电子束-物理气相沉积7YSZ热障涂层表面氧化铝纤维制备及其CMAS腐蚀性能

来源期刊:中国有色金属学报(英文版)2019年第11期

论文作者:张小锋 牛少鹏 邓子谦 刘敏 李洪 邓春明 邓畅光 周克崧

文章页码:2362 - 2370

关键词:热障涂层;CMAS腐蚀;铝改性;氧化铝纳米线

Key words:thermal barrier coating; CMAS corrosion; Al-modification; Al2O3 nanowires

摘 要:7YSZ (7wt.%Y2O3-ZrO2) 作为热障涂层使用最广的材料,其主要制备方法包括电子束-物理气相沉积(EB-PVD)。随着涡轮前进口温度的逐步提高,CMAS (CaO-MgO-Al2O3-SiO2) 熔盐腐蚀等因素逐渐成为影响柱状结构EB-PVD 7YSZ热障涂层服役寿命的关键因素。本文作者提出一种镀铝表面改性技术,即在柱状涂层表面采用磁控溅射技术制备一层Al膜,然后施加真空热处理工艺。一方面,Al和7YSZ涂层发生原位反应形成α-Al2O3 层,抑制CMAS熔盐高温渗透;另一方面,在真空热处理过程中Al膜在高温下发生蒸发和形核,最终在7YSZ热障涂层表面形成氧化铝纳米线,抑制高温下熔融CMAS流动。

Abstract: The commonly-employed material for thermal barrier coatings (TBCs) is 7 wt.%Y2O3-ZrO2 (7YSZ), generally deposited by electron beam-physical vapor deposition (EB-PVD). Due to the increasing demand for higher operating temperature in aero-derivative gas turbines, a lot of effort has been made to prevent the premature failure of columnar 7YSZ TBCs, which is induced by the microstructure degradation, sintering and spallation after the deposition of infiltrated siliceous mineral (consisting of calcium-magnesium-aluminum-silicate (CaO-MgO-Al2O3-SiO2, i.e., CMAS)). A new method called Al-modification for columnar 7YSZ TBCs against CMAS corrosion was present. The Al film was magnetron-sputtered on the surface of the columnar 7YSZ TBCs, followed by performing vacuum heat treatment of the Al-deposited TBCs. During the heat treatment, the molten Al reacted with ZrO2 to form α-Al2O3 overlay that effectively hindered CMAS infiltration. Moreover, the Al film could evaporate and re-nucleate, leading to the generation of Al2O3 nanowires, which further restrained the moving of molten CMAS.

Trans. Nonferrous Met. Soc. China 29(2019) 2362-2370

Xiao-feng ZHANG, Shao-peng NIU, Zi-qian DENG, Min LIU, Hong LI, Chun-ming DENG, Chang-guang DENG, Ke-song ZHOU

National Engineering Laboratory for Modern Materials Surface Engineering Technology,

Key Laboratory of Guangdong for Modern Surface Engineering Technology, Guangdong Institute of New Materials, Guangzhou 510650, China

Received 22 February 2019; accepted 16 October 2019

Abstract: The commonly-employed material for thermal barrier coatings (TBCs) is 7 wt.%Y2O3-ZrO2 (7YSZ), generally deposited by electron beam-physical vapor deposition (EB-PVD). Due to the increasing demand for higher operating temperature in aero-derivative gas turbines, a lot of effort has been made to prevent the premature failure of columnar 7YSZ TBCs, which is induced by the microstructure degradation, sintering and spallation after the deposition of infiltrated siliceous mineral (consisting of calcium-magnesium-aluminum-silicate (CaO-MgO-Al2O3-SiO2, i.e., CMAS)). A new method called Al-modification for columnar 7YSZ TBCs against CMAS corrosion was present. The Al film was magnetron-sputtered on the surface of the columnar 7YSZ TBCs, followed by performing vacuum heat treatment of the Al-deposited TBCs. During the heat treatment, the molten Al reacted with ZrO2 to form α-Al2O3 overlay that effectively hindered CMAS infiltration. Moreover, the Al film could evaporate and re-nucleate, leading to the generation of Al2O3 nanowires, which further restrained the moving of molten CMAS.

