文章编号:1004-0609(2013)08-2069-08

ZM21及ZM61合金的热变形行为与动态再结晶临界条件的表征

童小山1,彭 建1, 2,石大伟1,潘复生1, 2,彭 毅1

(1. 重庆大学 材料科学与工程学院,重庆 400044;

2. 国家镁合金材料工程技术研究中心,重庆 400045)

摘 要:采用Gleeble-1500热/力模拟试验机进行压缩实验,研究Mg-2Zn-1Mn (ZM21)与Mg-6Zn-1Mn (ZM61)合金在变形温度523~723 K、应变速率0.01~10 s-1范围内的流变应力行为,并以热压缩实验为基础,建立两种合金的动态模型加工图,引入材料加工硬化率θ,结合θ—σ曲线拐点判据识别合金发生动态再结晶的临界应变εc。结果表明,ZM21与ZM61合金在热压缩过程中发生明显的动态回复与动态再结晶;随着Zn含量的增加,ZM61合金的变形激活能比ZM21合金的升高约20%,并且ZM61合金在高温变形时更容易出现失衡;两者发生动态再结晶的临界应变εc均随着应变速率的增加而升高,随变形温度的升高而降低。

关键词:镁合金;热压缩;动态再结晶;临界应变

中图分类号:TG 146.2 文献标志码:A

Thermal compression behavior and characterization of dynamic recrystallization critical conditions for ZM21 and ZM61 magnesium alloys

TONG Xiao-shan1, PENG Jian1, 2, SHI Da-wei1, PAN Fu-sheng1, 2, PENG Yi1

(1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. National Engineering Research Center for Magnesium Alloys, Chongqing 400045, China)

Abstract: The thermal compression behavior of Mg-2Zn-1Mn (ZM21) and Mg-6Zn-1Mn (ZM61) magnesium alloys was investigated by uniaxial compression tests on Gleeble-1500 thermal simulation test machine at the temperature ranging from 523 K to 723 K and strain rate ranging from 0.01 s-1 to 10 s-1. According to the experimental results, the hot processing maps based on the dynamic materials modeling were drawn. The critical strain εc that the dynamical recrystallization occurs was identified by introducing the hard working rate θ and inflection point of θ—σ curves under different deformation. The results show that the dynamic recovery and dynamic recrystallization occur obviously during hot compression of ZM21and ZM61 alloys. Compared with ZM21 alloy, the deformation activation energy of ZM61 alloy increases by 20% because of the increase of Zn content, and the ZM61 alloy is more unstable than ZM21 alloy. The critical strain εc of both alloys increases with the increase of strain rate and decreases with the increase of deformation temperature.

Key words: magnesium alloy; thermal compression; dynamic recrystallization; critical strain

镁晶体结构的特殊性,导致镁合金室温塑性及成形性较差,极大地限制了镁合金尤其是变形镁合金在工业上的应用。而热机械加工(Thermo mechanical processing, TMP)是改善镁合金加工性的有效方法[1]。

对于镁及镁合金,扩展位错较宽难以束集,位错的滑移和攀移困难,从而动态回复速度很慢,亚组织中位错密度较高,剩余的储能足以引起再结晶[2],因此,动态再结晶成为改善镁合金塑性及细化组织的途径之一。

Mg-Zn-Mn合金作为一种新型的低成本变形镁合金,应用前景十分广泛。Mg-2Zn-1Mn(ZM21)合金由于合金化程度低,具有较好的热加工成形性能。根据文献[3],ZM21合金采用静液挤压实现了每分钟超过120 m。但是ZM21合金制品室温力学性能不高。因 此,在ZM21合金基础上增加Zn含量使得合金制品的力学性能得以提高。张丁非等[4]研究发现Zn含量为6%(质量分数)时,合金的力学性能达到最佳。另有研究表明,Mg-6Zn-1Mn(ZM61)合金经时效处理后,其变形强度能够达到ZK60的水平[5]。但是,Zn的加入一方面使得合金热裂倾向增加,另一方面使得镁的扩展位错变宽难以发生集束,非基面滑移更困难,发生动态再结晶倾向增大[6],因此有必要明确Zn元素对镁合金热变形规律的影响。

