h,浸出温度60 ℃,搅拌速度300 r/min(充分搅拌)条件下,考察液固比对铁、铜、锌浸出率的影响,结果如图4(c)所示。由图4(c)可知,液固比对铜、锌浸出率影响较小,铜的浸出率较低,维持在1%以内,锌的浸出率基本在20%以下;当液固比从10:1增加到12:1时,铁的浸出率从91.19%增加到97.63%,当液固比大于12:1时,铁的浸出率增加速度变缓,增大液固比对铁的浸出有利,但是液固比过大会导致浸出液中剩余酸量较大,不利于后期的结晶。

废旧合金刀头的主要金属成分为铁、铜、锌和锡,根据相关元素的电极反应及标准电位[13, 22],从表2可以可知,在酸性条件下用硝酸是很好的氧化剂,先用稀H2SO4为浸出剂浸出处理废旧合金刀头,原料中铁易转化为硫酸亚铁而溶解于溶液中,选择性的浸出废旧合金刀头中的铁组分,然后使用较高浓度H2SO4作浸出剂并加入氧化剂来处理铁浸渣,铁浸渣中的铜、锌和锡等快速溶解进入溶液中,在试验条件下,金刚石和碳化钨非常稳定,浸出后残渣经过滤、漂洗和筛分即可得金刚石颗粒(0.2~0.5mm)和碳化钨粉 (20~30 μm)[20]。

图4 浸出过程的主要工艺条件参数对铁、锌和铜浸出率的影响

Fig. 4 Main technological parameters in leaching process on leaching efficiency of Cu, Zn and Sn

2.2 铜高效浸出试验研究

2.2.1 硫酸浓度和浸出时间的影响

表2 相关元素的电极反应及标准电位

Table 2 Electrode reaction and standard electrode potential of related elements

在浸出温度80 ℃,浸出时间26 h,液固比10:1,搅拌速度300 r/min(充分搅拌),氧化剂硝酸浓度23 g/L的条件下,考察硫酸浓度对铜、锌、锡的浸出率的影响,结果分别如图5(a)、图5(b)以及图5(c)所示。由图5(a)可知,铁浸渣中铜的浸出率随硫酸浓度的增加而增加。当浸出时间在22 h 以内,铜的浸出率随着硫酸浓度的增加而迅速增加,且在硫酸浓度350 g/L条件下铜浸出率增加速度最快;但是当浸出时间超过22 h以后,硫酸浓度大于250 g/L条件下的铜浸出率的增加速度变缓,硫酸浓度150 g/L和200 g/L条件下的铜浸出率仍然在快速上升。这说明在硫酸浓度大于250 g/L条件下,当浸出时间达到22 h 时铁浸渣中的大部分铜已经被浸出,因此随着浸出时间的增加,铜的浸出速度将会变慢;硫酸浓度低于250 g/L时,由于硫酸用量不足,以致浸出渣中还有部分铜存在,所以继续增加硫酸浓度铜的浸出速度仍然较快。由于H2SO4浓度为300 g/L、350 g/L的浸出液中有CuSO4结晶析出,不利于后续浸出液的处理,CuSO4 结晶的XRD谱如图6(a)所示。综合考虑下,硫酸浓度为250 g/L,浸出时间为26 h较合适。由图5(b)可知,铁浸渣中锌的浸出率随着硫酸浓度的增加而增加,这可能是因为随着硫酸浓度的增加,在氧化性条件下,铁浸渣中的铜解体较快,裸露出的锌可以与硫酸溶液反应。当浸出26 h,硫酸浓度大于250 g/L条件下,锌的浸出率均可达到99%以上。由图5(c)可知,在浸出时间在4 h以内,锡的浸出率随着硫酸浓度的增加而增加,但随着浸出时间的增加,锡浸出率又迅速降低。浸出时间在4~22 h之间,锡的浸出率随时间的变化不明显,浸出时间超过22 h 时,锡的浸出率继续随时间的增加而降低。这可能是因为反应初期,溶液中的硫酸和硝酸浓度较高,对铁浸渣的氧化速度较快,因此溶液中锡离子的浓度在反应初始阶段在较高的浓度,并且在反应初始阶段,溶液中酸浓度较高,锡离子进入溶液后可以稳定存在,在反应中后期,当铁浸渣中的锡氧化为锡离子进入溶液后,随着反应进行,溶液中酸被消耗导致浓度降低,锡离子水解成锡泥(氧化锡),所以溶液中的锡离子浓度较低。锡泥的XRD谱如图6(b)所示。