Key words: thermal barrier coating; CMAS corrosion; Al-modification; Al2O3 nanowires

1 Introduction

Modern gas turbines for energy and transportation particularly rely on thermal barrier coatings (TBCs) for improved efficiency and power [1,2]. Typically, the TBCs, made up of 7 wt.%Y2O3-ZrO2 (7YSZ), are commonly used as the insulation materials to improve the durability of engine components. Due to the porosity and low thermal conductivity, 7YSZ TBCs can provide excellent high-temperature insulation performance [3,4]. These TBCs are mainly produced by atmospheric plasma spraying (APS) [5], electron beam-physical vapor deposition (EB-PVD) [6] and plasma spray-physical vapor deposition (PS-PVD) [7,8]. EB-PVD is a method that has been widely adopted in industrial application because of its product showing high performance like good strain tolerance and excellent erosion resistance. However, siliceous minerals, including sand, runway debris, and volcanic ash (named CaO-MgO-Al2O3-SiO2 (CMAS)), will be deposited on the surface of hot component during working. This causes hot chemical corrosion on TBCs surface, eventually leading to the premature failure of TBCs [9-11].

Due to the severe negative effects of CMAS attack on the service life of 7YSZ TBCs, new composition or infrastructure designs of 7YSZ TBCs are demanded to increase their resistance to the CMAS infiltration. The most commonly adopted strategy, called infiltration mitigation, is to use a reactive material to induce partial or full crystallization of molten CMAS glass through chemical interaction, which seals the porous features of the coating and stops any further infiltration [11]. The already applied methods under this strategy include: doping of more resistant stabilizers in ceramic coating (such as Al2O3, TiO2) and rare earth oxides (such as CeO2, La2O3, Gd2O3) [12-14]; laser glazing and remelting of ceramic coating, providing a dense layer to prevent molten CMAS from penetrating into porous coating [14,15]; fabrication of a dense alumina overlay or dense Pt film on surface of ceramic coating [16,17].

A novel approach with lower cost, simpler operation as well as higher performance was presented in this work to protect 7YSZ TBCs from CMAS corrosion. An Al film was firstly deposited on the surface of EB-PVD 7YSZ coating by magnetron sputtering. Then, α-Al2O3 overlay was synthesized on the top of the columnar grains of the coating through in-situ reaction between Al and ZrO2 during vacuum heat treatment. This approach could help to decrease the size of the inter-columnar gap and slow down the oxidation rate of bond coating. Besides, this method improved the bending strength of single columnar grain and eventually enhanced the erosion resistance of the top coating. This method could offer a better CMAS corrosion resistance when each top 7YSZ column was coated with a homogenous α-Al2O3 overlay. Furthermore, during the vacuum heat treatment, Al2O3 nanowires were formed through evaporation and re-nucleation of the Al atoms, which could hinder the flow and infiltration of the molten CMAS too.

2 Experimental

Bond coating NiCoCrAlY and top coating 7YSZ were fabricated by EB-PVD sequentially on Ni-based superalloy, forming columnar 7YSZ TBCs. An Al film with a thickness of 5 μm was then deposited on the TBCs surface by magnetron sputtering. At the end, the Al-deposited TBCs underwent a vacuum heat treatment.

The (2 wt.% CaO2-21 wt.% MgO-17 wt.% Al2O3- 42 wt.% SiO2) corrosion performances of TBCs with and without Al-modification were investigated and compared. The CMAS powders were sprinkled on the surface of 7YSZ coating (0.2 g/cm2). Then, the samples were heated at 1200 °C for 24 h followed by air cooling. The microstructures and compositions of 7YSZ TBCs were characterized by field emission-scanning electron microscopy (FE-SEM, Nova-Nono430, FEI) equipped with energy dispersive spectroscopy (EDS, Oxford INCAx-sight 6427). The phase structures of TBCs were identified by X-ray diffraction (XRD, D8-Advance, Bruker). The surface microstructures of Al-modified TBCs before and after CMAS corrosion tests were characterized by transmission electron microscopy (TEM, Titan Themis 200, FEI) assisted with focused ion beam (FIB, 450S, FEI).

3 Results and discussion

3.1 New TBCs design

The 7YSZ TBCs prepared by EB-PVD have columnar structure. The columns are perpendicular to the substrate. Due to the different-sized gap among columns, the TBCs have good strain tolerance property. However, the 7YSZ coating will suffer CMAS corrosion when operating temperature is over the melting point of CMAS [18,19]. The inter-columnar gap would offer a direct pathway for inward diffusion of the molten CMAS from the external environment at such high temperature, resulting in loss of strain tolerance and decrease of thermal insulation of the TBCs [20]. In addition, the dissolution/re-precipitation activities between CMAS and 7YSZ coating can lead to the transformation of yttria-stabilized ZrO2 into yttria-depleted ZrO2, generating micro-crack in TBCs [10,19,21]. Therefore, to avoid the inward diffusion of molten CMAS along the columnar gaps is critical to improve the CMAS corrosion resistance of the 7YSZ coating.