目前,关于Mg-Zn-Mn合金热成形方面的研究很少,而关于Zn对镁合金高温变形时流变行为和动态再结晶的影响规律研究更少见报道。张丁非等[7]仅研究了ZM61合金在573~663 K、0.001~0.1 s-1变形条件下的热变形行为,发现ZM61 镁合金的热流变行为可用包含Arrhenius 项的 Zener-Hollomon 参数来描述。近年来,基于热压缩模拟研究,国内外也开始把加工图作为一种便捷的途径来确定镁合金的热加工工艺制度[8]。SIVAKESAVAM等[9]应用动态材料模型(DMM)绘制出ZM21合金的加工图,图中出现一个功率耗散的峰值:温度450 ℃、应变速率0.01 s-1时,耗散效率达到最大值33%,为Mg-2Zn-1Mn合金进行热加工的最佳变形工艺。但是已有文献对ZM61合金DMM加工图研究未见报道,更未涉及Zn含量的添加对两种合金在热变形条件下塑性变形参数作比较。因此,本文作者以具有高塑性的ZM21合金和高强度的ZM61合金作为研究对象,补充Mg-Zn-Mn系合金在其他文献中没有包含的变形温度和应变速率下的热变形行为,通过本构方程、材料加工硬化率θ,判据识别合金发生动态再结晶的临界应变εc等方法完善ZM21和ZM61合金的动态加工图,以期为制定合理的热加工工艺提供指导。

1 实验

试验用Mg-2Zn-1Mn和Mg-6Zn-1Mn镁合金实际成分见表1,其中Mn以Mg-Mn中间合金的形式加入,Zn以纯金属的方式加入,采用电阻炉熔炼,熔剂保护,金属模浇注成d 90 mm铸锭。铸锭经400 ℃、10 h均匀化处理后,机械加工成尺寸为d 10 mm×12 mm的圆柱形压缩试样。为减小压缩时试样两端面的摩擦力,在压缩试样两端开浅凹槽,以便加入含石墨的固体润滑剂。变形温度为 523~723 K,应变速率为0.01、0.10、1.0和10 s-1,预设最大变形程度为60%。压缩前升温速度为10 K/s,保温3 min,变形结束后立即水淬,以保留其高温变形组织。

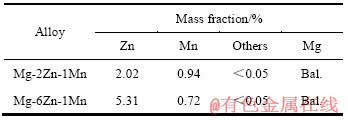

表1 Mg-Zn-Mn镁合金的化学成分

Table 1 Chemical compositions of Mg-Zn-Mn alloy

2 结果与讨论

2.1 合金的真应力—真应变曲线

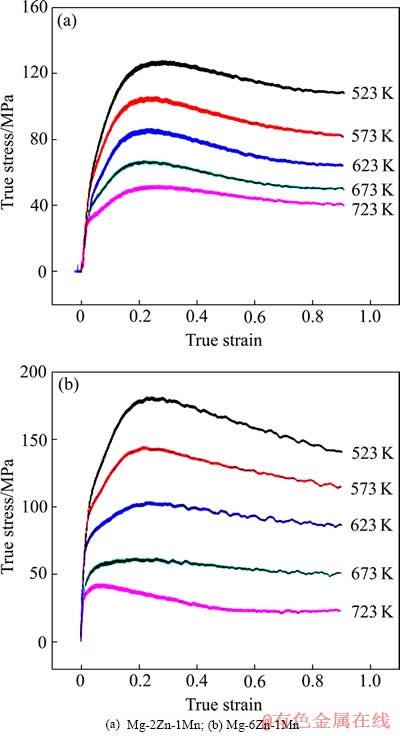

图1所示为ZM21及ZM61合金在应变速率为1.0 s-1、不同变形温度下的真应力—真应变曲线。由图1可以看出,两种合金真应力—真应变曲线呈现动态再结晶的特征,即存在明显的峰值或者稳态流变现象;合金的峰值应力和稳态应力随着变形温度的升高或应变速率的降低而显著降低,说明Mg-Zn-Mn合金属于热敏感型和应变速率敏感型材料。