图5 硫酸浓度和浸出时间对金属浸出率的影响

Fig. 5 Effect of sulfuric acid concentration and leaching time on metal leaching efficiency

图6 CuSO4结晶和锡泥的XRD谱

Fig. 6 XRD pattern of CuSO4 crystallization(a) and tin sludge(b)

2.2.2 浸出温度的影响

在硫酸浓度250 g/L,浸出时间26 h,液固比10:1,搅拌速度300 r/min(充分搅拌),氧化剂硝酸浓度23 g/L的条件下,考察浸出温度对铜、锌、锡的浸出率的影响,结果分别如图7(a)、图7(b)以及图7(c)所示。由图7(a)可知,铁浸渣中铜的浸出率随浸出温度的增加而增加,且浸出温度80 ℃条件下铜浸出率增加速度最快。在浸出温度80 ℃,浸出时间18 h条件下,铜的浸出率迅速达到97.60%,继续增加浸出时间至26 h,铜浸出率增长缓慢,最终可达到 99.54%;在浸出时间26 h,浸出温度分别为40 ℃和60 ℃下,铜的浸出率分别为68.06%和81.36%,综合考虑浸出效率和铜的浸出率,选择浸出温度为80 ℃较宜。由图7(b)可知,随着浸出温度的增加,锌的浸出率随之增加,且在浸出温度80 ℃条件下铜浸出率增加速度最快。在浸出时间26 h,浸出温度为80 ℃条件下,锌的浸出率可达到99.79%。这可能是因为当浸出温度增加时,增加了离子的扩散系数和反应所需的活化能[27],铁浸渣中的铜溶解后,合金中裸露出的锌可以与硫酸溶液反应。由图7(c)可知,在浸出时间为26 h条件下,浸出液中的锡离子浸出率均降低到6%以下,这可能是因为在浸出反应的初始阶段,浸出温度越高浸出反应速率越快,铁浸渣的氧化速度越快,当铁浸渣中的锡氧化为锡离子进入溶液后,在反应初始阶段,溶液中酸浓度较高,锡离子可以稳定存在,随着反应的进行,在反应中后期,由于溶液中酸浓度降低,锡离子水解成锡泥(氧化锡),所以溶液中的锡离子浓度较低。

图7 浸出温度对金属浸出率的影响

Fig. 7 Effect of leaching temperature on metal leaching efficiency

2.2.3 氧化剂浓度的影响

在浸出温度80 ℃,液固比10:1,搅拌速度300 r/min(充分搅拌),硫酸浓度250 g/L条件下,考察氧化剂硝酸浓度对铜、锌、锡的浸出率的影响,结果分别如图8(a)、图8(b)以及图8(c)所示。由图8(a)可知,随着硝酸浓度的增加铜浸出率逐渐增加,当硝酸浓度23 g/L,浸出时间为12 h时,铜的浸出率为88.40%,综合考虑反应速率和铜的浸出率,选择硝酸浓度为23 g/L较合适。由图8(b)可知:随着硝酸浓度的增加,锌的浸出率随之增加。这可能是因为氧化剂硝酸浓度的增加促进了铁浸渣中铜解体的速率,随之铁浸渣中的锌可以与溶液中的酸反应。由图8(c)可知,随着氧化剂硝酸浓度的增加,锡的浸出率呈现出先增加再下降的趋势。这可能是因为,当氧化剂硝酸浓度增加时,铁浸渣中的锡氧化速度加快,在反应初始阶段,溶液中酸浓度较高,锡离子可以稳定存在,随着反应的进行,在反应中后期,由于溶液中酸浓度降低,锡离子水解为锡泥(氧化锡),导致溶液中的锡离子浓度较低。

根据以上试验结果进行综合试验。在硫酸浓度250 g/L,氧化剂硝酸浓度23 g/L,浸出时间26 h,浸出温度80 ℃,液固比10:1,搅拌速度300 r/min(充分搅拌)的条件下,多次实验结果表明,铁浸渣中铜的浸出率达到99.9%以上,同时94%以上的锡和所有的金刚石进入尾渣中,实现了铜的高效浸出。