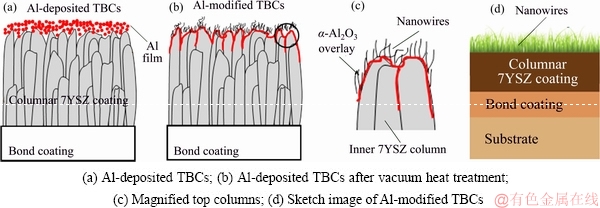

The novel TBCs design, namely Al-modification on the surface of 7YSZ TBCs, as shown in Fig. 1(a), was proposed herein to solve the above-mentioned problem. The surface of the columnar 7YSZ coating was covered by Al film with an appropriate thickness, determined by the thickness and porosity of 7YSZ coating. Subsequently, the Al-deposited TBCs were heat-treated under vacuum, during which the Al film melted and infiltrated into porous ceramic coating along the inter-columnar gaps. An in-situ reaction then occurred at the interface of molten Al and ZrO2 columns, forming α-Al2O3 phase [22-24] based on chemical equation:

13Al+3ZrO2—2α-Al2O3+3Al3Zr (1)

As a result, the top of each 7YSZ column was coated with an α-Al2O3 dense overlay, as illustrated in Fig. 1(b). In this case, the inter-columnar gap decreased, and some small gaps were even bridged by the α-Al2O3 layer. It is reported that this has no significant negative influence on strain tolerance [10].

To further hinder the CMAS from infiltrating into columnar TBCs, Al2O3 nanowires are expected to grow on the surface of Al-modified TBCs, as shown in Figs. 1(c, d). Nanowires have the structure with at least one of their dimensions in the range of 1-100 nm, as a typical example, several microns long with a diameter less than 100 nm. The nanowires can be synthesized by the basic vapor-phase technique [25,26]. When the reactor is heated under vacuum, the source vapors inter-react and grow to nanowires. They deposit onto the catalyst supported synthesis in the vapor-phase method for the following reasons: (1) the substrate supports the catalyst clusters and allows control of cluster temperature; (2) the substrate induces preferential precipitation at substrate-catalyst cluster interface. Therefore, the use of substrate is essential for maintaining 1-D growth in captor-phase precursors typically.

3.2 Al-modified 7YSZ TBCs

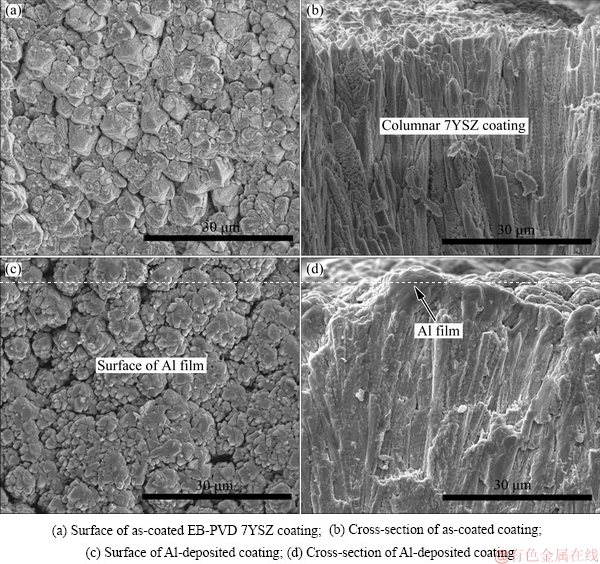

As is well-known, typical columnar structure with different-sized gaps exists in as-coated EB-PVD 7YSZ (Figs. 2(a, b)). Figures 2(c, d) show that the EB-PVD 7YSZ TBCs were covered by Al film through magnetron sputtering. Island-like Al film was deposited on the surface of 7YSZ coating, as seen in Fig. 2(c), and a strong bond between the film and the 7YSZ coating supposedly existed according to the compact contacting interface between Al layer and columns, as seen from cross-sectional microstructure presented in Fig. 2(d). These observations prove the effectiveness of the above- proposed TBCs design.