从图1还可以看出,相对于ZM21合金,ZM61合金的峰值流变应力较高,且在相同变形温度(如T=623 K)下,合金的真应力—真应变曲线的锯齿状尖波动现象增强。这可能是由于Zn的增加导致镁的扩展位错变宽难以发生集束,非基面滑移更困难,使ZM61合金发生动态再结晶倾向增大;另一方面可能是动态再结晶引起的软化与已再结晶晶粒的变形和重新硬化交替进行,流变曲线出现周期性类似锯齿状的流变特征。

2.2 Mg-Zn-Mn合金高温塑性变形过程中变形参数及本构方程的确定

图1 Mg-Zn-Mn合金在应变速率为1.0 s-1、不同变形温度下的真应力—真应变曲线

Fig. 1 True stress—strain curves of Mg-Zn-Mn alloys at strain rate of 1.0 s-1 and different deformation temperatures

热加工变形是一个类似于高温蠕变的受位借运动速率控制的热激活过程,对不同热加工条件下的数据分析表明,合金的流变应力、应变速率和变形温度之间存在以下关系[10]:

在低应力水平条件下( <0.8):

<0.8):

(1)

(1)

在高应力水平条件下( >1.2):

>1.2):

(2)

(2)

在所有应力条件下:

(3)

(3)

式中:A1、A2、A、n1、n、 均为材料常数;R为摩尔气体常数,8.314 J/(mol·K);T为热力学温度;Q为变形激活能,是材料发生塑性变形时,金属原子发生剧烈的热运动需要跨越的一个能量“门槛值”,是表征材料热变形的重要参数。利用

均为材料常数;R为摩尔气体常数,8.314 J/(mol·K);T为热力学温度;Q为变形激活能,是材料发生塑性变形时,金属原子发生剧烈的热运动需要跨越的一个能量“门槛值”,是表征材料热变形的重要参数。利用 —

— 和

和 —

— 关系式,采用最小二乘法回归求出n和β值,则

关系式,采用最小二乘法回归求出n和β值,则 。根据实验结果得出ZM21合金和ZM61合金

。根据实验结果得出ZM21合金和ZM61合金 值分别为

值分别为 =0.016 58,

=0.016 58, =0.011 92。

=0.011 92。

当应变速率为常数时,假定变形激活能Q在很小的温度范围内保持不变,根据式(3)可计算变形激活能如下:

(4)

(4)

因此,根据 —

— 与

与 —1/T的关系(见图2),由式(4)分别得到ZM21和ZM61合金在高温下热变形的激活能Q1=166.19 kJ/mol,Q2=198.20 kJ/mol。与ZM21合金相比,ZM61合金的变形激活能较高,增大约20%。这是由于Zn原子的加入会降低镁合金的层错能,进一步使扩展位错宽 化,动态再结晶倾向增加。另外,Zn原子的增加会与基体形成更多Mg-Zn等第二相粒子[7],在高温塑性变形过程中会阻碍位错的运动。这些都使得位借的交滑移和攀移困难,更容易发生孪生变形,且孪晶处容易发生再结晶形核[11]。动态再结晶的形成和长大会消耗大量的位错,从而潜在位错源数量减少且启动更为困难,这将导致ZM61合金的变形激活能增大。

—1/T的关系(见图2),由式(4)分别得到ZM21和ZM61合金在高温下热变形的激活能Q1=166.19 kJ/mol,Q2=198.20 kJ/mol。与ZM21合金相比,ZM61合金的变形激活能较高,增大约20%。这是由于Zn原子的加入会降低镁合金的层错能,进一步使扩展位错宽 化,动态再结晶倾向增加。另外,Zn原子的增加会与基体形成更多Mg-Zn等第二相粒子[7],在高温塑性变形过程中会阻碍位错的运动。这些都使得位借的交滑移和攀移困难,更容易发生孪生变形,且孪晶处容易发生再结晶形核[11]。动态再结晶的形成和长大会消耗大量的位错,从而潜在位错源数量减少且启动更为困难,这将导致ZM61合金的变形激活能增大。

通过引入Zener-Hollomon参数来描述变形速率与变形温度对变形的影响[12]:

(5)