2.3 浸出渣及产品分析

2.3.1 浸铁过程浸出渣

浸铁过程的浸出渣,即铁浸渣,经过干燥、洗涤和混匀后送样分析,主要化学成分组成和 XRD谱分别如表3和图9所示。可以看出,铁浸渣中铁元素含量为5.31%,铜元素含量高至65.01%,说明废旧合金刀头中铁组分被选择性浸出,而铜组分得到了富集进入渣中,同时还含有锌、铁锡、镍等有价金属元素,富集的铜和剩余组分在浸铜工艺处理。

图8 氧化剂浓度对金属浸出率的影响

Fig. 8 Effect of oxidant concentration on metal leaching efficiency

表3 铁浸渣的化学成分组成

Table 3 Chemical of composition of leaching residue from leaching process of iron (mass fraction, %)

由图 9 铁浸渣的XRD谱可知,XRD谱中主要有Cu、WC、Zn、Sn和金刚石等物质的衍射峰,Cu和Zn峰明显,含量较高,XRD 分析结果与铁浸渣的物相分析基本保持一致,在铁浸渣中没有发现金属元素Fe和Ni的衍射峰,可能是是因为金属元素的无定形性质和相对较低的含量,导致无法发现明显的矿物相衍射峰。

图9 铁浸渣的XRD谱

Fig. 9 XRD pattern of leaching residue from leaching process of iron

采用SEM-EDS分析了铁浸渣磨碎后的微观形貌特征并进行微区成分分析,该原料 SEM 图和 X 射线能谱分析结果分别如图 10所示。可以看出,原料内部呈孔隙状。结合 EDS分析,其主要的元素分布为Cu、Zn、Sn 和Fe元素及极少量Si、Cl、P等元素,表明铁浸渣物的相可能主要为 Cu、Zn、Sn及Fe的合金,主要元素结合紧密。此外还掺杂有极少量的Si、Cl、P等杂质物相。

2.3.2 浸铜过程浸出渣

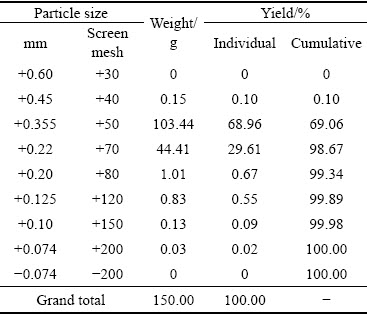

浸铜过程的浸出渣,即浸铜尾渣,经过分析,其主要化学成分为金刚石,筛分分析结果如表4所示,浸出渣中金刚石0.2~0.45 mm粒级占99.34%,处理后可返回金刚石合金刀头的制作。

2.4 工业化试验研究

通过实验室数据在工业化试验上的调试应用,利用“两段浸出-分步结晶-物理分选”技术处理废旧合金刀头,可以生产出七水合硫酸亚铁产品、五水硫酸铜产品及金刚石等,浸铁和浸铜过程的锌和镍等金属元素富集到一定程度时可利用萃取进行回收,生产的七水合硫酸亚铁可用于污水处理剂,五水硫酸铜可用于电镀行业、制作颜料和农药等;金刚石可返回合金刀头的制作,锡泥可作为含锡原料可直接售卖。本研究通过实验室探索和工业化试验研究,得出废旧合金刀头综合回收利用技术工艺过程合理,易于实现工业生产,可制备出符合要求的合格产品,最终实现废旧金刚石刀头的全量化利用。工业化试验不仅验证了实验室研究结果的正确性,还表明湿法过程中产生的废水可以循环利用,整个工艺过程无废水排除。工业化现场主要设备和产品如图11所示。

图10 铁浸渣的SEM像及EDS谱

Fig. 10 SEM images(a) and EDS spectra((b)-(f)) of leaching residue from leaching process of iron

表4 金刚石筛分分析结果

Table 4 Result of diamond screening analysis

图11 现场主要设备和产品图

Fig. 11 Drawing of main equipment and products on site

3 结论

1) 通过“两段浸出-分步结晶-物理分选”的选冶联合清洁处理技术处理废旧合金刀头,在硫酸浓度130 g/L、液固比12:1、搅拌速度300 r/min、浸出温度60 ℃和时间36 h的条件下,废旧金刚石刀头中铁的浸出率为97.6%,且99%以上的铜和100%的金刚石进入渣中,实现了铁的选择性分离。