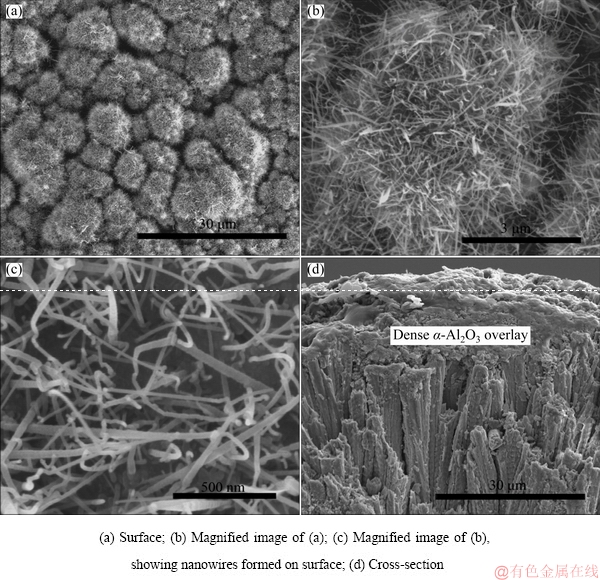

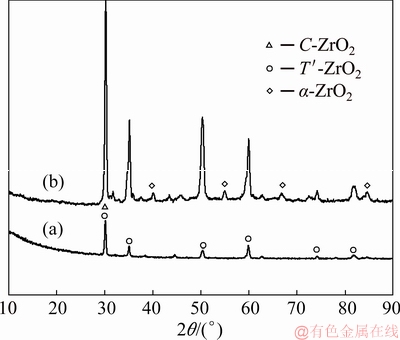

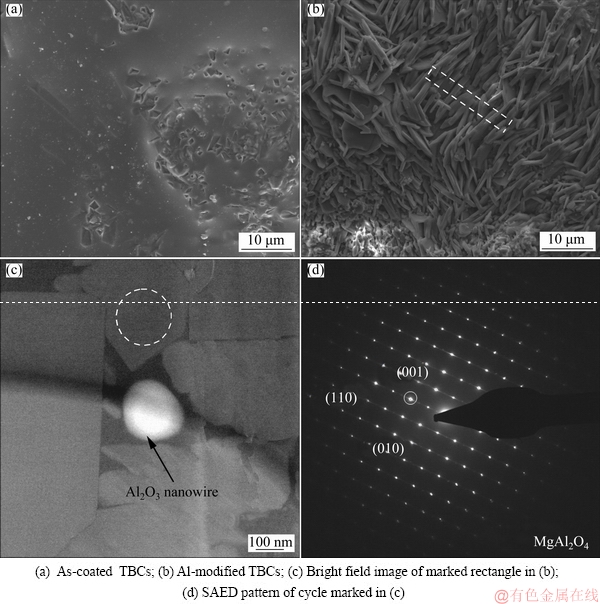

After vacuum heat treatment, the Al-deposited 7YSZ TBCs were transformed into Al-modified 7YSZ TBCs, whose microstructure is depicted in Fig. 3. It can be seen from Figs. 3(a-c) that a lot of nanowires grew on the island-like surface. A dense overlay was formed on columnar 7YSZ TBCs and just below the loose layer of nanowires, as shown in Fig. 3(d). Both the overlay and the nanowire were composed of α-Al2O3 according to the XRD phase analysis, as represented in Fig. 4, and the TEM analysis. Their formation processes can be explained as follows. During the heat treatment, the molten Al firstly infiltrated into inner 7YSZ TBCs along the inter-gap among columns to form a dense overlay [10], and parts of molten Al film simultaneously evaporated and recrystallized to generate nanowires. Then, the Al overlay and nanowires could react with ZrO2 to produce α-Al2O3 at this temperature according to Refs. [21,22].

Fig. 1 Design diagram of Al-modified EB-PVD TBCs

Fig. 2 SEM images of as-coated EB-PVD 7YSZ coating with deposition of Al film

Fig. 3 SEM images of Al-modified EB-PVD 7YSZ coating

Fig. 4 XRD patterns of as-coated EB-PVD 7YSZ TBCs (a) and Al-modified EB-PVD 7YSZ TBCs (b)

3.3 TEM characterization of nanowires

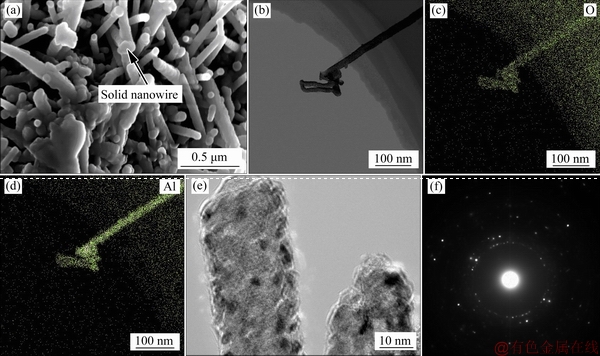

The nanowire samples from the Al-modified TBCs for TEM analysis were prepared by ultrasonic treatment. The nanowires are of solid construction, confirmed through the cross-section view of the broken nanowires in Fig. 5(a). The elemental mappings of the broken wire (Fig. 5(b)) are shown in Figs. 5(c, d). The high revolution-TEM (HRTEM) image (Fig. 5(e)) and the selected-area electron diffraction (SAED) pattern (Fig. 5(f)) both indicated that the nanowire had polycrystalline microstructure, and no crystal growth orientation took place.