(5)

对式(5)两边取对数,得到如下线性关系:

(6)

(6)

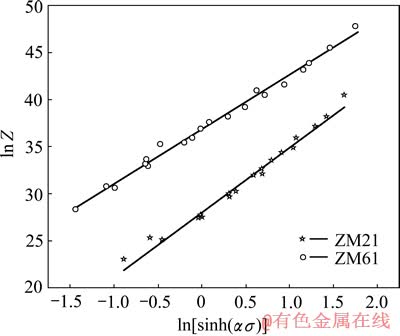

由式(6)对 —

— 作线性回归,得到ZM21和ZM61合金应力指数分别为n1=6.868 2,n2=5.840 6,见图3,其截距分别为ln A1=28.099 4, ln A2=36.892 4,则A1=1.597 4×1012,A2=1.052 3×1016。

作线性回归,得到ZM21和ZM61合金应力指数分别为n1=6.868 2,n2=5.840 6,见图3,其截距分别为ln A1=28.099 4, ln A2=36.892 4,则A1=1.597 4×1012,A2=1.052 3×1016。

图2 合金高温塑性变形时峰值应力与应变速率的关系

Fig. 2 Relationship between strain rate and peak stress of alloys during high temperature plastic deformation

图3 Mg-Zn-Mn合金热变形时 —

— 的关系

的关系

Fig. 3 Relationship between  and

and  of Mg-Zn-Mn alloys

of Mg-Zn-Mn alloys

根据双曲正弦函数的定义以及式(5),可将流变应力σ表示为

(7)

(7)

将上述求得的Q值代入式(5),可得到Mg-Zn-Mn合金Z参数表示式(Z1为ZM21合金,Z2为ZM61合金):

(8)

(8)

(9)

(9)

将求得的 、n和A值代入式(7)中,可得到Mg-Zn-Mn合金用Z参数表示的峰值应力σ、变形温度T和应变速率

、n和A值代入式(7)中,可得到Mg-Zn-Mn合金用Z参数表示的峰值应力σ、变形温度T和应变速率 的本构方程(σ1为ZM21合金的,σ2为ZM61合金的):

的本构方程(σ1为ZM21合金的,σ2为ZM61合金的):

(10)

(10)

(11)

(11)

2.3 Mg-Zn-Mn合金动态DMM加工图

PARASAD等[13]基于动态材料模型(DMM)提出的加工图理论,将热成形工艺与成形性能有机的结合在一起,能清晰准确地反映金属在热变形过程中应变速率、变形温度与金属的成形性能之间的关系,已经在镁及其合金早期的研究中得到了验证,对优化材料的热加工工艺参数、改善材料的加工性、控制组织及避免缺陷的产生具有重要指导作用[14-15]。

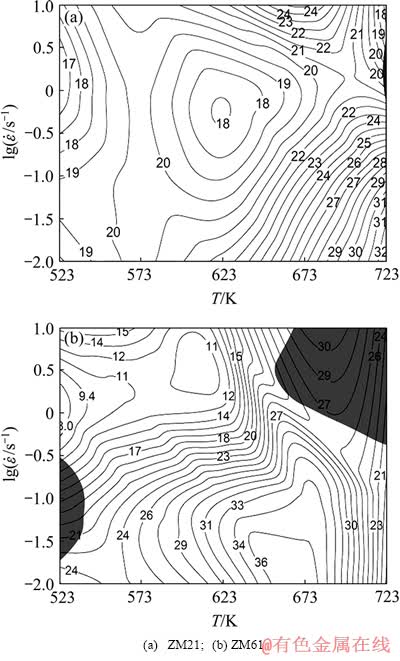

应变为0.6时ZM21与ZM61合金的DMM加工图如图4所示。图4中,等值线是能量耗散率η值,阴影区域对应合金变形过程中的流变失衡区。从图4可以看出,温度范围在693~723 K、应变速率为0.01~0.1 s-1范围内,能量耗散率均大于30%,且温度723 K、应变速率0.01 s-1时,耗散效率达到最大值为32%,此区域为ZM21合金适合热加工成形区域。而在温度为723 K、应变速率在1~3.2 s-1区域内,合金发生流失稳,所以避免在这个区域内进行热加工。对于ZM61合金,在高温变形时存在2个非稳定区域,第一个区域是在523~553 K、0.018~0.316 s-1变形区域内,第二个区域是683~723 K、0.398 s-1。此外,温度范围在623~698 K、应变速率为0.01~0.365 s-1范围内,能量耗散率均大于30%,此区域为ZM61合金适合热加工成形区域。