2) 在硫酸浓度250 g/L、硝酸浓度23 g/L、液固比10:1、浸出温度80 ℃、浸出时间26 h和搅拌速度300 r/min条件下,铁浸渣中铜的浸出率达到99.9%以上,同时94%以上的锡和所有的金刚石进入尾渣中,实现了铜的高效浸出。浸铜尾渣经摇床分选可以实现金刚砂的高效回收。最终实现废旧合金刀头的全量化利用。

3) 工业化试验不仅验证了实验室研究结果的正确性,还表明湿法过程中产生的废水可以循环利用,整个工艺过程无废水排除。

REFERENCES

[1] 周玉海, 秦 哲, 王成勇. 金刚石刀具性能及其应用研究[J]. 机械设计与制造, 2009(6): 158-160.

ZHOU Yu-hai, QIN Zhe, WANG Cheng-yong. Study on performance and application of diamond tools[J]. Machinery Design & Manufacture, 2009(6): 158-160.

[2] HSIEH Yu-zan, LIN Shun-tian. Diamond tool bits with iron alloys as the binding matrices[J]. Materials Chemistry and Physics, 2001, 72(2): 121-125.

[3] 颜玲亚. 我国金刚石资源开发利用及供需分析[J]. 中国非金属矿工业导刊, 2015(1): 30-32.

YAN Ling-ya. Analysis on development and utilization of diamond resource and supply demand in China[J]. China Non-metallic Minerals Industry, 2015(1): 30-32.

[4] 李天敏, 赵 民. 金刚石圆锯片生产工艺过程[J]. 石材, 2017(7): 16-22.

LI Tian-min, ZHAO Min. Production process of diamond circular saw blade[J]. Stone, 2017(7): 16-22.

[5] 彭艳菊, 吕林素, 周振华. 中国金刚石资源分布及开发利用现状[J]. 宝石和宝石学杂志, 2013, 15(4): 1-7.

PENG Yan-ju, Lü Lin-su, ZHOU Zhen-hua. Distribution and utilization of diamond resources in China[J]. Journal of Gems and Gemmology, 2013, 15(4): 1-7.

[6] 郭灵虹, 陈世途. 废弃金刚石刀具选择性浸出及回收工艺研究[J]. 四川有色金属, 1996(1): 19-23.

GUO Ling-hong, CHEN Shi-tu. Study on selective leaching and recovery of waste diamond tools[J]. Sichuan Nonferrous Metals, 1996(01): 19-23.

[7] 高冰媛, 于爱兵, 李 照. 金刚石工具的回收与再利用[J]. 工具技术, 2010, 44(1): 11-14.

GAO Bing-yuan, YU Ai-bing, LI Zhao. Recycling and reusing of diamond tools[J]. Tool Engineering, 2010, 44(1): 11-14.

[8] 谭世同, 曹淑敏. 从金刚石工具中回收金刚石[J]. 石材, 1995(2): 38.

TAN Shi-tong, CAO Shu-min. Recovery of diamond from diamond tools[J]. Stone, 1995(2): 38.

[9] 薛 平, 李光强, 秦庆伟, 等. 从废旧金刚石刀头中酸浸分离有价金属热力学分析及试验研究[J]. 湿法冶金, 2017, 36(1): 19-23.

XUE Ping, LI Guang-qiang, QIN Qing-wei, et al. Thermodynamic analysis and experimental research on acid leaching of valuable metals from waste diamond cutters[J]. Hydrometallurgy of China, 2017, 36(1): 19-23.

[10] 曲志平. 废残金刚石刀头的回收利用[J]. 中国物资再生, 1997(7): 20-22.

QU Zhi-ping. Recovery and utilization of waste diamond cutters[J]. China Resources Comprehensive Utilization, 1997(7): 20-22.

[11] SKURY A L D, BOBROVNITCHII G S, MONTEIRO S N, et al. Recovery of synthetic diamonds from scrapped sawblades[J]. Separation and Purification Technology, 2004, 35(3): 185-190.

