文章编号:1004-0609(2007)08-1291-06

流动温压成形W70Cu异形件

曹顺华,谢 湛,蔡志勇,李春香,邹仕民

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:尝试采用含量较高的粘结剂利用流动温压成形结合熔渗制备W70Cu杯状异形件。通过改变钨骨架中Cu粉类型(包括雾化Cu粉,电解Cu粉和超细Cu粉)、粘结剂添加量和成形温度,考察不同工艺参数对杯状试样的密度分布影响,以获得流动温压成形异形钨骨架的最佳工艺。结果表明:添加体积分数35%的粘结剂时提高压制温度会明显改善钨骨架孔隙度分布的均匀性;同时,由于不同Cu粉具有不同的表面形貌及粒度,对于钨骨架的孔隙度分布均匀性也有较大的影响。压制温度55 ℃时添加表面光滑形状规则的超细Cu粉和35%(体积分数)粘结剂的混合粉末成形的钨骨架的孔隙分布最均匀, 该骨架在1 200 ℃熔渗30 min后,密度分布均匀,整体密度达到14.2 g/cm3(相对密度为99.0%)。

关键词:W70Cu;流动温压成形;形状复杂零件;熔渗

中图分类号:TF 125 文献标识码:A

W70Cu part with complex shape manufacture by warm flow compaction

CAO Shun-hua, XIE Zhan, CAI Zhi-yong, LI Chun-xiang, ZOU Shi-min

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: W70Cu materials with a complex “cup” shape manufactured by a novel process (warm flow compaction+ sintering filtration) were studied systematically. The effects of the type of copper powder (atomization copper powder, electrolytic copper powder and ultra-fine grained copper powder), content of binder, and pressing temperature on porosity distribution were investigated. The results show that the complex W-skeleton with a homogeneous porosity distribution can be obtained with 35% binder addition and fairly high temperature for compaction. Meanwhile, different types of copper powders with different particle sizes and surface morphologies greatly affect the porosity distribution of the complex W-skeleton. The W-skeleton with a homogeneous porosity distribution can be obtained at 55 ℃, as the ultra-fine copper powder with slick and regular surface is used as a copper source and 35% binder is dispersed in the powder composite. As a result, a homogeneous density distribution and a general density of 14.2 g/cm3 (relative density 99.0%) can be achieved by infiltrating at 1 200 ℃ for 30 min.

Key words: W70Cu; warm flow compaction; complex shape part; infiltration

W/Cu复合材料兼有W和Cu 的优点,即具有高的密度、良好的导热性和导电性、小的热膨胀系数,被广泛用于强电弧烧损或强耐热环境中[1?5] 。目前,通常采用混合粉液相烧结法[4]和熔渗技术[6?7]制备W/Cu复合材料。前者由于W、Cu之间的不互溶性,很难制备出高致密复合材料。而后者则能得到高致密度的铜钨复合材料。制备工艺是否合理直接影响铜钨合金的组织[7],进而影响铜钨合金的导电性、硬度、强度等性能[8?11]。

制备孔隙分布均匀的异形钨骨架,一直是熔渗制备W-Cu复合材料的难题。2001年德国Fraunhofer研究所开发了流动温压技术,用以制备具有复杂形状的粉末冶金零件[12?16]。该工艺是在温压工艺基础上结合金属注射成形工艺的优点而发展起来的,以不锈钢粉为例,将粗粉(粒度为150 μm 左右)和一定比例(10%~20%)的细粉(粒度为<22 μm)以及热塑性润滑剂进行混合,经温压工艺制造形状复杂的粉末冶金件。其关键技术是提高粉末在压力作用下的流动性。该工艺制品具有性能均一、高密度、低成本等特点[12?13] 。利用该工艺可成形形状非常复杂的零件,如垂直于压制方向上的凹槽、孔以及螺纹孔等。