图4 应变为0.6时合金的热加工图

Fig. 4 Processing maps of alloy at ε=0.6

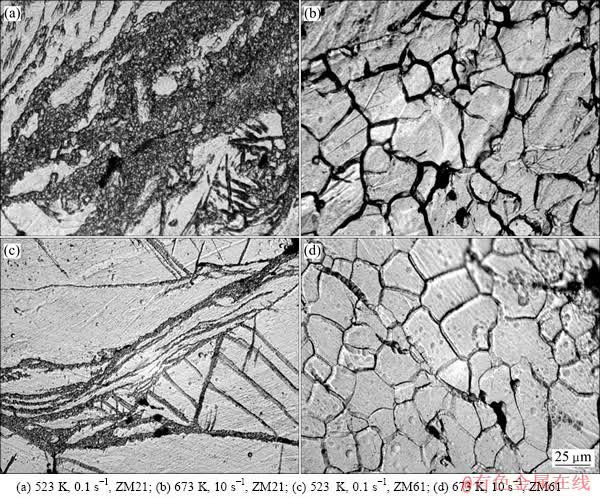

相比于ZM21合金,ZM61合金在高温变形时出现失衡区域增大。在低温、低应变速率条件下,合金晶界不均匀变形容易出现“项链”状组织而出现局部流变失衡[16]。由图5(a)所示为ZM21合金在250 ℃、0.1 s-1变形条件下的显微组织。合金大部分区域发生了动态再结晶,在局部变形量较大的区域出现了许多了细小的再结晶晶粒,但“项链”状组织不明显。相反,ZM61合金在相同变形条件下,变形的大晶粒被动态再结晶小晶粒包围,呈现出典型的“项链”状组织特征,导致ZM61合金出现局部流变失稳,如图5(c)所示。两者合金在400 ℃、10 s-1变形条件下的显微组织如图5(b)和(d)所示,两者合金组织均以等轴动态再结晶晶粒为主。材料在高温、高应变速率下,变形过程中大量的热量难以散出,易出现绝热剪带而导致合金出现流变失稳现象[12]。此外,Zn含量的增加使得合金的热裂倾向增加,这些原因导致ZM61合金高温变形时出现失衡区域较ZM21合金的大。

2.4 Mg-Zn-Mn合金动态再结晶临界条件的表征

动态再结晶通过细化晶粒改善材料的加工性能, 在热加工过程中起到了重要的作用,有必要探讨热加工工艺参数对合金动态再结晶行为的影响。临界应变是表征动态再结晶启动及演变过程的重要参数之一,准确描述变形条件对临界应变的影响规律是建立动态再结晶动力学模型的关键[17]。

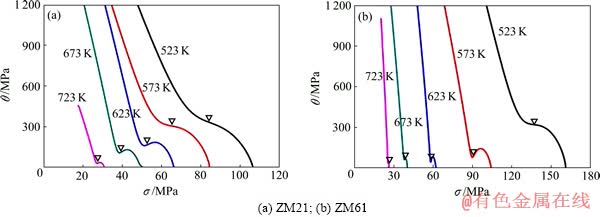

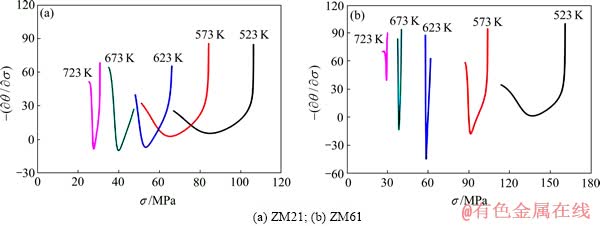

当应变速率与变形温度一定时,应力随应变的变化率称之为加工硬化速率,即 。YOO等[18]和TAN等[19]在考虑不可逆热力学基础上,认为

。YOO等[18]和TAN等[19]在考虑不可逆热力学基础上,认为 —

— 曲线的转折点意味着动态再结晶的发生。近年来,一些学者采用此法判断镁、铝等合金的动态再结晶临界条件,达到较高的精度[20-22]。材料动态再结晶的特征可以从加工硬化率