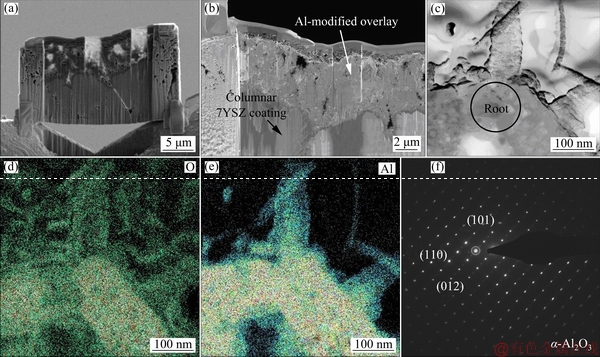

The thickness of the Al-modified overlay was ascertained as around 5 μm based on the images of the sample machined by focus ion beam (FIB), as seen in Figs. 6(a, b). As shown in Fig. 6(c), many roots of nanowires were observed on the surface of the overlay. The element mappings of the overlay (Figs. 6(d, e)) and the SAED pattern of the marked root (Fig. 6(f)) demonstrated the formation of α-Al2O3 phase in both the overlay and the nanowire.

3.4 Growth mechanism of nanowire

In this new design of TBCs, the Al2O3 nanowires play an important role in the improvement of CMAS corrosion resistance. As stated above, the Al2O3 nanowires were synthesized by thermal evaporation of Al film during vacuum heat treatment based on the vapor-solid (VS) mechanism.

Fig. 5 TEM image of Al-modified TBCs after ultrasonic process (a), bright field image of nanowire (b), corresponding EDS of nanowire in (b) regarding O (c) and Al (d), HRTEM image (e) of nanowire tip in (b), and SAED pattern (f) of nanowire in (e)

Fig. 6 Slice sample milled by FIB for TEM analysis (a), bright field image of top columnar YSZ coating (b), bright field of nanowire root (c), corresponding EDS mappings in (c) regarding O (d) and Al (e) correspondingly, and SAED pattern of root in (c) showing α-Al2O3 phase (f)

The VS growth of one-dimensional (1-D) materials consists of the following four typical sequential steps (seen in Figs. 7(a-d)) [27,28]: (1) Al film melts and infiltrates into columnar 7YSZ coating, accompanied with Al evaporation, when the temperature is above the Al melting point; (2) The molten Al reacts with ZrO2 in the way that vapor Al atoms combine with O to form Al2O3 unit cells, leading to the supersaturation of the Al2O3 nucleus over the time; (3) α-Al2O3 crystal grows; (4) Nanowires grow through stacking of Al2O3 unit cells based on the lowest energy principle.

Fig. 7 Schematic diagrams of nanowire nucleation and growth mechanism during vacuum heat treatment

The growth of the nanowire in this work shares the same mechanism as VS growth of one-dimensional (1-D) materials as presented above. The basic process could be illustrated in detail as follows (see Fig. 7(e)): (1) Evaporated Al atoms combined with O to form Al2O3 unit cells during the heat treatment; (2) Al2O3 unit cells dissociated and adsorbed at the surface of Al-modified TBCs; (3) The adsorbed Al2O3 unit cells diffused toward the vapor/solid interface; (4) The adsorbed Al2O3 unit cells in the nucleus of α-Al2O3 crystal diffused toward solid/solid interface (bulk diffusion); (5) New Al2O3 unit cells appeared through the merge of the solid-solid interfaces of Al2O3 unit cells; (6) The adsorption and desorption processes of Al2O3 unit cells occurred on the nanowire; (7) Elements diffused from the substrate to the nanowire; (8) Elements distribution took place in the vapor phase (direct impingement on nucleus) due to the proximity of other competing growth processes; (9) Distribution of molecule flux due to the proximity of other competing growth processes [28].

During the growth of Al2O3 nanowires, the formation of nucleus could be explained by the minimization of its free energy. The difference in chemical potential (μ) between a curved surface (radius, r) and planar surface (radius, r=∞) can be obtained by Gibbs-Thompson equation:

(2)

(2)

where γ is the surface energy of the nucleus and Ω is the molar volume of the species within the nuclei.

The above equation can be used to describe the critical diameter of pure phase nucleus and the vapor-solid equilibrium differences for nucleus. Assuming the same reference state for gas-phase species, one can express the chemical potential of gas-phase species in terms of partial pressures. At equilibrium, the chemical potentials are given by

μ1=μg (For nucleus) (3)

(For planar surface) (4)

(For planar surface) (4)

Subtracting Eq. (3) from Eq. (2) results in

(5)

(5)

where p/p∞ represents the vapor-phase supersaturation within the gas phase, K is the Boltzmann constant and T is the temperature.