本文作者试图利用流动温压成形复杂形状的钨骨架,结合熔渗技术能制备高密度钨铜异形件。

1 实验

实验原料有W粉(粒度3 μm),雾化Cu粉(粒度74 μm),电解Cu粉(粒度43 μm),超细Cu粉(粒度13 μm)。骨架中添加2.5%(质量分数)Cu粉,为提高熔渗性能添加0.3%(质量分数)Ni粉,粉末按球料比(质量比)1?2干混6 h。实验设计30%和35%(体积分数)两种粘结剂的添加量,混合粉末在一定温度下混炼2 h后制粒,压制成d 18 mm的圆柱形预成形坯。将预成形坯加热到压制温度(45~90 ℃)后,在63.6 MPa的压力下压制成杯状试样,如图1所示。

钨骨架坯件在H2气氛预烧结。以3 ℃/min的速度升温至960 ℃,烧结30 min。

利用线切割将烧结坯沿轴向切下一个条样,如图2所示。制样后利用leica MEF3A型金相显微镜对试样进行面孔隙度分析。将试样逆流动方向等距取17个观测点。分析这17个点的面孔隙度,得出试样轴向的孔隙分布规律。

图1 流动温压成形钨骨架形状

Fig.1 Shape of tungsten skeleton by warm flow compaction (nm)

图2 金相观测点编号示意图

Fig.2 Sketch of points studied by optics microscope

随后钨骨架与Cu在1 200 ℃下进行熔渗,熔渗时间为30 min。制备W70Cu材料。将熔渗后的样品沿径向切割成9个部分,如图3所示。利用排水法测得各部分密度。

图3 熔渗后切割测试密度编号示意图

Fig.3 Sketch of density of different parts for test after infiltrating

2 结果与讨论

2.1 压制温度对钨骨架孔隙度分布的影响

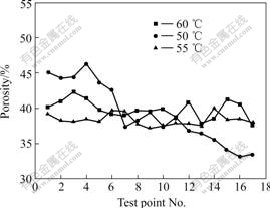

图4所示为添加电解Cu粉,粘结剂添加量为35%(体积分数)的混合粉末,在55、60和65℃时所成形的骨架960 ℃烧结后孔隙度的变化。从图4可知,55和60 ℃成形的骨架孔隙度曲线变化都较平滑,孔隙分布均匀。而50 ℃曲线变化较大,测试点1的孔隙度偏大是由于压制温度较低,导致混合粉末流动性能不佳,混合粉末无法完整填充模腔,致使压坯在杯口(测试点1)附近残留有宏观孔隙。而在杯底位置(测试点17),粉末无法流动,在压力作用下被压实,导致测试点17的孔隙度较小。

图4 添加电解铜粉钨骨架孔隙度的分布

Fig.4 Porosity distribution of tungsten skeleton by adding electrolytic copper powder and 35% binder

由于粉末颗粒的流动性能有限,混合粉末的流动行为的变化主要随粘结剂的流变行为而变化。Cross-Arrhenius粘度模型可以解释在不同温度下,粘结剂的粘度变化规律。Cross粘度模型中聚合物粘度为温度、剪切速率的函数,并考虑了压力对粘度的影响。

Cross-Arrhenius粘度模型[17]:

根据Cross-Arrhenius粘度模型,在压力一定的条件下,τ*和剪切速率γ&为常数,即粘度为温度的函数。由于η0与Tb/T呈指数关系,当T减小时,η0急剧增大,代入式(1)后导致流动指数η增大。所以当温度过低时,粘结剂的流动性能下降,导致混合粉末流动性能不佳,成形的试样孔隙度分布不均匀,孔隙度曲线变化较大。