曲线的转折点意味着动态再结晶的发生。近年来,一些学者采用此法判断镁、铝等合金的动态再结晶临界条件,达到较高的精度[20-22]。材料动态再结晶的特征可以从加工硬化率 和流变应力

和流变应力 的关系来分析[22]。为准确识别

的关系来分析[22]。为准确识别 —

— 曲线上拐点,对

曲线上拐点,对 —

— 曲线进一步求偏导可以得到如图7所示的

曲线进一步求偏导可以得到如图7所示的 —

— 曲线,图6中拐点对应图7中曲线的最小值点。

曲线,图6中拐点对应图7中曲线的最小值点。

图5 两种合金在不同变形条件下的显微组织

Fig. 5 Microstructures of alloys under different deformation conditions

图6 在应变速率0.1 s-1下合金应变硬化速率θ与流变应力σ的关系

Fig. 6 Relationship between θ and σ of alloys under 0.1 s-1

图7 在应变速率0.1 s-1下合金 与σ的关系

与σ的关系

Fig. 7 Relationship between and σ of alloys at 0.1 s-1

and σ of alloys at 0.1 s-1

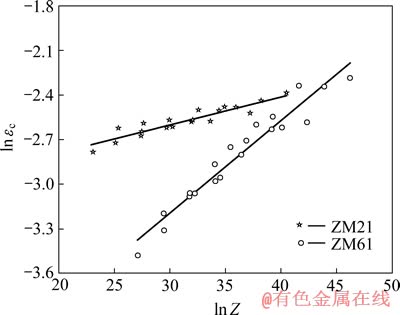

通过引入Zener-Hollomon参数分析变形温度T和变形速率 对合金再结晶临界应变εc的影响。根据实验得到的εc 作ln εc—ln Z曲线(见图8),通过线性回归获得以下关系式(εc1为ZM21合金,εc2为ZM61合金):

对合金再结晶临界应变εc的影响。根据实验得到的εc 作ln εc—ln Z曲线(见图8),通过线性回归获得以下关系式(εc1为ZM21合金,εc2为ZM61合金):

(12)

(12)

(13)

(13)

因此,ZM21和ZM61镁合金发生动态再结晶的临界条件如下:

(14)

(14)

(15)

(15)

由以上分析可以看出,在热变形过程中ZM61合金动态结晶发生的临界应变量对变形工艺参数较ZM21合金敏感。同时,临界应变εc随着应变速率 的增加而增大,随变形温度T的升高而降低。这是因为温度升高,合金中原子热振荡及扩散速率增加,促进了位错的交滑移和攀移,动态再结晶越容易发生,使动态再结晶的临界应变量减小。此外,应变速率的增大,位错的滑移和攀移过程变短,增加了动态再结晶的形核数量和晶粒长大速率,不利于动态再结晶的软化作用,使得动态再结晶软化和应变硬化达到平衡的临界应变量增大。

的增加而增大,随变形温度T的升高而降低。这是因为温度升高,合金中原子热振荡及扩散速率增加,促进了位错的交滑移和攀移,动态再结晶越容易发生,使动态再结晶的临界应变量减小。此外,应变速率的增大,位错的滑移和攀移过程变短,增加了动态再结晶的形核数量和晶粒长大速率,不利于动态再结晶的软化作用,使得动态再结晶软化和应变硬化达到平衡的临界应变量增大。

图8 临界应变ln εc与ln Z参数的关系

Fig. 8 Relationship between ln εc and ln Z parameter

3 结论

1) ZM21及ZM61合金真应力—真应变曲线呈现动态再结晶的特征,即存在明显的峰值或者稳态流变现象;合金的峰值应力和稳态应力随着变形温度的升高或应变速率的降低而显著降低。