Based on Eqs. (2) and (4), the concentration (partial pressure, p) of the gas phase in equilibrium with a nucleus of known size is given as

(6)

(6)

Equation (6) shows that partial pressure of the species with a nucleus radius of r in equilibrium has to be larger than that with a planar surface. The partial pressure of gas-phase solutes in equilibrium with the nucleus radius, r, and pressure, p can be presented as follows:

pr=p∞exp(zγΩ/rkT) (7)

where p∞ is the equilibrium partial pressure of the gas-phase solutes with a planar surface.

According to the above equations, the critical nucleation radius for pure phase condensation (nucleus from in situ synthesis of Al and ZrO2, can be calculated as follows:

(8)

(8)

where rc is the critical size of nucleus. Supersaturation, in this case, can be realized by changing the partial pressure, p, which means that the size of Al2O3 wire depends on heat treatment pressure.

3.5 CMAS corrosion characterization

The cross-sectional morphologies of the samples (for as-coated and Al-modified EB-PVD 7YSZ TBCs) after CMAS corrosion resistance tests were characterized, as shown in Fig. 8. The amount of Si in Al-modified TBCs is less than that of as-coated TBCs according to Figs. 8(b, d). This is attributed to the formation of an Al2O3 overlay on the surface of Al-modified TBCs (Fig. 8(c)) compared with as-coated TBCs (Fig. 8(a)). Besides, a dense overlay (Fig. 6(b)) hindered the molten CMAS from infiltrating into TBCs along the gap among columns. On the contrary, this hindering effect did not exist in as-coated TBCs. The infiltrated CMAS reacted with the 7YSZ columns, significantly decreasing the toughness of top coating [29,30]. This is the reason for the occurrence of spallation (brittle fracture) in as-coated TBCs, as seen in Fig. 8(a).

There are two positive effects for EB-PVD TBCs against CMAS corrosion. Firstly, Al2O3 nanowires can hinder the movement of CMAS during the high temperature operation. Secondly, due to the high activity of Al2O3 nanowires, they can react with CMAS quickly. Figure 9(a) shows the surface morphology of the as-coated 7YSZ TBCs after CMAS corrosion test at 1200 °C for 24 h. The surface looks smooth, which could be due to the formation of CMAS glass. However, many sheet-like phases are observed on the surface of the Al-modified TBCs, as shown in Fig. 9(b), and Al2O3 nanowires are surrounded by many corrosion-generated phases (Fig. 9(c)). The round area marked in Fig. 9(c) is refractory MgAl2O4 phase based on SAED analysis result (Fig. 9(d)). This phase was formed through chemical interaction between Al2O3 nanowires and CMAS, and it is highly resistant to corrosion [31,32]. Thus, Al2O3 nanowires can act as a barrier to prevent from molten CMAS penetration for TBCs.

4 Conclusions

(1) Al2O3 nanowires were generated on the surface of Al-modified TBCs due to the thermal evaporation and re-nucleation of the Al film based on the vapor-solid (VS) mechanism.

(2) The Al-modified 7YSZ TBCs had a better CMAS resistance than the as-coated TBCs. This was attributed to the formation of the α-Al2O3 overlay, hindering the molten CMAS infiltrating into the EB-PVD TBCs along the inter-gap among columns.

Fig. 8 Cross-sectional images of EB-PVD 7YSZ TBCs after CMAS corrosion test at 1200 °C for 24 h

Fig. 9 Surface morphologies of EB-PVD 7YSZ TBCs after CMAS corrosion test at 1200 °C for 24 h

(3) Al2O3 nanowires grown on the surface of Al-modified TBCs could restrain the moving of molten CMAS. The generation of refractory MgAl2O4 phase, induced by Al2O3 nanowires, could further hinder the CMAS infiltration. Moreover, the application of this approach is not confined to the EB-PVD TBCs, but can be popularized in APS and PS-PVD TBCs too.

References

[1] SAHITH M S, GIRIDHARA G, KUMAR R S. Development and analysis of thermal barrier coatings on gas turbine blades—A Review [J]. Mater Today: Proceedings, 2018, 5: 2746-2751.

[2] RHYS-JONES T N. Coatings for blade and vane applications in gas turbines [J]. Corrosion Sci, 1989, 29: 623-646.

[3] ZHANG W W, LI G R, ZHANG Q, YANG G J. Multiscale pores in TBCs for lower thermal conductivity [J]. J Therm Spray Technol, 2017, 26: 1183-1197.

[4] CHEN L, YANG G J. Epitaxial growth and cracking of highly tough 7YSZ splats by thermal spray technology [J]. J Advanced Ceram, 2018, 7: 17-29.

[5] HUA Y, CAI C Y, WANG Y G, YU H C, ZHOU Y C, ZHOU G W. YSZ/NiCrAlY interface oxidation of APS thermal barrier coatings [J]. Corros Sci, 2018, 142: 22-30.