2.2 粘结剂含量对钨骨架孔隙度分布的影响

图5所示为添加30%和35%(体积分数)粘结剂、雾化Cu粉的混合粉末在55 ℃压制、960 ℃烧结后试样不同观测点的孔隙率。可以看出,添加35%粘结剂的混合粉末在55 ℃压制烧结后得到的试样孔隙度曲线变化平缓,孔隙度偏差在2%以内,可知试样在流动方向上孔隙度分布较均匀。而当粘结剂添加量下降到30%后,试样各观测点孔隙度偏差较大,在杯口位置,即观测点1处孔隙度较大。而在杯底位置,即观测点17处孔隙度最小,孔隙度偏差达到7%。这主要是由于粘结剂添加量较小,混合粉末的粘度较大,在较低温度下流动性能不佳,造成流动方向上孔隙度有增大趋势。

图5 添加雾化铜粉钨骨架孔隙度的分布

Fig.5 Porosity distribution of tungsten skeleton by adding atomization copper powder

由Einstein粘度定律进行定性分析:

由式(2)可以看出,在粘结剂含量升高以后,粉末所占的体积减小,即φ变小,ηγ也相应减小。温度一定时,粘结剂的粘度是一定的,则混合粉末这个分散系的粘度也随着ηγ减小而减小。所以粘结剂含量较高的混合粉末的粘度较小,在较低温度下即可表现出较好的流动性能,能成形孔隙度小和孔隙分布均匀的压坯。

增加粘结剂添加量还有利于在粉末颗粒表面形成完整的润滑膜,在压制过程中,减小颗粒与颗粒之间、颗粒与模壁之间的摩擦力,使试样密度分布均匀。

2.3 原料粉末对钨骨架成形性的影响

不同Cu粉形貌如图6所示。可以看出,电解Cu粉形貌为树枝状而一次颗粒粒径细小,雾化Cu、超细Cu粉则为表面光滑的多面体,总体而言,超细Cu粉的二次颗粒粒径要比电解Cu粉细很多。

图6 Cu粉的SEM形貌

Fig.6 SEM morphologies of different kinds of copper powders:

(a) Electrolytic copper powder; (b) Atomization copper powder; (c) Ultra-fine grained copper powder

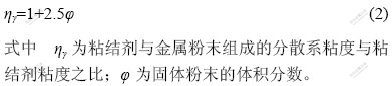

图7所示为添加35%(体积分数)粘结剂,在55 ℃压制960 ℃预烧时,添加不同类型Cu粉的骨架烧结后孔隙度的分布。可以发现,骨架中添加雾化Cu粉的试样孔隙度分布曲线最平缓,但孔隙度略高;添加电解粉和超细粉末的试样孔隙沿压制方向虽有小幅变化,但整体孔隙分布也较为均一且孔隙度略低;这说明添加35%粘结剂在流动成形3种类型粉末形成密度较为均匀的骨架时还是比较合适的。在含电解Cu粉和超细Cu粉的预烧骨架中,孔隙度分布曲线出现轻微扰动的可能原因主要是粉末和粘结剂混料时没有达到理想的均匀程度所致。虽然电解Cu粉的一次颗粒粒径大且形状不规则,在压制力作用下细粒径的一次粉末颗粒将从“团聚”体中部分分离出来,同超细粉一样,拥有比较高的表面积,这赋予了粉末?粘结剂体系比较高的粉末流动性,其结果是压制成型后的骨架孔隙度较小(大约为40%);而雾化粉压制得到的骨架孔隙度较高(大约为45%)。3种骨架的显微组织如图8所示。由图可以看出,添加超细Cu粉时,骨架组织均匀,晶粒细小,不存在Cu或W富积的区域。这种组织形貌的钨骨架有利于熔渗。

图7 粘结剂添加量为35.%,添加不同类型Cu粉在55 ℃成形骨架的孔隙度分布

Fig.7 Porosity distribution of tungsten skeleton shaped at 55 ℃ by adding different copper powders and 35% binder

图8 粘结剂添加量为35%,添加不同类型Cu粉在55 ℃成形钨骨架的显微组织

Fig.8 Microstructures of tungsten skeleton shaped at 55 ℃ by adding different copper powders and 35% binder:

(a) Tungsten/atomization copper powder; (b) Tungsten/electrolytic copper powder; (c) Tungsten/ultra-fine grained copper powder

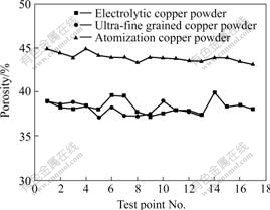

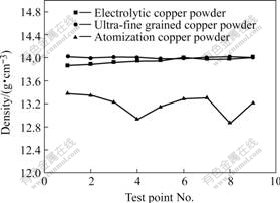

2.4 原料粉末对于熔渗后样品密度分布的影响

对利用最佳条件下制备的钨骨架进行熔渗。熔渗后,不同原料粉末样品密度分布如图9所示。可以看出,钨骨架中添加超细Cu粉时,熔渗后样品各部分密度较为均匀。而添加雾化Cu粉的钨骨架在熔渗后,样品不同测试位置的密度相差较大,且整体密度偏低。出现这种现象的主要原因是由于雾化Cu杂质含量较高,降低熔渗时熔渗剂Cu对于钨颗粒表面的润湿性,导致熔渗后样品密度分布不均匀,表面质量较差;同时,预烧骨架的孔隙度偏高也是造成熔渗密度偏低的原因。

图10所示为添加不同Cu粉的钨骨架在熔渗后的金相照片。可以看出,添加超细Cu粉和电解Cu粉的样品金相组织都较为细小且分布均匀;而添加雾化Cu粉的样品出现了大量孔洞。

图9 添加不同类型Cu粉的骨架熔渗后样品的密度分布

Fig.9 Density distribution of tungsten skeleton after infiltrating by adding different copper powders

图10 添加不同Cu粉的钨骨架熔渗后样品的显微组织

Fig.10 Microstructures of tungsten skeleton with different copper powders: (a) Tungsten/ultra-fine grained copper powder;

(b) Tungsten/electrolytic copper powder; (c) Tungsten/ atomization copper powder

3 结论

1) 超细铜粉和电解铜粉由于具有微细的一次颗粒组成,其粉末-粘结剂系统拥有较高的粉末流动性,成形的骨架在密度分布均匀性方面均高于雾化铜粉为原料的体系,骨架经熔渗后显微组织均匀且无孔洞出现;相对而言,超细铜粉的效果略高于电解铜粉;而含雾化铜粉的体系所得的骨架密度较低,烧结密度分布不均匀,显微组织中存在空洞。

2) 压制时较理想的成形工艺为:粘结剂添加量为35%(体积分数),成形骨架的温度为55~60 ℃。

REFERENCES

[1] 曹顺华, 林信平, 李炯义. 纳米晶W-Cu复合粉末烧结行为[J]. 中国有色金属学报, 2005, 15(2): 248?255.

CAO Shun-hua, LIN Xin-ping, LI Jiong-yi. Sintering behavior of nanograined W-Cu composite powder[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 248?255.

[2] 黄伯云, 范景莲. 纳米钨合金材料的研究与应用[J]. 中国钨业, 2001, 15(6): 38?44.

HUANG Bai-yun, FAN Jing-lian. Research and application of nano-tungsten material[J]. China Tungsten Industry, 2001, 15(6): 38?44.

[3] 陶应启, 王祖平. 钨铜复合材料的制造工艺[J]. 粉末冶金技术, 2002, 20(1): 49?51.

TAO Ying-qi, WANG Zu-ping. Manufacture methods of tungsten-copper composites[J]. Powder Metallurgy Technology, 2002, 20(1): 49?51.

[4] Kim J C, Ryu S S, Kim Y D. Densification behavior of mechanically alloyed W-Cu composite powders by the double rearrangement process[J]. Scr Metal Mater, 1998, 39(6): 669?676.

[5] Yang B, German R. Powder injection molding and infiltration sintering of superfine grain W-Cu[J]. The International Journal of Powder Metallurgy, 1997, 33(4): 55?63.