2) 采用包含Arrhenius项的Z参数法构建了ZM21及ZM61合金高温塑性变形时峰值应力、变形温度和应变速率之间的本构方程,并且相对于ZM21合金,ZM61合金的变形激活能提高约20%。

3) ZM21及ZM61合金的DMM加工图表明,相比于ZM21合金,ZM61合金在高温变形时出现失衡区域增大,但适合ZM61合金进行热加工成形的区域亦增大。

4) 引入加工硬化率θ,结合θ—σ曲线拐点判据识别合金发生动态再结晶的临界应变εc,并建立了临界应变εc与Z参数之间的定量关系,表明ZM21和ZM61合金发生动态再结晶的临界应变εc都随着应变速率的增加而升高,随变形温度的增加而降低。

REFERENCES

[1] 刘楚明, 刘子娟, 朱秀荣, 周海涛. 镁及镁合金动态再结晶研究进展[J]. 中国有色金属学报, 2006, 16(1): 1-12.

LIU Chu-ming, LIU Zi-juan, ZHU Xiu-rong, ZHOU Hai-tao. Research and development progress of dynamic recrystallization in pure magnesium and its alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(1): 1-12.

[2] 王 斌, 易丹青, 方西亚, 刘群会, 吴春萍. ZK60及ZK60 (0.9Y)镁合金高温变形行为的热模拟研究[J]. 稀有金属材料与工程, 2010, 39(1): 106-111.

WANG Bin, YI Dan-qing, FANG Xi-ya, LIU Qun-hui, WU Chun-ping. Thermal simulation on hot deformation behavior of ZK60 and ZK60 (0.9Y) magnesium alloys[J]. Rare Metal Materials and Engineering, 2010, 39(1): 106-111.

[3] SWIOSTEK J, LETZING D, KAINER K U. Hydrostatic extrusion at 100 ℃ and its effect on the grain size and mechanical properties of magnesium alloys[J]. Metal Science and Heat Treatment, 2006, 48(11/12): 499-503.

[4] ZHANG Ding-fei, SHI Guo-liang, ZHAO Xia-bing, QI Fu-gang. Microstructure evolution and mechanical properties of Mg-x%Zn-1%Mn (x=4, 5, 6, 7, 8, 9) wrought magnesium alloys[J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 15-25.

[5] PARK S S, BAE G T, KANG D H, JUNG I H, SHIN K S, KIM N J. Microstructure and tensile properties of twin-roll cast Mg-Zn-Mn-Al alloys[J]. Scripta Materialia, 2007, 57: 793-796.

[6] 陈振华. 镁合金[M]. 北京: 化学工业出版社, 2004: 28-50.

CHEN Zhen-hua. Magnesium[M]. Beijing: Chemical Industry Press, 2004: 28-50.

[7] 张丁非, 方 霖, 段红玲, 戴庆伟. ZM61镁合金的热变形行为[J]. 材料热处理学报, 2011, 32(4): 25-29.

ZHANG Ding-fei, FANG Lin, DUAN Hong-ling, DAI Qing-wei. Constitutive equation of thermal compression deformation for ZM61 magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2011, 32(4): 25-29.

[8] 王宏伟, 易丹青, 王 斌, 蔡金铃, 钱 峰, 陈缇萦. Mg-6.3Zn-0.7Zr-0.9Y-0.3Nd 镁合金的高温塑性变形行为的热压缩模拟[J]. 中国有色金属学报, 2010, 20(3): 378-384.

WANG Hong-wei, YI Dan-qing, WANG Bin, CAI Jin-ling, QIAN Feng, CHEN Ti-ying. Hot compressive deformation simulation of Mg-6.3Zn-0.7Zr-0.9Y-0.3Nd magnesium alloy at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 378-384.

[9] SIVAKESAVAM O, PRASAD Y V R K. Hot deformation behaviour of as-cast Mg-2Zn-1Mn alloy in compression: A study with processing map[J]. Materials Science and Engineering A, 2003, 362: 118-124.

[10] LI L, ZHOU J, DUSZCZYK J. Determination of a constitutive relationship for AZ31B magnesium alloy and validation through comparison between simulated and real extrusion[J]. Materials Science and Engineering A, 2006, 172: 372-380.