[6] GUO H B, GONG S K, KHOR K A, XU H B. Effect of thermal exposure on the microstructure and properties of EB-PVD gradient thermal barrier coatings [J]. Surf Coat Technol, 2003, 168: 23-29.

[7] ZHANG X F, ZHOU K S, DENG C M, LIU M, DENG Z Q, DENG C G, SONG J B. Gas-deposition mechanisms of 7YSZ coating based on plasma spray-physical vapor deposition [J]. J Eur Ceram Soc, 2016, 36: 697-703.

[8] DENG Z Q, ZHANG X F, ZHOU K S, LIU M, DENG C M, MAO J, CHEN Z K. 7YSZ coating prepared by PS-PVD based on heterogeneous nucleation [J]. Chinese J Aeronautics, 2018, 31: 820-825.

[9] PENG H, WANG L, GUO L, MIAO W H, GUO H B, GONG S K. Degradation of EB-PVD thermal barrier coatings caused by CMAS deposits [J]. Progress in Natural Science: Mater Int, 2012, 22: 461-467.

[10] ZHANG X F, ZHOU K S, LIU M, DENG C M, DENG C G, SONG J B, TONG X. Enhanced properties of Al-modified EB-PVD 7YSZ thermal barrier coatings [J]. Ceram Int, 2016, 42: 13969-13975.

[11] NARAPARAJU R, PUBBYSETTY R P, MECHNICH P, SCHULZ U. EB-PVD alumina (Al2O3) as a top coat on 7YSZ TBCs against CMAS/VA infiltration: Deposition and reaction mechanisms [J]. J Eur Ceram Soc, 2018, 38: 3333-3346.

[12] DREXLER J M, GLEDHILL A D, SHINODA K, VASILIEV A L, REDDY K, SAMPATH M S, PADTURE N P. Jet engine coatings for resisting volcanic ash damage [J]. Adv Mater, 2011, 23: 2388-2388.

[13] RAMASWAMY P, SEETHARAMU S, VARMA K B R, RAO K J. Al2O3-ZrO2 composite coatings for thermal barrier coatings [J]. Composites Sci Technol, 1997, 57: 81-89.

[14] VOURDAS N, MARATHONITI E, PANDIS P K, ARGIRUSIS C, SOURKOUNI G, LEGROS C, MIRZA S, STATHOPOULOS V N. Evaluation of LaAlO3 as top coat material for thermal barrier coatings [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 1582-1592.

[15] GHASEMI R, SHOJA-RAZAVI R, MOZAFARINIA R, JAMALI H, HAJIZADEH-OGHAZ M, AHMADI-PIDANI R. The influence of laser treatment on hot corrosion behavior of plasma-sprayed nanostructured yttria: Protectiveness of stabilized zirconia thermal barrier coatings [J]. J Eur Ceram Soc, 2014, 34: 2013-2021.

[16] MORKS M F, BERNDT C C, DURANDET Y, BRAND M, WANG J. Microscopic observation of laser glazed yttria-stabilized zirconia coatings [J]. Applied Surf Sci, 2010, 56: 6213-6218.

[17] WANG L, GUO, LI Z H, PENG H, MA Y, GONG S K, GUO H B. Protectiveness of Pt and Gd2Zr2O7 layers on EB-PVD YSZ thermal barrier coatings against calcium–magnesium–alumina–silicate (CMAS) attack [J]. Ceram Int, 2015, 41: 11662-11669.

[18] CHEN Z, WU N Q, SINGH J, MAO S X. Effect of Al2O3 overlay on hot-corrosion behavior of yttria-stabilized zirconia coating in molten sulfate-vanadate salt [J]. Thin Solid Films,2003, 443: 46-52.

[19] AHLBORG N L, ZHU D M. Calcium-magnesium-alumino-silicate (CMAS) reactions and degradation mechanisms of advanced environmental barrier coatings [J]. Surf Coat Technol, 2013, 237: 79-87.

[20] CHEN X. Calcium–magnesium–alumina–silicate (CMAS) delamination mechanisms in EB-PVD thermal barrier coatings [J]. Surf Coat Technol, 2006, 200: 3418-3427.

[21] CRAIG M, NDAMK N L, WELLMAN R G, NICHOLLS J R. CMAS degradation of EB-PVD TBCs: The effect of basicity [J]. Surf Coat Technol, 2015, 270: 145-153.

[22] KAVEENDRAN B, WANG G S, HUANG L J. In situ (Al3Zr, Al2O3) metal matrix composite with novel reinforcement distributions fabricated by reaction hot pressing [J]. J Alloys Compd, 2013, 581: 16-22.