[12] XUE Ping, LI Guang-qiang, YANG Yong-xiang, et al. Recovery of valuable metals from waste diamond cutters through ammonia-ammonium sulfate leaching[J]. International Journal of Minerals, Metallurgy, and Materials, 2017, 24(12): 1352-1360.

[13] 汪礼敏, 张国成, 马 飞. 废旧金刚石工具酸分解回收有价金属的理论及实验研究[J]. 稀有金属, 2010, 34(6): 919-923.

WANG Li-min, ZHANG Guo-cheng, MA Fei. Theoretical and experimental study on acid decomposition of waste diamond tools for recycling of valuable metals[J]. Chinese Journal of Rare Metals, 2010, 34(6): 919-923.

[14] 郭学益, 田庆华, 刘 咏, 等. 有色金属资源循环研究应用进展[J]. 中国有色金属学报, 2019, 29(9): 1859-1901.

GUO Xue-yi, TIAN Qing-hua, LIU Yong, et al. Progress in research and application of non-ferrous metal resources recycling[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(9): 1859-1901.

[15] 韩俊伟, 刘 维, 覃文庆, 等. 高铁锌焙砂选择性还原焙烧-两段浸出锌[J].中国有色金属学报, 2014, 24(2): 511-518.

HAN Jun-wei, LIU Wei, QIN Wen-qing, et al. Leaching zinc from high iron-bearing zinc calcine after selective reduction roasting[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(2): 511-518.

[16] 韩俊伟, 刘 维, 覃文庆, 等. CO还原焙烧铁酸锌的选择性分解行为[J]. 中国有色金属学报, 2016, 26(6): 1324-1331.

HAN Jun-wei, LIU Wei, QIN Wen-qing, et al. Selective decomposition behavior of zinc ferrite by reduction roasting with CO[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(6): 1324-1331.

[17] 郭学益, 江晓健, 刘静欣, 等. 梯级碱溶分步提取废弃电路板中有价金属[J]. 中国有色金属学报, 2017, 27(2): 406-413.

GUO Xue-yi, JIANG Xiao-jian, LIU Jing-xin, et al. Recovery of metal values from waste printed circuit boards using a cascading alkali leaching process[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(2): 406-413.

[18] 李陵晨, 杨建广, 闫万鹏, 等. SnCl4-HCl体系废电路板元器件的分离及锡的回收[J]. 中国有色金属学报, 2019, 29(7): 1543-1550.

LI Ling-chen, YANG Jian-guang, YAN Wan-peng, et al. Separation of electronic components from waste printed circuit board and tin recovery in SnCl4-HCl system[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(7): 1543-1550.

[19] 陈 冰, 吕元录, 杨建广, 等. 用浸出-隔膜电沉积法从废弃金刚石刀头中回收铁试验研究[J]. 湿法冶金, 2017, 36(6): 479-484.

CHEN Bing, Lü Yuan-lu, YANG Jian-guang, et al. Recovery of iron from diamond tools by leaching-membrane electrodeposition process[J]. Hydrometallurgy of China, 2017, 36(6): 479v484.

[20] 苏念英, 崔嘉麟. 废金刚石刀具中钴的回收利用[J]. 广西化工, 1997(3): 58-60.

SU Nian-ying, CUI Jia-lin. Recovery of cobalt in waste diamond cutter[J]. Technology & Development of Chemical Industry, 1997(3): 58-60.

[21] 张从良, 彭国胜, 王 岩. 废金刚石刀具中铜钴镍的回收工艺研究[J]. 无机盐工业, 2006(9): 54-55.

ZHANG Cong-liang, PENG Guo-sheng, WANG Yan. Study on the recovery technique of copper cobalt and nickel in waste diamond cutter[J]. Inorganic Chemicals Industry, 2006(9): 54-55.

[22] 郑小清, 蒙德仲, 周新木. 废刀具中金刚石等有价物质的综合回收[J]. 江西化工, 2008(4): 197-199.

ZHENG Xiao-qing, MENG De-zhong, ZHOU Xin-mu. Discussion how to recycle valuable substance in waste diamond cutting tool[J]. Jiangxi Chemical Industry, 2008(4): 197-199.

[23] 马 飞. 废旧金刚石工具综合回收利用研究[J]. 超硬材料工程, 2011, 23(5): 27-31.