[11] 杨续跃, 张之岭, 张 雷, 吴新星, 王 军. 应变速率对 AZ61 镁合金动态再结晶行为的影响[J]. 中国有色金属学报, 2011, 21(8): 1801-1807.

YANG Xu-yue, ZHANG Zhi-ling, ZHANG Lei, WU Xin-xing, WANG Jun. Influence of strain rate on dynamic recrystallization behavior of AZ61 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(8): 1801-1807.

[12] 周 舸, 丁 桦, 曹富荣, 赵文娟, 候红亮, 李志强. TC21 合金的热压缩变形行为及变形机理[J]. 中国有色金属学报, 2011, 21(9): 2111-2118.

ZHOU Ge, DING Hua, CAO Fu-rong, ZHAO Wen-juan, HOU Hong-liang, LI Zhi-qiang. Hot compression deformation and deformation mechanisms of TC21 alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(9): 2111-2118.

[13] PRASAD Y V R K, GEGEL H L, DORAIVELU S M, MALAS J C, MORGAN J T, LARK K A, BARKER D A. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242[J]. Metallurgical Transactions A, 1984, 15: 1883-1883.

[14] 汪凌云, 范永革. AZ31镁合金的中温流变失稳特征[J]. 中国有色金属学报, 2005, 15(10): 1602-1606.

WANG Ling-yun, FAN Yong-ge. Instability flow characteristics of AZ31 magnesium alloy at moderate temperature[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(10): 1602-1606.

[15] 李红英, 刘 洋, 胡继东, 曹翠婷, 魏冬冬. ZA27合金的热变形及加工图[J]. 中国有色金属学报, 2012, 22(2): 365-369.

LI Hong-ying, LIU Yang, HU Ji-dong, CAO Cui-ting, WEI Dong-dong. Hot deformation and processing map of ZA27 alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 365-369.

[16] 汪凌云, 范永革, 黄光杰, 黄光胜. 镁合金AZ31B的高温塑性变形及加工图[J]. 中国有色金属学报, 2004, 14(7): 1068-1072.

WANG Ling-yun, FAN Yong-ge, HUANG Guang-jie, HUANG Guang-sheng. Plastic deformation at elevated temperature and processing maps of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1068-1072.

[17] HE Yun-bin, PAN Qing-lin, CHEN Qin, ZHANG Zhi-ye, LIU Xiao-yuan, LI Wen-bin. Modeling of strain hardening and dynamic recrystallization of ZK60 magnesium alloy during hot deformation[J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 246-254.

[18] YOO M H, AGNEW S R, MORRIS J R, HO K M. Non-basal slip systems in HCP metals and alloys: source mechanisms[J]. Materials Science and Engineering A, 2001, 319/321: 87-92.

[19] TAN J C, TAN M J. Dynamic continuous recrystallization characteristics in two stage deformation of Mg-3Al-1Zn alloy sheet[J]. Materials Science and Engineering A, 2003, 339: 124-132.

[20] JOHN J J, XAVIER Q, LAN J, MARTIN E. The Avrami kinetics of dynamic recrystallization[J]. Acta Materialia, 2009, 57(9): 2748-2756.

[21] QUAN Guo-zheng, MAO Yuan-ping, LI Gui-sheng, LI Wen-quan, WANG Yang, ZHOU Jie. A characterization for the dynamic recrystallization kinetics of as-extruded 7075 aluminum alloy based on true stress—strain curves[J]. Computational Materials Science, 2012, 55: 65-72.

[22] LIU J, CUI Z, RUAN L. A new kinetics model of dynamic recrystallization for magnesium alloy AZ31B[J]. Materials Science and Engineering A, 2011, 529: 300-310.

(编辑 龙怀中)

基金项目:国家“十二五”科技支撑计划(2011BAE22B03-3);重庆市科委资助项目(CTSC2010AA4045,2010CSTC-HDLS,CSTS2010BB4068)

收稿日期:2012-06-20;修订日期:2012-09-14

通信作者:彭 建,教授,博士;电话:023-65112291;E-mail: jpeng@cqu.edu.cn