[23] ZHU H G, YAO Y Q, LI J L, CHEN S, ZHAO J, WANG H Z. Study on the reaction mechanism and mechanical properties of aluminum matrix composites fabricated in an Al-ZrO2-B system [J]. Mater Chem Phys, 2011, 127: 179-184.

[24] ZHANG X F, ZHOU K S, XU W, CHEN B Y, SONG J B, LIU M. In situ synthesis of α-alumina layer at top yttrium-stabilized zirconia thermal barrier coatings for oxygen barrier [J]. Ceram Int, 2014, 40: 12703-12708.

[25] ZHANG X F, ZHOU K S, XU W, CHEN B Y, SONG J B, LIU M. In situ synthesis of alumina layer on thermal barrier coating for protection against CMAS (CaO-MgO-Al2O3-SiO2) corrosion [J]. Surf Coat Technol, 2015, 261: 54-59.

[26] BOSTANI B, PARVINI AHMADI N, YAZDANI S, ARGHAVANINA R. Co-electrodeposition and properties evaculation of functionally gradient nickel coated ZrO2 composite coating [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 66-76.

[27] DARIANI R S, QALEH Z N. Microstructure characterization of TiO2 nanowires fabricated by thermal evaporation process [J]. Thin Solid Films, 2013, 542: 192-198.

[28] MEYYAPPAN M, MAHENDRA K S. Inorganic nanowires applications, properties, and characterization [M]. CRC Press, Taylor & Francis Group, 2009.

[29] NARAPARAJU R, CHAVEZ J J G, SCHULZ U, RAMANA C V. Interaction and infiltration behavior of Eyjafjallajokull, Sakurajima volcanic ashes and a synthetic CMAS containing FeO with/in EB-PVD ZrO2-65wt%Y2O3 coating at high temperature [J]. Acta Mater, 2017, 136: 164-180.

[30] ZHENG H, CHEN Z, LI G, SHU X, PENG P. High temperature corrosion mechanism YSZ coatings subject to calcium-magnesium- aluminosilicate (CMAS) deposites: First-principles calculations [J]. Corros Sci, 2017, 126: 286-294.

[31] DREXLER J M, ORTIZ A L, PADTURE N P. Composition effects of thermal barrier coating ceramics on their interaction with molten Ca-Mg-Al-silicate (CMAS) glass [J]. Acta Mater, 2012, 60: 5437-5447.

[32] SHAN X, ZOU Z H, GU L J, YANG L X, GUO F W, ZHAO X F, XIAO P. Buckling failure in air-played thermal barrier coatings induced by molten silicate attack [J]. Scripta Mater, 2016, 113: 71-74.

张小锋,牛少鹏,邓子谦,刘 敏,李 洪,邓春明,邓畅光,周克崧

广东省新材料研究所 现代材料表面工程技术国家工程实验室,

广东省现代表面工程技术重点实验室,广州 510650

摘 要:7YSZ (7wt.%Y2O3-ZrO2) 作为热障涂层使用最广的材料,其主要制备方法包括电子束-物理气相沉积(EB-PVD)。随着涡轮前进口温度的逐步提高,CMAS (CaO-MgO-Al2O3-SiO2) 熔盐腐蚀等因素逐渐成为影响柱状结构EB-PVD 7YSZ热障涂层服役寿命的关键因素。本文作者提出一种镀铝表面改性技术,即在柱状涂层表面采用磁控溅射技术制备一层Al膜,然后施加真空热处理工艺。一方面,Al和7YSZ涂层发生原位反应形成α-Al2O3 层,抑制CMAS熔盐高温渗透;另一方面,在真空热处理过程中Al膜在高温下发生蒸发和形核,最终在7YSZ热障涂层表面形成氧化铝纳米线,抑制高温下熔融CMAS流动。

关键词:热障涂层;CMAS腐蚀;铝改性;氧化铝纳米线

(Edited by Bing YANG)

Foundation item: Project (2017YFB0306100) supported by the National Key Research & Development Plan of China; Projects (51801034, 51771059) supported by the National Natural Science Foundation of China; Projects (2018GDASCX-0949, 2018GDASCX-0950, 2017GDASCX-0111) supported by the Guangdong Academy of Sciences, China; Projects (2017B090916002, 2017A070701027) supported by the Guangdong Technical Research Program, China; Projects (2016A030312015, 2017A030310315) supported by the Natural Science Foundation of Guangdong Province, China; Projects (201605131008557, 201707010385) supported by the Technical Research Program of Guangzhou City, China

Corresponding author: Xiao-feng ZHANG, E-mail: zxf200808@126.com; Shao-peng NIU, Tel: +86-20-37238263, Fax: +86-20-37238531, E-mail:

niushaopeng@gdinm.com

DOI: 10.1016/S1003-6326(19)65142-3