MA Fei. Study on comprehensive recovery and utilization of waste diamond tools[J]. Superhard Material Engineering, 2011, 23(5): 27-31.

[24] WANG Li-min, ZHANG Guo-cheng, MA Fei. A study on comprehensive recycling of waste diamond tools[J]. Rare Metals, 2012, 31(1): 88-91.

[25] CELEP O, AYDIN G, KARAKURT I. Diamond recovery from waste sawblades: A preliminary investigation[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2013, 227(6): 917-921.

[26] 郭 勇, 秦庆伟, 毕 凡, 等. 废旧金刚石刀具在氨水-硫酸铵溶液中选择性溶解铜锌[J]. 湿法冶金, 2016, 35(5): 418-421.

GUO Yong, QIN Qing-wei, BI Fan, et al. Investigation on leaching of copper and zinc from spent diamond tools using ammonia-ammonium sulfate solution[J]. Hydrometallurgy of China, 2016, 35(5): 418-421.

[27] HAN Jun-wei, OU Zhen-yu, LIU Wei, et al. Recovery of antimony and bismuth from tin anode slime after soda roasting-alkaline leaching[J]. Separation and Purification Technology, 2020, 242: 116789.

High-efficiency hydrometallurgical separation of valuable components from waste alloy cutters

LI Liang-yu, HAN Jun-wei, JIAO Fen, LIU Wei, QIN Wen-qing

(School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: In order to solve the problem that it is difficult to separate valuable components from waste alloy cutters efficiently, a cleaning treatment technology of “two-stage leaching, fractional crystallization and physical separation” was proposed, that is to say, FeSO4·7H2O is obtained by selective leaching of iron with low concentration sulfuric acid solution and crystallization of iron rich liquid at low temperature. Copper is extracted from iron leaching residue by acid oxidation leaching process, and CuSO4·5H2O is obtained by crystallization of copper rich liquid after purification. At the same time, the monomer dissociation of diamond and WC in copper leaching residue was realized, through gravity separation process, the diamond and WC can be separated efficiently, and finally the waste alloy cutters can be fully utilized. In this paper, the effects of technological parameters on leaching behavior of valuable metals in iron and copper leaching processes were studied, and the physical separation of diamond was also studied. The results show that: under the conditions of H2SO4 concentration of 130 g/L, L/S ratio of 12:1, stirring speed of 300 r/min, leaching temperature of 60 ℃ and leaching time of 36 h, the leaching efficiency of iron in waste alloy cutters is 97.6%, and more than 99% of copper and 100% of diamond enter into the iron leaching residue, realizing the selective separation of iron. Under the conditions of H2SO4 concentration of 250 g/L, oxidant HNO3 concentration of 23 g/L, L/S ratio of 10:1, stirring speed of 300 r/min, leaching temperature of 80 ℃ and leaching time of 26 h, the leaching efficiency of copper in iron leaching residue can reach more than 99.9%, while more than 94% of tin and all diamonds enter into the copper leaching residue, realizing the high-efficiency leaching of copper. The high efficiency recovery of diamond can be achieved by shaking table separation of copper leaching tailings. The industrial test not only verified the correctness of the laboratory research results, but also showed that the wastewater generated in the wet process can be recycled, and no wastewater was discharged in the whole process.

Key words: waste alloy; leaching; resource recovery; copper recovery; diamond

Foundation item: Project(51804342) supported by the National Natural Science Foundation of China; Project (2019YFC1907301) supported by the National Key Research and Development Program of China; Project(2020CX038) supported by the Innovation-driven Plan of Central South University, China; Project(2019JJ50805) supported by the Natural Science Foundation of Hunan Province

Received date: 2021-04-02; Accepted date: 2021-07-14

Corresponding author: HAN Jun-wei; Tel: +86-731-88830884; E-mail: hanjunwei2008@163.com

(编辑 )

基金项目:国家自然科学基金资助项目(51804342);国家重点研发计划资助项目(2019YFC1907301);湖南省自然科学基金资助项目(2019JJ50805);中南大学创新驱动计划资助项目(2020CX038)

收稿日期:2021-04-02;修订日期:2021-07-14

通信作者:韩俊伟,副教授,博士;电话:0731-88830884;E-mail:hanjunwei2008@163.com