[6] 林信平, 曹顺华, 李炯义, 谢 湛, 蔡志勇. 纳米晶W-25Cu复合粉末烧结行为的研究[J]. 中国钨业, 2005, 20(1): 39?43.

LIN Xin-ping, CAO Shun-hua, LI Jiong-yi, XIE Zhan, CAI Zhi-yong. Reaserch on sintering behavior of nanograined W-25Cu composite powder[J]. China Tungsten Industry, 2005, 20(1): 39?43.

[7] Maneshian M H, Simchi A, Hesabi Z R. Synthesis and characterization of W-Cu nanocomposites developed by mechanical alloying[J]. Mater Sci Eng A, 2006, 433(1/2): 161?168

[8] 王志法, 刘正春, 姜国圣. W/Cu 电子封装材料的气密性[J]. 中国有色金属学报, 1999, 9(2): 323?326.

WANG Zhi-fa, LIU Zheng-chun, JIANG Guo-sheng. Hermeticity of W/Cu composites for semiconductor package[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(2): 323?326.

[9] Yang B, German R M. Powder injection molding and infiltration sintering of superfine grain W-Cu[J]. The International Journal of Powder Metallurgy, 1997(4): 55?63.

[10] Lee G G, Ha G H, Kim B K. Synthesis of high density ultrafine W/Cu composite alloy by mechano-thermochemical process[J]. Powder Metallurgy, 2000, 43(1): 79?82.

[11] Hong S H, Kim B K. Fabrication of W-20%Cu composite nanopowder and sintered alloy with high thermal conductivity[J]. Materials Letters, 2003, 57: 2761?2767.

[12] 肖志瑜, 柯美元, 李元元, 倪东惠. 温压工艺最新进展—流动温压技术[J]. 粉末冶金工业, 2002, 12(5): 28?32.

XIAO Zhi-yu, KE Mei-yuan, LI Yuan-yuan, NI Dong-hui. New development of warm compaction—warm flow compaction[J]. Powder Metallurgy Industry. 2002, 12(5): 28?32.

[13] Veltl G, Oppert A, Petzoldt F. Warm flow compaction fasters more complex PM parts[J]. Metal Powder Report , 2001, 56(2): 26?28.

[14] 张菊红, 肖志瑜, 李元元. 粉末冶金流动温压成形技术[J]. 粉末冶金技术, 2006, 24(1): 45?48.

ZHANG Ju-hong, XIAO Zhi-yu, LI Yuan-yuan. Powder warm flow compaction technology[J]. Powder Metallurgy Technology, 2006, 24(1): 45?48.

[15] 易健宏, 叶途明, 彭元东. 粉末冶金温压工艺的研究进展及展望[J]. 粉末冶金技术, 2005, 25(2): 140?144.

YI Jian-hong, YE Tu-ming, PENG Yuan-dong. Research progress and prospect of the process in warm compaction in powder metallurgy[J]. Powder Metallurgy Technology, 2005, 25(2): 140?144.

[16] 李元元, 肖志瑜, 罗术华, 王 军. 粉末冶金流动温压技术及其思考[J]. 粉末冶金材料科学与工程, 2006, 11(4): 189?193.

LI Yuan-yuan, XIAO Zhi-yu, LUO Shu-hua, WANG Jun. Warm flow compaction technology of powder metallurgy and its considerations[J]. Materials Science and Engineering of Powder Metallurgy, 2006, 11(4): 189?193.

[17] 董斌斌, 申长雨. 薄壁件注射成型流动分析[J]. 塑料工业, 2003, 31(4): 25?29.

DONG Bin-bin, XIAO Chang-yu. Simulation analysis of thin-wall part molding by injection molding[J]. China Plastics Industry, 2003, 31(4): 25?29.

收稿日期:2006-12-24;修订日期:2007-04-13

通讯作者:曹顺华,教授;电话:0731-8836954;E-mail: shuacao@126.com

(编辑 陈爱华)